ASTM E991-98

(Practice)Standard Practice for Color Measurement of Fluorescent Specimens

Standard Practice for Color Measurement of Fluorescent Specimens

SCOPE

1.1 This practice describes procedures for measuring the colors of fluorescent specimens as they would be perceived when illuminated by daylight, and for calculating tristimulus values and chromaticity coordinates for these conditions.

1.2 This practice applies to the use of the one-monochromator spectrophotometer employing polychromatic illumination of the specimen and monochromatic detection of the radiant energy.

1.3 This practice can be used to provide specifications for fluorescent colors in either the 1931 or the 1964 CIE system.

1.4 This practice covers only fluorescent specimens that emit visible light. It is not intended for use with other types of luminescent materials such as phosphorescent, chemiluminescent, or electroluminescent.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 991 – 98

Standard Practice for

Color Measurement of Fluorescent Specimens

This standard is issued under the fixed designation E991; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Thecolorsoffluorescentspecimensshouldbemeasuredunderilluminatingandviewingconditions

(spectral and geometric) that duplicate those of anticipated use. The measurement of fluorescent

specimens is more exacting than that of nonfluorescent specimens because the relative contributions

ofreflectedandfluorescedradiationwillvarywiththespectralcharacterofthesourceilluminatingthe

specimen. This places important restrictions on the instrumentation used for measurement. This

practice covers the instrumental appearance measurement of fluorescent materials using a one-

monochromator spectrophotometer.

1. Scope E308 Practice for Computing the Colors of Objects by

Using the CIE System

1.1 This practice describes procedures for measuring the

E805 PracticeforIdentificationofInstrumentalMethodsof

colors of fluorescent specimens as they would be perceived

Color or Color-Difference Measurement of Materials

when illuminated by daylight, and for calculating tristimulus

E1164 Practice for Obtaining Spectrophotometric Data for

values and chromaticity coordinates for these conditions.

Object-Color Evaluation

1.2 This practice applies to the use of one-monochromator

E1247 TestMethodforIdentifyingFluorescenceinObject-

spectrophotometer employing polychromatic illumination of

Color Specimens by Spectrophotometry

the specimen and monochromatic detection of the radiant

E1349 Test Method for Reflectance Factor and Color by

energy.

Spectrophotometry Using Bidirectional Geometry

1.3 This practice can be used to provide specifications for

E1767 Practice for Specifying the Geometry of Observa-

fluorescent colors in either the 1931 or the 1964 CIE system.

tionsandMeasurementstoCharacterizetheAppearanceof

1.4 This practice covers only fluorescent specimens that

Materials

emit visible light. It is not intended for use with other types of

2.2 CIE Standards:

luminescent materials such as phosphorescent, chemilumines-

CIE Publication No. 15.2, Colorimetry

cent, or electroluminescent.

CIE Publication No. 51, AMethod forAssessing the Qual-

1.5 This standard does not purport to address all of the

ity of Daylight Simulators for Colorimetry

safety concerns, if any, associated with its use. It is the

CIE Publication No. 76, Intercomparison on Measurement

responsibility of the user of this standard to establish appro-

of(Total)SpectralRadianceFactorofLuminescentSpeci-

priate safety and health practices and determine the applica-

mens

bility of regulatory limitations prior to use.

3. Terminology

2. Referenced Documents

3.1 ThetermsanddefinitionsinTerminologyE284applyto

2.1 ASTM Standards:

3 this practice.

E284 Terminology of Appearance

3.2 Definitions:

3.2.1 fluorescence, n—photoluminescence that ceases when

excitation ceases.

This practice is under the jurisdiction ofASTM Committee E-12 on Color and 3.2.1.1 Discussion—Fluorescence is distinguished from

Appearance and is the direct responsibility of Subcommittee E12.05 on Fluores-

phosphorescencebyatimedelaygenerallylessthan10ns.See

cence.

photoluminescence and phosphorescence.

Current edition approved June 10, 1998. Published September 1998. Originally

published as E991–84. Last previous edition E991–97.

Measurement of the fluorescent properties of materials for the purpose of

chemical analysis is not covered in this practice. The CIE documents can be obtained from USNC/CIE Publications, c/o TLA

Annual Book of ASTM Standards, Vol 06.01. Lighting Consultants, 7 Pond St., Salem MA 01970.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E991–98

3.2.2 peak spectral radiance factor, b , n—largest mea- specimen differs somewhat from that of illuminant D65 (3, 4),

peak

sured spectral radiance factor of a specimen. thecalculationanduseofcorrectedspectralradiancefactorsof

3.2.3 source conformance factor, SCF, n— the square root fluorescent materials for colorimetric purposes are not ad-

of the mean square deviation between the relative spectral dressed by this practice.

irradiance distribution curves of an instrument illuminating 4.5 When the fluorescent specimen has an angular subtense

source measured at the sample port and a specified CIE of <4° at the eye (for example, objects viewed from a distance

standard illuminant. such as a buoy at sea or a road sign on the roadway), use the

3.2.3.1 Discussion—The ultraviolet source conformance CIE 1931 (2°) standard observer. When the fluorescent speci-

factor, SCF ,iscalculatedovertherangefrom300to380nm; men has an angular subtense of >4° at the eye (for example, a

uv

the visible source conformance factor, SCF , is calculated large textile sample observed nearby), use the CIE 1964 (10°)

vis

over the range from 380 to 700 nm. supplementary standard observer.

3.2.4 ultraviolet-activated fluorescence, n— fluorescence 4.6 While the two-monochromator method (5,6,7) is con-

resultingprincipallyfromabsorptionofultravioletradiantflux, sidered the referee procedure, this one-monochromator prac-

shorter than 380 nm in wavelength. tice has found significant application for the color measure-

3.2.5 visible-activatedfluorescence,n—fluorescenceresult- ment of fluorescent specimens.

ingprincipallyfromabsorptionofvisibleradiantflux,approxi-

5. Instrument Requirements

mately 380 to 780 nm in wavelength.

5.1 The color measurement of fluorescent specimens under

4. Significance and Use

this practice requires the use of a one-monochromator spectro-

4.1 This practice describes the color measurement of fluo-

photometer meeting the following minimum criteria:

rescent specimens as they would appear when illuminated by

5.1.1 The spectrophotometer shall illuminate the specimen

CIE Illuminant D65. Since the CIE has not recommended a

withpolychromaticillumination,usuallybydirectillumination

standard source corresponding to this illuminant, this practice

from a daylight simulator.

requires that D65 be simulated within specified limits by the

5.1.2 The monochromator shall be located between the

spectral power distribution illuminating the specimen.

specimen and the detector system.

4.2 This practice applies to the instrumental color measure-

5.1.3 The wavelength measurement interval should be 10

ment of specimens exhibiting fluorescent emission within the

nmorless.SeePracticeE308andPracticeE1164forspectral

visible range. For methods to determine whether specimens

bandpass recommendations.

exhibit fluorescence, see Test Method E1247.

5.2 Requirements for CIE illuminant D65 Simulation—The

4.3 Therecommendedmeasurementgeometryforthisprac-

instrument source shall simulate CIE Illuminant D65, with a

tice is the 45/0 (or equivalent 0/45) illuminating and viewing

relative spectral irradiance distribution at the specimen port

geometry (see Practice E805 and Test Method E1349). It is

closely duplicating that of D65. Two alternative criteria are

therefereeconditionforthispractice.Theuseofhemispherical

providedtodeterminewhethertheD65simulationisadequate:

geometry is not recommended. When hemispherical geometry

5.2.1 The ultraviolet source conformance factor, SCF ,

uv

using an integrating sphere is utilized, the light emission from

over the range from 300 to 380 nm shall be less than 15.0 and

thefluorescentspecimenchangesthespectralirradianceonthe

the visible source conformance factor, SCF over the range

vis

specimen from that of the required D65 (1,2).

from 380 to 700 nm shall be less than 10.0 (seeAppendix X1

4.3.1 The use of hemispherical geometry using an integrat-

for calculation of SCF and SCF ).

uv vis

ing sphere may be permissible if it can be shown that the

1 2

l~2!

/

spectral sphere error is negligible. The spectral sphere error

SCF 5 ~S 2 S ! (1)

F ( D65 INST G

n

l 1!

~

associated with hemispherical geometry decreases as the mea-

surement area relative to the internal area of the sphere is

where:

decreased.When the spectral sphere error is negligible, results

l (1) = minimum wavelength of the range evaluated,

obtained using hemispherical geometry may for some speci-

l(2) = maximum wavelength of the range evaluated,

mens under specific measurement conditions approach those n = number of sample points,

S = relative spectral irradiance of CIE illuminant

obtained using 45/0 (0/45) geometry (2).

D65

D65, normalized to 100.0 at 560 nm, and

NOTE 1—In addition to the spectral sphere error, there are also

S = relative spectral irradiance incident on the speci-

INST

geometric differences between hemispherical geometry using an integrat-

men, determined by spectroradiometry and simi-

ing sphere and 45/0 (0/45) geometry which can affect the measurement

larly normalized to 100.0 at 560 nm.

result for highly non-Lambertian materials.

5.2.2 The D65 simulator shall have a rating not worse than

4.4 While procedures are available in the literature to

BB (CIELAB) relative to D65 as determined by the method of

correct data obtained when the spectral irradiance on the

CIE Publication No. 51.

5.2.3 In contrast to ultraviolet-activated fluorescent speci-

mens, the ultraviolet content of the illuminant does not play a

The illuminating and viewing geometry denoted by 45/0 (0/45) in this practice

is equivalent to the 45:0 (0:45) notation in Practice E1767. The use of Practice

significant role in the color measurement of visible-activated

E1767 notation is recommended for the complete description of measurement

fluorescent specimens (8). For the instrumental color measure-

geometry including aperture size, etc.

mentofvisible-activatedfluorescentspecimens,theinstrument

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this practice. sourceshallonlyberequiredtohavea SCF lessthan10.0,or

vis

E991–98

a rating not worse than B (CIELAB) in the visible range 8.3 The accuracy with which the illuminating source simu-

relative to D65 as determined by the method of CIE Publica- lates CIE Illuminant D65 must be determined periodically by

tion No. 51. measurement of the spectral distribution of irradiance at the

5.3 The instrument must be capable of producing as output specimen port of the instrument.

spectral radiance factor as a function of wavelength over the

NOTE 3—Possiblythegreatestsinglesourceofvariabilityinfluorescent

range from 400 to 700 nm in increments of 10 nm or less.The

color measurement is differences between the spectral distribution of the

preferred range is from 380 to 780 nm.

source illuminating the specimen at the sample port and the specified CIE

5.4 For geometrically sensitive fluorescent specimens, the illuminant.

illuminating and viewing geometry shall consist of direct

9. Report

specimen irradiation by the illuminator system at an angle of

45 62°fromthenormal,withanapertureanglenotexceeding 9.1 Report the following information (see Practices E805

and E1164):

4°, and viewing at an angle of 0 6 2° (along the normal) with

an aperture angle not exceeding 4° (the combination denoted 9.1.1 Specimen Description—Include the following:

9.1.1.1 Specimen identification and type, for example

by 45/0) (9) or the equivalent 0/45 geometry.

whether the sample is opaque, translucent or transparent, a

5.4.1 For specimens known to be relatively insensitive to

measurementgeometry,theilluminatingandviewinggeometry textile or plastic, retroreflective, ultraviolet-activated or

visible-activated.

shouldconsistofdirectspecimenirradiationbytheilluminator

systematanangleof45 62°fromthenormaltothespecimen 9.1.1.2 Specimen Substrate—The instrumental color mea-

surement of specimens that are not opaque can be influenced

surface. The angle between the direction of viewing and the

normal to the specimen surface should not exceed 10°. The by the spectral reflectance of the material behind the specimen

(10). Specimens are typically measured mounted on the sub-

angle between the axis and any ray of an illuminating beam

should not exceed 8°. The same restriction applies to the strate upon which they are to used.

9.1.2 Instrument Parameters—Including the following:

viewing beam. The equivalent 0/45° geometry is allowed (see

Practice E1164). 9.1.2.1 Measurement Conditions—Indicate whether annu-

lar, circumferential, or uniplanar measurement conditions.

6. Procedure

9.1.2.2 The spectral parameters, including the wavelength

6.1 OperatethespectrophotometerinaccordancewithPrac-

range, wavelength measurement interval, and spectral band-

tice E1164 and Test Method E1349. This includes mandatory

pass.

standardization of the following:

9.1.2.3 The adequacy of the D65 simulation of the instru-

6.1.1 Zero setting of the reflectance scale,

ment source at the sample port as determined in 5.2 of this

6.1.2 Full-scale value of the reflectance scale of the instru-

practiceintermsof SCF,orCIELABratinginaccordancewith

ment by use of the white standard. Follow the instrument

the method of Publication CIE No. 51.

manufacturer’s instructions.

9.2 Measurement Results:

6.2 Express spectral radiances obtained as radiance factors

9.2.1 The CIE tristimulus values (X, Y, Z) or chromaticity

relative to the perfect reflecting diffuser assigned a value of

coordinates (x, y, Y) for CIE Illuminant D65 for either the CIE

1.000 (100.0%) at each wavelength. 1931 (2°) standard observer or the CIE 1964 (10°) supplemen-

tary standard observer.

7. Calculation

9.2.2 The wavelength of peak spectral radiance factor from

7.1 Calculate CIE tristimulus values and chromaticity coor-

the measured spectral radiance factors obtained.

dinates for CIE Illuminant D65 and either the CIE 1931 (2°)

standard observer or the CIE 1964 (10°) supplementary stan-

10. Precision and Bias

dard observer (see Practice E308).

10.1 Theprecisionandbiasoftheprocedureinthispractice

is being determined.

8. Standardization and Verification

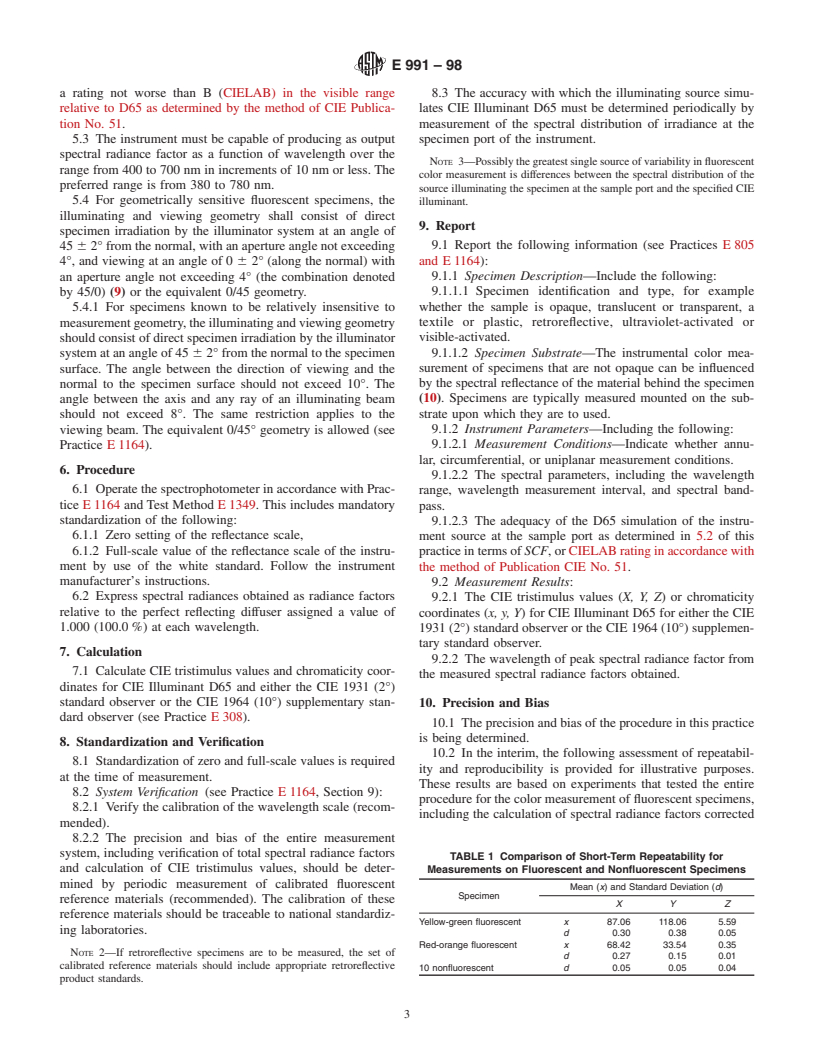

10.2 In the interim, the following assessment of repeatabil-

8.1 Standardization of zero and full-scale values is required

ity and reproducibility is provided for illustrative purposes.

at the time of measurement.

These results are based on experiments that tested the entire

8.2 System Verification (see Practice E1164, Section 9):

procedureforthecolormeasurementoffluorescentspecimens,

8.2.1 Verify the calibration of the wavelength scale (recom-

including the calculation of spectral radiance factors corrected

mended).

8.2.2 The precision and bias of the entire measurement

system, including

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.