ASTM D3623-78a(2012)

(Test Method)Standard Test Method for Testing Antifouling Panels in Shallow Submergence

Standard Test Method for Testing Antifouling Panels in Shallow Submergence

SIGNIFICANCE AND USE

4.1 This method is designed as a screening test in evaluating antifouling coating systems. Results of the standard system in a specific marine environment are included to assist in interpreting results (see Annex A2).

4.2 Antifouling systems providing positive comparisons with the standard system should be considered acceptable for use in protecting underwater marine structures.

4.3 The degree and type of fouling will vary depending on the environment. Hence, differences in geographic location of test sites, in time of year when panels are exposed, and in weather conditions from 1 year to the next can affect results. Therefore, a fouling census on a nontoxic surface is taken. For the exposure to be valid the nontoxic surface should show heavy fouling, and the standard system should show significantly less fouling than the nontoxic surface (see Annex A3 and Annex A4).

SCOPE

1.1 This test method covers a procedure for testing antifouling compositions in shallow marine environments and a standard antifouling panel of known performance to serve as a control in antifouling studies. Note 1—Subcommittee D01.45 has a revised rating procedure now being evaluated by round robin.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the application of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3623 − 78a (Reapproved 2012)

Standard Test Method for Testing

Antifouling Panels in Shallow Submergence

This standard is issued under the fixed designation D3623; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope MIL-P-15931B Paint, Antifouling, Vinyl, Red (Formula

121/63)

1.1 Thistestmethodcoversaprocedurefortestingantifoul-

MIL-S-22698A Steel Plate, Carbon, Structural

ing compositions in shallow marine environments and a

standard antifouling panel of known performance to serve as a

3. Terminology

control in antifouling studies.

3.1 Definitions:

NOTE 1—Subcommittee D01.45 has a revised rating procedure now

3.1.1 shallow submergence—an immersion to depths be-

being evaluated by round robin.

tween 0.3 and 3.0 m (1 and 10 ft).

1.2 The values stated in SI units are to be regarded as the

3.2 Abbreviations:

standard. The values given in parentheses are for information

3.2.1 The following abbreviations are used in reporting test

only.

results:

1.3 This standard does not purport to address all of the

Al algae

safety concerns, if any, associated with its use. It is the

Barn barnacles

E.B. encrusting bryozoans

responsibility of the user of this standard to establish appro-

Hyd hydroids

priate safety and health practices and determine the applica-

Sl slime

tion of regulatory limitations prior to use.

Tun tunicates

C.F. completely fouled

F.R. fouling resistance rating

2. Referenced Documents

A.F. antifouling rating

A.C. anticorrosive rating

2.1 ASTM Standards:

O.P. overall performance rating

A569/A569M Specification for Steel, Carbon (0.15

CO coelenterates

Maximum,Percent),Hot-RolledSheetandStripCommer-

F.B. filamentous bryozoans

Mol molluscs

cial (Withdrawn 2000)

PC polychaetes

D2200Practice for Use of Pictorial Surface Preparation

3.2.2 Algal Mups may be delineated by classification nota-

Standards and Guides for Painting Steel Surfaces

tion by phyllum as follows:

2.2 U.S. Military Specifications (See alsoAnnex A1):

Al-b Phaeophyta (brown)

MIL-P-15328DPrimer Pretreatment (Formula 117 for Met-

Al-bg Cyanophyta (blue-green)

als)

Al-g Chlorophyta (green)

MIL-P-15929CPrimer Coating, Shipboard, Vinyl-Red Lead

Al-r Rhodophyta (red)

(Formula 119—For Hot Spray)

4. Significance and Use

4.1 Thismethodisdesignedasascreeningtestinevaluating

This test method is under the jurisdiction of ASTM Committee D01 on Paint

antifouling coating systems. Results of the standard system in

and Related Coatings, Materials, andApplications and is the direct responsibility of

a specific marine environment are included to assist in inter-

Subcommittee D01.45 on Marine Coatings.

preting results (see Annex A2).

Current edition approved June 1, 2012. Published August 2012. Originally

approved in 1978. Last previous edition approved in 2004 as D3623–78a(2004).

4.2 Antifouling systems providing positive comparisons

DOI: 10.1520/D3623-78AR12.

with the standard system should be considered acceptable for

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

use in protecting underwater marine structures.

Standards volume information, refer to the standard’s Document Summary page on

4.3 The degree and type of fouling will vary depending on

the ASTM website.

The last approved version of this historical standard is referenced on

the environment. Hence, differences in geographic location of

www.astm.org.

test sites, in time of year when panels are exposed, and in

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

weather conditions from 1 year to the next can affect results.

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

dodssp.daps.dla.mil. Therefore, a fouling census on a nontoxic surface is taken. For

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3623 − 78a (2012)

the exposure to be valid the nontoxic surface should show of panels and the application of various types of antifouling

heavy fouling, and the standard system should show signifi- paintstheuseofappropriateprotectiveclothingandequipment

cantly less fouling than the nontoxic surface (see Annex A3 is required consistent with local, state, and federal government

and Annex A4). regulations, and recognized industrial and technical standards.

Spills, overspray, and unused material should not be flushed

5. Apparatus

down the drain, but should be disposed of as hazardous waste.

5.1 Blast CleaningApparatuscapableofpreparingpanelsin

8. Procedure

compliance with 8.1.

8.1 Abrasive blast the required number of panels to near-

5.2 Application Equipment consisting of brush, roller, con-

whitemetal(Sa2 ⁄2ofMethodD2200)toobtainaprofileof25

ventional spray, or airless spray. Usually the equipment is

to 38 µm (1 to 1.5 mils).

dictated by the physical properties of the coating and the film

thickness desired.

NOTE 2—Aprofile of 25 to 38 µm (1 to 1.5 mils) can be obtained with

the following parameters: (1) Type and size of grit, No. 46 (sand); (2)

5.3 Exposure Rack to provide firm positioning of the speci-

Pressure, 620 kPa (90 psi); (3)Angle, 90 deg; (4) Distance from surface,

men panels such that they are held vertically in place in spite

75 to 125 mm (3 to 5 in.); (5) Nozzle size, 9 mm ( ⁄8 in.).

of the current and are electrically insulated from metallic

8.2 Ontheclean,dry,uncontaminated,blastedsurfaceapply

contact with the rack or other panels. The rack should be

to each standard panel one coat of pretreatment coating

positioned such that the prevailing tidal currents will move

MIL-P-15328D to give a nominal dry film thickness of 13 µm

parallel to the panel face, and the panels will be immersed to a

( ⁄2 mil).

depthofaminimumof0.3m(1ft)andamaximumof3m(10

ft). In a rack where the panels are stacked front to back, they

NOTE 3—All coating drying times are for a minimum temperature of

should be spaced at least 60 mm (2 ⁄2 in.) apart, with the two

21°C and a maximum relative humidity of 70%.

end positions filled with blank panels. In a rack where the

8.3 Within 24 h of application of the pretreatment coating

panelsaremountedsidebyside,thedistancebetweenadjacent

apply the first coat of red lead vinyl primer MIL-P-15929C.

panels should be a minimum 1.5 mm ( ⁄2 in.).

Apply a total of four coats of red lead vinyl primer to give a

nominal dry film thickness of 150 µm (6 mils ). Allow a

6. Materials

minimum of 2 h and a maximum of 24 h drying between coats

6.1 Test Panel—The substrate for the standard antifouling

of red lead vinyl primer.

coating system shall be medium low-carbon steel plate per

8.4 Allowing a minimum of 2 h and a maximum of 24 h

SpecificationA569/A569M, 3mmthickby150to250mmby

dryingafterthelastcoatofredleadvinylprimer,applythefirst

250 to 300 mm ( ⁄8 in. thick by 6 to 10 by 10 to 12 in.) with a

coat of vinyl antifouling coating MIL-P-15931B to the stan-

2 2

minimum area per side of 465 cm (72 in. ). A 6-mm ( ⁄4-in.)

dard panels, and the test coating to the test panels. A 19-mm

diameter hole, ⁄2 to 1 in. from the top and centered shall be

( ⁄4-in.) numbered vinyl tape can be applied before the second

drilled for holding the panel while handling and painting. The

coat of antifouling coating for identification. Allowing a

test coating system shall be applied to that substrate for which

minimum of 2 h and a maximum of 24 h drying after the first

itisdesignedprovidedthereisaminimumareapersideof466

coat, apply a second coat of the respective antifouling coating

2 2

cm (72 in. ).

to give a nominal dry film thickness for both antifouling coats

6.2 Standard Coating System—The standard antifouling

of 100 µm (4 mils).

coating system shall consist of:

8.5 Before immersion permit the second coat of antifouling

6.2.1 Green pretreatment coating conforming to U.S. Mili-

coating to dry a minimum of 4 h and a maximum of 2 weeks,

tary Specification MIL-P-15328B (Formula 117), B revision

the latter time allowing for shipping the panels to the immer-

only.

sion site.

6.2.2 Vinyl red lead primer conforming to U.S. Military

8.6 Exposeforaminimumperiodof1yearatanimmersion

Specification MIL-P-15929C (Formula 119), C revision only.

6.2.3 Vinyl antifouling coating conforming to U.S. Military site with a high incidence of fouling as indicated by attach-

ments on a dark nontoxic surface such as slate. A monthly

Specification MIL-P-15931B (Formula 121/63), B revision

only. fouling census as well as a yearly accumulation when appro-

priate is required.

6.3 Test Coating System—The test antifouling coating may

be applied to the standard primer system, or to any other 8.7 Evaluate the antifouling panels for surface fouling and

suitable anticorrosive primer system. physical condition of the film system at least monthly as

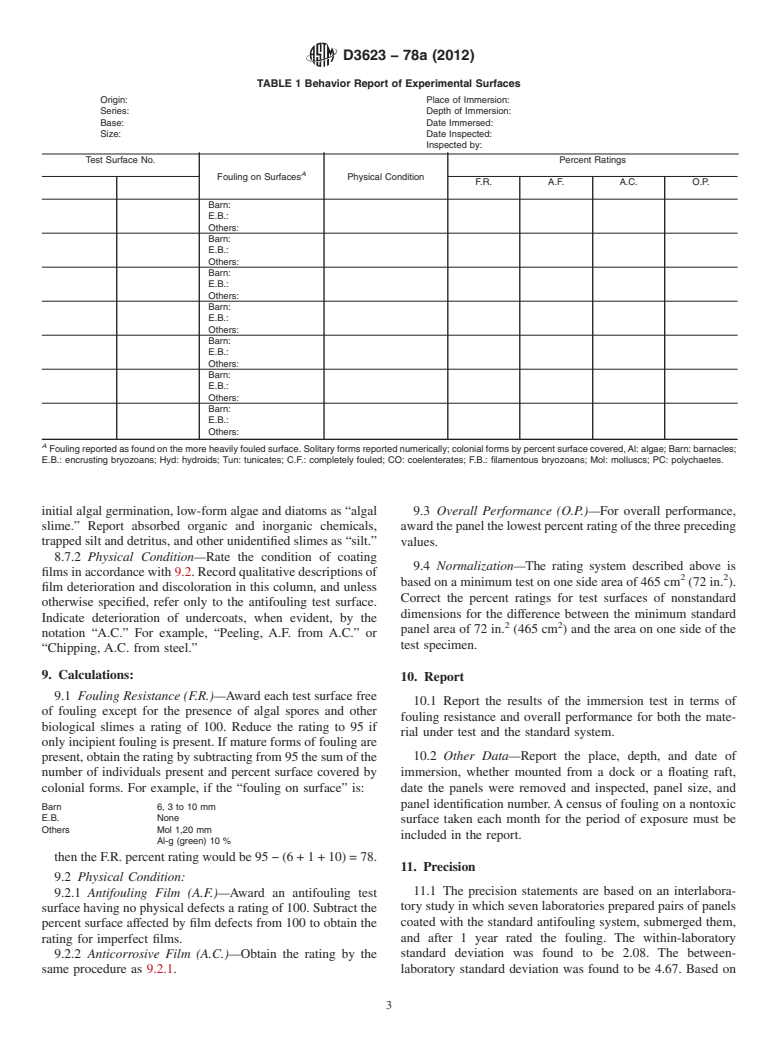

follows using the report form in Table 1.

7. Safety Precautions

8.7.1 Fouling on Surfaces—Rate fouling present on that

portionoftheantifoulingtestsurfacewhichisintactatthetime

7.1 Warning—Antifouling paints contain toxic materials

of inspection (see 9.1). Rate both sides of the panel if

that could cause skin and eye irritation on contact and adverse

appropriate. Ignore fouling present on the substrate or on

physiological effects if ingested or inhaled. In the preparation

anticorrosive undercoats. Barnacles, polychaetes,

coelenterates,etc.,thatareimmatureorlooselyattachedshould

See also U.S. Military Specification MIL-S-22698, Type 1, Class A. be so reported in the appropriate space. Report fouling by

D3623 − 78a (2012)

TABLE 1 Behavior Report of Experimental Surfaces

Origin: Place of Immersion:

Series: Depth of Immersion:

Base: Date Immersed:

Size: Date Inspected:

Inspected by:

Test Surface No. Percent Ratings

A

Fouling on Surfaces Physical Condition

F.R. A.F. A.C. O.P.

Barn:

E.B.:

Others:

Barn:

E.B.:

Others:

Barn:

E.B.:

Others:

Barn:

E.B.:

Others:

Barn:

E.B.:

Others:

Barn:

E.B.:

Others:

Barn:

E.B.:

Others:

A

Fouling reported as found on the more heavily fouled surface. Solitary forms reported numerically; colonial forms by percent surface covered,Al: algae; Barn: barnacles;

E.B.: encrusting bryozoans; Hyd: hydroids; Tun: tunicates; C.F.: completely fouled; CO: coelenterates; F.B.: filamentous bryozoans; Mol: molluscs; PC: polychaetes.

initial algal germination, low-form algae and diatoms as “algal 9.3 Overall Performance (O.P.)—For overall performance,

slime.” Report absorbed organic and inorganic chemicals,

awardthepanelthelowestpercentratingofthethreepreceding

trappedsiltanddetritus,andotherunidentifiedslimesas“silt.”

values.

8.7.2 Physical Condition—Rate the condition of coating

9.4 Normalization—The rating system described above is

filmsinaccordancewith9.2.Recordqualitativedescriptionsof

2 2

basedonaminimumtestononesideareaof465cm (72in. ).

film deterioration and discoloration in this column, and unless

Correct the percent ratings for test surfaces of nonstandard

otherwise specified, refer only to the antifouling test surface.

dimensions for the difference between the minimum standard

Indicate deterioration of undercoats, when evident, by the

2 2

panel area of 72 in. (465 cm ) and the area on one side of the

notation “A.C.” For example, “Peeling, A.F. from A.C.” or

test specimen.

“Chipping, A.C. from steel.”

9. Calculations:

10. Report

9.1 Fouling Resistance (F.R.)—Award each test surface free

10.1 Report the results of the immersion test in terms of

of fouling except for the presence of algal spores and other

fouling resistance and overall performance for both the mate-

biological slimes a rating of 100. Reduce the rating to 95 if

rial under test and the standard system.

onlyincipientfoulingispresent.Ifmatureformsoffoulingare

10.2 Other Data—Report the place, depth, and date of

present,obtaintheratingbysubtractingfrom95thesumofthe

number of individuals present and percent surface covered by immersion, whether mounted from a dock or a floating raft,

colonial forms. For example, if the “fouling on surface” is: date the panels were removed and inspected, panel size, and

panel identification number.Acensus of fouling on a nontoxic

Barn 6, 3 to 10 mm

E.B. None

surface taken each month for the period of exposure must be

Others Mol 1,20 mm

included in the report.

Al-g (green) 10 %

thentheF.R.percentratingwouldbe95−(6+1+10)=78.

11. Precision

9.2 Physical Condition:

11.1 The precision statements are based on an interlabora-

9.2.1 Antifouling Film (A.F.)—Award an antifouling test

tory study in which seven laboratories prepared pairs of panels

surfacehavingnophysicaldefectsaratingof100.Subtractthe

coated with the standard antifouling system, submerged them,

percent surface affected by film defects from 100 to obtain the

rating for imperfect films. and after 1 year rated the fouling. The within-laboratory

standard deviation was found to be 2.08. The between-

9.2.2 Anticorrosive Film (A.C.)—Obtain the rating by the

same procedure as 9.2.1. laboratory standard deviation was found to be 4.67. Based on

D3623 − 78a (2012)

thesestandarddeviations,thefollowingcriteriashouldbeused 12. Keywords

to judge the acceptability of results at the 95% confidence

12.1 antifouling; antifouling coatings; fouling; immersion;

level:

performance; static

11.1.1 Repeatability—Two results each the mean of dupli-

cates obtained by the same operator should be considered

suspect if they differ by more than seven units.

11.1.2 Reproducibility—Two results each the mean of du-

plicates obtained by operators in different laboratories should

be considered suspect if they differ by more than 16 units.

ANNEXES

(Mandatory Information)

A1. STANDARD COATING SYSTEM FORMULAS

TABLE A1.1 Green Pretreatment Coating, MIL-P-15328D (Formula 117)

Pounds per 100 gal Gallons per 100 gal

of Mixed Material of Mixed Material

Ingredients of resin component (80 gal):

A

Polyvinyl-butyral resin 56 6.10

B

Zinc chromate (insoluble type) 54 1.78

Magnesium-silicate (Type A or B of Specification MIL-M-15173) 8 0.34

Lampblack (Specification TT-L-70) 0.6 0.04

Butyl alcohol, normal (Spec. TT-B-846) 125 18.48

C

Isopropyl alcohol, 99 % 353 53.80

Water 15 1.80

Ingredients of acid component (20 gal):

Phosphoric acid (Class A of Spec. O-P-313) 28 2.0

Water 25 3.0

C

Isopropyl alcohol, 99 % 99 15.0

A

The resin shall be a polyvinyl partial butyral resin containing only poly(vinyl butyral), poly(vinyl alcohol), and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.