ASTM D2099-05

(Test Method)Standard Test Method for Dynamic Water Resistance of Shoe Upper Leather by the Maeser Water Penetration Tester

Standard Test Method for Dynamic Water Resistance of Shoe Upper Leather by the Maeser Water Penetration Tester

SIGNIFICANCE AND USE

This test method is intended to estimate the water resistance of shoe upper leather. The flex imparted to the leather is similar to the flex given the vamp of the shoe in actual wear.

Note 1—There is an indication that this test method cannot be used interchangeably for specification purposes with Test Method D 2098.

SCOPE

1.1 This test method covers the determination of the dynamic water resistance of shoe upper leather by the Maeser water penetration tester. It is applicable to all types of shoe upper leather. Certain waterproof processes can cause contamination of the stainless steel balls. When this happens, visual inspection is recommended. This test method does not apply to wet blue.

1.2 Initial water penetration and water absorption can be measured by this test method.

1.3 This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D2099–05

Standard Test Method for

Dynamic Water Resistance of Shoe Upper Leather by the

1

Maeser Water Penetration Tester

This standard is issued under the fixed designation D2099; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Apparatus

1.1 This test method covers the determination of the dy- 4.1 Balance, sensitive to 0.01 g.

namic water resistance of shoe upper leather by the Maeser 4.2 MaeserWaterPenetrationTester, asshowninFig.1,or

water penetration tester. It is applicable to all types of shoe its equivalent. The essential features of the machine are:

upper leather. Certain waterproof processes can cause contami- 4.2.1 Specimen Holder, made of two V-shaped clamps with

nation of the stainless steel balls. When this happens, visual wedges for holding the specimen. The clamps shall be 2.5 6

inspection is recommended. This test method does not apply to 0.1 in. (635 6 2.5 mm) apart, inside measurement, when their

wet blue. tops are in the same horizontal plane. One clamp shall be in a

1.2 Initial water penetration and water absorption can be fixed position. The other clamp shall be pivoted as shown in

measured by this test method. Fig. 1 and attached, through a connecting link, to a motor-

1.3 This standard does not purport to address all of the driven eccentric which turns at 90 6 5 r/min. In one rotation of

safety concerns, if any, associated with its use. It is the the eccentric, the center of the top of the movable clamp shall

responsibility of the user of this standard to establish appro- move a distance of 1 6 0.05 in. (25.4 6 1.3 mm) below the

priate safety and health practices and determine the applica- horizontal and return.

bility of regulatory limitations prior to use. 4.2.2 Water Tank, made of copper, stainless steel, or other

noncorrosive material. It shall be of such a size that it can be

2. Referenced Documents

placed around the clamps and of such a depth that, when in

2

2.1 ASTM Standards: position for use, the top is 1.25 to 1.5 in. (31.7 to 38.1 mm)

D1610 Practice for Conditioning Leather and Leather Prod- above the lowest point of the flexed clamp.

ucts for Testing

4.3 Base for the Water Tank, which is removable from

D2098 Test Method for Dynamic Water Resistance of Shoe between the machine frame and the water tank.

Upper Leather by the Dow Corning Leather Tester

4.4 Two systems can be used to determine the number of

cycles through which the specimen is flexed. One shall be a

3. Significance and Use

mechanical reset counter connected to the movable clamp. The

3.1 This test method is intended to estimate the water

other system shall be electrical and consist of a high and

resistance of shoe upper leather. The flex imparted to the

common electrode. The recommended resistance across the

leather is similar to the flex given the vamp of the shoe in

common electrodes is 50 000 V. When the resistance falls

actual wear.

below this value, the relay will be energized. The high

electrode shown is inside the leather specimen in contact with

NOTE 1—There is an indication that this test method cannot be used

the steel balls. The common electrode is in a salt solution

interchangeably for specification purposes with Test Method D2098.

which is in continuous contact with the specimen during

flexing.

1

This test method is under the jurisdiction ofASTM Committee D31 on Leather

4.5 Initial water penetration is detected by a current leakage

and is the direct responsibility of Subcommittee D31.03 on Footwear.

from the high electrode through the specimen to the common

Current edition approved April 1, 2005. Published May 2005. Originally

electrode in the conducting solution. This causes a thyatron

approved in 1962. Last previous edition approved in 2000 as D2099–00. DOI:

10.1520/D2099-05.

tube to fire, opening the relay and stopping the machine.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5. Reagents and Materials

Standards volume information, refer to the standard’s Document Summary page on

5.1 Magnet, to facilitate removal of stainless steel balls.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

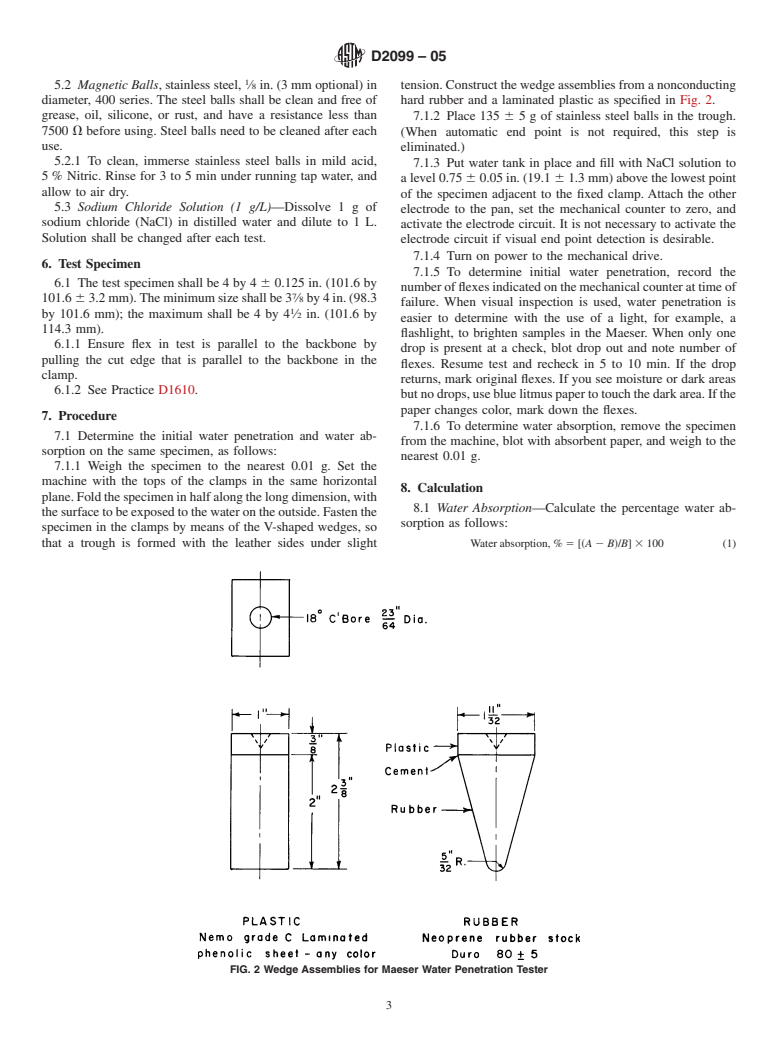

---------------------- Page: 1 ----------------------

D2099–05

FIG. 1 Maeser Water Penetration Tester

FIG. 1 Maeser Water Penetration Tester (continued)

2

---------------------- Page: 2 ----------------------

D209

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.