ASTM D522-93a(2001)

(Test Method)Standard Test Methods for Mandrel Bend Test of Attached Organic Coatings

Standard Test Methods for Mandrel Bend Test of Attached Organic Coatings

SCOPE

1.1 These test methods cover the determination of the resistance to cracking (flexibility) of attached organic coatings on substrates of sheet metal or rubber-type materials.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 522 – 93a (Reapproved 2001)

Standard Test Methods for

Mandrel Bend Test of Attached Organic Coatings

This standard is issued under the fixed designation D 522; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

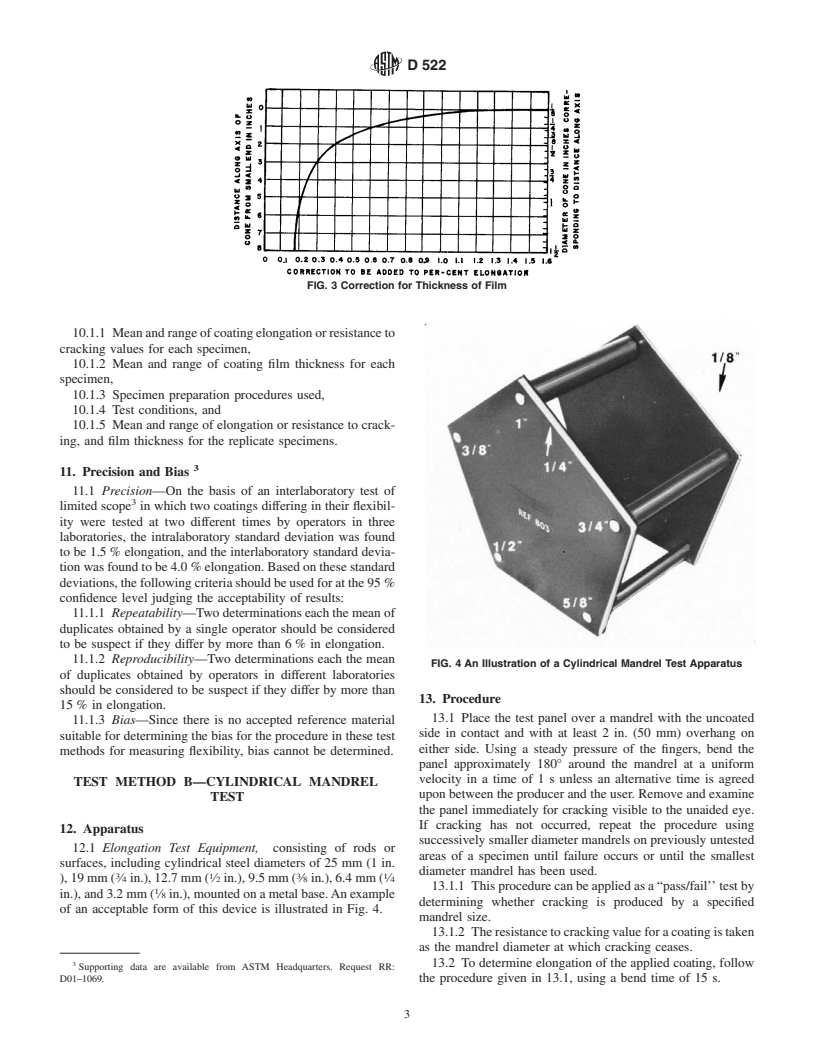

1. Scope a conical mandrel. InTest Method B the coated panels are bent

over cylindrical mandrels of various diameters.

1.1 These test methods cover the determination of the

resistance to cracking (flexibility) of attached organic coatings

4. Significance and Use

on substrates of sheet metal or rubber-type materials.

4.1 Coatings attached to substrates are elongated when the

1.2 The values stated in SI units are to be regarded as the

substrates are bent during the manufacture of articles or when

standard. The values given in parentheses are for information

thearticlesareabusedinservice.Thesetestmethodshavebeen

only.

useful in rating attached coatings for their ability to resist

1.3 This standard does not purport to address all of the

cracking when elongated. They have been useful in evaluating

safety concerns, if any, associated with its use. It is the

the flexibility of coatings on flexible substrates.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Test Specimen

bility of regulatory limitations prior to use.

5.1 Substrates:

5.1.1 If the purpose of the test is to determine the percent of

2. Referenced Documents

elongation of the coating material, the substrate shall be

2.1 ASTM Standards:

cold-rolled steel strip 0.8 mm ( ⁄32 in.) (22 gage) thick.

D 823 Practices for Producing Films of Uniform Thickness

5.1.2 If the purpose of the test is to rate the coated material

of Paint, Varnish, and Related Products on Test Panels

for resistance to cracking, the substrate may be any type of

D 1005 Test Methods for Measurement of Dry-Film Thick-

sheet metal or rubber-type material (for example, steel, alumi-

ness of Organic Coatings Using Micrometers

num, tinplate, or synthetic rubber). The thickness of the sheet

D 1186 Test Methods for Nondestructive Measurement of

metalmaybelessthan0.8mm( ⁄32in.)andthethicknessofthe

Dry Film Thickness of Nonmagnetic Coatings Applied to

2 rubber-type materials may be as great as 13 mm ( ⁄2 in.).

a Ferrous Base

5.1.3 The recommended panel size is 100 mm (4 in.) in

D 1400 Test Method for Nondestructive Measurement of

width and 150 mm (6 in.) in length.The maximum size that the

DryFilmThicknessofNonconductiveCoatingsAppliedto

2 conical mandrel can accommodate is 115 mm (4 ⁄2 in.) wide

a Nonferrous Metal Base

and 190 mm (7 ⁄2 in.) long.

3. Summary of Test Method 5.1.4 The surface preparation of the substrate shall be

agreed upon between the purchaser and the seller. Prior to the

3.1 The coating materials under test are applied at uniform

application of the coating, round slightly the edges of metal

thickness to panels of sheet metal or rubber-type materials.

panels to remove burrs in order to eliminate anomalous edge

After drying or curing the coated panels are bent over a

effects.

mandrel and the resistance to cracking of the coating is

determined. In Test Method A the coated panels are bent over

NOTE 1—If elongations are to be determined for coatings applied to

substrates other than 0.8 mm ( ⁄32 in.) thick cold-rolled steel, they must be

measured with a special mandrel jig as described in Appendix X1.2.

5.2 Coated Panels:

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD-1onPaint

and Related Coatings, Materials, andApplications and is the direct responsibility of

5.2.1 Apply uniform coatings of the materials under test to

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

thesubstratesinaccordancewithPracticesD 823andairdryor

Current edition approved Sept. 15, 1993. Published November 1993. Originally

bake under conditions mutually agreeable to the purchaser and

published as D 522 – 39. Last previous edition D 522 – 93.

Annual Book of ASTM Standards, Vol 06.01. the seller. If percent elongation is to be measured, a minimum

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 522

thickness of 1.0 mil is required on 0.8 mm ( ⁄32 in.) thick talc, between the specimen and the drawbar and hold in

cold-rolled steel. Perform a minimum of three determinations position only by the pressure of the drawbar against the paper.

of coating thickness on each of the specimens in accordance 8.2 Move the lever through about 180° at uniform velocity

with Test Methods D 1005, D 1186, or D 1400. to bend the specimen approximately 135°. If the purpose of the

5.2.2 From precoated sheets cut at least three specimens of test is to measure elongation, the bend should be 15 s. To

the size given in 5.1.3. Use only plane (flat) sheets and round determine crack resistance under more simulated use condi-

the edges of the panels slightly as in 5.1.4. The coating surface tions, the bend time should be about 1 s unless an alternative

shall be free of oil and other foreign matter that might increase time is agreed upon between the producer and the user.

the flexibility of the coating or interfere with the observation 8.3 Examine the bent surface of the specimen immediately

for cracking. Measure the film thickness as in 5.2.1. with the unaided eye for cracking. Having determined and

suitably marked the end of the crack farthest from the small

6. Conditioning and Number of Tests

end of the mandrel, which shall be considered as the end point,

bring the drawbar to the starting position and remove the panel

6.1 Condition the test specimens for at least 24 h at 23 6

from the mandrel. Measure the distance from the farthest end

2°C ( 73.5 6 3.5°F) and 50 6 5 % relative humidity, and test

of the crack to the small end of the mandrel. This distance is

in the same environment or immediately on removal therefrom

used to compute the elongation. The mandrel diameter at

unless otherwise specified by the purchaser and seller.

which cracking ceased is taken as the resistance to cracking

6.2 Test at least three replicate specimens in Test MethodA

value.

and at least two replicate specimens in Test Method B at each

mandrel diameter of interest.

NOTE 2—In some cases, the measured distance is used as a measure of

crack resistance.

TEST METHOD A—CONICAL MANDREL TEST

9. Calculation

7. Apparatus

9.1 When required, determine the elongation of the finish

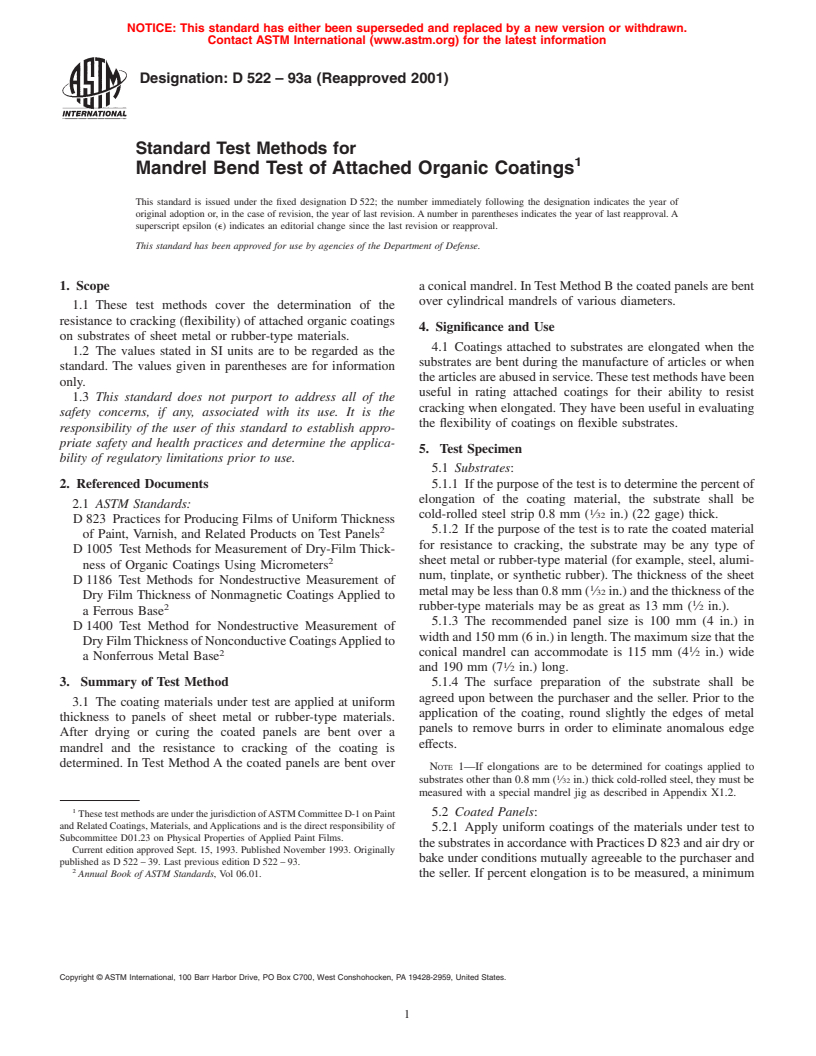

from the plotted curve in Fig. 2. This curve represents the

7.1 Conical Mandrel Tester , consisting of a metal cone, a

relationshipbetweenthepercentelongationandthediameterof

rotating panel-bending arm, and panel clamps, all mounted on

the conical mandrel for a 1.0 mil coating thickness. The

a metal base as illustrated in Fig. 1.

relationbetweenthedistancealongtheconicalmandrelandthe

7.1.1 Cone, smooth steel, 8 in. (200 mm) in length, with a

corresponding diameter has also been plotted on this curve.

diameter of 3 mm ( ⁄8 in.) at one end and a diameter of 38 mm

9.2 Adjust the percent elongation value obtained from Fig.

(1 ⁄2 in.) at the other end.

2 for coating thickness by adding the correction obtained from

Fig. 3.

8. Procedure

8.1 With the operating lever of the apparatus in a horizontal

NOTE 3—Example—Suppose visual examination of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.