ASTM E428-05a

(Practice)Standard Practice for Fabrication and Control of Metal, Other than Aluminum Reference, Blocks Used in Ultrasonic Examination

Standard Practice for Fabrication and Control of Metal, Other than Aluminum Reference, Blocks Used in Ultrasonic Examination

SIGNIFICANCE AND USE

Reference blocks fabricated in accordance with this practice will exhibit specific area-amplitude and distance-amplitude relationships only with an immersion test at 5 MHz using the search unit, test instrument and test parameters described in this practice. Comparison test at other frequencies or with uncalibrated instruments will not necessarily give the same relationships shown in this practice. See Reference (1) for area-amplitude limitations at other frequencies and transducer diameters. Also see Reference (2) for cautions regarding use of standard blocks for test standardizations.

SCOPE

1.1 This practice covers a procedure for fabrication and control of metal alloy reference blocks used in ultrasonic examination that have a flat-surface sound entry, are cylindrical in shape, and contain flat-bottom holes (FBH) which may be used for checking the performance of ultrasonic examination instrumentation and search units and for standardization and control of ultrasonic examination of metal alloy products. The reference blocks described are suitable for use with either the direct-contact method or immersion pulse-echo ultrasonic methods.

1.2 While this procedure is basically designed for the fabrication and control of carbon and alloy steel blocks to be used in conjunction with the examination of these materials, the fabrication and control procedures may also be suitable for the preparation of blocks for other types of materials such as nickel-base alloys, certain types of aluminum alloys, and so forth. Additional procedures and controls may be required when fabricating reference blocks from other than carbon or alloy steel material. This practice shall in no way preclude the specification or addition of any supplemented requirements as deemed necessary for the specific application. This practice, however, must not be confused with, nor does it supersede Practice E127, specifically governing the fabrication and evaluation of 7075-T6 aluminum alloy ultrasonic standard reference blocks.

Note 1--Practice E127 and Guide E1158 also describe procedures for selecting material, fabricating blocks, and checking response. Unlike this practice, Practice E127 has requirements for evaluation relative to a specified standard target.

1.3 The values stated in inch-pound units are to be regarded as the standard.

1.4This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 428 – 05a

Standard Practice for

Fabrication and Control of Metal, Other than Aluminum

1

Reference, Blocks Used in Ultrasonic Examination

This standard is issued under the fixed designation E 428; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This specification has been approved for use by agencies of the Department of Defense.

selecting material, fabricating blocks, and checking response. Unlike this

1. Scope

practice, Practice E 127 has requirements for evaluation relative to a

1.1 This practice covers a procedure for fabrication and

specified standard target.

control of metal alloy reference blocks used in ultrasonic

1.3 The values stated in inch-pound units are to be regarded

examinationthathaveaflat-surfacesoundentry,arecylindrical

as standard.

in shape, and contain flat-bottom holes (FBH) which may be

1.4 This standard does not purport to address all of the

used for checking the performance of ultrasonic examination

safety problems, if any, associated with its use. It is the

instrumentation and search units and for standardization and

responsibility of the user of this standard to establish appro-

control of ultrasonic examination of metal alloy products. The

priate safety and health practices and determine the applica-

reference blocks described are suitable for use with either the

bility of regulatory limitations prior to use.

direct-contact method or immersion pulse-echo ultrasonic

methods.

2. Referenced Documents

3

NOTE 1—Use of flat-surface reference blocks may not be suitable for

2.1 ASTM Standards:

2

cylindrical materials (3) .

E 127 Practice for Fabricating and Checking Aluminum

1.2 While this procedure is basically designed for the

Alloy Ultrasonic Standard Reference Blocks

fabrication and control of carbon and alloy steel blocks to be E 1158 Guide for Material Selection and Fabrication of

used in conjunction with the examination of these materials,

Reference Blocks for the Pulsed Longitudinal Wave Ultra-

the fabrication and control procedures may also be suitable for sonic Examination of Metal and Metal Alloy Production

the preparation of blocks for other types of materials such as Material

nickel-base alloys, certain types of aluminum alloys, and so

E 1316 Terminology for Nondestructive Testing

forth. Additional procedures and controls may be required

3. Terminology

when fabricating reference blocks from other than carbon or

alloy steel material. This practice shall in no way preclude the 3.1 Definitions—For definitions of terms used in this prac-

specification or addition of any supplemented requirements as tice, see Terminology E 1316.

deemed necessary for the specific application. This practice,

4. Summary of Practice

however, must not be confused with, nor does it supersede

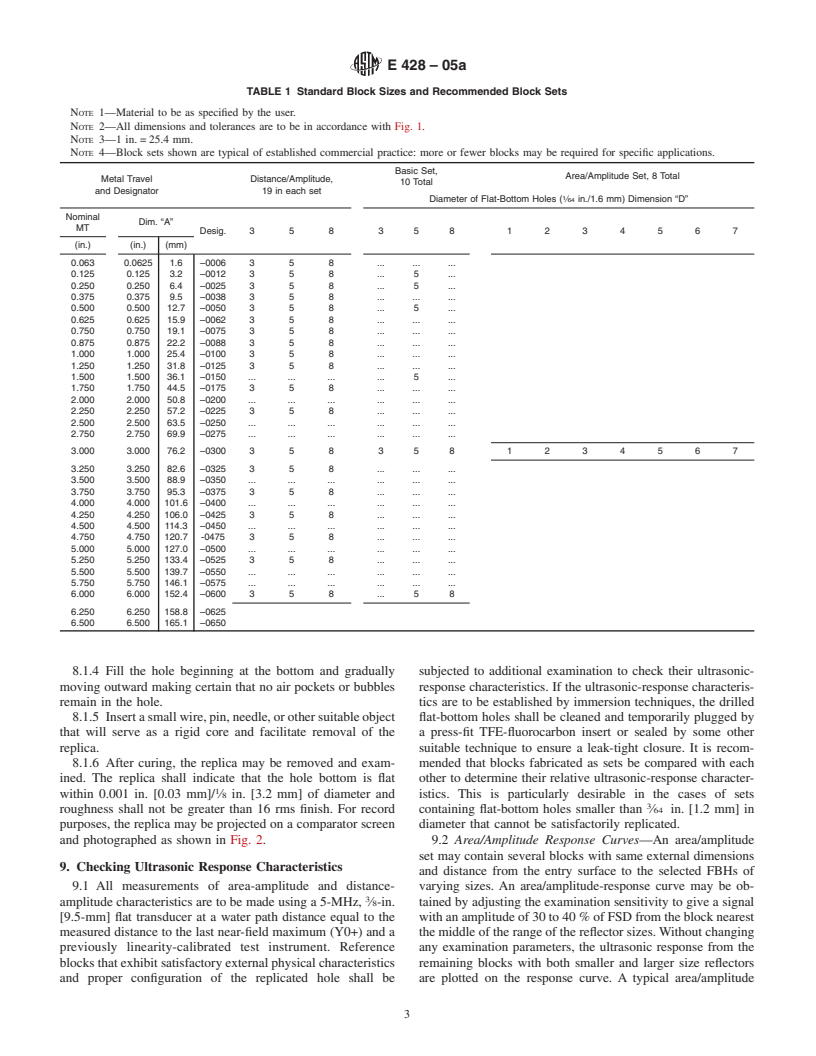

4.1 This practice details a basic fabrication and control

Practice E 127, specifically governing the fabrication and

evaluation of 7075-T6 aluminum alloy ultrasonic standard procedure and defines the minimum requirements to be met in

matching carbon and alloy steel reference blocks with the

reference blocks.

material to be examined. Additional supplemental require-

NOTE 2—PracticeE 127andGuideE 1158alsodescribeproceduresfor

ments may be needed when using this practice to fabricate

reference blocks from other types of materials or with larger

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.06 on

Ultrasonic Testing Procedures.

3

Current edition approved Dec. 1, 2005. Published January 2006. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1971. Last previous edition approved in 2005 as E 428 - 05. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers in parentheses refer to the list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E 428 – 05a

diameter holes. The physical characteristics of the hole may be group of materials may be acoustically penetrable with rela-

established by evaluating plastic replicas. It must be recog- tively similar results and may satisfy the requirements of 6.1.4.

nized however that there are limitations on the size hole that At frequencies such as 5.0 MHz and higher, microstructure

may be replicated and evaluated. changes usually y

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.