ASTM D5456-01

(Specification)Standard Specification for Evaluation of Structural Composite Lumber Products

Standard Specification for Evaluation of Structural Composite Lumber Products

SCOPE

1.1 This specification recognizes the complexity of structural glued products. Consequently, this specification includes both specific procedures and statements of intent that sampling and analysis must relate to the specific product.

1.2 This specification was developed in the light of currently manufactured products as defined in 3.2. Materials that do not conform to the definitions are beyond the scope of this specification. A brief discussion is found in Appendix X1.

1.3 Details of manufacturing procedures are beyond the scope of this specification.

Note 1—There is some potential for manufacturing variables to affect the properties of members that are loaded for sustained periods of time. Users of this specification are advised to consider the commentary on this topic, in Appendix X1.

1.4 This specification primarily considers end use in dry service conditions such as with most protected framing members, where the average equilibrium moisture content for solid-sawn lumber is less than 16 %. The conditioning environment of 6.3 is considered representative of such uses.

1.5 The performance of structural composite lumber is affected by wood species, wood element size and shape, adhesive and production parameters. Therefore, products produced by each individual manufacturer shall be evaluated to determine their product properties, regardless of the similarity in characteristics to products produced by other manufacturers. Where a manufacturer produces product in more than one facility, each production facility shall be evaluated independently. For additional production facilities, any revisions to the full qualification program in accordance with this specification shall be be approved by the independent qualifying agency.

1.6 This specification is intended to provide manufacturers, regulatory agencies, and end users with a means to evaluate a composite lumber product intended for use as a structural material.

1.7 This specification covers initial qualification sampling, mechanical and physical tests, analysis, and design value assignments. Requirements for a quality-control program and cumulative evaluations are included to ensure maintenance of allowable design values for the product.

1.8 This specification, or parts thereof, shall be applicable to structural composite lumber portions of manufactured structural components.

1.9 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5456 – 01

Standard Specification for

1

Evaluation of Structural Composite Lumber Products

This standard is issued under the fixed designation D 5456; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Structural composite lumber is intended for use as an engineering material for a variety of end-use

applications. The composition of the lumber varies by wood species, adhesive composition, wood

element size, shape, and arrangement. To provide the intended performance, composite lumber

products require: (1) an evaluation of the mechanical and physical properties and their response to

end-use environments, and (2) establishment of and conformance to standard performance specifica-

tions for quality.

Procedures contained in this specification are also to be used for establishing the design properties

and for checking the effectiveness of property assignment and quality assurance procedures.

The quality assurance sections in this specification are intended to serve as a basis for designing

quality-control programs specific to each product. The objective is to ensure that design values

established in the qualification process are maintained.

This specification is arranged as follows:

Section

Qualification Testing 5

Determination of Allowable Values 6

Independent Inspection 7

Quality Assurance 9

1. Scope ronment of 5.3 is considered representative of such uses.

1.5 The performance of structural composite lumber is

1.1 This specification recognizes the complexity of struc-

affected by wood species, wood element size and shape,

tural glued products. Consequently, this specification includes

adhesive and production parameters. Therefore, products pro-

both specific procedures and statements of intent that sampling

duced by each individual manufacturer shall be evaluated to

and analysis must relate to the specific product.

determine their product properties, regardless of the similarity

1.2 This specification was developed in the light of cur-

in characteristics to products produced by other manufacturers.

rently manufactured products as defined in 3.2. Materials that

Where a manufacturer produces product in more than one

do not conform to the definitions are beyond the scope of this

facility, each production facility shall be evaluated indepen-

specification. A brief discussion is found in Appendix X1.

dently. For additional production facilities, any revisions to the

1.3 Details of manufacturing procedures are beyond the

full qualification program in accordance with this specification

scope of this specification.

shall be be approved by the independent qualifying agency.

NOTE 1—There is some potential for manufacturing variables to affect

1.6 This specification is intended to provide manufacturers,

the properties of members that are loaded for sustained periods of time.

regulatory agencies, and end users with a means to evaluate a

Users of this specification are advised to consider the commentary on this

composite lumber product intended for use as a structural

topic, in Appendix X1.

material.

1.4 This specification primarily considers end use in dry

1.7 This specification covers initial qualification sampling,

service conditions such as with most protected framing mem-

mechanical and physical tests, analysis, and design value

bers, where the average equilibrium moisture content for

assignments. Requirements for a quality-control program and

solid-sawn lumber is less than 16 %. The conditioning envi-

cumulative evaluations are included to ensure maintenance of

allowable design values for the product.

1

1.8 This specification, or parts thereof, shall be applicable to

This specification is under the jurisdiction of ASTM Committee D07 on Wood

and is the direct responsibility of Subcommittee D07.02 on Lumber and Engineered

structural composite lumber portions of manufactured struc-

Wood Products.

tural components.

Current edition approved April 10, 2001. Published June 2001. Originally

1.9 The values stated in inch-pound units are to be regarded

published as D 5456 – 93. Last previous edition D 5456 – 99a.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

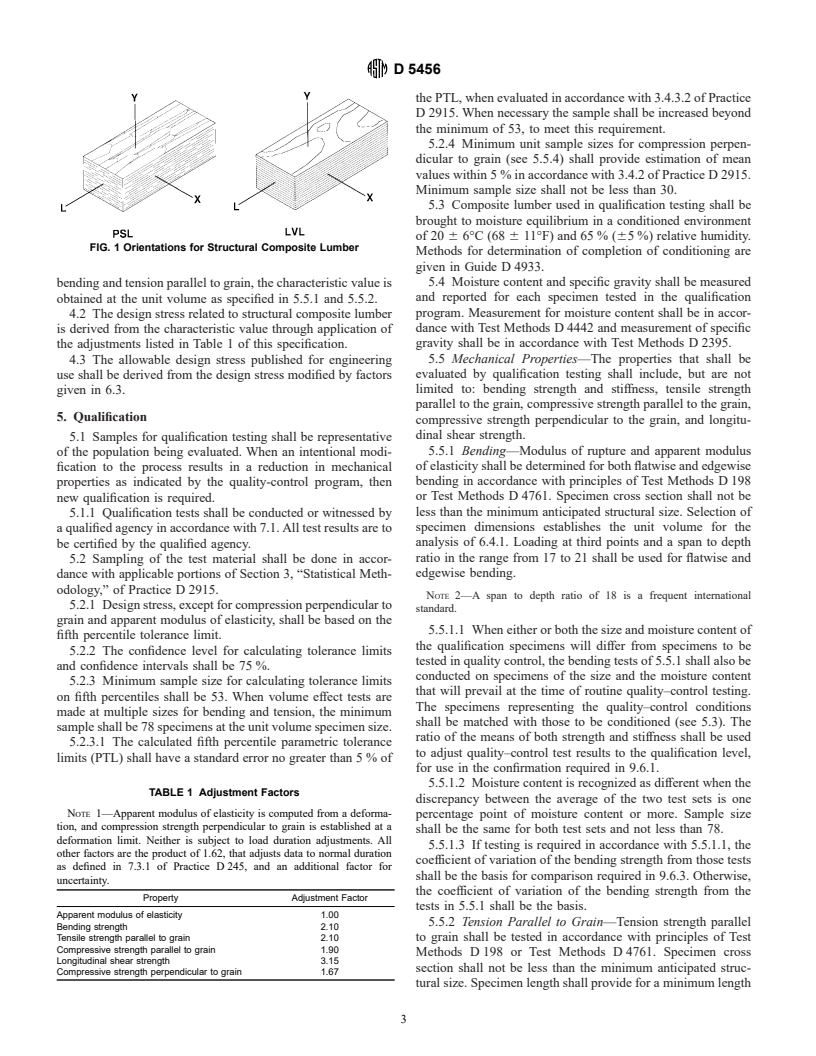

D 5456

8

as the standard. The SI units given in parentheses are for Under Direct-Voltage Stress

information only. D 4442 Test Methods for Direct Moisture Content Measure-

5

1.10 This standard does not purport to address all of the ment of Wood and Wood-Base Materials

safety concerns, if any, associated with its use. It is the D 4761 Test Methods for Mechanical

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.