ASTM D4093-95(2005)e1

(Test Method)Standard Test Method for Photoelastic Measurements of Birefringence and Residual Strains in Transparent or Translucent Plastic Materials

Standard Test Method for Photoelastic Measurements of Birefringence and Residual Strains in Transparent or Translucent Plastic Materials

SIGNIFICANCE AND USE

The observation and measurement of strains in transparent or translucent materials is extensively used in various modeling techniques of experimental stress analysis.

Internal strains induced in manufacturing processes such as casting, molding, welding, extrusion, and polymer stretching can be assessed and part exhibiting excessive strains identified. Such measurements can lead to elimination of defective parts, process improvement, control of annealing operation, etc.

When testing for physical properties, polariscopic examination of specimens is required, to eliminate those specimens exhibiting abnormal internal strain level (or defects). For example: Test Methods D 638 (Note 8) and D 882 (Note 11) recommend a polariscopic examination.

The birefringence of oriented polymers can be related to orientation, shrinkage, etc. The measurements of birefringence aid in characterization of these polymers.

For many materials, there may be a specification that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that material specification before using this test method. Table 1 of Classification System D 4000 lists the ASTM materials standards that currently exist.

SCOPE

1.1 This test method covers measurements of direction of principal strains, 1 and 2, and the photoelastic retardation, , using a compensator, for the purpose of analyzing strains in transparent or translucent plastic materials. This test method can be used to measure birefringence and to determine the difference of principal strains or normal strains when the principal directions do not change substantially within the light path.

1.2 In addition to the method using a compensator described in this test method, other methods are in use, such as the goniometric method (using rotation of the analyzer) mostly applied for measuring small retardation, and expressing it as a fraction of a wavelength. Nonvisual methods employing spectrophotometric measurements and eliminating the human judgment factor are also possible.

1.3 Test data obtained by this test method is relevant and appropriate for use in engineering design.

1.4 The values stated in either SI units or inch-pound units are to be regarded as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 1

There is no known ISO equivalent to this test method.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D4093 – 95 (Reapproved 2005)

Standard Test Method for

Photoelastic Measurements of Birefringence and Residual

Strains in Transparent or Translucent Plastic Materials

This standard is issued under the fixed designation D4093; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made throughout in July 2005.

INTRODUCTION

Light propagates in transparent materials at a speed, v, that is lower than its speed in vacuum, c. In

isotropic unstrained materials the index of refraction, n = c/v, is independent of the orientation of the

planeofvibrationoflight.Transparentmaterials,whenstrained,becomeopticallyanisotropicandthe

index of refraction becomes directional. The change in index of refraction is related to strains. If n

o

istherefractiveindexofunstrainedmaterial,thethreeprincipalindicesofrefraction, n,becomelinear

i

functions of strain:

n − n = ( A ´

i o ij j

Usingphotoelastictechniques(initiallydevelopedtomeasurestressesintransparentmodels)strains

in plastics can be assessed. In isotropic materials, two material constants, A and B, are sufficient to

describe their optomechanical behavior:

A = A when i = j, and

ij

A = B when i fi j.

ij

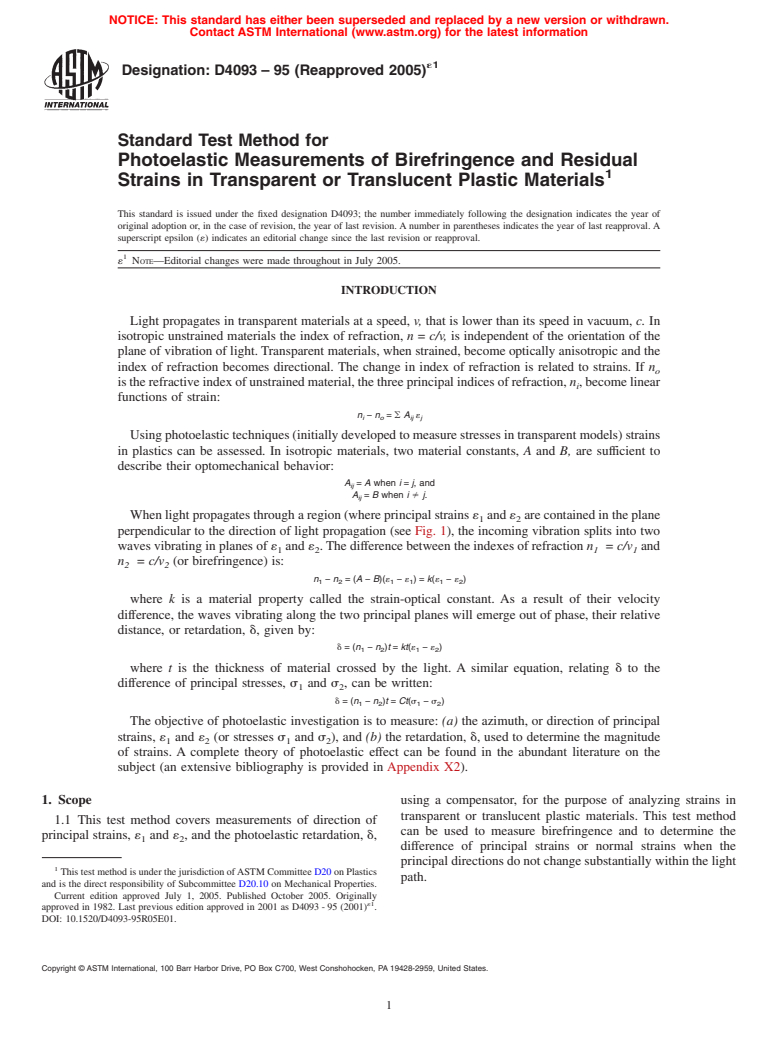

Whenlightpropagatesthrougharegion(whereprincipalstrains ´ and ´ arecontainedintheplane

1 2

perpendicular to the direction of light propagation (see Fig. 1), the incoming vibration splits into two

wavesvibratinginplanesof ´ and ´ .Thedifferencebetweentheindexesofrefraction n = c/v and

1 2 1 1

n = c/v (or birefringence) is:

2 2

n − n =(A − B)(´ − ´ )= k(´ − ´ )

1 2 1 1 1 2

where k is a material property called the strain-optical constant. As a result of their velocity

difference, the waves vibrating along the two principal planes will emerge out of phase, their relative

distance, or retardation, d, given by:

d =(n − n )t = kt(´ − ´ )

1 2 1 2

where t is the thickness of material crossed by the light. A similar equation, relating d to the

difference of principal stresses, s and s , can be written:

1 2

d =(n − n )t = Ct(s − s )

1 2 1 2

The objective of photoelastic investigation is to measure: (a) the azimuth, or direction of principal

strains, ´ and ´ (or stresses s and s ), and (b) the retardation, d, used to determine the magnitude

1 2 1 2

of strains. A complete theory of photoelastic effect can be found in the abundant literature on the

subject (an extensive bibliography is provided in Appendix X2).

1. Scope using a compensator, for the purpose of analyzing strains in

transparent or translucent plastic materials. This test method

1.1 This test method covers measurements of direction of

can be used to measure birefringence and to determine the

principal strains, ´ and ´ , and the photoelastic retardation, d,

1 2

difference of principal strains or normal strains when the

principaldirectionsdonotchangesubstantiallywithinthelight

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

path.

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

Current edition approved July 1, 2005. Published October 2005. Originally

´1

approved in 1982. Last previous edition approved in 2001 as D4093-95 (2001) .

DOI: 10.1520/D4093-95R05E01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D4093 – 95 (2005)

FIG. 1 Propagation of Light in a Strained Transparent Material

1.2 Inadditiontothemethodusingacompensatordescribed 3.1.1 compensator—an optical device used to measure re-

in this test method, other methods are in use, such as the tardation in transparent birefringent materials.

goniometric method (using rotation of the analyzer) mostly

3.1.2 polarizer—polarizing element transmitting light vi-

applied for measuring small retardation, and expressing it as a

brating in one plane only.

fraction of a wavelength. Nonvisual methods employing spec-

3.1.3 quarter-wave plate—a transparent filter providing a

trophotometricmeasurementsandeliminatingthehumanjudg- 1

relative retardation of ⁄4 wavelength throughout the transmit-

ment factor are also possible.

ting area.

1.3 Test data obtained by this test method is relevant and

3.2 Definitions of Terms Specific to This Standard:

appropriate for use in engineering design.

3.2.1 birefringence—retardation per unit thickness, d/t.

1.4 The values stated in either SI units or inch-pound units

3.2.2 retardation, d—distance (nm) between two wave

aretoberegardedasstandard.Thevaluesstatedineachsystem

fronts resulting from passage of light through a birefringent

may not be exact equivalents; therefore, each system shall be

material. (Also called “relative retardations.”)

used independently of the other. Combining values from the

3.2.3 strain, ´-strain (or deformation per unit length)—

two systems may result in nonconformance with the standard.

could be permanent, plastic strain introduced in manufacturing

1.5 This standard does not purport to address all of the

process, or elastic strain related to the existing state of stress.

safety concerns, if any, associated with its use. It is the

Both types of strains will produce strain-birefringence in most

responsibility of the user of this standard to establish appro-

polymers.Birefringencecanalsoresultfromopticalanisotropy

priate safety and health practices and determine the applica-

due to crystalline orientation.

bility of regulatory limitations prior to use.

3.2.4 strain-optical constant, k—material property, relating

NOTE 1—There is no known ISO equivalent to this test method.

the strains to changes of index of refraction (dimensionless).

2. Referenced Documents k 5 ~n 2 n !/~´ 2´ !

1 2 1 2

2.1 ASTM Standards:

3.2.5 stress-optical constant, C—material property relating

D618 Practice for Conditioning Plastics for Testing

the stresses to change in index of refraction. C is expressed in

2 −12 2

D638 Test Method for Tensile Properties of Plastics

m /N or Brewsters (10 m /N). C is usually temperature-

D882 Test Method for Tensile Properties of Thin Plastic

dependent.

Sheeting

C 5 ~n 2 n !/~s 2s !

1 2 1 2

D4000 Classification System for Specifying Plastic Materi-

als

4. Summary of Test Method

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method 4.1 To analyze strains photoelastically, two quantities are

measured: (a) the directions of principal strains and (b) the

3. Terminology

retardation, d, using light paths crossing the investigated

material in normal or angular incidence.

3.1 Definitions:

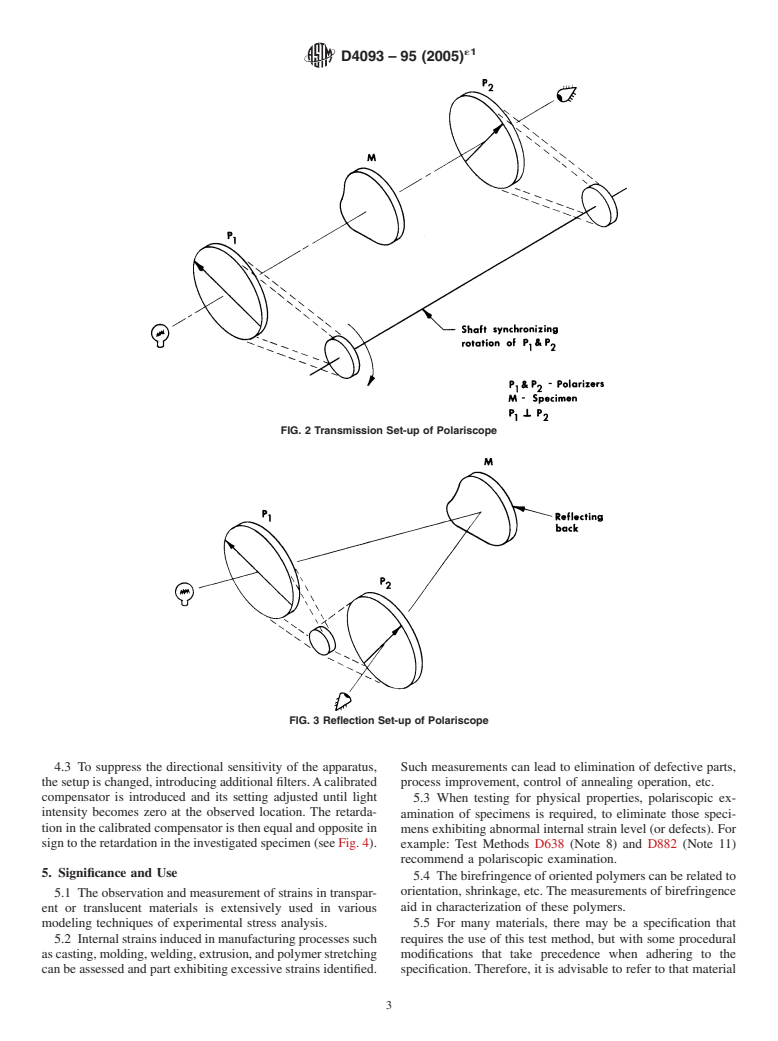

4.2 The investigated specimen or sample is introduced

between the polarizers (see Fig. 2 and Fig. 3). A synchronous

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

rotationofpolarizersfollowsuntillightintensitybecomeszero

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

at the observed location. The axes of the polarizers are then

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. parallel to direction of strains, revealing these directions.

´1

D4093 – 95 (2005)

FIG. 2 Transmission Set-up of Polariscope

FIG. 3 Reflection Set-up of Polariscope

4.3 To suppress the directional sensitivity of the apparatus, Such measurements can lead to elimination of defective parts,

thesetupischanged,introducingadditionalfilters.Acalibrated process improvement, control of annealing operation, etc.

compensator is introduced and its setting adjusted until light

5.3 When testing for physical properties, polariscopic ex-

intensity becomes zero at the observed location. The retarda-

amination of specimens is required, to eliminate those speci-

tioninthecalibratedcompensatoristhenequalandoppositein

mensexhibitingabnormalinternalstrainlevel(ordefects).For

signtotheretardationintheinvestigatedspecimen(seeFig.4).

example: Test Methods D638 (Note 8) and D882 (Note 11)

recommend a polariscopic examination.

5. Significance and Use

5.4 Thebirefringenceoforientedpolymerscanberelatedto

orientation, shrinkage, etc.The measurements of birefringence

5.1 Theobservationandmeasurementofstrainsintranspar-

aid in characterization of these polymers.

ent or translucent materials is extensively used in various

modeling techniques of experimental stress analysis. 5.5 For many materials, there may be a specification that

5.2 Internalstrainsinducedinmanufacturingprocessessuch requires the use of this test method, but with some procedural

ascasting,molding,welding,extrusion,andpolymerstretching modifications that take precedence when adhering to the

canbeassessedandpartexhibitingexcessivestrainsidentified. specification. Therefore, it is advisable to refer to that material

´1

D4093 – 95 (2005)

specification before using this test method. Table 1 of Classi- 6.1.3 Quarter-Wave Plates—Two quarter-wave plates are

ficationSystemD4000liststheASTMmaterialsstandardsthat required in the procedure described below (see 9.2):

currently exist. 6.1.3.1 The retardation of each quarter-wave plate shall be

142 6 15 nm, uniform throughout its transmission area. The

difference in retardation between the two quarter-wave plates

6. Apparatus

should not exceed 65 nm.

6.1 The apparatus used to measure strains is shown sche-

6.1.3.2 The quarter-wave plates will be indexed, to permit

matically in Fig. 4. It consists of the following items:

theirinsertioninthefieldoftheapparatuswiththeiraxesat45°

6.1.1 Light Source:

to the polarizers direction. The two quarter-wave plates shall

6.1.1.1 Transmitted-Light Set-Up—An incandescent lamp

havetheiraxescrossed(thatis,theiropticalaxesperpendicular

or properly spaced fluorescent tubes covered with a diffuser

toeachother),thusinsuringthatthefieldremainsatmaximum

should provide a uniformly diffused light. To ensure adequate

darkness when both quarter-wave plates are inserted (see Fig.

brightness, minimum illumination required is 0.3 W/in.

5).

(0.0465 W/cm ). Maximum light source power is limited to

6.1.4 Compensator—The compensator is the essential

ensure that the specimen temperature will not change more

means of measuring retardation. The following types of com-

than 2°C during the test. The incandescent lamp must be

pensators can be used:

selected to provide a color temperature no lower than 3150 K.

6.1.4.1 Linear Compensator —In the linear compensator

Thereshouldbenovisiblenonuniformity,darkorbrightspots

the retardation in the compensator is linearly variable along its

on the diffuser surface, when no specimen is inserted in the

length.Agraduated scale shall be attached to the compensator

apparatus.

body in such a manner that slippage cannot occur. The

6.1.1.2 Reflection-Light Source—For the reflection set-up

calibration characteristic of the compensator shall include the

an incandescent, reflector-equipped projection lamp is re-

position along its length (as indicated by the scale) of the line

quired. The lamp shall be equipped with proper lenses to

where the retardation is zero and the number of divisions d per

ensure uniform illumination of the investigated object. At a

unit retardation (usually one wavelength). (The retardation per

distanceof2ft(610mm)fromthelampanareaof1ft (0.093

division is D= l/d.) The scale density shall be sufficient to

m )shouldbeilluminated,withnovisibledarkorbrightspots.

provideclearvisibilityforobserving1%oftheusefulrangeof

The lamp power should be at least 150 W.

the compensator.

6.1.2 Polarizer—The polarizing element shall be kept 4

6.1.4.2 Uniform Field Compensator —The uniform field

clean. The ratio of the transmittance of polarizers with their

compensator is usually constructed from two optical wedges

axes parallel, to the transmittance of the polarizers with their

movedbymeansofaleadscrew,theamountofrelativemotion

axes perpendicular to each other (or in crossed position),

being linearly related to the total thickness and the retardation.

should not be less than 500.Aglass-laminated construction of

The lead screw motion shall be controlled by a dial drum or

polarizers is recommended. The polarizers must be mechani-

counter. Calibration of this compensator shall include the

cally or electrically coupled to insure their mutually perpen-

dicular setting while rotated together to measure directions. A

graduated scale must be incorporated to indicate the common

Also known as “Babinet” compensator.

rotation of polarizers to a fixed reference mark. Also known as “Babinet-Soleil” compensator.

´1

D4093 – 95 (2005)

FIG. 4 Apparatus

FIG. 5 Direction Measuring Set-up

position, as indicated by the drum or counter, where the 7. Test Specimen

retardation is zero and the number of division of drum or

7.1 Sheet,film,ormoregenerally,aconstant-thicknessitem

counter d per unit of retardation. (The retardation per division

can be examined using a transmission set-up. For use in

isD= l/d.)

reflection, a reflecting surface must be provided. This can be

6.1.4.3 Compensators have a limited range of measured

accomplished by painting one side of the specimen with

retardation. In case the retardation in the sample exceeds the

aluminum paint. Alternatively, it is possible to place the

rangeofthecompensatorused,insertionofanoffsetretarderis

examined sheet specimen against a clean metal surface (pref-

needed. The offset retarder must be calibrated and positioned

erably aluminum) or an aluminum-painted surface.

along the axes of the compensator, between the analyzer and

7.2 Examination of complex surfaces or shapes sometimes

the sample.

requires the use of an immersion liquid. The examined item is

6.1.5 Filter—Monochromatic light is required to perform

placed inside a tank containing a liquid selected to exhibit

various operations in photoelasticity and some operations

approximately the same index of refraction as the tested item.

cannotbesuccessfullyaccomplishedusingwhitelight.Inthose

This technique is commonly used to examine three-

instances a monochromatic light can be obtained introducing

dimensional shapes.

within the light path, a filter transmitting only light of the

7.3 If conditioning is required, Procedure A of Practice

desired wave length. To best correlate with observation in

D618 shall be used.

white light, a narrow band-pass filter with peak transmittance

at 570 6 6 nm and a maximum transmitted band-width (at

half-peak point) of 10 nm should be used. Krylon aluminum aerosol can spray paint was found satisfactory.

------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.