ASTM E1931-97

(Guide)Standard Guide for X-Ray Compton Scatter Tomography

Standard Guide for X-Ray Compton Scatter Tomography

SCOPE

1.1 Purpose--this guide covers a tutorial introduction to familiarize the reader with the operational capabilities and limitations inherent in X-ray Compton Scatter Tomography (CST). Also included is a brief description of the physics and typical hardware configuration for CST.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1931 – 97

Standard Guide for

X-Ray Compton Scatter Tomography

This standard is issued under the fixed designation E 1931; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope NDE methods. Chief among the limitations is the difficulty in

performing CST on thick sections of high-Z materials. CST is

1.1 Purpose—This guide covers a tutorial introduction to

best applied to thinner sections of lower Z materials. The

familiarize the reader with the operational capabilities and

following provides a general idea of the range of CST

limitations inherent in X-ray Compton Scatter Tomography

applicability when using a 160 Kv constant potential X-ray

(CST). Also included is a brief description of the physics and

source:

typical hardware configuration for CST.

Material Practical Thickness Range

1.2 Advantages—X-ray Compton Scatter Tomography

(CST) is a radiologic nondestructive examination method with

Steel Up to about 3 mm ( ⁄8 in.)

several advantages that include:

Aluminum Up to about 25 mm (1 in.)

Aerospace composites Up to about 50 mm (2 in.)

1.2.1 The ability to perform X-ray examination without

access to the opposite side of the test object;

The limitations of the technique must also consider the

1.2.2 The X-ray beam need not completely penetrate the test

required X, Y, and Z axis resolutions, the speed of image

object allowing thick objects to be partially examined. Thick

formation, image quality and the difference in the X-ray

test objects become part of the radiation shielding thereby

scattering characteristics of the parent material and the internal

reducing the radiation hazard;

features that are to be imaged.

1.2.3 The ability to image test object subsurface features

1.5 The values stated in both inch-pound and SI units are to

with minimal influence from surface features;

be regarded separately as the standard. The values given in

1.2.4 The ability to obtain high-contrast images from low

parentheses are for information only.

subject contrast materials that normally produce low-contrast

1.6 This standard does not purport to address all of the

images when using traditional transmitted beam X-ray imaging

safety concerns, if any, associated with its use. It is the

methods; and

responsibility of the user of this standard to establish appro-

1.2.5 The ability to obtain depth information for test object

priate safety and health practices and to determine the

features thereby providing three-dimensional examination. The

applicability of regulatory limitations prior to use.

ability to obtain depth information presupposes the use of a

2. Referenced Documents

highly collimated detector system having a narrow angle of

acceptance.

2.1 ASTM Standards:

1.3 Applications—This guide does not specify which test

E 747 Test Method for Controlling Quality of Radiographic

objects are suitable, or unsuitable, for CST. As with most

Testing Using Wire Penetrameters

nondestructive examination techniques, CST is highly applica-

E 1025 Practice for Hole-Type Image Quality Indicators

tion specific thereby requiring the suitability of the method to

Used for Radiography

be first demonstrated in the application laboratory. This guide

E 1255 Practice for Radioscopy

does not provide guidance in the standardized practice or

E 1316 Standard Terminology for Nondestructive Examina-

application of CST techniques. No guidance is provided

tions

concerning the acceptance or rejection of test objects examined

E 1441 Guide for Computed Tomography (CT) Imaging

with CST.

E 1453 Guide for the Storage of Media that Contains

1.4 Limitations—As with all nondestructive examination

Radioscopic Data

methods, CST has limitations and is complementary to other

E 1475 Guide for Data Fields for Computerized Transfer of

Digital Radiological Test Data

E 1647 Practice for Determining Contrast Sensitivity in

Radioscopy

This guide is under the jurisdiction of ASTM Committee E-07 on Nondestruc-

tive Testing and is the direct responsibility of Subcommittee E07.01 on Radiology

(X and Gamma) Method.

Current edition approved Dec. 10, 1997. Published June 1998. Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E1931–97

2.2 ANSI/ASNT Standards: actual test object are the best means for CST performance

ASNT Recommended Practice No. SNT-TC-1A Personnel monitoring. Conventional radiologic performance measuring

Qualification and Certification in Nondestructive Test- devices, such as Test Method E 747 and Practice E 1025 image

ing quality indicators or Practice E 1647 contrast sensitivity gages

ANSI/ASNT CP-1 89 Standard for Qualification and Certi- are designed for transmitted X-ray beam imaging and are of

fication in Nondestructive Testing Personnel little use for CST. With appropriate calibration, CST can be

2.3 Military Standard: utilized to make three-dimensional measurements of internal

MIL-STD-410 Nondestructive Testing Personnel Qualifica- test object features.

tion and Certification

5. Significance and Use

3. Terminology

5.1 Principal Advantage of Compton Scatter Tomography—

The principal advantage of CST is the ability to perform

3.1 Definitions:

three-dimensional X-ray examination without the requirement

3.1.1 CST, being a radiologic examination method, used

for access to the back side of the test object. CST offers the

much that the same vocabulary as other X-ray examination

possibility to perform X-ray examination that is not possible by

methods. A number of terms used in this standard are defined

any other method. The CST sub-surface slice image is mini-

in Terminology E 1316. It may also be helpful to read Guide

mally affected by test object features outside the plane of

E 1441.

examination. The result is a radioscopic image that contains

4. Summary of Guide information primarily from the slice plane. Scattered radiation

limits image quality in normal radiographic and radioscopic

4.1 Description—Compton Scatter Tomography is a

imaging. Scatter radiation does not have the same detrimental

uniquely different nondestructive test method utilizing pen-

effect upon CST because scatter radiation is used to form the

etrating X-ray or gamma-ray radiation. Unlike computed

image. In fact, the more radiation the test object scatters, the

tomography (CT), CST produces radioscopic images which are

better the CST result. Low subject contrast materials that

not computed images. Multiple slice images can be simulta-

cannot be imaged well by conventional radiographic and

neously produced so that the time per slice image is in the

radioscopic means are often excellent candidates for CST. Very

range of a few seconds. CST produces images that are thin with

high contrast sensitivities and excellent spatial resolution are

respect to the test object thickness (slice images) and which are

possible with CST tomography.

at right angles to the X-ray beam. Each two-dimensional slice

5.2 Limitations—As with any nondestructive testing

image (X–Y axes) is produced at an incremental distance along

method, CST has its limitations. The technique is useful on

and orthogonal to the X-ray beam (Z–axis). A stack of CST

reasonably thick sections of low-density materials. While a 1

images therefore represents a solid volume within the test

in. (25 mm) depth in aluminum or 2 in. (50 mm) in plastic is

object. Each slice image contains test object information which

achievable, the examination depth is decreased dramatically as

lies predominantly within the desired slice. To make an

the material density increases. Proper image interpretation

analogy as to how CST works, consider a book. The test object

requires the use of standards and test objects with known

may be larger or smaller (in length, width and depth) then the

internal conditions or representative quality indicators (RQIs).

analogous book. The CST slice images are the pages in the

The examination volume is typically small, on the order of a

book. Paging through the slice images provides information

few cubic inches and may require a few minutes to image.

about test object features lying at different depths within the

Therefore, completely inspecting large structures with CST

test object.

requires intensive re-positioning of the examination volume

4.2 Image Formation—CST produces one or more digital

that can be time-consuming. As with other penetrating radia-

slice plane images per scan. Multiple slice images can be

tion methods, the radiation hazard must be properly addressed.

produced in times ranging from a few seconds to a few minutes

depending upon the examined area, desired spatial resolution

6. Technical Description

and signal-to-noise ratio. The image is digital and is typically

6.1 General Description of Compton Scatter Tomography—

assembled by microcomputer. CST images are free from

Transmitted beam radiologic techniques used in radiography,

reconstruction artifacts as the CST image is produced directly

radioscopy and computed tomography have dominated the use

and is not a calculated image. Because CST images are digital,

of penetrating radiation for industrial nondestructive examina-

they may be enhanced, analyzed, archived and in general

tion. The transmitted beam technique depends upon the pen-

handled as any other digital information.

etrating radiation attenuation mechanisms of photoelectric

4.3 Calibration Standards—As with all nondestructive ex-

absorption and Compton scattering. For low-Z materials at

aminations, known standards are required for the calibration

energies up to about 50 keV, the photoelectric effect is the

and performance monitoring of the CST method. Practice E

dominant attenuation mechanism. As X-ray energy increases,

1255 calibration block standards that are representative of the

Compton scattering becomes the dominant attenuation mecha-

nism for large scattering angles in low-Z materials. Pair

production comes into play above 1.02 MeV and can become

Available from American National Standards Institute, 11 W. 42nd St., 13th

the dominant effect for higher X-ray energies. Photoelectric

Floor, New York, NY 10036.

4 absorption is strongly dependent upon the atomic number and

Available from Standardization Document Order Desk, Bldg. 4 Section D, 700

Robbins Ave. Philadelphia, PA 19111-5094, Ans:NPODS. also the electron density of the absorbing material. Compton

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E1931–97

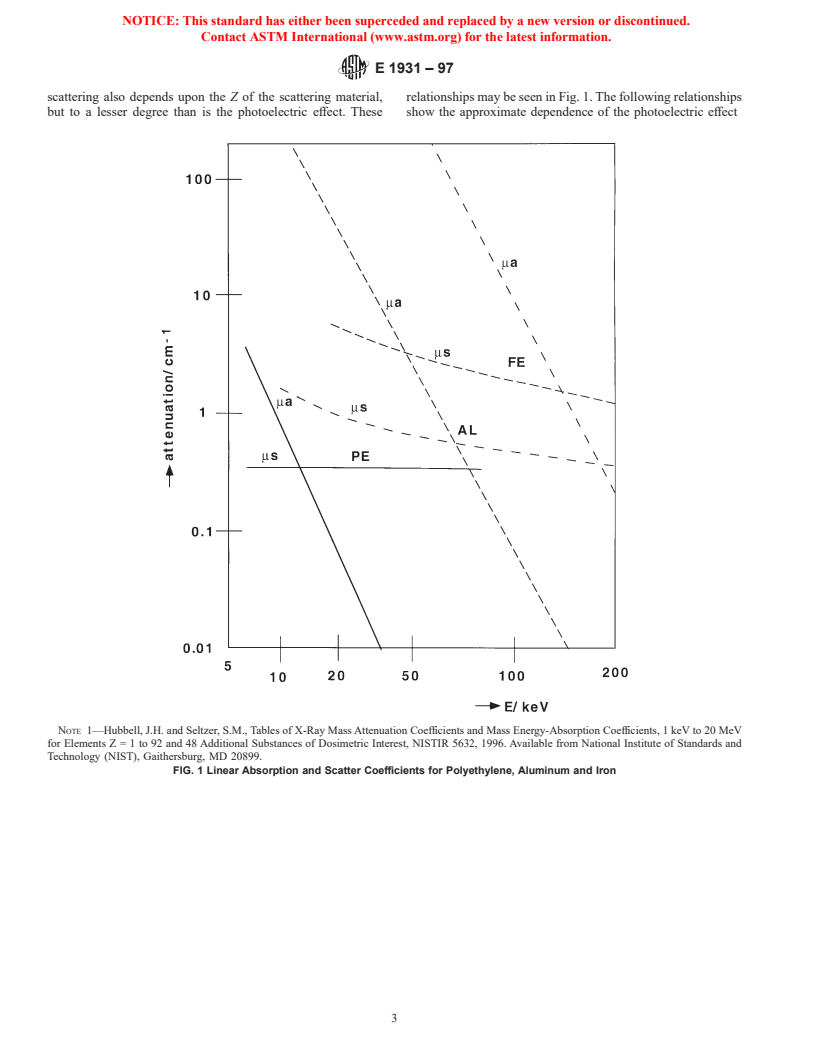

scattering also depends upon the Z of the scattering material, relationships may be seen in Fig. 1. The following relationships

but to a lesser degree than is the photoelectric effect. These show the approximate dependence of the photoelectric effect

NOTE 1—Hubbell, J.H. and Seltzer, S.M., Tables of X-Ray Mass Attenuation Coefficients and Mass Energy-Absorption Coefficients, 1 keV to 20 MeV

for ElementsZ=1to92and 48 Additional Substances of Dosimetric Interest, NISTIR 5632, 1996. Available from National Institute of Standards and

Technology (NIST), Gaithersburg, MD 20899.

FIG. 1 Linear Absorption and Scatter Coefficients for Polyethylene, Aluminum and Iron

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E1931–97

and Compton scattering upon target material Z and incident noise CST image and faster examination speed. For this reason

X-ray energy E:

an X-ray source is often a better choice than a radioisotope for

5 7/2

Photoelectric Effect Z / E CST. Radiation detection and other image forming consider-

Compton Scattering Z / E

ations may also differ substantially from other radiologic

Pair Production: Z (lnE - constant)

imaging methods.

6.1.1 CST is best suited for lower Z materials such as

6.3 Theory of Compton Scatter Tomography—In the energy

aluminum ( Z=13 ) using a commercially available 160 Kv

range appropriate for CST (roughly 50 keV to 1 MeV), the

X-ray generating system. Somewhat higher Z materials may be

primary interaction mechanisms between electromagnetic ra-

examined by utilizing a higher energy X-ray generator rated at

diation and matter are photoelectric absorption and inelastic

225, 320, or 450 Kv. It is useful to envision the CST process as

(Compton) scatter. Fig. 2 illustrates the principles of photo-

one where the X-rays that produce the CST image originate

electric absorption and Compton scattering. As an X-ray

from many discrete points within the inspected volume. Each

having an energy E collides with an electron, the electron

Compton scatter event generates a lower energy X-ray that 0

absorbs energy from the incoming X-ray photon and is ejected

emanates from the scattering site. Singly scattered X rays that

from its shell. In the case of photoelectric absorption, the

reach the detector carry information about the test object

material characteristics at the site where it was generated. The incoming photon’s energy is totally absorbed. As the energy E

scatter radiation is also affected by the material through which of the incoming photon increases, the probability of photoelec-

it passes on the way to the detector. The external source of tric absorption decreases while the probability of Compton

primary penetrating radiation, that may be either X rays or scattering increases. The Compton scattering creates a new

gamma rays, interact by the Compton scattering process. The

X-ray having and energy E , and travelling at an angle u with

primary radiation must have adequate energy and intensity to

respect to the direction of the original primary X-ray.

generate sufficient scattered radiation at the examination site to

6.3.1 Fig. 1 shows how material linear attenuation coeffi-

allow detection. The examination depth is limited to that depth

cients due to photoelectric absorption and Compton scattering

from which sufficient scattered radiation can reach the detector

vary with energy for polyethylene, aluminum and iron. The

to form a useable image. The test object is therefore effectively

linear absorption coefficient μ for all three materials falls

a

imaged from t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.