ASTM C609-07(2019)

(Test Method)Standard Test Method for Measurement of Light Reflectance Value and Small Color Differences Between Pieces of Ceramic Tile

Standard Test Method for Measurement of Light Reflectance Value and Small Color Differences Between Pieces of Ceramic Tile

SIGNIFICANCE AND USE

5.1 This test method describes the means of determining the LRV of a tile specimen. Certain building codes require the use of materials rated by LRV. Application of this test method provides the means for rating ceramic tile. LRVs reported for ceramic tile should include reference to the observer and illuminant for which the rating is valid.

5.2 LRV is a property dependent on the overall color of a tile specimen. Control of LRV is achieved through control of color and adherence to color specifications will govern the acceptability of a product with respect to LRV. Therefore, a product cannot be judged as having an unacceptable LRV unless the color of the product is found to be unacceptable.

5.3 Mixtures of several tile products are commonly installed on a surface, requiring a means to calculate LRV for a product mix. The rating obtained for an individual tile product can be used to calculate the LRV for a product mix using the following equation:

where: n = number of products included in the mix p1 to n = the proportion of the surface area taken up by each product, the sum of p1 to pn must equal one LRV1 to n = the LRV for each product used For example, a mixture of two products is used on a surface. Two thirds of the surface area is covered by product A with a LRV of 75 %, and one third of the surface is covered by product B with an LRV of 60 % (see Fig. 2). Using the equation, the product mix is found to have an LRV of 70 %.

FIG. 2 Example of a Product Mix Used on a Surface

5.4 The test method described herein provides instrumental means as the basis for judging color difference. Magnitude of color difference between pairs of ceramic tile can be determined and expressed in numerical terms.

5.5 Based on interlaboratory investigation,3 color difference ΔE of plain-colored tile, if determined according to this test method, should give excellent reproducibility with a standard deviation of not more than σ = ±0.15 units....

SCOPE

1.1 This test method covers the measurement of Light Reflectance Value (LRV) and visually small color difference between pieces of glazed or unglazed ceramic tile, using any spectrophotometer that meets the requirements specified in the test method. LRV and the magnitude and direction of the color difference are expressed numerically, with sufficient accuracy for use in product specification.

1.2 LRV may be measured for either solid-colored tile or tile having a multicolored, speckled, or textured surface. For tile that are not solid-colored, an average reading should be obtained from multiple measurements taken in a pattern representative of the overall sample as described in 9.2 of this test method. Small color difference between tiles should only be measured for solid-color tiles. Small color difference between tile that have a multicolored, speckled, or textured surface, are not valid.

1.3 For solid colored tile, a comparison of the test specimen and reference specimen should be made under incandescent, fluorescent and daylight illuminant conditions. The use of multiple illuminants allows the color difference measurement to be made without the risk of wrongly accepting a match when the tiles being compared are metamers. (See 3.1.4.)

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issue...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C609 −07 (Reapproved 2019)

Standard Test Method for

Measurement of Light Reflectance Value and Small Color

Differences Between Pieces of Ceramic Tile

This standard is issued under the fixed designation C609; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This test method covers the measurement of Light

Reflectance Value (LRV) and visually small color difference

2. Referenced Documents

between pieces of glazed or unglazed ceramic tile, using any

2.1 ASTM Standards:

spectrophotometer that meets the requirements specified in the

C242 Terminology of Ceramic Whitewares and Related

test method. LRV and the magnitude and direction of the color

Products

difference are expressed numerically, with sufficient accuracy

D2244 Practice for Calculation of Color Tolerances and

for use in product specification.

Color Differences from Instrumentally Measured Color

1.2 LRV may be measured for either solid-colored tile or

Coordinates

tile having a multicolored, speckled, or textured surface. For

E259 Practice for Preparation of Pressed Powder White

tile that are not solid-colored, an average reading should be

Reflectance Factor Transfer Standards for Hemispherical

obtained from multiple measurements taken in a pattern

and Bi-Directional Geometries

representative of the overall sample as described in 9.2 of this

E284 Terminology of Appearance

test method. Small color difference between tiles should only

be measured for solid-color tiles. Small color difference

3. Terminology

between tile that have a multicolored, speckled, or textured

3.1 Definitions:

surface, are not valid.

*

3.1.1 color difference, ∆E and ∆E —the vector sum of the

H

1.3 For solid colored tile, a comparison of the test specimen * * * *

three component differences ∆L , ∆a , and ∆b for ∆E and

and reference specimen should be made under incandescent,

∆L ,∆a ,∆b for ∆E . The superscript * indicates color

H H H H

fluorescent and daylight illuminant conditions. The use of

difference based on the use of CIELAB color space equations,

multiple illuminants allows the color difference measurement

while the subscript H indicates color difference based on the

tobemadewithouttheriskofwronglyacceptingamatchwhen

useoftheHunterequations. ∆E isexpressedinunitsofjudds,

H

the tiles being compared are metamers. (See 3.1.4.) *

while ∆E is a unit-less value. Either form of the ∆E can be

1.4 The values stated in inch-pound units are to be regarded solved for using the equation shown in 10.3. For both the

as the standard. The values given in parentheses are for CIELAB and Hunter equations, the values ∆ L, ∆a, and ∆b are

information only. obtained by calculating the component differences as follows:

1.5 This standard does not purport to address all of the

∆L 5 L 2 L

t r

safety concerns, if any, associated with its use. It is the

∆a 5 a 2 a

t r

responsibility of the user of this standard to establish appro-

∆b 5 b 2 b

t r

priate safety, health, and environmental practices and deter-

where:

mine the applicability of regulatory limitations prior to use.

t = test specimen, and

1.6 This international standard was developed in accor-

r = reference specimen.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

The quantity ∆E has a positive value and it describes the

Development of International Standards, Guides and Recom-

magnitude but not the direction of color difference between the

test specimen and the reference specimen. The direction of

ThistestmethodisunderthejurisdictionofASTMCommitteeC21onCeramic

Whitewares and Related Products and is the direct responsibility of Subcommittee

C21.06 on Ceramic Tile. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2019. Published August 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1967. Last previous edition approved in 2014 as C609 – 07 (2014). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/C0609-07R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C609−07 (2019)

color difference depends upon the algebraic signs of the 3.1.7 reproducibility—the standard deviation of results ob-

components ∆ L, ∆a, and ∆b. A positive ∆L value means that tained by different operators using the same or different types

the test specimen is lighter than the reference against which it of instruments in different laboratories.

is being compared, and a negative ∆L value means that the test

3.1.8 standard—the plaque or other media of established

specimen is darker. However, the algebraic signs of chroma-

tristimulus value, against which standardization of the instru-

ticity components, ∆ a and ∆b, do not convey an easily

ment is made.

visualized difference in color attributes and can best be

3.1.9 test specimen—any piece of tile whose LRV or color

visualized by plotting the corresponding points in the chroma-

difference from a reference specimen is to be evaluated.

ticity plane.

3.1.10 tile—See Terminology C242.

3.1.2 color space—the colors of opaque specimens such as

3.1.11 spectrophotometric—measurement of the spectral re-

ceramic tile are described in terms of three color scales L, a,

flectance or transmittance curve of a material.

and b. Scale L is a measure of lightness, a is a measure of

redness or greenness, and b is a measure of yellowness or

4. Summary of Test Method

blueness. The units for each of the three scales are so chosen

that they represent equally perceptible color differences. The

4.1 This test method explains the technique for measuring

interrelation of these color scales is more readily visualized if

the LRV and color of tile specimens with a spectrophotometric

the scales are represented geometrically as the three mutually

instrument that meets the specified requirements. Such instru-

perpendicularaxesofathree-dimensionalcolorspace,withthe

ments should give results comparable to differences observed

L axis in the vertical direction, the positive a axis (redness) to

by the human eye, and yield for each color a unique, three-

the right, and the positive b axis (yellowness) in a counter-

number characterization, having known relationship to the

clockwise direction from the positive a axis (see Fig. 1).

tristimulus values X, Y, and Z.

4.2 Spectrophotometic measurement systems commonly

provide measurement data in a variety of color units and allow

for automatic conversion of data from one color system to

another. Select equations are included in this test method for

*

manual determination of LRVfromY, L or L . Equations are

H

* * *

also provided for calculation of L ,a and b and L ,a and b

H H H

from tristimulus values X,Y, Z.The algebraic differences in L,

a, and b values, between any two specimens, are then used to

calculate the color difference, ∆E. If manual calculations are

required, consult the instrument supplier for conversions not

provided within this test method.

4.3 The complete description of the amount and direction of

a color difference between any two pieces of solid colored tile

canbegivensimplyasthethreerespectivedifferencesbetween

thepairsofvaluesfor L, a,and b.Forsomepurposes, ∆Ealone

providesenoughinformation,sinceitsmagnitudegivesafairly

good correlation with human opinions about the size of a color

difference.

4.4 To protect against approval of a metameric color match,

FIG. 1 Three-Dimensional Color Space

multiple illuminates must be used when evaluating color

difference between solid colored tiles.Atest specimen needs to

prove suitable with respect to a reference specimen under

3.1.3 light reflectance value, (LRV)—the luminance factor

incandescent, fluorescent and daylight illuminant conditions in

Y, of a sample expressed as a percent. Thus, a Y value of 70

order to be judged as acceptable.

wouldequatetoanLRVof70%.TheLRVindicatestheportion

of light cast on a sample that is not absorbed.

5. Significance and Use

3.1.4 metamers—See Terminology E284.

5.1 This test method describes the means of determining the

3.1.5 reference specimen—any tile for which a match is

LRV of a tile specimen. Certain building codes require the use

desired.

of materials rated by LRV. Application of this test method

3.1.6 repeatability—the standard deviation of results ob-

provides the means for rating ceramic tile. LRVs reported for

tained by the same operator using the same instrument in

ceramic tile should include reference to the observer and

successive measurements.

illuminant for which the rating is valid.

Illing, A. M., Balinkin, I., “Precision in Measurement of Small Color

Differences,” American Ceramic Society Bulletin , Vol 44, No. 12, 1965, pp. Billmeyer, F.W. Jr., Saltzman, M., Principles of Color Technology, 2nd Edition,

956–962. John Wiley & Sons, Inc., New York, NY, 1981 p. 78, 85.

C609−07 (2019)

5.2 LRV is a property dependent on the overall color of a illuminant conditions ensure the color differences calculated

tile specimen. Control of LRV is achieved through control of between a test and reference specimen account for the possible

color and adherence to color specifications will govern the occurrence of metamerism.

acceptability of a product with respect to LRV. Therefore, a

6. Apparatus

product cannot be judged as having an unacceptable LRV

unless the color of the product is found to be unacceptable. 6.1 Type of Instrument for LRV Measurement—Any color-

measuring spectrophotometric instrument capable of yielding

5.3 Mixturesofseveraltileproductsarecommonlyinstalled

data that can be transformed mathematically into the Interna-

on a surface, requiring a means to calculate LRV for a product

tional Commission of Illumination (CIE) tristimulus values X,

mix. The rating obtained for an individual tile product can be

Y, and Z, may be used. It must have a color difference, ∆E,

used to calculate the LRV for a product mix using the

repeatability (see 3.1.6)of σ = 60.2 units or less, based on five

following equation:

independent measurements. The well-known standard devia-

LRV 5 p LRV 1p LRV 1….1p LRV (1)

product mix ( 1 1 2 2 n n

tionequationshownasfollowsisusedtocalculatethestandard

where:

deviation.

½

n = number of products included in the mix

σ 5 F X 2 X /N (2)

@ ~ ! #

(j j j

p = the proportion of the surface area taken up by

1ton

6.2 Type of Instrument for Color Measurement—For the

each product, the sum of p to p must equal

1 n

measurement of solid colored tile, the spectrophotometric

one

measurement system must meet all of the requirements for

LRV to n = the LRV for each product used

LRV measurement and be capable of yielding tristimulus

For example, a mixture of two products is used on a surface.

values X, Y, and Z, for daylight, incandescent and fluorescent

Two thirds of the surface area is covered by product A with a

illuminants.

LRV of 75 %, and one third of the surface is covered by

6.3 Instrument Setup—For measurement of LRV and color

product B with an LRV of 60 % (see Fig. 2). Using the

difference, spectrophotometric measurements should be taken

equation, the product mix is found to have an LRV of 70 %.

with specular component included (SCI). If the instrument

being used is not capable of taking SCI measurements, then all

reported measurements must include a notation stating mea-

surement obtained with specular component excluded (SCE).

7. Standards

7.1 Primary Standard—The primary standard for reflec-

tancemeasurementisalayeroffreshlypreparedbariumsulfate

(see Practice E259).

7.2 Working Standard—Because of the difficulty of prepar-

ing a primary standard each time and its variability, calibrated

pieces of white opaque glass, porcelain enamel plaques, or

glazed ceramic tile are used as working standards and are

usually supplied by the manufacturer of the instrument. The

FIG. 2 Example of a Product Mix Used on a Surface

manufacturer of each type of instrument provides numerical

specifications for the working standards, which have a definite

5.4 The test method described herein provides instrumental

relationship to the CIE values X, Y, and Z.

means as the basis for judging color difference. Magnitude of

color difference between pairs of ceramic tile can be deter-

8. Test Specimens

mined and expressed in numerical terms.

1 1

8.1 Size—The preferred size of test specimens is 4 ⁄4 by 4 ⁄4

5.5 Based on interlaboratory investigation, color difference

in. (108 by 108 mm) because most instruments are equipped

∆E of plain-colored tile, if determined according to this test

with a holder of that size which assures that the identical

method, should give excellent reproducibility with a standard

surface area may be measured repeatedly. Specimens larger

deviation of not more than σ = 60.15 units. LRV should also

may be reduced to that size by cutting. The required sample

give excellent reproducibility when used for solid colored tile

size is dependent on the instrument being used to measure the

based on the relationship between LRV and either the Y

test and reference specimens. Many instruments can be con-

tristimulus or L value. However, LRV reproducibility for

figured to measure a sample using different size viewing

multicolored, speckled, or textured surface tile will be depen-

apertures. The largest area of view capable of being used

dent upon the degree of variation of the tile specimen, and will

without interference from the edges of the tile should be

require a different measurement procedure to minimize the

selected. However, the same aperture size should be used for

impact of the variation.

all measurements involved in a comparison. Tile with surfaces

5.6 The test method requires the use of multiple illuminants

for the determination of color difference between solid-colored

Duncan, A. J., Quality Control and Industrial Statistics, R. D. Irwin, Inc.,

tiles. Evaluation under incandescent, fluorescent and daylight Homewood, IL, 1959, p. 45.

C609−07 (2019)

1/3

smaller than the aperture opening may not be measured with L* 5 116 Y/Y 216 (4)

~ !

n

thistestmethod.Likewise,tilewithinsufficientflatareacannot 1/3 1/3

a* 5 500@~X/X ! 2 ~Y/Y ! #

n n

be tested for color difference.

1/3 1/3

b* 5 500@~Y/Y ! 2 ~Z/Z ! #

n n

8.2 Selection—When the tes

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C609 − 07 (Reapproved 2014) C609 − 07 (Reapproved 2019)

Standard Test Method for

Measurement of Light Reflectance Value and Small Color

Differences Between Pieces of Ceramic Tile

This standard is issued under the fixed designation C609; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of Light Reflectance Value (LRV) and visually small color difference between

pieces of glazed or unglazed ceramic tile, using any spectrophotometer that meets the requirements specified in the test method.

LRV and the magnitude and direction of the color difference are expressed numerically, with sufficient accuracy for use in product

specification.

1.2 LRV may be measured for either solid-colored tile or tile having a multicolored, speckled, or textured surface. For tile that

are not solid-colored, an average reading should be obtained from multiple measurements taken in a pattern representative of the

overall sample as described in 9.2 of this test method. Small color difference between tiles should only be measured for solid-color

tiles. Small color difference between tile that have a multicolored, speckled, or textured surface, are not valid.

1.3 For solid colored tile, a comparison of the test specimen and reference specimen should be made under incandescent,

fluorescent and daylight illuminant conditions. The use of multiple illuminants allows the color difference measurement to be made

without the risk of wrongly accepting a match when the tiles being compared are metamers. (See 3.1.4.)

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

C242 Terminology of Ceramic Whitewares and Related Products

D2244 Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates

E259 Practice for Preparation of Pressed Powder White Reflectance Factor Transfer Standards for Hemispherical and

Bi-Directional Geometries

E284 Terminology of Appearance

3. Terminology

3.1 Definitions:

* * * * *

3.1.1 color difference, ΔE and ΔE —the vector sum of the three component differences ΔL , Δa , and Δb for ΔE and

H

ΔL ,Δa ,Δb for ΔE . The superscript * indicates color difference based on the use of CIELAB color space equations, while the

H H H H

*

subscript H indicates color difference based on the use of the Hunter equations. ΔE is expressed in units of judds, while ΔE is

H

This test method is under the jurisdiction of ASTM Committee C21 on Ceramic Whitewares and Related Products and is the direct responsibility of Subcommittee C21.06

on Ceramic Tile.

Current edition approved Jan. 1, 2014Aug. 1, 2019. Published February 2014August 2019. Originally approved in 1967. Last previous edition approved in 20072014 as

C609 – 07.C609 – 07 (2014). DOI: 10.1520/C0609-07R14.10.1520/C0609-07R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C609 − 07 (2019)

a unit-less value. Either form of the ΔE can be solved for using the equation shown in 10.3. For both the CIELAB and Hunter

equations, the values Δ L, Δa, and Δb are obtained by calculating the component differences as follows:

ΔL 5 L 2 L

t r

Δa 5 a 2 a

t r

Δb 5 b 2 b

t r

where:

t = test specimen, and

r = reference specimen.

The quantity ΔE has a positive value and it describes the magnitude but not the direction of color difference between the test

specimen and the reference specimen. The direction of color difference depends upon the algebraic signs of the components Δ L,

Δa, and Δb. A positive ΔL value means that the test specimen is lighter than the reference against which it is being compared, and

a negative ΔL value means that the test specimen is darker. However, the algebraic signs of chromaticity components, Δ a and Δb,

do not convey an easily visualized difference in color attributes and can best be visualized by plotting the corresponding points

in the chromaticity plane.

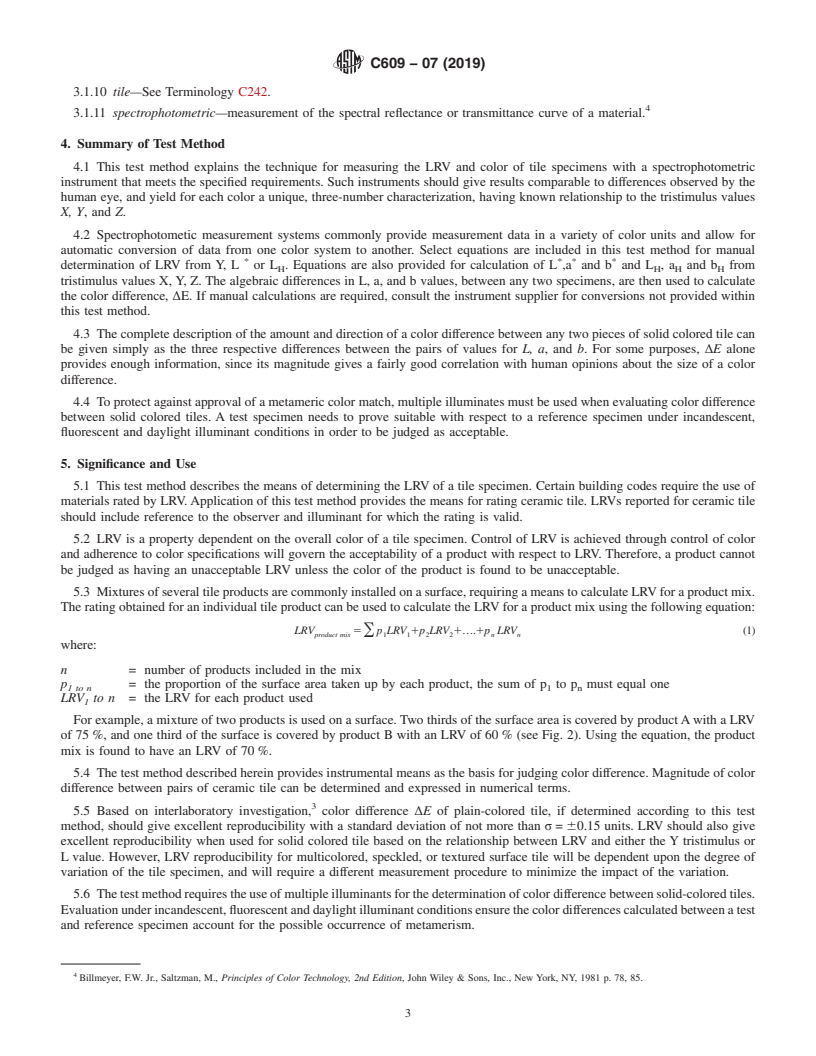

3.1.2 color space—the colors of opaque specimens such as ceramic tile are described in terms of three color scales L, a, and

b. Scale L is a measure of lightness, a is a measure of redness or greenness, and b is a measure of yellowness or blueness. The

units for each of the three scales are so chosen that they represent equally perceptible color differences. The interrelation of these

color scales is more readily visualized if the scales are represented geometrically as the three mutually perpendicular axes of a

three-dimensional color space, with the L axis in the vertical direction, the positive a axis (redness) to the right, and the positive

b axis (yellowness) in a counterclockwise direction from the positive a axis (see Fig. 1).

FIG. 1 Three-Dimensional Color Space

3.1.3 light reflectance value, (LRV)—the luminance factor Y, of a sample expressed as a percent. Thus, a Y value of 70 would

equate to an LRV of 70%. The LRV indicates the portion of light cast on a sample that is not absorbed.

3.1.4 metamers—See Terminology E284.

3.1.5 reference specimen—any tile for which a match is desired.

3.1.6 repeatability—the standard deviation of results obtained by the same operator using the same instrument in successive

measurements.

3.1.7 reproducibility—the standard deviation of results obtained by different operators using the same or different types of

instruments in different laboratories.

3.1.8 standard—the plaque or other media of established tristimulus value, against which standardization of the instrument is

made.

3.1.9 test specimen—any piece of tile whose LRV or color difference from a reference specimen is to be evaluated.

Illing, A. M., Balinkin, I., “Precision in Measurement of Small Color Differences,” American Ceramic Society Bulletin , Vol 44, No. 12, 1965, pp. 956–962.

C609 − 07 (2019)

3.1.10 tile—See Terminology C242.

3.1.11 spectrophotometric—measurement of the spectral reflectance or transmittance curve of a material.

4. Summary of Test Method

4.1 This test method explains the technique for measuring the LRV and color of tile specimens with a spectrophotometric

instrument that meets the specified requirements. Such instruments should give results comparable to differences observed by the

human eye, and yield for each color a unique, three-number characterization, having known relationship to the tristimulus values

X, Y, and Z.

4.2 Spectrophotometic measurement systems commonly provide measurement data in a variety of color units and allow for

automatic conversion of data from one color system to another. Select equations are included in this test method for manual

* * * *

determination of LRV from Y, L or L . Equations are also provided for calculation of L ,a and b and L , a and b from

H H H H

tristimulus values X, Y, Z. The algebraic differences in L, a, and b values, between any two specimens, are then used to calculate

the color difference, ΔE. If manual calculations are required, consult the instrument supplier for conversions not provided within

this test method.

4.3 The complete description of the amount and direction of a color difference between any two pieces of solid colored tile can

be given simply as the three respective differences between the pairs of values for L, a, and b. For some purposes, ΔE alone

provides enough information, since its magnitude gives a fairly good correlation with human opinions about the size of a color

difference.

4.4 To protect against approval of a metameric color match, multiple illuminates must be used when evaluating color difference

between solid colored tiles. A test specimen needs to prove suitable with respect to a reference specimen under incandescent,

fluorescent and daylight illuminant conditions in order to be judged as acceptable.

5. Significance and Use

5.1 This test method describes the means of determining the LRV of a tile specimen. Certain building codes require the use of

materials rated by LRV. Application of this test method provides the means for rating ceramic tile. LRVs reported for ceramic tile

should include reference to the observer and illuminant for which the rating is valid.

5.2 LRV is a property dependent on the overall color of a tile specimen. Control of LRV is achieved through control of color

and adherence to color specifications will govern the acceptability of a product with respect to LRV. Therefore, a product cannot

be judged as having an unacceptable LRV unless the color of the product is found to be unacceptable.

5.3 Mixtures of several tile products are commonly installed on a surface, requiring a means to calculate LRV for a product mix.

The rating obtained for an individual tile product can be used to calculate the LRV for a product mix using the following equation:

LRV 5 p LRV 1p LRV 1….1p LRV (1)

product mix ( 1 1 2 2 n n

where:

n = number of products included in the mix

p = the proportion of the surface area taken up by each product, the sum of p to p must equal one

1 to n 1 n

LRV to n = the LRV for each product used

For example, a mixture of two products is used on a surface. Two thirds of the surface area is covered by product A with a LRV

of 75 %, and one third of the surface is covered by product B with an LRV of 60 % (see Fig. 2). Using the equation, the product

mix is found to have an LRV of 70 %.

5.4 The test method described herein provides instrumental means as the basis for judging color difference. Magnitude of color

difference between pairs of ceramic tile can be determined and expressed in numerical terms.

5.5 Based on interlaboratory investigation, color difference ΔE of plain-colored tile, if determined according to this test

method, should give excellent reproducibility with a standard deviation of not more than σ = 60.15 units. LRV should also give

excellent reproducibility when used for solid colored tile based on the relationship between LRV and either the Y tristimulus or

L value. However, LRV reproducibility for multicolored, speckled, or textured surface tile will be dependent upon the degree of

variation of the tile specimen, and will require a different measurement procedure to minimize the impact of the variation.

5.6 The test method requires the use of multiple illuminants for the determination of color difference between solid-colored tiles.

Evaluation under incandescent, fluorescent and daylight illuminant conditions ensure the color differences calculated between a test

and reference specimen account for the possible occurrence of metamerism.

Billmeyer, F.W. Jr., Saltzman, M., Principles of Color Technology, 2nd Edition, John Wiley & Sons, Inc., New York, NY, 1981 p. 78, 85.

C609 − 07 (2019)

FIG. 2 Example of a Product Mix Used on a Surface

6. Apparatus

6.1 Type of Instrument for LRV Measurement—Any color-measuring spectrophotometric instrument capable of yielding data

that can be transformed mathematically into the International Commission of Illumination (CIE) tristimulus values X, Y, and Z,

may be used. It must have a color difference, ΔE, repeatability (see 3.1.6) of σ = 60.2 units or less, based on five independent

measurements. The well-known standard deviation equation shown as follows is used to calculate the standard deviation.

½

σ5 F X 2 X /N (2)

@ #

~ !

(j j j

6.2 Type of Instrument for Color Measurement—For the measurement of solid colored tile, the spectrophotometric measurement

system must meet all of the requirements for LRV measurement and be capable of yielding tristimulus values X, Y, and Z, for

daylight, incandescent and fluorescent illuminants.

6.3 Instrument Setup—For measurement of LRV and color difference, spectrophotometric measurements should be taken with

specular component included (SCI). If the instrument being used is not capable of taking SCI measurements, then all reported

measurements must include a notation stating measurement obtained with specular component excluded (SCE).

7. Standards

7.1 Primary Standard—The primary standard for reflectance measurement is a layer of freshly prepared barium sulfate (see

Practice E259).

7.2 Working Standard—Because of the difficulty of preparing a primary standard each time and its variability, calibrated pieces

of white opaque glass, porcelain enamel plaques, or glazed ceramic tile are used as working standards and are usually supplied

by the manufacturer of the instrument. The manufacturer of each type of instrument provides numerical specifications for the

working standards, which have a definite relationship to the CIE values X, Y, and Z.

8. Test Specimens

1 1

8.1 Size—The preferred size of test specimens is 4 ⁄4 by 4 ⁄4 in. (108 by 108 mm) because most instruments are equipped with

a holder of that size which assures that the identical surface area may be measured repeatedly. Specimens larger may be reduced

to that size by cutting. The required sample size is dependent on the instrument being used to measure the test and reference

specimens. Many instruments can be configured to measure a sample using different size viewing apertures. The largest area of

view capable of being used without interference from the edges of the tile should be selected. However, the same aperture size

should be used f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.