ASTM D4986-10

(Test Method)Standard Test Method for Horizontal Burning Characteristics of Cellular Polymeric Materials

Standard Test Method for Horizontal Burning Characteristics of Cellular Polymeric Materials

SIGNIFICANCE AND USE

This test method provides a means of measuring the time and extent of burning for cellular polymeric materials. It also provides a means of measuring burning rates for materials that continue to burn past the specified gage marks.

This test method provides a means of comparing the burning characteristics of materials of like thickness density, cell size, and skin irregularities, including the effect of falling particles of cellular polymeric materials. It is suitable for quality control, specification acceptance, and for research and development. Examples include filled or reinforced, rigid or flexible, or cut or formed materials

In this test method, the specimens are subjected to one or more specific sets of laboratory fire test exposure conditions. If different test conditions are substituted or if the anticipated end-use conditions are changed, it is not always possible from this test method to predict changes in the performance characteristics measured. Therefore, the results are strictly valid only for the fire test exposure conditions described in this procedure.

This test method is not intended to be a criterion for fire hazard. The fire hazard created by materials depends upon the form and end use of the material. Assessment of fire hazard includes, but is not limited to, many factors such as flame spread, burning rate, ease of ignition, fuel contribution, heat evolution, products of combustion, and others.

SCOPE

1.1 This fire-test-response test method describes a small-scale horizontally oriented burning test procedure for comparing the relative rate of burning and the extent and time of burning of cellular polymeric materials having a density less than 250 kg/m3.

1.2 The classification system described in the Appendix X1 is intended for quality assurance and the preselection of component materials for products.

1.3 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.4 The values stated in SI units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Note 3.

1.6 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

Note 1—This test method is equivalent to ISO 9772.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4986 − 10

Standard Test Method for

Horizontal Burning Characteristics of Cellular Polymeric

1

Materials

This standard is issued under the fixed designation D4986; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D5025 Specification for Laboratory Burner Used for Small-

Scale Burning Tests on Plastic Materials

1.1 This fire-test-response test method describes a small-

E176 Terminology of Fire Standards

scale horizontally oriented burning test procedure for compar-

E437 Specification for Industrial Wire Cloth and Screens

ing the relative rate of burning and the extent and time of

(Square Opening Series) (Discontinued 2000) Replaced

burning of cellular polymeric materials having a density less

3

3 by E 2016 (Withdrawn 2000)

than 250 kg/m .

2.2 ISO Standard:

1.2 The classification system described in the Appendix X1

ISO 9772 Cellular Plastics—Determination of Horizontal

is intended for quality assurance and the preselection of

Burning Characteristics of Small Specimens Subjected to

component materials for products. 4

a Small Flame

1.3 This standard measures and describes the response of

3. Terminology

materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all

3.1 Definitions:

factors required for fire hazard or fire risk assessment of the

3.1.1 For definitions of fire-related terms used in this test

materials, products, or assemblies under actual fire conditions.

method, refer to Terminology E176.

3.1.2 afterflame time, n—the length of time for which a

1.4 The values stated in SI units are to be regarded as

material continues to flame, under specified conditions, after

standard.

the ignition source has been removed.

1.5 This standard does not purport to address all of the

3.1.3 afterglow time, n—the length of time for which a

safety concerns, if any, associated with its use. It is the

materialcontinuestoglowunderspecifiedtestconditions,after

responsibility of the user of this standard to establish appro-

the ignition source has been removed or cessation of flaming,

priate safety and health practices and determine the applica-

or both.

bility of regulatory limitations prior to use. For a specific

hazard statement, see Note 3. 3.1.4 flame, v—to undergo combustion in the gaseous phase

1.6 Fire testing is inherently hazardous. Adequate safe- with emission of light.

guards for personnel and property shall be employed in

3.1.5 glow, n—visible light, other than from flaming, emit-

conducting these tests.

ted by a solid undergoing combustion.

NOTE 1—This test method is equivalent to ISO 9772.

4. Summary of Test Method

2. Referenced Documents

4.1 This test method for measuring the burning characteris-

2

2.1 ASTM Standards:

tics of cellular polymeric materials employs a small standard

D4483 Practice for Evaluating Precision for Test Method

test specimen 50 by 150 mm. The specimen is supported

Standards in the Rubber and Carbon Black Manufacturing

horizontally. One end is exposed to a specified gas flame for 60

Industries

s and the extent of burning is measured.

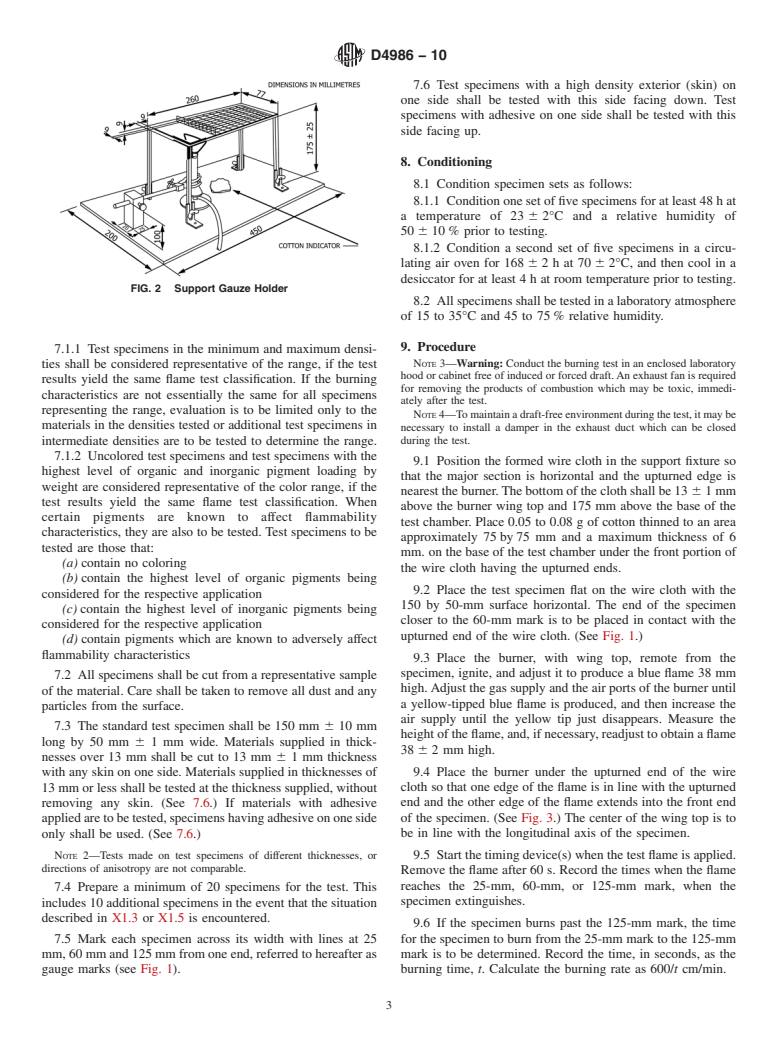

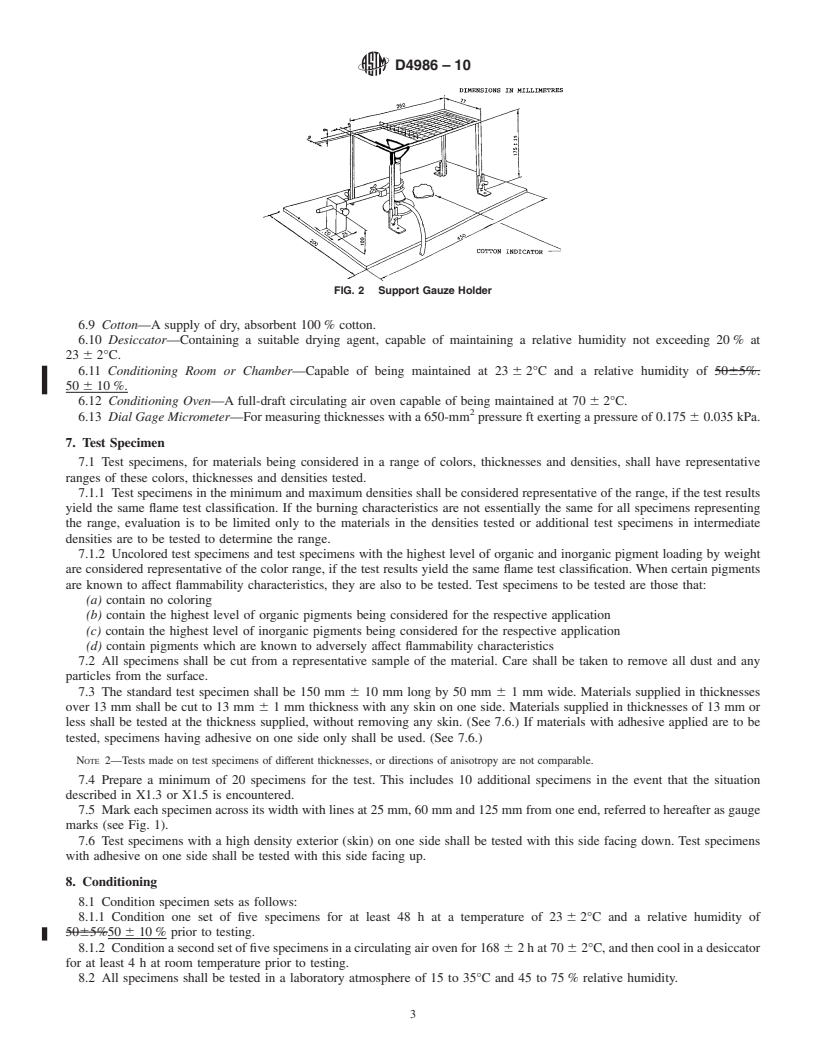

5. Significance and Use

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

5.1 This test method provides a means of measuring the

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties.

time and extent of burning for cellular polymeric materials. It

Current edition approved Jan. 1, 2010. Published February 2010. Originally

approved in 1989. Last previous edition approved in 2003 as D4986 – 03. DOI:

10.1520/D4986-10.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4986 − 10

also provides a means of measuring burning rates for materials 6.3 Wing Top—Wing top, having an opening 48 61mmin

that continue to burn past the specified gage marks. lengthby1.3 6 0.05mminwidthfittedtotheburner.(SeeFig.

1.)

5.2 This test method provides a means of comparing the

burning characteristics of materials of like thickness

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4986–03 Designation: D4986 – 10

Standard Test Method for

Horizontal Burning Characteristics of Cellular Polymeric

1

Materials

This standard is issued under the fixed designation D4986; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1This1.1 This fire-test-response test method describes a small-scale horizontally oriented burning test procedure for

comparing the relative rate of burning and the extent and time of burning of cellular polymeric materials having a density less than

3

250 kg/m .

1.2 The classification system described in theAppendix X1 is intended for quality assurance and the preselection of component

materials for products.

1.3 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled

conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products,

or assemblies under actual fire conditions.

1.4 The values stated in SI units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For a specific hazard statement, see Note 3. .

1.6 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these

tests.

NOTE1—This test method and ISO 9772 are technically equivalent. 1—This test method is equivalent to ISO 9772.

2. Referenced Documents

2

2.1 ASTM Standards:

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

D5025 Specification for Laboratory Burner Used for Small-Scale Burning Tests on Plastic Materials

E176 Terminology of Fire Standards

E437 Specification for Industrial Wire Cloth and Screens (Square Opening Series) (Discontinued 2000) Replaced by E 2016

2.2 ISO Standard:

ISO 9772 Cellular Plastics—Determination of Horizontal Burning Characteristics of Small Specimens Subjected to a Small

3

Flame

3. Terminology

3.1 Definitions—For definitions of fire-related terms used in this test method, refer to Terminology E176.

3.23.1.1 afterflame time, n—the length of time for which a material continues to flame, under specified conditions, after the

ignition source has been removed.

3.33.1.2 afterglow time, n—the length of time for which a material continues to glow under specified test conditions, after the

ignition source has been removed or cessation of flaming, or both.

3.43.1.3 flameflame, vb—to, v—to undergo combustion in the gaseous phase with emission of light.

3.53.1.4 glowglow, n—visible, n—visible light, other than from flaming, emitted by a solid undergoing combustion.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.30 on Thermal Properties.

CurrenteditionapprovedMay10,2003.PublishedJuly2003.Originallyapprovedin1989.Lastpreviouseditionapprovedin1998asD4986–98.DOI:10.1520/D4986-03.

Current edition approved Jan. 1, 2010. Published February 2010. Originally approved in 1989. Last previous edition approved in 2003 as D4986 – 03. DOI:

10.1520/D4986-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4986 – 10

4. Summary of Test Method

4.1 This test method for measuring the burning characteristics of cellular polymeric materials employs a small standard test

specimen 50 by 150 mm. The specimen is supported horizontally. One end is exposed to a specified gas flame for 60 s and the

extent of burning is measured.

5. Significance and Use

5.1 This test method pro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.