ASTM C1018-97

(Test Method)Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading) (Withdrawn 2006)

Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading) (Withdrawn 2006)

SCOPE

1.1 This test method evaluates the flexural performance of toughness parameters derived from fiber-reinforced concrete in terms of areas under the load-deflection curve obtained by testing a simply supported beam under third-point loading. Note 1-Toughness determined in terms of areas under the load-deflection curve is an indication of the energy absorption capability of the particular test specimen, and, consequently, its magnitude depends directly on the geometrical characteristics of the test specimen and the loading system.

1.2 This test method provides for the determination of a number of ratios called toughness indices that identify the pattern of material behavior up to the selected deflection criteria. These indices are determined by dividing the area under the load-deflection curve up to a specified deflection criterion, by the area up to the deflection at which first crack is deemed to have occurred. Residual strength factors that represent the average post-crack load retained over a specific deflection interval as a percentage of the load at first crack are derived from these indices. Note 2-Index values may be increased by preferential alignment of fibers parallel to the longitudinal axis of the beam caused by fiber contact with the mold surfaces or by external vibration. However, index values appear to be independent of geometrical specimen and testing variables, such as span length, which do not directly affect fiber alignment.

1.3 This test method provides for the determination of the first-crack flexural strength using the load corresponding to the point on the load-deflection curve defined in 3.1.1 as first crack, and the formula for modulus of rupture given in Test Method C78.

1.4 Values of flexural toughness and first-crack flexural strength stated in inch-pound units are to be regarded as the standard. Values of toughness indices and residual strength factors are independent of the system of units used to measure load and deflection.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method evaluates the flexural performance of toughness parameters derived from fiber-reinforced concrete in terms of areas under the load-deflection curve obtained by testing a simply supported beam under third-point loading.

Formerly under the jurisdiction of Committee C09 on Concrete and Concrete Aggregates, this test method was withdrawn in May 2006 due to lack of interest and support for its continued use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1018 – 97

Standard Test Method for

Flexural Toughness and First-Crack Strength of

Fiber-Reinforced Concrete (Using Beam With Third-Point

Loading)

This standard is issued under the fixed designation C1018; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method evaluates the flexural performance of

responsibility of the user of this standard to establish appro-

toughnessparametersderivedfromfiber-reinforcedconcretein

priate safety and health practices and determine the applica-

terms of areas under the load-deflection curve obtained by

bility of regulatory limitations prior to use.

testing a simply supported beam under third-point loading.

NOTE 1—Toughness determined in terms of areas under the load- 2. Referenced Documents

deflection curve is an indication of the energy absorption capability of the

2.1 ASTM Standards:

particular test specimen, and, consequently, its magnitude depends di-

C31 Practice for Making and Curing Concrete Test Speci-

rectly on the geometrical characteristics of the test specimen and the

mens in the Field

loading system.

C42 Test Method for Obtaining and Testing Drilled Cores

1.2 This test method provides for the determination of a

and Sawed Beams of Concrete

number of ratios called toughness indices that identify the

C78 Test Method for Flexural Strength of Concrete (Using

pattern of material behavior up to the selected deflection

Simple Beam with Third-Point Loading)

criteria. These indices are determined by dividing the area

C172 Practice for Sampling Freshly Mixed Concrete

under the load-deflection curve up to a specified deflection

C192 PracticeforMakingandCuringConcreteTestSpeci-

criterion, by the area up to the deflection at which first crack is

mens in the Laboratory

deemed to have occurred. Residual strength factors that repre-

C670 Practice for Preparing Precision and Bias Statements

sent the average post-crack load retained over a specific

for Test Methods for Construction Materials

deflection interval as a percentage of the load at first crack are

C823 Practice for Examination and Sampling of Hardened

derived from these indices.

Concrete in Constructions

NOTE 2—Index values may be increased by preferential alignment of

3. Terminology

fibers parallel to the longitudinal axis of the beam caused by fiber contact

with the mold surfaces or by external vibration. However, index values

3.1 Definitions of Terms Specific to This Standard:

appear to be independent of geometrical specimen and testing variables,

3.1.1 first crack—the point on the load-deflection curve at

such as span length, which do not directly affect fiber alignment.

which the form of the curve first becomes nonlinear (approxi-

1.3 This test method provides for the determination of the

mates the onset of cracking in the concrete matrix).

first-crackflexuralstrengthusingtheloadcorrespondingtothe

3.1.2 first-crack deflection—the deflection value on the

point on the load-deflection curve defined in 3.1.1 as first

load-deflection curve at first crack.

crack, and the formula for modulus of rupture given in Test

3.1.3 first-crack strength—thestressobtainedwhentheload

Method C78.

corresponding to first crack is inserted in the formula for

1.4 Values of flexural toughness and first-crack flexural

modulus of rupture given in Test Method C78.

strength stated in inch-pound units are to be regarded as the

3.1.4 first-crack toughness—the energy equivalent to the

standard. Values of toughness indices and residual strength

area under the load-deflection curve up to the first-crack

factors are independent of the system of units used to measure

deflection.

load and deflection.

3.1.5 toughness—the energy equivalent to the area under

the load-deflection curve up to a specified deflection.

3.1.6 toughness indices—the numbers obtained by dividing

1 theareauptoaspecifieddeflectionbytheareauptofirstcrack.

ThistestmethodisunderthejurisdictionofASTMCommitteeC-9onConcrete

andConcreteAggregatesandisthedirectresponsibilityofSubcommitteeC09.42on

Fiber-Reinforced Concrete.

Current edition approved Dec. 10, 1997. Published October 1998. Originally

published as C1018–84. Last previous edition C1018–94b. Annual Book of ASTM Standards, Vol 04.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1018

NOTE 3—Values of 5.0, 10.0, and 20.0 for I , I , and I respectively,

toughness indices are of little practical significance since they

5 10 20

as defined below, correspond to linear elastic material behavior up to first

are directly dependent upon geometrical variables associated

crack and perfectly plastic behavior thereafter (see Appendix X1).

with the specimen and the loading arrangement.

3.1.6.1 toughness index I — the number obtained by divid-

NOTE 4—In applications where the energy absorption capability of a

ing the area up to a deflection of 3.0 times the first-crack

structuralconcreteelementisimportant,itmaybepossibletoobtainsome

deflection by the area up to first crack.

indication of its performance by testing a specimen equivalent to the

3.1.6.2 toughness index I — the number obtained by di-

10 element in terms of size, span, and mode of loading.

viding the area up to a deflection of 5.5 times the first-crack

5.3 In determining which toughness index is most appropri-

deflection by the area up to first crack.

ate as a measure of material performance for a specific

3.1.6.3 toughness index I — the number obtained by di-

application, the level of serviceability required in terms of

viding the area up to a deflection of 10.5 times the first-crack

cracking and deflection shall be considered, and an index

deflection by the area up to first crack.

appropriate to the service conditions shall be selected in

3.1.6.4 residual strength factor R —the number obtained

5,10

accordancewiththerationaledescribedin9.6andinAppendix

by calculating the value of 20 ( I − I ).

10 5

X1.

3.1.6.5 residualstrengthfactorR —thenumberobtained

10,20

5.4 Values of toughness indices, residual strength factors,

by calculating the value of 10 ( I − I ).

20 10

and first-crack strength may be used for comparing the

4. Summary of Test Method

performance of various fiber-reinforced concretes during the

mixture proportioning process or in research and development

4.1 Molded or sawn beams of fiber-reinforced concrete are

work. They may also be used to monitor concrete quality, to

tested in flexure using the third-point loading arrangement

verifycompliancewithconstructionspecifications,ortoevalu-

specified in Test Method C78. Load and beam deflection are

ate the quality of concrete already in service.

monitored either continuously by means of an X-Y plotter, or

incrementally by means of dial gages read at sufficiently

NOTE 5—Values of toughness index at different ages may not be

frequent intervals to ensure accurate reproduction of the

comparable.

load-deflection curve. A point termed first crack which corre-

5.5 Values of toughness indices, residual strength factors,

sponds approximately to the onset of cracking in the concrete

andfirst-crackstrengthobtainedusingthe14by4by4in.(350

matrixisidentifiedontheloaddeflectioncurve.Thefirst-crack

by 100 by 100 mm) preferred standard size of molded

load and deflection are used to determine the first-crack

specimen may not necessarily correspond with the perfor-

flexural strength and to establish end-point deflections for

manceoflargerorsmallermoldedspecimens,concreteinlarge

toughness calculations. Computations of toughness and tough-

structuralunits,orspecimenssawnfromsuchunits,becauseof

ness indices are based on areas under the load-deflection curve

differencesinthedegreeofpreferentialfiberalignmentparallel

uptothefirst-crackdeflectionanduptothespecifiedend-point

to the longitudinal axis of the specimen. For molded speci-

deflection.

mens, they tend to increase as the degree of preferential fiber

alignment increases.

5. Significance and Use

5.5.1 Preferential fiber alignment is likely to occur in

5.1 Thefirst-crackstrengthcharacterizesthebehaviorofthe

molded specimens when fibers in the vicinity of the mold

fiber-reinforced concrete up to the onset of cracking in the

surfaces tend to align in the plane of the surface, and is most

matrix, while the toughness indices characterize the toughness

pronounced in specimens of small cross-section containing

thereafter up to specified end-point deflections. Residual

long fibers.

strength factors, which are derived directly from toughness

5.5.2 In thin concrete sections, such as overlays and shot-

indices, characterize the level of strength retained after first

crete linings, fibers tend to align in the plane of the section, so

crack simply by expressing the average post-crack load over a

in-place performance is best evaluated using either molded or

specific deflection interval as a percentage of the load at first

sawn specimens of depth equal to the thickness of the section.

crack. The importance of each depends on the nature of the

Consequently, toughness indices, residual strength values, and

proposed application and the level of serviceability required in

first-crack strengths for thin sections may differ from those for

terms of cracking and deflection. Toughness and first-crack

standard molded specimens of nominally identical concrete.

strength are influenced in different ways by the amount and

5.5.3 External vibration promotes preferential alignment of

type of fiber in the concrete matrix. In some cases, fibers may

fibers parallel to the vibrating surface of the form or screeding

greatly increase the toughness, toughness indices, and residual

device used, while internal vibration does not have this effect.

strength factors determined by this test method while produc-

Consequently, toughness indices, residual strength values, and

ing a first-crack strength only slightly greater than the flexural

first-crack strengths for identical concrete specimens prepared

strengthoftheplainconcretematrix.Inothercases,fibersmay

using the two kinds of vibration may differ.

significantly increase the first-crack strength with only rela-

tively small increases in toughness, toughness indices, and 5.5.4 Preferential fiber alignment is negligible in mass

residual strength factors. concrete because the aligning effect of mold surfaces is absent

5.2 The toughness indices and residual strength factors and because internal vibration is often used, so toughness

determined by this test method reflect the post-crack behavior indices, residual strength values, and first-crack strengths for

of fiber-reinforced concrete under static flexural loading. The standard molded specimens may differ from those for sawn

absolute values of toughness determined to compute the specimens of nominally identical concrete.

C 1018

NOTE 6—The degree of preferential fiber alignment may be less for

fibers that are flexible enough to be bent by contact with aggregate

particles or mold surfaces than for fibers rigid enough to remain straight

during mixing and specimen preparation.

6. Apparatus

6.1 Testing Machine—The testing machine shall be capable

of operating in a manner which produces a controlled and

constant increase of deflection of the specimen. A testing

arrangementwherespecimennetmid-spandeflectionisusedto

control the rate of increase of deflection using a closed-loop,

servo-controlledtestingsystemshallbeused.Testingmachines

that use stroke displacement control or load control are not

suitable for establishing the post-crack portion of the load-

deflection curve. The loading and specimen support system

shall be capable of reproducing third-point loading on the

specimen without eccentricity or torque. The system specified

in Test Method C78 is suitable.

NOTE 7—Load-deflection curves produced from closed-loop testing

systems may show substantial toughness for non-fibrous concrete in the

post-crack deflection area up to a deflection of 5.5 times the first-crack

deflection. Values of toughness indices I and I and residual strength R

5,10, should be used with caution, as they may not accurately reflect the

contribution of fibers to post-crack toughness at these deflections.

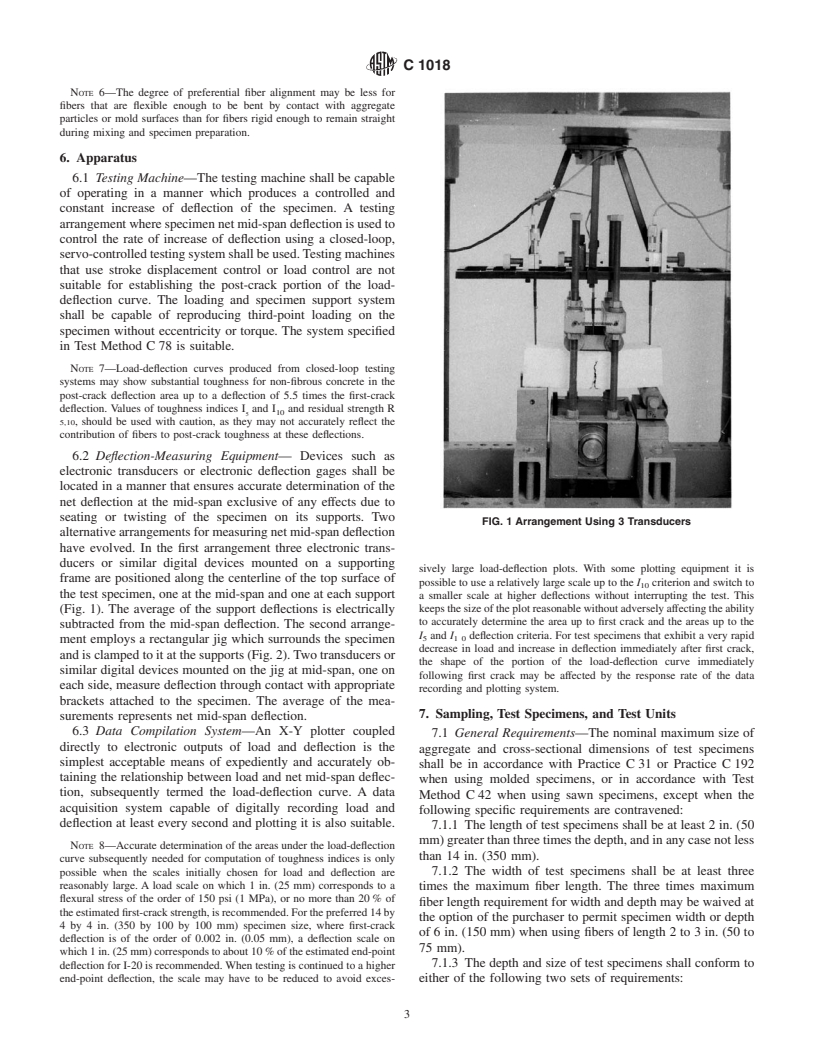

6.2 Deflection-Measuring Equipment— Devices such as

electronic transducers or electronic deflection gages shall be

located in a manner that ensures accurate determination of the

net deflection at the mid-span exclusive of any effects due to

seating or twisting of the specimen on its supports. Two

FIG. 1 Arrangement Using 3 Transducers

alternativearrangementsformeasuringnetmid-spandeflection

have evolved. In the first arrangement three electronic trans-

ducers or similar digital devices mounted on a supporting

sively large load-deflection plots. With some plotting equipment it is

frame are positioned along the centerline of the top surface of

possible to use a relatively large scale up to the I criterion and switch to

the test specimen, one at the mid-span and one at each support

a smaller scale at higher deflections without interrupting the test. This

(Fig. 1). The average of the support deflections is electrically keepsthesizeoftheplotreasonablewithoutadverselyaffectingtheability

to accurately determine the area up to first crack and the areas up to the

subtracted from the mid-span deflection. The second arrange-

I and I deflection criteria. For test specimens that exhibit a very rapid

5 10

ment employs a rectangular jig which surrounds the specimen

decrease in load and increase in deflection immediately after first crack,

andisclampedtoitatthesupports(Fig.2).Twotransducersor

the shape of the portion of the load-deflection curve immediately

similar digital devices mounted on the jig at mid-span, one on

following first crack may be affected by the response rate of the data

each side, measure deflection through contact with appropriate

recording and plotting system.

brackets attached to the specimen. The average of the mea-

7. Sampling, Test Specimens, and Test Units

surements represents net mid-span deflection.

6.3 Data Compilation System—An X-Y plotter coupled

7.1 General Requirements—The nominal maximum size of

directly to electronic outputs of load and deflection is the

aggregate and cross-sectional dimensions of test specimens

simplest acceptable means of expediently and accurately ob-

shall be in accordance with Practice C31 or Practice C192

taining the relationship between load and net mid-span deflec-

when using molded specimens, or in accordance with T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.