ASTM C1074-98

(Practice)Standard Practice for Estimating Concrete Strength by the Maturity Method

Standard Practice for Estimating Concrete Strength by the Maturity Method

SCOPE

1.1 This practice provides a procedure for estimating concrete strength by means of the maturity method. The maturity index is expressed either in terms of the temperature-time factor or in terms of the equivalent age at a specified temperature.

1.2 This practice requires establishing the strength-maturity relationship of the concrete mixture in the laboratory and recording the temperature history of the concrete for which strength is to be estimated.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1074 – 98

Standard Practice for

Estimating Concrete Strength

by the Maturity Method

This standard is issued under the fixed designation C 1074; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Testing of Concrete Compression Test Specimens

C 803/C 803M Test Method for Penetration Resistance of

1.1 This practice provides a procedure for estimating con-

Hardened Concrete

crete strength by means of the maturity method. The maturity

C 873 Test Method for Compressive Strength of Concrete

index is expressed either in terms of the temperature-time

Cylinders Cast in Place in Cylindrical Molds

factor or in terms of the equivalent age at a specified tempera-

C 900 Test Method for Pullout Strength of Hardened Con-

ture.

crete

1.2 This practice requires establishing the strength-maturity

C 918 Test Method for Measuring Early-Age Compressive

relationship of the concrete mixture in the laboratory and

Strength and Projecting Later-Age Strength

recording the temperature history of the concrete for which

C 1150 Test Method for the Break-Off Number of Con-

strength is to be estimated.

crete

1.3 The values stated in SI units are to be regarded as the

standard.

3. Terminology

1.4 This standard does not purport to address all of the

3.1 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.1.1 datum temperature—the temperature that is subtracted

responsibility of the user of this standard to establish appro-

from the measured concrete temperature for calculating the

priate safety and health practices and determine the applica-

temperature-time factor according to Eq 1.

bility of regulatory limitations prior to use.

3.1.2 equivalent age—the number of days or hours at a

2. Referenced Documents specified temperature required to produce a maturity equal to

the maturity achieved by a curing period at temperatures

2.1 ASTM Standards:

different from the specified temperature.

C 39 Test Method for Compressive Strength of Cylindrical

2 3.1.3 maturity—the extent of the development of a property

Concrete Specimens

of a cementitious mixture.

C 109/C 109M Test Method for Compressive Strength of

3.1.3.1 Discussion—While the term is used usually to

Hydraulic Cement Mortars (Using 2-in. or 50-mm Cube

describe the extent of relative strength development, it can also

Specimens)

be applied to the evolution of other properties that are

C 192/C 192M Practice for Making and Curing Concrete

dependent on the chemical reactions that occur in a cementi-

Test Specimens in the Laboratory

tious mixture. At any age, maturity is dependent on the curing

C 403/C 403M Test Method for Time of Setting of Concrete

history.

Mixtures by Penetration Resistance

3.1.4 maturity function—a mathematical expression that

C 511 Specification for Moist Cabinets, Moist Rooms, and

uses the measured temperature history of a cementitious

Water Storage Tanks Used in the Testing of Hydraulic

mixture during the curing period to calculate an index that is

Cements and Concretes

indicative of the maturity at the end of that period. Refer to

C 684 Test Method for Making, Accelerated Curing, and

Appendix X1 for additional discussion of this term.

3.1.5 maturity index—an indicator of maturity that is calcu-

lated from the temperature history of the cementitious mixture

This practice is under the jurisdiction of ASTM Committee C-9 on Concrete

by using a maturity function.

and Concrete Aggregates and is the direct responsibility of Subcommittee C09.64 on

Nondestructive and In-Place Testing.

3.1.5.1 Discussion—The computed index is indicative of

Current edition approved Nov. 10, 1998. Published March 1999. Originally

maturity provided there has been a sufficient supply of water

e1

published as C 1074 – 87. Last previous edition C 1074 – 93 .

for hydration or pozzolanic reaction of the cementitious

Annual Book of ASTM Standards, Vol 04.02.

Annual Book of ASTM Standards, Vol 04.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1074–98

materials during the time used in the calculation. Two widely

M(t) = the temperature-time factor at age t, degree-days or

used maturity indexes are the temperature-time factor and the

degree-hours,

equivalent age.

Dt = a time interval, days or hours,

3.1.6 maturity method—a technique for estimating concrete T = average concrete temperature during time interval,

a

strength that is based on the assumption that samples of a given

Dt, °C, and

T = datum temperature, °C.

concrete mixture attain equal strengths if they attain equal

o

values of the maturity index (1, 2, 3). 6.3 The other maturity function is used to compute equiva-

3.1.7 strength-maturity relationship—an empirical relation- lent age at a specified temperature as follows (4):

ship between compressive strength and maturity index that is

1 1

2Q 2

S D

T T

t 5 (e D t (2)

a s

obtained by testing specimens whose temperature history up to e

the time of test has been recorded.

where:

3.1.8 temperature-time factor—the maturity index com-

t = equivalent age at a specified temperature T , days or

e s

puted according to Eq 1.

h,

Q = activation energy divided by the gas constant, K,

4. Summary of Practice

T = average temperature of concrete during time interval

a

4.1 A strength-maturity relationship is developed by labo-

Dt,K,

ratory tests on the concrete mixture to be used.

T = specified temperature, K, and

s

4.2 The temperature history of the field concrete, for which

Dt = time interval, days or h.

strength is to be estimated, is recorded from the time of

6.4 Approximate values of the datum temperature, T , and

o

concrete placement to the time when the strength estimation is

the activation energy divided by the gas constant, Q, are given

desired.

in Appendix X1. Where maximum accuracy of strength esti-

4.3 The recorded temperature history is used to calculate the

mation is desired, the appropriate values of T or Q for a

o

maturity index of the field concrete.

specific concrete mixture can be determined according to the

4.4 Using the calculated maturity index and the strength-

procedures given in Annex A1.

maturity relationship, the strength of the field concrete is

estimated.

7. Apparatus

7.1 A device is required to monitor and record the concrete

5. Significance and Use

temperature as a function of time. Acceptable devices include

5.1 This practice can be used to estimate the in-place

thermocouples or thermistors connected to strip-chart recorders

strength of concrete to allow the start of critical construction

or digital data-loggers. The recording time interval shall be ⁄2

activities such as: (1) removal of formwork and reshoring; (2)

h or less for the first 48 h and1hor less thereafter. The

post-tensioning of tendons; (3) termination of cold weather

temperature recording device shall be accurate to within 61°C.

protection; and (4) opening of the roadways to traffic.

7.2 Alternative devices include commercial maturity instru-

5.2 This practice can be used to estimate strength of

ments, that automatically compute and display either

laboratory specimens cured under non-standard temperature

temperature-time factor or equivalent age.

conditions.

5.3 The major limitations of the maturity method are: (1) the NOTE 1—Commercial maturity instruments use specific values of

datum temperature or activation energy in evaluating the maturity index;

concrete must be maintained in a condition that permits cement

thus the displayed maturity index may not be indicative of the true value

hydration; (2) the method does not take into account the effects

for the concrete mixture being used. Refer to Appendix X1 for information

of early-age concrete temperature on the long-term ultimate

on correcting the displayed values.

strength; and (3) the method needs to be supplemented by other

indications of the potential strength of the concrete mixture.

8. Procedure to Develop Strength-Maturity Relationship

5.4 The accuracy of the estimated strength depends on

8.1 Prepare at least 15 cylindrical specimens according to

properly determining the maturity function for the particular

Practice C 192/C 192M . The mixture proportions and con-

concrete mixture.

stituents of the concrete shall be similar to those of the concrete

whose strength will be estimated using this practice.

6. Maturity Functions

8.2 Embed temperature sensors to within 615 mm of the

6.1 There are two alternative functions for computing the

centers of at least two specimens. Connect the sensors to

maturity index from the measured temperature history of the

maturity instruments or to temperature-recording devices such

concrete.

as data-loggers or strip-chart recorders.

6.2 One maturity function is used to compute the

temperature-time factor as follows:

NOTE 2—A method to assist in the proper positioning of the sensor is to

insert a small diameter rigid rod into the center of the freshly made

M t! 5 ( T 2 T ! Dt (1)

~ ~

a o

cylinder. The rod will push aside any interfering aggregate particles. The

rod is removed and the sensor is inserted into the cylinder. The side of the

where:

cylinder mold should be tapped with a rubber mallet or the tamping rod to

ensure that the concrete comes into contact with the sensor.

8.3 Moist cure the specimens in a water bath or in a moist

The boldface numbers in parentheses refer to the list of references at the end of

this practice. room meeting the requirements of Specification C 511.

C1074–98

8.4 Perform compression tests at ages of 1, 3, 7, 14, and 28

days in accordance with Test Method C 39. Test two specimens

at each age and compute the average strength. If the range of

compressive strength of the two specimens exceeds 10 % of

their average strength, test another cylinder and compute the

average of the three tests. If a low test result is due to an

obviously defective specimen, discard the low test result.

8.5 At each test age, record the average maturity index for

the instrumented specimens.

8.5.1 If maturity instruments are used, record the average of

the displayed values.

8.5.2 If temperature recorders are used, evaluate the matu-

rity according to Eq 1 or Eq 2. Use a time interval (Dt)of ⁄2

h or less for the first 48 h of the temperature record. Longer

time intervals may be used for the relatively constant portion of

the subsequent temperature record.

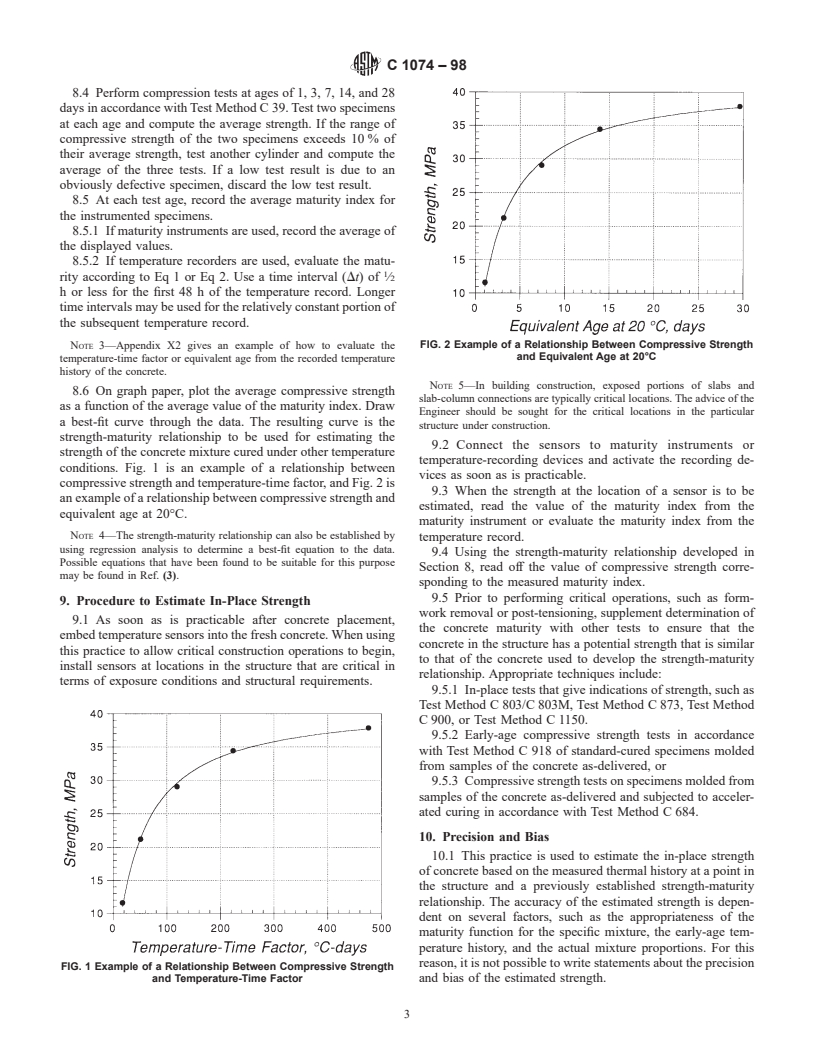

FIG. 2 Example of a Relationship Between Compressive Strength

NOTE 3—Appendix X2 gives an example of how to evaluate the

and Equivalent Age at 20°C

temperature-time factor or equivalent age from the recorded temperature

history of the concrete.

NOTE 5—In building construction, exposed portions of slabs and

8.6 On graph paper, plot the average compressive strength

slab-column connections are typically critical locations. The advice of the

as a function of the average value of the maturity index. Draw

Engineer should be sought for the critical locations in the particular

a best-fit curve through the data. The resulting curve is the

structure under construction.

strength-maturity relationship to be used for estimating the

9.2 Connect the sensors to maturity instruments or

strength of the concrete mixture cured under other temperature

temperature-recording devices and activate the recording de-

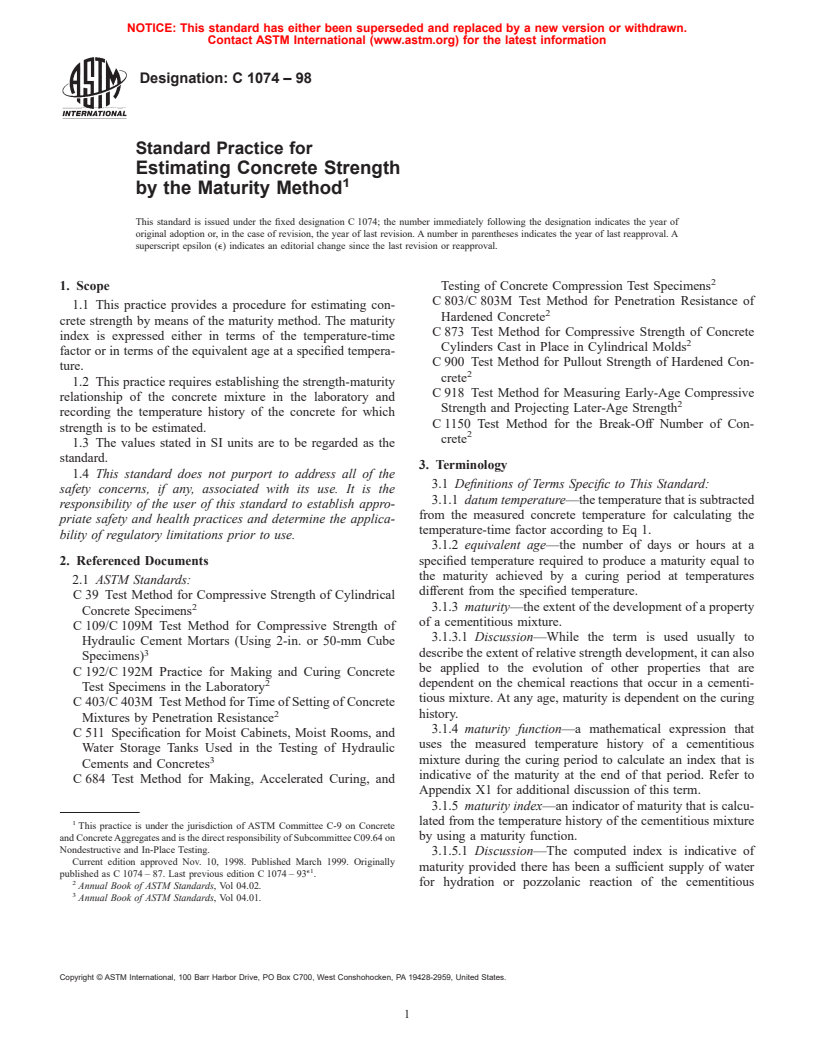

conditions. Fig. 1 is an example of a relationship between

vices as soon as is practicable.

compressive strength and temperature-time factor, and Fig. 2 is

9.3 When the strength at the location of a sensor is to be

an example of a relationship between compressive strength and

estimated, read the value of the maturity index from the

equivalent age at 20°C.

maturity instrument or evaluate the maturity index from the

NOTE 4—The strength-maturity relationship can also be established by

temperature record.

using regression analysis to determine a best-fit equation to the data.

9.4 Using the strength-maturity relationship developed in

Possible equations that have been found to be suitable for this purpose

Section 8, read off the value of compressive strength corre-

may be found in Ref. (3).

sponding to the measured maturity index.

9.5 Prior to performing critical operations, such as form-

9. Procedure to Estimate In-Place Strength

work removal or post-tensioning, supplement determination of

9.1 As soon as is practicable after concrete placement,

the concrete maturity with other tests to ensure that the

embed temperature sensors into the fresh concrete. When using

concrete in the structure has a potential strength that is similar

this practice to allow critical construction operations to begin,

to that of the concrete used to develop the strength-maturity

install sensors at locations in the structure that are critical in

relationship. Appropriate techniques include:

terms of exposure conditions and structural requirements.

9.5.1 In-place tests that give indications of strength, such as

Test Method C 803/C 803M, Test Method C 873, Test Method

C 900, or Test Method C 1150.

9.5.2 Early-age compressive strength tests in accordance

with Test Method C 918 of standard-cured specimens molded

from samples of the concrete as-delivered, or

9.5.3 Compressive strength tests on specimens molded from

samples of the concrete as-delivered and subjected to acceler-

ated curing in accordance with Test Method C 684.

10. Precision and Bias

10.1 This practice is used to estimate the in-place strength

of concrete based on the measured thermal history at a point in

the structure and a previously established strength-maturity

relationship. The accuracy of the estimated strength is depen-

dent on several factors, such as the appropriateness of the

maturity function for the specific mixture, the early-age tem-

perature history, and the actual mixture proportions. For this

reason, it is not possible to write statements about the precision

FIG. 1 Example of a Relationship Between Compressive Strength

and Temperature-Time Factor and bias of the estimated strength.

C1074–98

11. Keywords

11.1 maturity method; nondestructive testing; strength;

temperature

ANNEX

(Mandatory Information)

A1. DETERMINATION OF DATUM TEMPERATURE OR ACTIVATION ENERGY

A1.1 Procedure For example, if the time of the first test was 12 h, successive

compressive strength tests would be performed at 1, 2, 4, 8, 16,

A1.1.1 The testing required to experimentally determine the

and 32 days.

datum temperature or the activation energy can b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.