ASTM F1269-89(1995)e1

(Test Method)Test Methods for Destructive Shear Testing of Ball Bonds

Test Methods for Destructive Shear Testing of Ball Bonds

SCOPE

1.1 These test methods cover tests to determine the shear strength of a series of ball bonds made by either thermal compression or thermosonic techniques. Note 1Common usage at the present time considers the term "ball bond'' to include the enlarged spheriodal or nailhead portion of the wire, (produced by the flameoff and first bonding operation in the thermal compression and thermosonic process, or both,) the underlying bonding pad, and the ball bond-bonding pad interfacial-attachment area or weld interface.

1.2 These test methods cover ball bonds made with small diameter (from 18 to 76-µm (0.0007 to 0.003-in.)) wire of the type used in integrated circuits and hybrid microelectronic assemblies.

1.3 These test methods can be used only when the ball height and diameter are large enough and adjacent interfering structures are far enough away to allow suitable placement and clearance (above the bonding pad and between adjacent bonds) of the shear test ram.

1.4 These test methods are destructive. They are appropriate for use in process development or, with a proper sampling plan, for process control or quality assurance.

1.5 A nondestructive procedure is possible; although it may be contra indicated due to the possible interference with adjacent wire bonds and microcircuit components.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: F 1269 – 89 (Reapproved 1995)

Test Methods for

Destructive Shear Testing of Ball Bonds

This standard is issued under the fixed designation F 1269; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in June 1995.

1. Scope F 458 Practice for Nondestructive Pull Testing of Wire

Bonds

1.1 These test methods cover tests to determine the shear

F 459 Test Methods for Measuring Pull Strength of Micro-

strength of a series of ball bonds made by either thermal

electronic Wire Bonds

compression or thermosonic techniques.

2.2 NIST Document:

NOTE 1—Common usage at the present time considers the term “ball

NBS Handbook 105-1 Specification and Tolerances for

bond’’ to include the enlarged spheriodal or nailhead portion of the wire,

Reference Standards and Field Standards, Weights and

(produced by the flameoff and first bonding operation in the thermal

Measures

compression and thermosonic process, or both,) the underlying bonding

IOLM Class M2-Circular 547-1 Precision Laboratory Stan-

pad, and the ball bond-bonding pad interfacial-attachment area or weld

dards of Mass and Laboratory Weights

interface.

2.3 Military Standard:

1.2 These test methods cover ball bonds made with small

MIL-STD 883C, Method 2010

diameter (from 18 to 76-μm (0.0007 to 0.003-in.)) wire of the

type used in integrated circuits and hybrid microelectronic

3. Terminology

assemblies.

3.1 Definitions of Terms Specific to This Standard:

1.3 These test methods can be used only when the ball

3.1.1 ball lift—a separation of the ball bond at the bonding

height and diameter are large enough and adjacent interfering

pad interface with little or no residual (less than 25 % of the

structures are far enough away to allow suitable placement and

bond deformation area) ball metallization remaining on the

clearance (above the bonding pad and between adjacent bonds)

bonding pad (that remains essentially intact). In the case of

of the shear test ram.

gold ball bonds on aluminum pad metallization, a ball lift is

1.4 These test methods are destructive. They are appropriate

defined as a separation of the ball bond at the bonding pad

for use in process development or, with a proper sampling plan,

interface with little or no intermetallic formation either present

for process control or quality assurance.

or remaining (area of intermetallic less than 25 % of the bond

1.5 A nondestructive procedure is possible; although it may

deformation area).

be contra indicated due to the possible interference with

3.1.1.1 Discussion—ntermetallic refers to the aluminum

adjacent wire bonds and microcircuit components.

gold alloy formed at the ball bond pad metallization interfacial

1.6 The values stated in SI units are to be regarded as the

area where a gold ball bond is attached to an aluminum pad

standard. The values given in parentheses are for information

metallization.

only.

3.1.2 ball shear (weld interface separation)—an appre-

1.7 This standard does not purport to address all of the

ciable intermetallic (in the case of the aluminum-gold system)

safety concerns, if any, associated with its use. It is the

and ball metallization, or both, (in the case of the gold-to-gold

responsibility of the user of this standard to establish appro-

system) remains on the bonding pad (area of remaining metal

priate safety and health practices and determine the applica-

or intermetallic greater than 25 % of the bond deformation

bility of regulatory limitations prior to use. Fig. 1Fig. 2Fig.

area).

3Fig. 4Fig. 5Fig. 6Fig. 7Fig. 8Fig. 9

3.1.3 bonding pad lift (substrate metallization removal)—a

separation between the bonding pad and the underlying sub-

2. Referenced Documents

strate. The interface between the ball bond and the residual pad

2.1 ASTM Standards:

metallization attached to the ball remains intact.

These test methods are under the jurisdiction of ASTM Committee F-1 on

Electronics and is the direct responsibility of Subcommittee F01.07 on Wire

Annual Book of ASTM Standards, Vol 10.04.

Bonding.

Current edition approved Dec. 29, 1989. Published March 1990. Available from the National Technical Information Service, 5285 Port Royal

Panousis, N. T., and Fischer, M. W., “Nondestructive Shear Testing of Ball Rd., Springfield, VA 22161.

Bonds’’, International Journal of Hybrid Microelectronics, Vol 6, No. 1, 1983, p. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

142. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1269

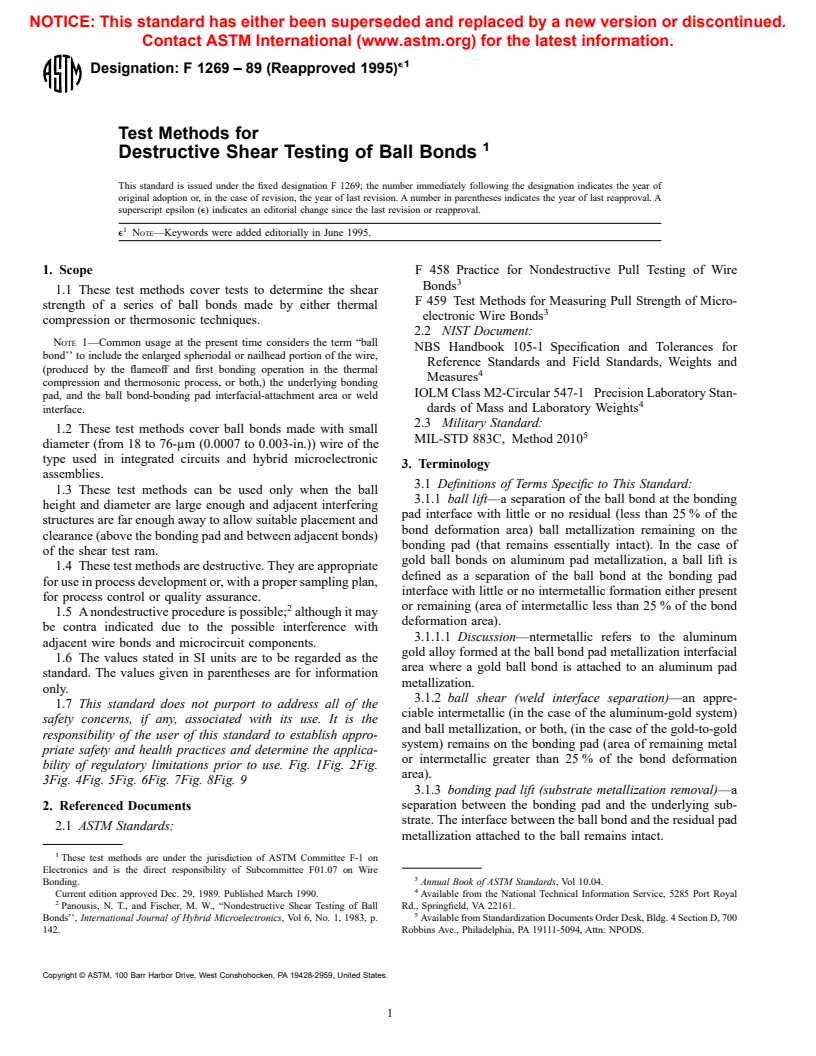

FIG. 1 Ball Shear Failure Modes

3.1.4 cratering—bonding pad lifts taking a portion of the cratering. Cratering caused prior to the shear test operation is

underlying substrate material with it. Residual pad and sub- unacceptable.

strate material are attached to the ball. The interface between Various aspects of the failure mode definitions are illustrated

the ball and this residual material remains intact. in Fig. 1.

3.1.4.1 Discussion—It should be noted that cratering can be

4. Summary of Test Methods

caused by several factors including the ball bonding operation,

the post-bonding processing, and even the act of shear testing 4.1 The microelectronic device with the ball bond (wire

itself. If cratering occurs, chemically etch off the ball bonds bond (see Practice F 458 and Test Methods F 459)) to be tested

and bond pads of untested units and microscopically check for is held firmly in an appropriate fixture. A shearing ram is

F 1269

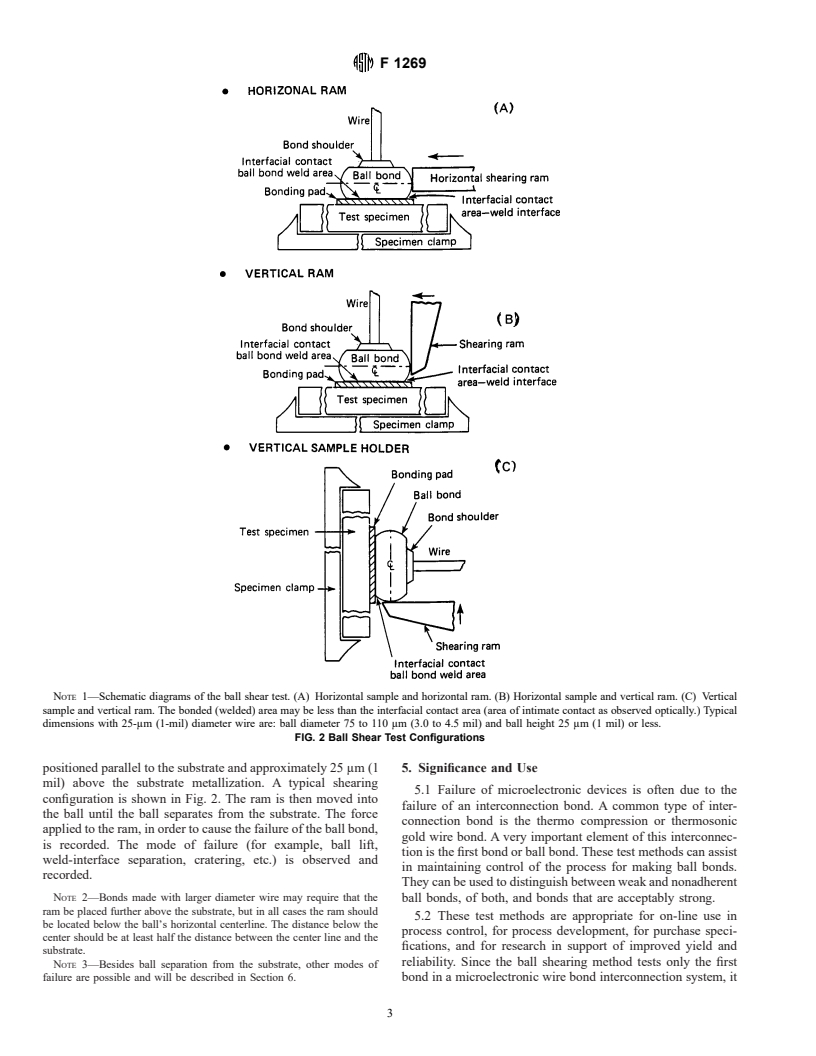

NOTE 1—Schematic diagrams of the ball shear test. (A) Horizontal sample and horizontal ram. (B) Horizontal sample and vertical ram. (C) Vertical

sample and vertical ram. The bonded (welded) area may be less than the interfacial contact area (area of intimate contact as observed optically.) Typical

dimensions with 25-μm (1-mil) diameter wire are: ball diameter 75 to 110 μm (3.0 to 4.5 mil) and ball height 25 μm (1 mil) or less.

FIG. 2 Ball Shear Test Configurations

positioned parallel to the substrate and approximately 25 μm (1 5. Significance and Use

mil) above the substrate metallization. A typical shearing

5.1 Failure of microelectronic devices is often due to the

configuration is shown in Fig. 2. The ram is then moved into

failure of an interconnection bond. A common type of inter-

the ball until the ball separates from the substrate. The force

connection bond is the thermo compression or thermosonic

applied to the ram, in order to cause the failure of the ball bond,

gold wire bond. A very important element of this interconnec-

is recorded. The mode of failure (for example, ball lift,

tion is the first bond or ball bond. These test methods can assist

weld-interface separation, cratering, etc.) is observed and

in maintaining control of the process for making ball bonds.

recorded.

They can be used to distinguish between weak and nonadherent

NOTE 2—Bonds made with larger diameter wire may require that the

ball bonds, of both, and bonds that are acceptably strong.

ram be placed further above the substrate, but in all cases the ram should

5.2 These test methods are appropriate for on-line use in

be located below the ball’s horizontal centerline. The distance below the

process control, for process development, for purchase speci-

center should be at least half the distance between the center line and the

fications, and for research in support of improved yield and

substrate.

reliability. Since the ball shearing method tests only the first

NOTE 3—Besides ball separation from the substrate, other modes of

failure are possible and will be described in Section 6. bond in a microelectronic wire bond interconnection system, it

F 1269

FIG. 3 Ball Shear Interferences

6,7

must be used in a complementary fashion with the wire bond 6.4 In bonding systems in which excessive intermetallic

pull test. growth has formed around the ball bond, the shearing ram may

contact the intermetallic rather than the ball bond and thus the

6. Inferences

shear readings can be in error (that is, weak ball bond shear is

masked by the shear strength of the strong intermetallic wreath

6.1 The most common interference is wire shear in which

surrounding it.

the ball is sheared too high or offline. Only a minor fragment

of the ball is attached to the wire. The major portion of the ball

7. Apparatus

remains on the pad with the bond-pad weld interface region

7.1 Ball Bond Shearing Machine—Apparatus for measuring

intact. Wire shear is illustrated in Fig. 1, View B.

6.2 Many of the common interference modes (such as wire the ball bond shear strength are required with the following

components:

shear) are caused by improper positioning of the ram during the

ball shear operation as shown in Fig. 3. Rams that are too high 7.1.1 Shearing Ram—Various shearing tools or rams have

been recommended in the technical literature, but the ones that

(Fig. 3, View B) or angled upward (Fig. 3, View D) result in

lower than normal shear strength values. Rams that are angled appear the most effective have a flat chisel shape with a

shearing edge dimension equal to approximately 1 to 2-ball

downward (Fig. 3, View C and Fig. 4) or positioned too low

(Fig. 3, View A) will strike the bonding pad and the substrate, diameters as shown in Fig. 5. For 25.4-μm (1-mil) diameter

wire this dimension would be approximately 0.152 mm (6

or both, (chip) and cause inordinately high shear strength as

well as potentially damage the shearing ram. mils).

7.1.2 Shearing and Gaging Mechanism—Mechanism for

6.3 Shearing gold ball bonds on gold metallization pads or

substrates can lead to friction rewelding as illustrated in Fig. 4. applying a measured vertical (or horizontal) force to the

As a strongly welded gold bond is sheared, the ball tends to tip shearing is needed. The mechanism shall incorporate a means

for recording maximum force applied and shall be capable of

away from the ram and contact the substrate as it moves. The

ball smears against the pad metallization and rewelds itself applying the shear force at a uniform rate of ram motion. Force

application rate can be variable (either continuously or in fixed

often several times before it finally clears the metallization.

steps) to accommodate different shearing conditions and con-

figurations, or both. In no case should the ram speed exceed 6.0

mm/s.

Charles, Jr., H. K., and Clatterbaugh, G. V., “Ball Bond Shearing—A

Complement to the Wire Bond Pull Test’’, International Journal of Hybrid

NOTE 4—It has been shown that the shear force is independent of force

Microelectronics, Vol 6, No. 1, 1983, p. 171.

application rate in the range from 0.25 to 6.0 mm/s.

Harman, G. G. “The Microelectronic Ball-Bond Shear Test—A Critical Review

NOTE 5—Electronic-strain gage-force reading mechanisms are pre-

and Comprehensive Guide to its Use’’, International Journal of Hybrid Microelec-

tronics, Vol 6, No. 1, 1983, p. 127. ferred; however, the dynamometer type mechanisms known as“ gram

F 1269

FIG. 4 Gold-to-Gold Friction Rewelding

gages’’ may be used satisfactorily providing careful calibration test

mechanism for calibration, are needed. In the case of horizontal

procedures are employed.

shearing ram motion, the tester mechanism should rotate 90° to

allow the weights to be hung from the shearing ram. Other

7.1.2.1 The range of the force reading gage shall be selected

indirect methods of calibration may also be possible for this

so that the maximum scale reading will be no greater than three

configuration.

times the expected average ball bond shear strength. Antici-

7.1.6 Shear Test Tolerances—The shear test sample holder

pated force ranges for the various wire sizes and materials

covered by these test methods are summarized in Fig. 6. or the shear test ram must be able to be positioned to tolerances

better than 610 μm (6 0.4 mils) and the X and Y directions

NOTE 6—The maximum scale range of the electronic strain gage with

(plane of the bonding pad) and 5.0 μm (60.2 mils) in the Z or

digital readout may be larger than three times the expected average shear

the above substrate direction. The shearing rams over travel

strength providing the accuracy specified in 10.7.6 is maintained over the

(distance it proceeds from the point of ball contact) should be

entire range of the load cell.

limited to 2-ball diameters. Additional over travel may be

7.1.3 Microscope and Light Source—Zoom microscope

allowed in cases where the excessive ram motion does not

with a light source for viewing the device under test is needed.

damage other bonds or the device under test.

The minimum magnification shall be at least 603.

7.2 Typical shear test configurations are illustrated in Fig. 7.

7.1.4 Device Holder— A clamping mechanism for rigidly

View a shows a horizontal test system with horizontal shearing

holding the device under test in either a horizontal or vertical

ram motion. View b presents a vertical test system with vertical

position depending upon shear tester configuration is required

shearing ram motion.

(see 7.2).

7.1.5 Calibration Masses—At least five masses (weights)

8. Sampling

with mass values known to an accuracy of 0.5 % (or better,

such as NBS Class T or IOLM Class M2 (NBS Handbook 8.1 Since the shear test method is destructive, it shall be

105-1 and Circular 547. IOLM) ) sized to cover the shearing performed on a sampling basis. The sample selected should be

and gaging mechanism range of force measurements and representative of the ball bonds of interest. The size of the

suitably configured so that they may be supported by the shear sample and the method of selection shall be agreed upon by the

F 1269

FIG. 6 Shear Force Versus Diameter of the Bonded Area for

Various Wire Materials and Sizes

NOTE 1—Tool face is 1 to 2 ball diameters.

FIG. 5 Schematic Representation of Shearing Tool 25.4μμμ m

Diameter Wire

parties to the test. The sample space should be as large as

practical (nominally 35 bonds) to ensure the proper statistical

inferences from quantities such as the mean shear force (X)

and its standard deviation (s).

9. Calibration

9.1 Calibrate the ball bond shearing machine at the begin-

ning and of each series of tests, or at the beginning and end of

each day if the test sequence spans more than one day.

9.2 For multifunct

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.