ASTM D1078-05

(Test Method)Standard Test Method for Distillation Range of Volatile Organic Liquids

Standard Test Method for Distillation Range of Volatile Organic Liquids

SIGNIFICANCE AND USE

This test method provides a method of measurement of distillation range of volatile organic liquids. The relative volatility of organic liquids can be used with other tests for identification and measurement of quality. Therefore, this test method provides a test procedure for assessing compliance with a specification.

This test method also provides an empirical value of residue, solvent recovery capacity, and loss (or non-recovery) on heating. Organic liquids are used as solvents in many chemical processes. As the relative volatility, residual matter and recovery capability affect the efficiency of these processes, this test method is useful in manufacturing control.

SCOPE

1.1 This test method covers the determination of the distillation range of liquids boiling between 30 and 350C, that are chemically stable during the distillation process, by manual or automatic distillation procedures.

1.2 This test method is applicable to organic liquids such as hydrocarbons, oxygenated compounds, chemical intermediates, and blends thereof.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 For purposes of determining conformance of an observed or a calculated value using this test method to relevant specifications, test result(s) shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E 29.

1.5 For hazard information and guidance, see the supplier's Material Safety Data Sheet.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1078–05

Designation:195/98

Standard Test Method for

1

Distillation Range of Volatile Organic Liquids

This standard is issued under the fixed designation D1078; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* E1 Specification for ASTM Liquid-in-Glass Thermometers

E29 Practice for Using Significant Digits in Test Data to

1.1 This test method covers the determination of the distil-

Determine Conformance with Specifications

lation range of liquids boiling between 30 and 350°C, that are

E133 Specification for Distillation Equipment

chemically stable during the distillation process, by manual or

E299 Test Method for Trace Amounts of Peroxides In

automatic distillation procedures.

Organic Solvents

1.2 This test method is applicable to organic liquids such as

2.2 ASTM Adjuncts:

hydrocarbons, oxygenated compounds, chemical intermedi-

DeterminationofPrecisionandBiasforUseinTestMethods

ates, and blends thereof.

3

for Petroleum Products and Lubricants

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions:

1.4 For purposes of determining conformance of an ob-

3.1.1 initial boiling point, n—the temperature indicated by

served or a calculated value using this test method to relevant

the distillation thermometer at the instant the first drop of

specifications, test result(s) shall be rounded off “to the nearest

condensate leaves the condenser tube.

unit” in the last right-hand digit used in expressing the

3.1.2 dry point, n—the temperature indicated at the instant

specification limit, in accordance with the rounding-off method

the last drop of liquid evaporates from the lowest point in the

of Practice E29.

distillation flask, disregarding any liquid on the side of the

1.5 For hazard information and guidance, see the supplier’s

flask.

Material Safety Data Sheet.

3.1.3 decomposition point, n—the thermometer reading that

1.6 This standard does not purport to address all of the

coincideswiththefirstindicationsofthermaldecompositionof

safety concerns, if any, associated with its use. It is the

the liquid in the flask.

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety and health practices and determine the applica-

3.2.1 final boiling point, n—the maximum thermometer

bility of regulatory limitations prior to use. Specific hazard

reading obtained during the test.

statements are given in Section 7.

3.2.1.1 Discussion—This usually occurs after the evapora-

2. Referenced Documents tion of all liquid from the bottom of the flask. The term

2 “maximum temperature” is a frequently used synonym.

2.1 ASTM Standards:

3.2.2 end point 5 minutes, n—the thermometer reading

D86 Test Method for Distillation of Petroleum Products at

obtained5minafterthe95 %distillationpointifnodryorfinal

Atmospheric Pressure

boiling point occurs.

1

4. Summary of Test Method

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

4.1 A100-mLspecimenisdistilledunderconditionsequiva-

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

lent to a simple batch differential distillation. The temperature

Current edition approved May 15, 2005. Published June 2005. Originally

approved in 1949. Last previous edition approved in 2003 as D1078 – 03. DOI:

of the mercury in the thermometer is equilibrated with that of

10.1520/D1078-05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters. Request Adjunct No.

the ASTM website. ADJD6300.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1078–05

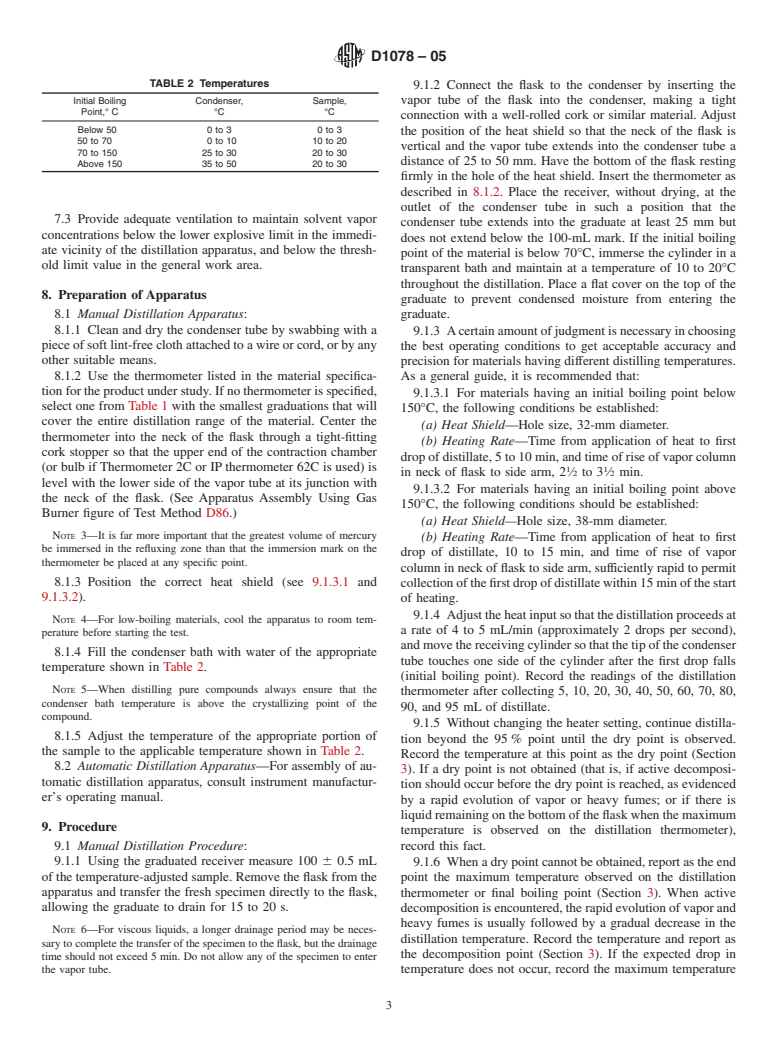

TABLE 1 Thermometers

the refluxing liquid before the distillate is taken over. Boiling

temperatures observed on a partial immersion thermometer are ASTM Sub-

Thermometer IP Range, °C division,

corrected to standard atmospheric pressure to give true boiling

Number °C

temperatures.

A A

2C 62C −5 to + 300 1.0

A A B

3C 73C −5 to + 400

5. Significance and Use

14C . 38 to 82 0.1

37C 77C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.