ASTM B918-01

(Practice)Standard Practice for Heat Treatment of Wrought Aluminum Alloys

Standard Practice for Heat Treatment of Wrought Aluminum Alloys

ABSTRACT

This practice is intended for use in the heat treatment of wrought aluminum alloys for general purpose applications. Aluminum alloys are typically heated in air chamber furnaces or molten salt baths. Though lead baths, oil baths, or fluidized beds may be used, uncontrolled heating is not permitted. The furnace temperature uniformity and calibration shall conform to the specified requirements. Preparation for heat treatment of alloys shall follow the racking, spacing, and cleanliness requirements. Solution heat treatment shall follow the recommended soaking times and quenching procedures. Precipitation heat treatment shall conform to the prescribed times, temperatures, and annealing procedures. The alloys shall be subjected to tensile testing, eutectic melting and heat-treat-induced porosity analysis, intergranular corrosion test, and Alclad diffusion test.

SCOPE

1.1 This practice is intended for use in the heat treatment of wrought aluminum alloys for general purpose applications.

1.1.1 The heat treatment of wrought aluminum alloys used in specific aerospace applications is covered in AMS 2772.

1.1.2 Heat treatment of aluminum alloy castings for general purpose applications is covered in Practice B 917/B 917M.

1.2 Times and temperatures appearing in the heat-treatment tables are typical for various forms, sizes, and manufacturing methods and may not provide the optimum heat treatment for a specific item.

1.3 Some alloys in the 6xxx series may achieve the T4 temper by quenching from within the solution temperature range during or immediately following a hot working process, such as upon emerging from an extrusion die. Such alternatives to furnace heating and immersion quenching are indicated in , by Footnote L, for heat treatment of wrought aluminum alloys. However, this practice does not cover the requirements for a controlled press heat treatment. (Refer to Practice B 807 for press heat treatment of aluminum alloys.)

1.4 This practice is in inch-pound units.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B918–01

Standard Practice for

Heat Treatment of Wrought Aluminum Alloys

This standard is issued under the fixed designation B 918; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

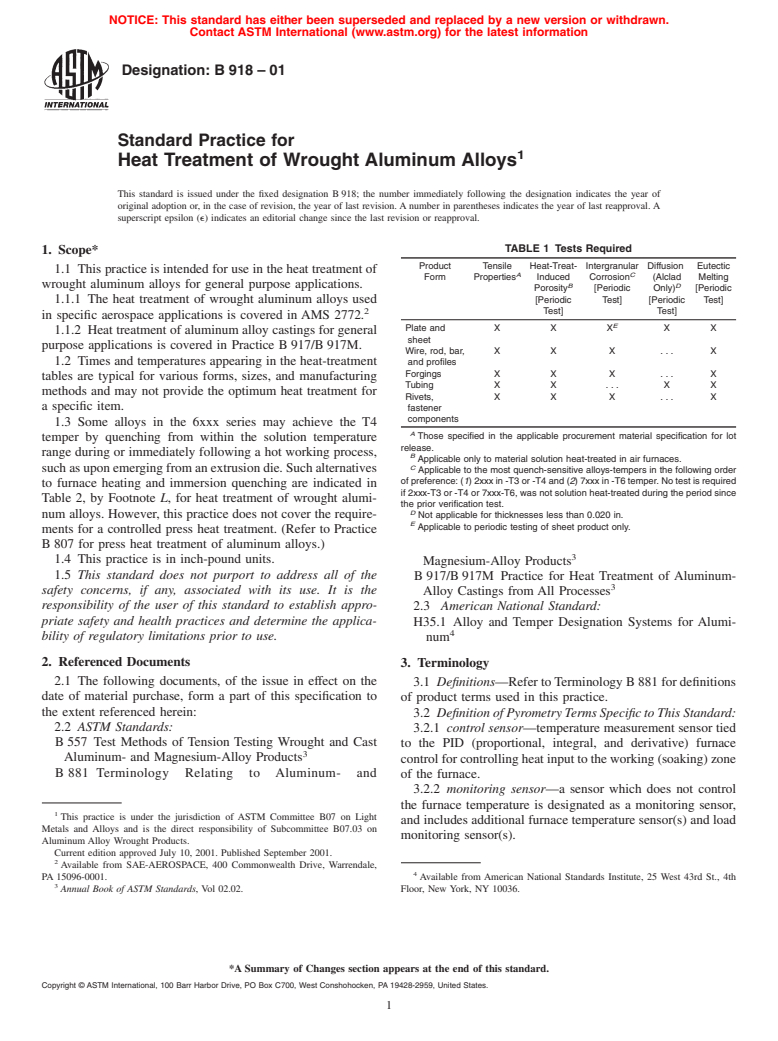

TABLE 1 Tests Required

1. Scope*

Product Tensile Heat-Treat- Intergranular Diffusion Eutectic

1.1 This practice is intended for use in the heat treatment of

A C

Form Properties Induced Corrosion (Alclad Melting

wrought aluminum alloys for general purpose applications. B D

Porosity [Periodic Only) [Periodic

1.1.1 The heat treatment of wrought aluminum alloys used [Periodic Test] [Periodic Test]

2 Test] Test]

in specific aerospace applications is covered in AMS 2772.

E

Plate and XX X XX

1.1.2 Heat treatment of aluminum alloy castings for general

sheet

purpose applications is covered in Practice B 917/B 917M.

Wire, rod, bar, X X X . X

1.2 Times and temperatures appearing in the heat-treatment

and profiles

Forgings X X X . . . X

tables are typical for various forms, sizes, and manufacturing

Tubing X X . . . X X

methods and may not provide the optimum heat treatment for

Rivets, X X X . X

a specific item. fastener

components

1.3 Some alloys in the 6xxx series may achieve the T4

A

Those specified in the applicable procurement material specification for lot

temper by quenching from within the solution temperature

release.

range during or immediately following a hot working process,

B

Applicable only to material solution heat-treated in air furnaces.

C

suchasuponemergingfromanextrusiondie.Suchalternatives

Applicable to the most quench-sensitive alloys-tempers in the following order

of preference: (1) 2xxx in -T3 or -T4 and (2) 7xxx in -T6 temper. No test is required

to furnace heating and immersion quenching are indicated in

if 2xxx-T3 or -T4 or 7xxx-T6, was not solution heat-treated during the period since

Table 2, by Footnote L, for heat treatment of wrought alumi-

the prior verification test.

D

num alloys. However, this practice does not cover the require-

Not applicable for thicknesses less than 0.020 in.

E

Applicable to periodic testing of sheet product only.

ments for a controlled press heat treatment. (Refer to Practice

B 807 for press heat treatment of aluminum alloys.)

1.4 This practice is in inch-pound units. Magnesium-Alloy Products

1.5 This standard does not purport to address all of the

B 917/B 917M Practice for Heat Treatment of Aluminum-

safety concerns, if any, associated with its use. It is the Alloy Castings from All Processes

responsibility of the user of this standard to establish appro-

2.3 American National Standard:

priate safety and health practices and determine the applica-

H35.1 Alloy and Temper Designation Systems for Alumi-

bility of regulatory limitations prior to use.

num

2. Referenced Documents

3. Terminology

2.1 The following documents, of the issue in effect on the

3.1 Definitions—Refer toTerminology B 881 for definitions

date of material purchase, form a part of this specification to

of product terms used in this practice.

the extent referenced herein:

3.2 Definition of Pyrometry Terms Specific to This Standard:

2.2 ASTM Standards:

3.2.1 control sensor—temperature measurement sensor tied

B 557 Test Methods of Tension Testing Wrought and Cast

to the PID (proportional, integral, and derivative) furnace

Aluminum- and Magnesium-Alloy Products

controlforcontrollingheatinputtotheworking(soaking)zone

B 881 Terminology Relating to Aluminum- and

of the furnace.

3.2.2 monitoring sensor—a sensor which does not control

the furnace temperature is designated as a monitoring sensor,

This practice is under the jurisdiction of ASTM Committee B07 on Light

and includes additional furnace temperature sensor(s) and load

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

monitoring sensor(s).

Aluminum Alloy Wrought Products.

Current edition approved July 10, 2001. Published September 2001.

Available from SAE-AEROSPACE, 400 Commonwealth Drive, Warrendale,

PA 15096-0001. Available from American National Standards Institute, 25 West 43rd St., 4th

Annual Book of ASTM Standards, Vol 02.02. Floor, New York, NY 10036.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B918–01

combustion contact the work, particularly if the gases are high in water

3.2.3 test sensor—temperature measurement sensor(s) used

vapor or contain compounds of sulfur. In general, the high-strength

in furnace temperature uniformity surveys.

wrought alloys of the 2xxx and 7xxx series are most susceptible.

Low-strength and Alclad (two sides) products are practically immune to

4. Equipment

this type of damage. Anodic films and proprietary heat-treat coatings are

4.1 Heating Media—Aluminum alloys are typically heat-

also useful in protecting against porosity resulting from solution heat

treated in air chamber furnaces or molten salt baths; however,

treatment. Surface discoloration is a normal result of solution heat

lead baths, oil baths, or fluidized beds, may be used. However, treatment of aluminum alloys and should not be interpreted as evidence of

damage from overheating or as heat-treat induced porosity (see 7.4.2.1).

the use of uncontrolled heating is not permitted. Whichever

heating means are employed, careful evaluation is required to

4.1.2 Salt baths heat the work rapidly and uniformly. The

ensure that the alloy being heat-treated responds properly to

temperature of the bath can be closely controlled, an important

heat-treatment and is not damaged by overheating or by the

consideration in solution heat treatment of wrought aluminum

heat-treatment environment.

alloys. High-temperature oxidation of aluminum is not a

4.1.1 Air chamber furnaces may be oil- or gas-fired or may

problem in salt baths.

be electrically heated. Furnace components that are signifi-

4.2 Furnace Temperature Uniformity and Calibration Re-

cantly hotter than the metal should be suitably shielded for

quirements:

metal less than 0.250 in. thick to prevent adverse radiation

4.2.1 After establishment of thermal equilibrium or a recur-

effects. The atmosphere in air chamber furnaces must be

rent temperature pattern, the temperature in the working

controlled to prevent potential porosity resulting from solution

(soaking) zone, for all furnace control and test sensors, shall

heat treatment (see Note 1). The suitability of the atmosphere

maintain temperature in the working (soaking) zone within the

in an air-chamber furnace can be demonstrated by testing, in

following allowable ranges:

accordancewith7.4.2.1,thatproductsprocessedinthatfurnace

4.2.1.1 50°F range for furnaces used only for full annealing

are free from heat-treat induced porosity.

at 825°F and higher, except 20°F range if the annealing

temperature is within 15°F of the middle of the solution heat

NOTE 1—Heat-treat induced porosity may lower mechanical properties

treating temperature range specified in Table 2.

and commonly causes blistering of the surface of the material. The

condition is most likely to occur in furnaces in which the products of

A

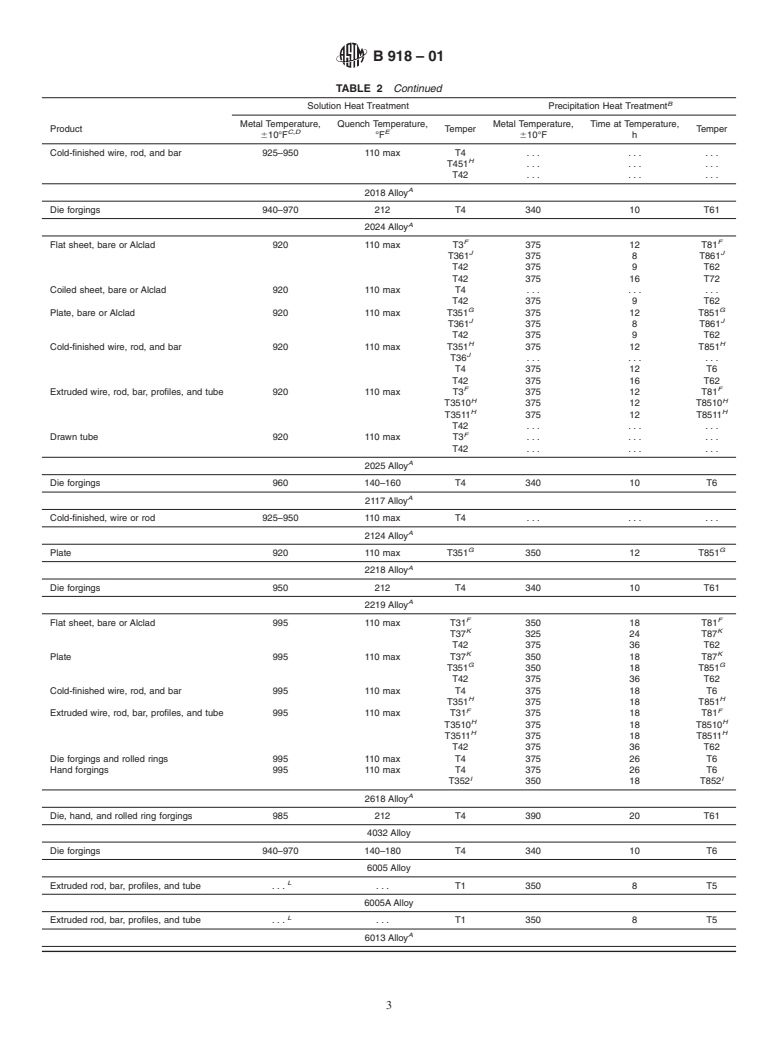

TABLE 2 Recommended Heat Treatment for Wrought Aluminum Alloys

B

Solution Heat Treatment Precipitation Heat Treatment

Metal Temperature, Quench Temperature, Metal Temperature, Time at Temperature,

Product Temper Temper

C,D E

610°F °F 610°F h

A

2011 Alloy

F F

Cold-finished wire, rod, and bar 945-995 110 max T3 320 14 T8

T4 . . .

G

T451 . . .

F

Drawn tube 975 110 max T3 . . .

G

T4511

A

2014 Alloy

F

Flat sheet, bare or Alclad 935 110 max T3 . . .

T42 320 18 T62

Coiled sheet, bare or Alclad 935 110 max T4 320 18 T6

T42 320 18 T62

G G

Plate, bare or Alclad 935 110 max T451 320 18 T651

T42 . . .

Cold-finished wire, rod, and bar 935 110 max T4 320 18 T6

or 350 8

H H

T451 320 18 T651

or 350 8

T42 320 18 T62

or 350 8

Extruded wire, rod, bar, profiles, and tube 935 110 max T4 320 18 T6

or 350 8

H H

T4510 320 18 T6510

or 350 8

H H

T4511 320 18 T6511

or 350 8

T42 320 18 T62

or 350 8

Drawn tube 935 110 max T4 320 18 T6

T42 320 18 T62

Die forgings 935 140–180 T4 340 10 T6

I I

Hand forgings and rolled rings 935 140–180 T452 340 10 T652

T4 340 10 T6

A

2017 Alloy

B918–01

TABLE 2 Continued

B

Solution Heat Treatment Precipitation Heat Treatment

Metal Temperature, Quench Temperature, Metal Temperature, Time at Temperature,

Product Temper Temper

C,D E

610°F °F 610°F h

Cold-finished wire, rod, and bar 925–950 110 max T4 . . .

H

T451 . . .

T42 . . .

A

2018 Alloy

Die forgings 940–970 212 T4 340 10 T61

A

2024 Alloy

F F

Flat sheet, bare or Alclad 920 110 max T3 375 12 T81

J J

T361 375 8 T861

T42 375 9 T62

T42 375 16 T72

Coiled sheet, bare or Alclad 920 110 max T4 . . .

T42 375 9 T62

G G

Plate, bare or Alclad 920 110 max T351 375 12 T851

J J

T361 375 8 T861

T42 375 9 T62

H H

Cold-finished wire, rod, and bar 920 110 max T351 375 12 T851

J

T36 . . .

T4 375 12 T6

T42 375 16 T62

F F

Extruded wire, rod, bar, profiles, and tube 920 110 max T3 375 12 T81

H H

T3510 375 12 T8510

H H

T3511 375 12 T8511

T42 . . .

F

Drawn tube 920 110 max T3 . . .

T42 . . .

A

2025 Alloy

Die forgings 960 140–160 T4 340 10 T6

A

2117 Alloy

Cold-finished, wire or rod 925–950 110 max T4 . . . . . . . . .

A

2124 Alloy

G G

Plate 920 110 max T351 350 12 T851

A

2218 Alloy

Die forgings 950 212 T4 340 10 T61

A

2219 Alloy

F F

Flat sheet, bare or Alclad 995 110 max T31 350 18 T81

K K

T37 325 24 T87

T42 375 36 T62

K K

Plate 995 110 max T37 350 18 T87

G G

T351 350 18 T851

T42 375 36 T62

Cold-finished wire, rod, and bar 995 110 max T4 375 18 T6

H H

T351 375 18 T851

F F

Extruded wire, rod, bar, profiles, and tube 995 110 max T31 375 18 T81

H H

T3510 375 18 T8510

H H

T3511 375 18 T8511

T42 375 36 T62

Die forgings and rolled rings 995 110 max T4 375 26 T6

Hand forgings 995 110 max T4 375 26 T6

I I

T352 350 18 T852

A

2618 Alloy

Die, hand, and rolled ring forgings 985 212 T4 390 20 T61

4032 Alloy

Die forgings 940–970 140–180 T4 340 10 T6

6005 Alloy

L

Extruded rod, bar, profiles, and tube . . . . . . T1 350 8 T5

6005AAlloy

L

Extruded rod, bar, profiles, and tube . . . . . . T1 350 8 T5

A

6013 Alloy

B918–01

TABLE 2 Continued

B

Solution Heat Treatment Precipitation Heat Treatment

Metal Temperature, Quench Temperature, Metal Temperature, Time at Temperature,

Product Temper Temper

C,D E

610°F °F 610°F h

Sheet, bare 1055 110 max T4 375 4 T6

or 345 8

G

Plate, bare 1020–1050 110 max . . . 345 8–16 T651

H

Cold-finished wire, rod, and bar 1050 110 max . . . 375 4 T651

F

... 375 4 T8

6053 Alloy

Cold-finished wire and rod 970 110 max T4 355 8 T61

Die forgings 970 110 max T4 340 10 T6

A

6061 Alloy

M

Sheet, bare or Alclad 960–1075 110 max T4 320 18 T6

T42 320 18 T62

G G

Plate 960–1075 110 max T451 320 18 T651

T42 320 18 T62

N,O

Tread Sheet and Plate 960–1075 110 max T4 320 18 T6

P

Cold-finished wire, rod, and bar 960–1075 110 max T4 340 8 T6

or 320 18

F Q,R

T3 340 8 T89

or 320 18

S

T4 340 8 T94

or 320 18

H H

T451 340 8 T651

or 320 18

T42 340 8 T62

or 320 18

L

Extruded rod, bar, profiles, and tube . . . . T1 350 8 T51

L P

960–1075 110 max T4 350 8 T6

H H

T4510 350 8 T6510

H H

T4511 350 8 T6511

T42 350 8 T62

L P

Structural profiles 960–1075 110 max T4 350 8 T6

L P

Pipe 960–1075 110 max T4 350 8 T6

Drawn tube 960–1075 110 max T4 340 8 T6

or 320 18

T42 340 8 T62

or 320 18

Die and hand forgings 960–1075 110 max T4 340 8 T6

or 320 18

Rolled rings 960–1075 110 max T4 350 8 T6

T T

T452 350 8 T652

6063 Alloy

L

Extruded rod, bar, tube, and profiles . . . . T1 400 1to2 T5

or 360 3

T1 400 1to2 T52

or 360 3

L P

970 110 max T4 360 6 T6

or 350 8

T42 360 6 T62

or 350 8

Drawn tube 970 110 max T4 350 8 T6

F R

350 8 T83

T3

F R

T3 350 8 T831

F R

T3 350 8 T832

F

T31 . . .

T42 350 8 T62

L P

Pipe 970 110 max T4 360 6 T6

or 350 8

6066 Alloy

Extruded rod, bar, profiles, and tube 960–1010 110 max T4 350 8 T6

H H

T4510 350 8 T6510

H H

T4511 350 8 T6511

T42 350 8 T62

Die forgings 960–1010 110 max T4 350 8 T6

6070 Alloy

Extruded rod, bar, profiles, and tube 1015 110 max T4 320 18 T6

T42 320 18 T62

6101 Alloy

B918–01

TABLE 2 Continued

B

Solution Heat Treatment Precipitation Heat Treatment

Metal Temperature, Quench Temperature, Metal Temperature, Time at Temperature,

Product Temper Temper

C,D E

610°F °F 610°F h

L P

Extruded rod, bare tube, pipe and 970 110 max T4 390 10 T6

structural profiles T4 440 5 T61

T4 410 9 T63

T4 535 7 T64

T4 430 3 T65

6105 Alloy

L

Extruded rod, bar, profiles, and tube . . . . . . T1 350 8 T5

6110 Alloy

S

Cold-finished wire, rod, and bar 980–1050 110 max T4 380 8 T9

6151 Alloy

Die forgings 950–980 110 max T4 340 10 T6

Rolled rings 960 110 max T4 340 10 T6

I I

T452 340 10 T652

6201 Alloy

R

Wire 950 110 max T3 320 4 T81

6262 Alloy

Cold-finished wire, rod, and bar 960–1050 110 max T4 340 8 T6

S

T4 340 8 T9

H H

T451 340 8 T651

L

Extruded rod, bar, profiles, and tube 960–1050 110 max T4 350 12 T6

H H

T4510 350 12 T6510

H H

T4511 350 12 T6511

T42 350 12 T62

Drawn tube 960–1050 110 max T4 340 8 T6

S

T4 340 8 T9

T42 340 8 T62

6351 Alloy

L

Extruded rod, bar, profiles, and tube . . . . T1 350 8 T5

350 8 T51

250 10 T54

or 350 8

L

... ... T11 ... ... ...

L P

960–1010 110 max T4 350 8 T6

6463 Alloy

L

Extruded rod, bar, profiles, and tube . . . . T1 400 1 T5

or 360 3

L P

970 110 max T4 350 8 T6

or 360 6

7001 Alloy

U

Extruded rod, bar, profiles, and tube 870 110 max W 250 24 T6

H,U H

W510 250 24 T6510

H,U H

W511 250 24 T6511

U

W 250 24 T62

7005 Alloy

L

Extruded rod, bar, and profiles . . . . . . T1 room temperature 72 plus T53

225 8 plus

300 16

7049 Alloy

H,U H

Extruded rod, bar, and profiles 875 110 max W511 room temperature 48 plus T76511

250 24 plus

325 12 to 14

H,U H

W511 room temperature 48 plus T73511

250 24 plus

300 12 to 21

U

Die and hand forgings 875 140–160 W room temperature 48 plus T73

250 24 plus

330 10 to 16

I,U I

W52 room temperature 48 plus T7352

250 24 plus

330 10 to 16

7050 Alloy

B918–01

TABLE 2 Continued

B

Solution Heat Treatment Precipitation Heat Treatment

Metal Temperature, Quench Temperature, Metal Temperature, Time at Temperature,

Product Temper Temper

C,D E

610°F °F 610°F h

G,U G

Plate 890 110 max W51 250 3to6plus T7451

330 24 to 30

G,U G

W51 250 3to6plus T7651

330 12 to 15

U

Cold-finished wire, rod 890 110 max W 250 4 plus T7

355 8to12

H,U H

E

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.