ASTM F1863-98

(Test Method)Standard Test Method for Measuring the Night Vision Goggle-Weighted Transmisivity of Transparent Parts

Standard Test Method for Measuring the Night Vision Goggle-Weighted Transmisivity of Transparent Parts

SCOPE

1.1 This test method covers apparatuses and procedures that are suitable for measuring the NVG-weighted transmissivity of transparent parts including those that are large, thick, curved, or already installed. This test method is sensitive to transparencies that vary in transmissivity as a function of wavelength.

1.2 Since the transmissivity (or transmission coefficient) is a ratio of two radiance values, it has no units. The units of radiance recorded in the intermediate steps of this test method are not critical; any recognized units of radiance (for example, watts/m2-str) may be used, as long as it is consistent.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1863 – 98

Standard Test Method for

Measuring the Night Vision Goggle-Weighted Transmissivity

of Transparent Parts

This standard is issued under the fixed designation F 1863; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Test Methods D 1003 and F 1316 apply to the transmissivity measurement of transparent materials,

the former being for small flat samples, and the latter for larger, curved pieces such as aircraft

transparencies. Additionally, in D 1003, the transmissivity is measured perpendicular to the surface of

test sample and both test methods measure only in the visible light spectral region. Night vision

goggles (NVGs) are being used in aircraft and other applications (for example, marine navigation,

driving) with increasing frequency. These devices amplify both visible and near-infrared (NIR)

spectral energy. Overall visual performance can be degraded if the observer uses the NVGs while

looking through a transparency that has poor transmissivity in the visible and NIR spectral regions.

This test method describes both direct and analytical measurement techniques that determine the

NVG-weighted transmissivity of transparent pieces including ones that are large, curved, or held at the

installed position.

1. Scope D 1003 Test Method for Haze and Luminous Transmittance

of Transparent Plastics

1.1 This test method covers apparatuses and procedures that

E 177 Practice for Use of the Terms Precision and Bias in

are suitable for measuring the NVG-weighted transmissivity of

ASTM Test Methods

transparent parts including those that are large, thick, curved,

E 691 Practice for Conducting an Interlaboratory Study to

or already installed. This test method is sensitive to transpar-

Determine the Precision of a Test Method

encies that vary in transmissivity as a function of wavelength.

F 1316 Test Method for Measuring the Transmissivity of

1.2 Since the transmissivity (or transmission coefficient) is a

Transparent Parts

ratio of two radiance values, it has no units. The units of

radiance recorded in the intermediate steps of this test method

3. Terminology

are not critical; any recognized units of radiance (for example,

2 3.1 Definitions:

watts/m -str) may be used, as long as it is consistent.

3.1.1 analytical test method, n—the test method that uses

1.3 This standard does not purport to address all of the

spectral transmissivity data of a transparent part collected by

safety concerns, if any, associated with its use. It is the

the use of either spectraphotometric or spectraradiometric

responsibility of the user of this standard to establish appro-

instrumentation. The data are then examined using analytic

priate safety and health practices and determine the applica-

methods to determine the NVG-weighted transmissivity of the

bility of regulatory limitations prior to use.

part.

2. Referenced Documents 3.1.2 direct test method, n—the test method that uses the

actual luminous output, as measured by a photometer, properly

2.1 ASTM Standards:

coupled to the eyepiece of the test NVG. The NVG-weighted

transmissivity of the part is then determined by forming the

This test method is under the jurisdiction of ASTM Committee F-7 on

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on

Transparent Enclosures and Materials.

Current edition approved April 10, 1998. Published July 1998. Annual Book of ASTM Standards, Vol 08.01.

2 4

RCA Electro-Optics Handbook, RCA/Solid State Division/Electro Optics and Annual Book of ASTM Standards, Vol 14.02.

Devices. Technical Series EOH-11. Lancaster, PA; 1974. Annual Book of ASTM Standards, Vol 15.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1863

ratio of the NVG output luminance with the transparent part in the NVG and its objective lens is aimed at and focused on a

place to the luminance output without the part. target. The target can be either an evenly illuminated white,

3.1.3 NVG-weighted spectral transmissivity, n—the spectral

diffusely reflecting surface or a transilluminated screen (light-

transmissivity of a transparent part multiplied by the spectral

box). The illumination is provided by a white, incandescent

sensitivity of a given NVG (see Fig. 1).

light source. Handle the samples carefully as not to cause any

3.1.4 NVG-weighted transmissivity (T ), n—the spectral

NVG damage. Do not clean them with any solvents. Use part-

transmissivity of a transparent part multiplied by the spectral

specific, prescribed cleaning materials and methods.

sensitivity of a given NVG integrated with respect to wave-

4.1.1 Direct Test Method—Attached directly to the eyepiece

length (see Fig. 1, Eq 1 and Eq 2).

of the NVG is a photodetector. It has been found that the

3.1.5 NVG spectral sensitivity, n—the sensitivity of an

measured field of view (FOV) should be smaller than the

NVG as a function of input wavelength.

uniformly illuminated portion of the target. The target illumi-

3.1.6 photometer, n—a device that measures luminous in-

nation is adjusted so that the output of the NVGs is about 1.7

tensity or brightness by converting (weighting) the radiant

cd/m (0.5 fL). This ensures that the NVG input is not

intensity of an object using the relative sensitivity of the human

2,5

saturated; the automatic gain control (AGC) is not active. The

visual system as defined by the photopic curve.

luminance output of the NVG is measured and then repeated

3.1.7 photopic curve, n—the photopic curve is the spectral

with the transparent material in place. The transmissivity is

sensitivity of the human eye for daytime conditions as defined

equal to the NVG output luminance with the transparent

by the Commission Internationale d’Eclairage (CIE) 1931

2,6

material in place divided by the NVG output luminance

standard observer.

3.1.8 transmission coeffıcient, n—see transmissivity. without the material (see Eq 1). The result is the NVG-

3.1.9 transmissivity, n—the transmissivity of a transparent weighted transmissivity (T ) of the transparent material.

NVG

medium is the ratio of the luminance of an object measured

4.1.2 Analytical Test Method—Without the sample in place,

through the medium to the luminance of the same object

measure the light source’s spectral energy distribution from

measured directly.

450 through 950 nm in 5-nm incremental steps. Place the

sample into the spectrophotometer or spectraradiometer fix-

4. Summary of Test Method

ture. Perform spectral measurements, also from 450 through

4.1 General Test Conditions—The test method can be

950 nm in 5-nm incremental steps. Obtain from the NVG

performed in any light-controlled area (for example, light-tight

manufacturer the spectral sensitivity of the goggle that will be

room, darkened hangar, or outside at night away from strong

used in conjunction with the part. Perform the analytic method

light sources). The ambient illumination must be very low

as defined in Eq 2 to derive the T .

NVG

because of the extreme sensitivity of the NVGs. A fixture holds

Wyszecki, Gunter, and Stiles, WS, Color Science: Concepts and Methods,

Quantitative Data and Formulae, 2nd ed., New York, John Wiley and Sons, 1982.

FIG. 1 An Example of How the Spectral Sensitivity of a Generation 3 NVG Multiplied by the Spectral Transmissivity of a Transparent

Part Equals the NVG-Weighted Spectral Transmissivity of That Part. Integrating the Curve with Respect to Wavelength Yields the Part’s

NVG-Weighted Transmissivity (T ) Value

NVG

F 1863

5. Significance and Use moonlight through starlight-only conditions. The goggle that is

used for test should be the same as that used with the given

5.1 Significance—This test method provides a means to

transparent material.

measure the compatibility of a given transparency through

6.5 Photometer—Any calibrated photometer may be used

which NVGs are used at night to view outside, nighttime

for this measurement. However, the detector must be properly

ambient illuminated natural scenes.

coupled to the NVG eyepiece, and the FOV over which the

5.2 Use—This test method may be used on any transparent

light is integrated must be known.

part, including sample coupons. It is primarily intended for use

on large, curved, or thick parts that may already be installed

7. Test Specimen

(for example, windscreens on aircraft).

7.1 If necessary, clean the part to be measured using the

procedure prescribed for the specific material. Use of non-

6. Apparatus

standard cleaning methods can irrevocably damage the part.

6.1 Test Environment—This test method can be performed

No special conditions other than cleaning are required.

in any light-controlled area (for example, light-tight room,

darkened hangar, or outside at night away from strong light

8. Calibration and Standardization

sources) since the NVGs are extremely sensitive to both visible

8.1 It is not necessary that the photometer be calibrated in

and near infrared light. Extraneous light sources (for example,

absolute luminance units since the measurement involves the

exit signs, telephone pole lights, status indicator lights on

division of two measured quantities yielding a dimensionless

equipment, and so forth) can also interfere with the measure-

value. A generic photodetector can be substituted for the

ment.

photometer if its FOV is known.

6.2 White Diffuse Target—The white target can be any

uniformly diffusely reflecting or translucent material (for

9. Procedure

example, cloth, flat white painted surface, plastic). The target

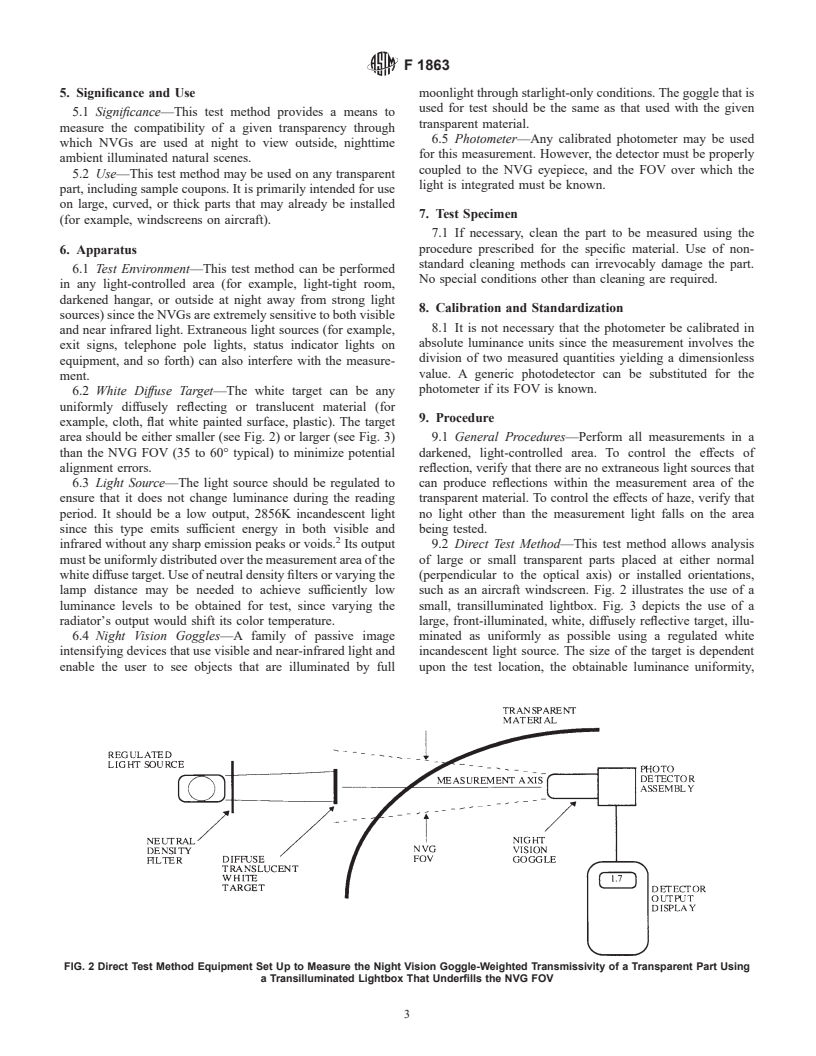

area should be either smaller (see Fig. 2) or larger (see Fig. 3) 9.1 General Procedures—Perform all measurements in a

than the NVG FOV (35 to 60° typical) to minimize potential darkened, light-controlled area. To control the effects of

alignment errors. reflection, verify that there are no extraneous light sources that

6.3 Light Source—The light source should be regulated to can produce reflections within the measurement area of the

ensure that it does not change luminance during the reading transparent material. To control the effects of haze, verify that

pe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.