ASTM C943-10

(Practice)Standard Practice for Making Test Cylinders and Prisms for Determining Strength and Density of Preplaced-Aggregate Concrete in the Laboratory

Standard Practice for Making Test Cylinders and Prisms for Determining Strength and Density of Preplaced-Aggregate Concrete in the Laboratory

SIGNIFICANCE AND USE

This practice is used for making test cylinders or prisms of PA concrete. Cylinders are used for determining compressive strength and approximate density. Prisms, cut from cylinders, eliminate the surface effect and thus more accurately represent the actual density of PA concrete in place.

SCOPE

1.1 This practice covers procedures for making standard test cylinders used to determine the compressive strength and density of preplaced-aggregate (PA) concrete.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C943 − 10

Standard Practice for

Making Test Cylinders and Prisms for Determining Strength

and Density of Preplaced-Aggregate Concrete in the

1

Laboratory

This standard is issued under the fixed designation C943; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 Thispracticecoversproceduresformakingstandardtest 3.1 Definitions:

cylinders used to determine the compressive strength and 3.1.1 For definitions of terms used in this test method, refer

density of preplaced-aggregate (PA) concrete. to Terminologies C125 and C219.

1.2 The values stated in SI units are to be regarded as the

4. Summary of Practice

standard. The values given in parentheses are for information

4.1 Coarse aggregate is placed in a standard cylinder mold

only.

having end plates to which pipe fittings have been attached.

1.3 This standard does not purport to address all of the

Grout is pumped into the mold until full. The test cylinder,

safety concerns, if any, associated with its use. It is the

demolded after hardening, may be cured and used for deter-

responsibility of the user of this standard to establish appro-

mination of strength or cut into prisms for the determination of

priate safety and health practices and determine the applica-

unit weight.

bility of regulatory limitations prior to use.

5. Significance and Use

2. Referenced Documents

2 5.1 This practice is used for making test cylinders or prisms

2.1 ASTM Standards:

of PA concrete. Cylinders are used for determining compres-

C125 Terminology Relating to Concrete and Concrete Ag-

sive strength and approximate density. Prisms, cut from

gregates

cylinders, eliminate the surface effect and thus more accurately

C192/C192M Practice for Making and Curing Concrete Test

represent the actual density of PA concrete in place.

Specimens in the Laboratory

C219 Terminology Relating to Hydraulic Cement

6. Apparatus

C637 Specification for Aggregates for Radiation-Shielding

6.1 Cylinder Molds (Fig. 1), cast iron or steel, for making

Concrete

150 by 300-mm (6 by 12-in.) cylinders. Base and top plates

C937 Specification for Grout Fluidifier for Preplaced-

shall be arranged for tight assembly to the cylinder.All mating

Aggregate Concrete

and inside surfaces shall be machined smooth such that the

C938 Practice for Proportioning Grout Mixtures for

assembled mold will be essentially watertight. End plates shall

Preplaced-Aggregate Concrete

be drilled and tapped at their centers for standard 19 mm

C939 Test Method for Flow of Grout for Preplaced-

3

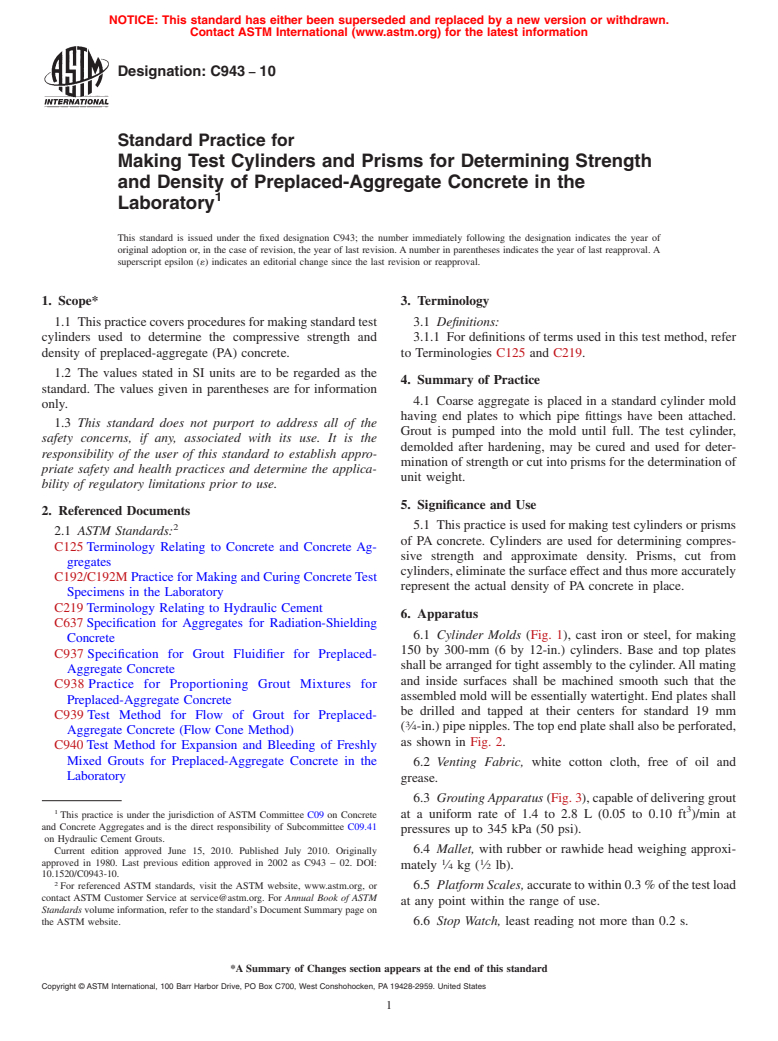

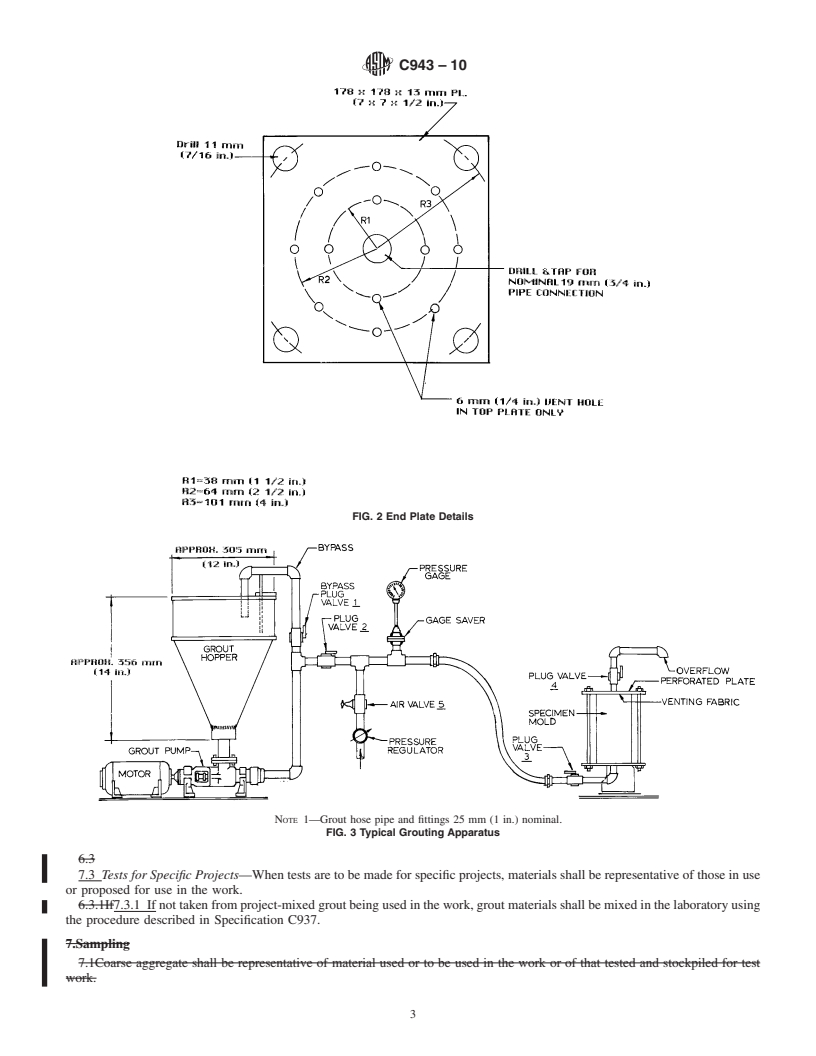

( ⁄4-in.) pipe nipples.The top end plate shall also be perforated,

Aggregate Concrete (Flow Cone Method)

as shown in Fig. 2.

C940 Test Method for Expansion and Bleeding of Freshly

Mixed Grouts for Preplaced-Aggregate Concrete in the

6.2 Venting Fabric, white cotton cloth, free of oil and

Laboratory

grease.

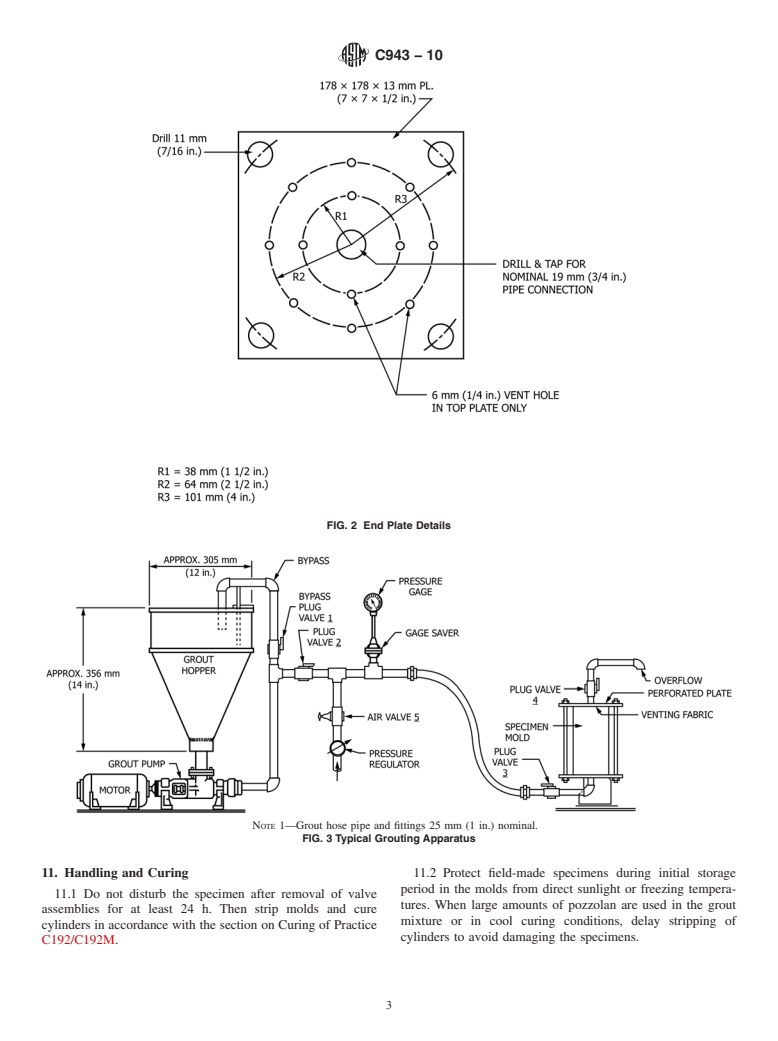

6.3 Grouting Apparatus (Fig. 3), capable of delivering grout

3

1

This practice is under the jurisdiction of ASTM Committee C09 on Concrete at a uniform rate of 1.4 to 2.8 L (0.05 to 0.10 ft )/min at

and Concrete Aggregates and is the direct responsibility of Subcommittee C09.41

pressures up to 345 kPa (50 psi).

on Hydraulic Cement Grouts.

Current edition approved June 15, 2010. Published July 2010. Originally 6.4 Mallet, with rubber or rawhide head weighing approxi-

approved in 1980. Last previous edition approved in 2002 as C943 – 02. DOI: 1 1

mately ⁄4 kg ( ⁄2 lb).

10.1520/C0943-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6.5 Platform Scales,accuratetowithin0.3 %ofthetestload

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

at any point within the range of use.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.6 Stop Watch, least reading not more than 0.2 s.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C943 − 10

part in 250. Compute the volume from the averages of two

measurementsofeachdimension,takentothenearest0.25mm

(0.01 in.).

10. Procedure

10.1 Temperature:

10.1.1 When test cylinders are prepared in the laboratory,

bring all materials to and maintain the laboratory in a tempera-

ture range of 23.0 6 2.0°C (73.5 6 3.5°F).

10.1.2 When test cylinders are prepared in the field, record

ambient temperature in the vicinity of test operation.

10.2 Placeeachcylindermolduprightonitsbottomplateon

a firm, level surface.

10

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C943–02 Designation:C943–10

Standard Practice for

Making Test Cylinders and Prisms for Determining Strength

and Density of Preplaced-Aggregate Concrete in the

1

Laboratory

This standard is issued under the fixed designation C943; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers procedures for making standard test cylinders used to determine the compressive strength and density

of preplaced-aggregate (PA) concrete.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Aggregates

C192/C192M Practice for Making and Curing Concrete Test Specimens in the Laboratory

C219 Terminology Relating to Hydraulic Cement

C637 Specification for Aggregates for Radiation-Shielding Concrete

C937 Specification for Grout Fluidifier for Preplaced-Aggregate Concrete

C938 Practice for Proportioning Grout Mixtures for Preplaced-Aggregate Concrete

C939 Test Method for Flow of Grout for Preplaced-Aggregate Concrete (Flow Cone Method)

C940 Test Method for Expansion and Bleeding of Freshly Mixed Grouts for Preplaced-Aggregate Concrete in the Laboratory

3. Summary of Practice

3.1Coarse aggregate is placed in a standard cylinder mold having end plates to which pipe fittings have been attached. Grout

ispumpedintothemolduntilfull.Thetestcylinder,demoldedafterhardening,maybecuredandusedfordeterminationofstrength

or cut into prisms for the determination of unit weight. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer to Terminologies C125 and C219.

4. Significance and Use

4.1This practice is used for making test cylinders or prisms of PA concrete. Cylinders are used for determining compressive

strength and approximate density. Prisms, cut from cylinders, eliminate the surface effect and thus more accurately represent the

actual density of PA concrete in place. Summary of Practice

4.1 Coarse aggregate is placed in a standard cylinder mold having end plates to which pipe fittings have been attached. Grout

ispumpedintothemolduntilfull.Thetestcylinder,demoldedafterhardening,maybecuredandusedfordeterminationofstrength

or cut into prisms for the determination of unit weight.

5. Significance and Use

5.1 This practice is used for making test cylinders or prisms of PA concrete. Cylinders are used for determining compressive

1

This practice is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.41 on

Concrete for Radiation Shielding.

Current edition approved Dec. 10, 2002. Published February 2003. Originally approved in 1980. Last previous edition approved in 1996 as C943–96. DOI:

10.1520/C0943-02. on Hydraulic Cement Grouts.

Current edition approved June 15, 2010. Published July 2010. Originally approved in 1980. Last previous edition approved in 2002 as C943–02. DOI: 10.1520/C0943-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C943–10

strength and approximate density. Prisms, cut from cylinders, eliminate the surface effect and thus more accurately represent the

actual density of PA concrete in place.

6. Apparatus

5.1

6.1 Cylinder Molds (Fig. 1), cast iron or steel, for making 150 by 300-mm (6 by 12-in.) cylinders. Base and top plates shall

be arranged for tight assembly to the cylinder. All mating and inside surfaces shall be machined smooth such that the assembled

3

mold will be essentially watertight. End plates shall be d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.