ASTM E1304-97(2020)

(Test Method)Standard Test Method for Plane-Strain (Chevron-Notch) Fracture Toughness of Metallic Materials

Standard Test Method for Plane-Strain (Chevron-Notch) Fracture Toughness of Metallic Materials

SIGNIFICANCE AND USE

5.1 The fracture toughness determined by this test method characterizes the resistance of a material to fracture by a slowly advancing steady-state crack (see 3.2.5) in a neutral environment under severe tensile constraint. The state of stress near the crack front approaches plane strain, and the crack-tip plastic region is small compared with the crack size and specimen dimensions in the constraint direction. A KIv or KIvj value may be used to estimate the relation between failure stress and defect size when the conditions described above would be expected, although the relationship may differ from that obtained from a KIc value (see Note 1). Background information concerning the basis for development of this test method in terms of linear elastic fracture mechanics may be found in Refs (6-15).

5.1.1 The KIv, KIvj, or KIvM value of a given material can be a function of testing speed (strain rate) and temperature. Furthermore, cyclic forces can cause crack extension at KI values less than KIv, and crack extension can be increased by the presence of an aggressive environment. Therefore, application of KIv in the design of service components should be made with an awareness of differences that may exist between the laboratory tests and field conditions.

5.1.2 Plane-strain fracture toughness testing is unusual in that there can be no advance assurance that a valid KIv, KIvj, or KIvM will be determined in a particular test. Therefore, it is essential that all the criteria concerning the validity of results be carefully considered as described herein.

5.2 This test method can serve the following purposes:

5.2.1 To establish the effects of metallurgical variables such as composition or heat treatment, or of fabricating operations such as welding or forming, on the fracture toughness of new or existing materials.

5.2.2 For specifications of acceptance and manufacturing quality control, but only when there is a sound basis for specification of minimum ...

SCOPE

1.1 This test method covers the determination of plane-strain (chevron-notch) fracture toughnesses, KIv or KIvM, of metallic materials. Fracture toughness by this method is relative to a slowly advancing steady state crack initiated at a chevron-shaped notch, and propagating in a chevron-shaped ligament (Fig. 1). Some metallic materials, when tested by this method, exhibit a sporadic crack growth in which the crack front remains nearly stationary until a critical load is reached. The crack then becomes unstable and suddenly advances at high speed to the next arrest point. For these materials, this test method covers the determination of the plane-strain fracture toughness, KIvj or KIvM, relative to the crack at the points of instability.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1304 − 97 (Reapproved 2020)

Standard Test Method for

Plane-Strain (Chevron-Notch) Fracture Toughness of

Metallic Materials

This standard is issued under the fixed designation E1304; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 This test method covers the determination of plane-

1.5 This international standard was developed in accor-

strain (chevron-notch) fracture toughnesses, K or K ,of

Iv IvM

dance with internationally recognized principles on standard-

metallic materials. Fracture toughness by this method is

ization established in the Decision on Principles for the

relative to a slowly advancing steady state crack initiated at a

Development of International Standards, Guides and Recom-

chevron-shaped notch, and propagating in a chevron-shaped

mendations issued by the World Trade Organization Technical

ligament (Fig. 1). Some metallic materials, when tested by this

Barriers to Trade (TBT) Committee.

method, exhibit a sporadic crack growth in which the crack

front remains nearly stationary until a critical load is reached.

2. Referenced Documents

The crack then becomes unstable and suddenly advances at

2.1 ASTM Standards:

highspeedtothenextarrestpoint.Forthesematerials,thistest

E4Practices for Force Calibration and Verification of Test-

method covers the determination of the plane-strain fracture

toughness, K or K , relative to the crack at the points of ing Machines

Ivj IvM

E8/E8MTest Methods for Tension Testing of Metallic Ma-

instability.

terials

NOTE 1—One difference between this test method and Test Method

E399Test Method for Linear-Elastic Plane-Strain Fracture

E399 (which measures K ) is that Test Method E399 centers attention on

Ic

Toughness of Metallic Materials

the start of crack extension from a fatigue precrack. This test method

E1823TerminologyRelatingtoFatigueandFractureTesting

makes use of either a steady state slowly propagating crack, or a crack at

the initiation of a crack jump. Although both methods are based on the

principles of linear elastic fracture mechanics, this difference, plus other

3. Terminology

differences in test procedure, may cause the values from this test method

tobelargerthan K valuesinsomematerials.Therefore,toughnessvalues 3.1 Definitions:

Ic

determined by this test method cannot be used interchangeably with K .

Ic 3.1.1 The terms described in Terminology E1823 are appli-

cable to this test method.

1.2 This test method uses either chevron-notched rod speci-

−3/2

3.1.2 stress-intensity factor, K [FL ]—the magnitude of

mens of circular cross section, or chevron-notched bar speci- I

the mathematically ideal crack-tip stress field (stress-field

mens of square or rectangular cross section (Figs. 1-10). The

singularity) for mode I in a homogeneous linear-elastic body.

terms “short rod” and “short bar” are used commonly for these

3.1.2.1 Discussion—Valuesof Kformode Iaregivenbythe

types of chevron-notched specimens.

following equation:

1.3 The values stated in inch-pound units are to be regarded

½

K 5 limit σ 2πr

@ #

I y x

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only r →0

x

and are not considered standard.

where:

1.4 This standard does not purport to address all of the

r = distance from the crack tip to a location where the

x

safety concerns, if any, associated with its use. It is the

stress is calculated and

responsibility of the user of this standard to establish appro-

σ = the principal stress r normal to the crack plane.

y x

3.2 Definitions of Terms Specific to This Standard:

This test method is under the jurisdiction ofASTM Committee E08 on Fatigue

and Fracture and is the direct responsibility of Subcommittee E08.07 on Fracture

Mechanics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 15, 2020. Published May 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1989. Last previous edition approved in 2014 as E1304–97(2014). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E1304-97R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1304 − 97 (2020)

longerchangewithfurthercrackextension.Althoughcrack-tip

conditions can be a function of crack velocity, the steady-state

crack-tip conditions for metals have appeared to be indepen-

dent of the crack velocity within the range attained by the

loading rates specified in this test method.

3.2.6 effective unloading slope ratio, r—the ratio of an

effective unloading slope to that of the initial elastic loading

slope on a test record of force versus specimen mouth opening

displacement.

3.2.6.1 Discussion—This unloading slope ratio provides a

methodofdeterminingthecracklengthatvariouspointsonthe

NOTE 1—The crack commences at the tip of the chevron-shaped

test record and therefore allows evaluation of stress intensity

ligament and propagates (shaded area) along the ligament, and has the

coefficient Y* (see 3.2.11). The effective unloading slope ratio

length “a” shown. (Not to scale.)

is measured by performing unloading-reloading cycles during

FIG. 1 Schematic Diagrams of Chevron-Notched Short Rod (a)

thetestasindicatedschematicallyinFig.4andFig.5.Foreach

and Short Bar (b) Specimens

unloading-reloading trace, the effective unloading slope ratio,

r, is defined in terms of the tangents of two angles:

3.2.1 plane-strain (chevron-notch) fracture toughness, K

Iv

−3/2

r 5 tan θ/tanθ

o

or K [FL ]—under conditions of crack-tip plane strain in a

Ivj

chevron-notched specimen: K relates to extension resistance

Iv

where:

with respect to a slowly advancing steady-state crack. K

Ivj

tan θ = the slope of the initial elastic line, and

o

relates to crack extension resistance with respect to a crack

tan θ = the slope of an effective unloading line.

which advances sporadically.

Theeffectiveunloadinglineisdefinedashavinganoriginat

3.2.1.1 Discussion—For slow rates of loading the fracture

the high point where the displacement reverses direction on

toughness, K or K , is the value of stress-intensity factor as

Iv Ivj

unloading (slot mouth begins to close) and joining the low

measuredusingtheoperationalprocedure(andsatisfyingallof

point on the reloading line where the force is one half that at

the validity requirements) specified in this test method.

the high point.

3.2.2 plane-strain (chevron-notch) fracture toughness, K

IvM

3.2.6.2 Discussion—For a brittle material with linear elastic

−3/2

[FL ]—determined similarly to K or K (see 3.2.1) using

Iv Ivj

behavior the unloading-reloading lines of an unloading-

the same specimen, or specimen geometries, but using a

reloading cycle would be linear and coincident. For many

simpler analysis based on the maximum test force. The

engineering materials, deviations from linear elastic behavior

analysisisdescribedinAnnexA1.Unloading-reloadingcycles

and hysteresis are commonly observed to a varying degree.

as described in 3.2.6 are not required in a test to determine

These effects require an unambiguous method of obtaining an

K . 3

IvM

effective unloading slope from the test record (6-5).

3.2.3 smooth crack growth behavior—generally,thattypeof

3.2.6.3 Discussion—Although r is measured only at those

crack extension behavior in chevron-notch specimens that is

crack positions where unloading-reloading cycles are

characterized primarily by slow, continuously advancing crack

performed, r is nevertheless defined at all points during a

growth, and a relatively smooth force displacement record

chevron-notch specimen test. For any particular point it is the

(Fig. 4). However, any test behavior not satisfying the condi-

value that would be measured for r if an unloading-reloading

tions for crack jump behavior is automatically characterized as

cycle were performed at that point.

smooth crack growth behavior.

3.2.7 critical slope ratio, r —the unloading slope ratio at

c

3.2.4 crack jump behavior—in tests of chevron-notch

the critical crack length.

specimens, that type of sporadic crack growth which is

3.2.8 critical crack length—the crack length in a chevron-

characterizedprimarilybyperiodsduringwhichthecrackfront

notch specimen at which the specimen’s stress-intensity factor

is nearly stationary until a critical force is reached, whereupon

coefficient, Y* (see 3.2.11 and Table 3), is a minimum, or

the crack becomes unstable and suddenly advances at high

equivalently, the crack length at which the maximum force

speed to the next arrest point, where it remains nearly station-

would occur in a purely linear elastic fracture mechanics test.

ary until the force again reaches a critical value, etc. (see Fig.

At the critical crack length, the width of the crack front is

5).

approximately one third the dimension B (Figs. 2 and 3).

3.2.4.1 Discussion—A chevron-notch specimen is said to

3.2.9 high point, High—the point on a force-displacement

have a crack jump behavior when crack jumps account for

plot, at the start of an unloading-reloading cycle, at which the

more than one half of the change in unloading slope ratio (see

displacement reverses direction, that is, the point at which the

3.2.6) as the unloading slope ratio passes through the range

specimen mouth begins closing due to unloading (see points

from0.8r to1.2r (see3.2.6and3.2.7,and8.3.5.2).Onlythose

c c

labeled High in Figs. 4 and 5).

sudden crack advances that result in more than a 5% decrease

inforceduringtheadvancearecountedascrackjumps(Fig.5).

3.2.5 steady-state crack—a crack that has advanced slowly

The boldface numbers in parentheses refer to the list of references at the end

until the crack-tip plastic zone size and crack-tip sharpness no of this standard.

E1304 − 97 (2020)

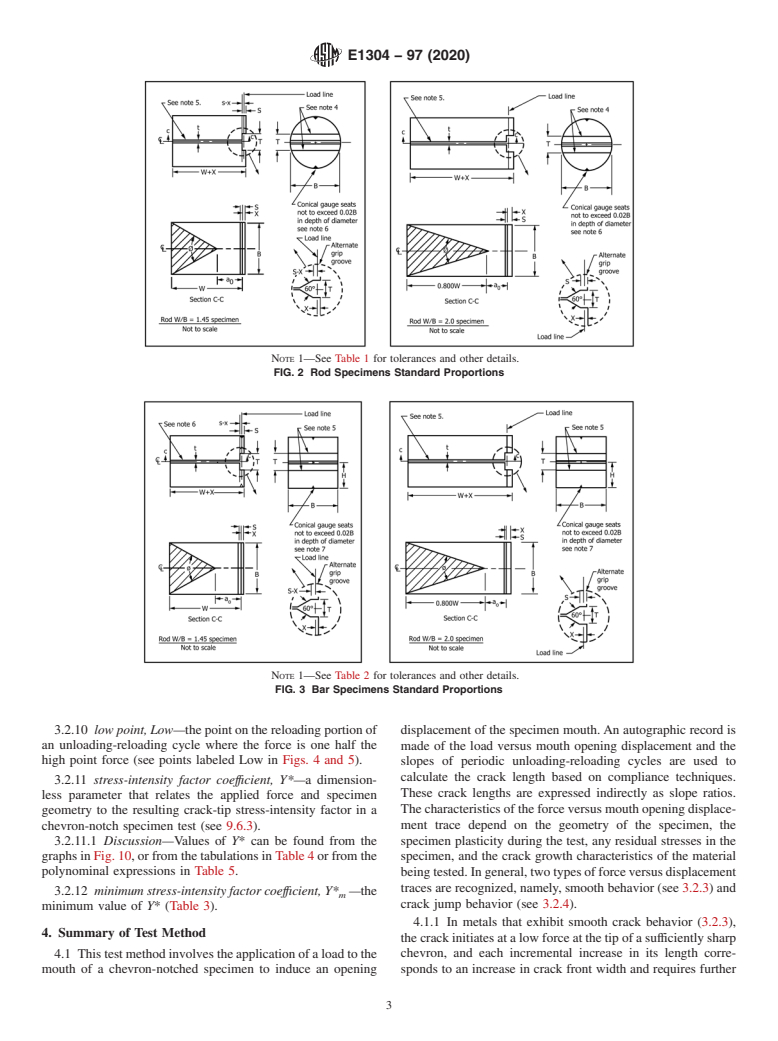

NOTE 1—See Table 1 for tolerances and other details.

FIG. 2 Rod Specimens Standard Proportions

NOTE 1—See Table 2 for tolerances and other details.

FIG. 3 Bar Specimens Standard Proportions

3.2.10 low point, Low—thepointonthereloadingportionof displacement of the specimen mouth.An autographic record is

an unloading-reloading cycle where the force is one half the made of the load versus mouth opening displacement and the

high point force (see points labeled Low in Figs. 4 and 5).

slopes of periodic unloading-reloading cycles are used to

calculate the crack length based on compliance techniques.

3.2.11 stress-intensity factor coeffıcient, Y*—a dimension-

These crack lengths are expressed indirectly as slope ratios.

less parameter that relates the applied force and specimen

Thecharacteristicsoftheforceversusmouthopeningdisplace-

geometry to the resulting crack-tip stress-intensity factor in a

chevron-notch specimen test (see 9.6.3). ment trace depend on the geometry of the specimen, the

3.2.11.1 Discussion—Values of Y* can be found from the specimen plasticity during the test, any residual stresses in the

graphsinFig.10,orfromthetabulationsinTable4orfromthe specimen, and the crack growth characteristics of the material

polynominal expressions in Table 5. beingtested.Ingeneral,twotypesofforceversusdisplacement

traces are recognized, namely, smooth behavior (see3.2.3) and

3.2.12 minimum stress-intensity factor coeffıcient, Y* —the

m

crack jump behavior (see 3.2.4).

minimum value of Y*(Table 3).

4.1.1 In metals that exhibit smooth crack behavior (3.2.3),

4. Summary of Test Method

thecrackinitiatesatalowforceatthetipofasufficientlysharp

chevron, and each incremental increase in its length corre-

4.1 Thistestmethodinvolvestheapplicationofaloadtothe

mouth of a chevron-notched specimen to induce an opening sponds to an increase in crack front width and requires further

E1304 − 97 (2020)

R# 0.010B

φ # 60°

s

t# 0.03B

NOTE 1—These requirements are satisfied by slots with a round bottom

whenever t ≤ 0.020B.

FIG. 6 Slot Bottom Configuration

FIG. 4 Schematic of a Load-Displacement Test Record for

Smooth Crack Growth Behavior, with Unloading/Reloading

Cycles, Data Reduction Constructions, and Definitions of Terms

FIG. 5 Schematic of a Load-Displacement Test Record for Crack

NOTE 1—Machine finish all over equal to or better than 64 µin.

Jump Behavior, with Unloading/Reloading Cycles, Data Reduc-

tion Constructions, and Definitions of Terms NOTE 2—Unless otherwise specified, dimensions 60.010B; angles

62°.

NOTE 3—Grip hardness should be RC=45 or greater.

increase in force. This force increase continues until a point is FIG. 7 Suggested Loading Grip Design

reached where further increases in force provide energy in

excess of that required to advance the crack. This maximum

forcepointcorrespondstoawidthofcrackfrontapproximately toughness determined by this procedure is termed K .An

Iv

one third the specimen diameter or thickness. If the loading alternative procedure, described in Annex A1, omits the

systemissufficientlystiff,thecrackcanbemadetocontinueits unloading cycles and uses the maximum test force to calculate

smooth crack growth under decreasing force. Two unloading- a plane-strain fracture toughness K , where M signifies the

IvM

reloadingcyclesareperformedtodeterminethelocationofthe use of the maximum force. Values of K versus K are

Iv IvM

crack, the force used to calculate K , and to provide validity discussed in Annex A1.

Iv

checks on the test. The fracture toughness is calculated from 4.1.2 A modified procedure is used to determine K when

Ivj

theforcerequiredtoadvancethecrackwhenthecrackisatthe crack jump behavior is encountered. In this procedure,

critical crack length (see 3.2.8). The plane-strain fracture unloading-reloading cycles are used to determine the crack

E1304 − 97 (2020)

NOTE 1—Compiled from Refs (1), (2), (3), and (4).

FIG. 10 Normalized Stress-Intensity Factor Coefficients as a

Function of Slope Ratio (r) for Chevron-Notch Specimens

TABLE 1 Rod Dimensions

NOTE 1—All surfaces to be 64-µin. finish or better.

NOTE 2—Side grooves may be made with a plunge cut with a circular

blade, such that the sides of the chevron ligament have curved profiles,

provided that the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.