ASTM F256-94(1999)

(Specification)Standard Specification for Chromium-Iron Sealing Alloys with 18 or 26 Percent Chromium

Standard Specification for Chromium-Iron Sealing Alloys with 18 or 26 Percent Chromium

SCOPE

1.1 This specification covers two chromium-iron alloys, the former, (UNS K91800), nominally 18% chromium, balance iron, the latter, (UNS K92801), nominally 28% chromium, in strip, bar, wire, and rod forms intended primarily for sealing to glass in electronic applications.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following hazard caveat pertains only to the test method portion, Sections 16 and 17, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: F 256 – 94 (Reapproved 1999)

Standard Specification for

Chromium-Iron Sealing Alloys with 18 or 26 Percent

Chromium

This standard is issued under the fixed designation F 256; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope F 140 Practice for Making Reference Glass-Metal Butt

Seals and Testing for Expansion Characteristics by Polari-

1.1 This specification covers two chromium-iron alloys, the

metric Methods

former, (UNS K91800), nominally 18 % chromium, balance

F 144 Practice for Making Reference Glass-Metal Sand-

iron, the latter, (UNS K92801), nominally 28 % chromium, in

wich Seal and Testing for Expansion Characteristics by

strip, bar, wire, and rod forms intended primarily for sealing to

Polarimetric Methods

glass in electronic applications.

1.2 The values stated in inch-pound units are to be regarded

3. Terminology

as the standard. The values given in parentheses are for

3.1 Definitions of Terms Specific to This Standard:

information only.

3.1.1 bar:

1.3 The following hazard caveat pertains only to the test

3.1.1.1 hot-finished rounds, squares, and hexagons, ⁄4 in.

method portion, Sections 16 and 17, of this specification. This

(6.4 mm) and over in diameter or size.

standard does not purport to address all of the safety concerns,

3.1.1.2 hot-finished flats, ⁄4 in. to 10 in. (6.4 to 254 mm),

if any, associated with its use. It is the responsibility of the user

inclusive, in width and ⁄8 in. (3.2 mm) and over in thickness.

of this standard to establish appropriate safety and health

3.1.1.3 cold-finished rounds, squares, octagons, hexagons

practices and determine the applicability of regulatory limita-

and shapes, over ⁄2 in. (12.7 mm) in diameter or size.

tions prior to use.

3.1.1.4 cold-finished flats, ⁄8 in. (9.5 mm) and over in width

2. Referenced Documents and ⁄8 in. (3.2 mm) and over in thickness (see Discussions).

Discussion—Widths less than ⁄8 in. (9.5 mm) and thick-

2.1 ASTM Standards:

nesses less than ⁄16 in. (4.8 mm) are generally described as flat

A 370 Test Methods and Definitions for MechanicalTesting

wire.

of Steel Products

1 3

Discussion—Thicknesses of ⁄8 in. (3.2 mm) to under ⁄16 in.

E3 Methods of Preparation of Metallographic Specimens

(4.8 mm) can also be described as cold-rolled strip or, if in cut

E18 Test Methods for Rockwell Hardness and Rockwell

lengths, bar.

Superficial Hardness of Metallic Materials

3.1.2 rod—hot-rolled, or hot-rolled, annealed, and pickled,

E29 Practice for Using Significant Digits in Test Data to

rounds, squares, octagons, hexagons and shapes, in coils, for

Determine Conformance with Specifications

1 3

subsequent cold drawing or cold rolling, ⁄4 in. or ⁄4 in. (6.4 or

E38 Methods for Chemical Analysis of Nickel-Chromium

19.0 mm) in diameter or size.

and Nickel-Chromium-Iron Alloys

3.1.3 strip—cold-finished coils or cut lengths, under 24 in.

E 228 Test Method for Linear Thermal Expansion of Solid

(610mm)downtoandincluding ⁄16in.(4.8mm)inwidth,and

Materials with a Vitreous Silica Dilatometer

under ⁄16 in. down to and including 0.005 in. (0.13 mm) in

F14 Practice for Making and Testing Reference Glass-

thickness.

Metal Bead-Seal

3.1.4 No. 1 edge—a rolled edge either round or square as

specified.

This specification is under the jurisdiction of Committee F01 on Electronics

3.1.5 No. 3 edge—an edge produced by slitting.

and is the direct responsibility of Subcommittee F01.03 on Metallic Materials.

3.1.6 No. 5 edge—an approximately square edge produced

Current edition approved April 15, 1994. Published June 1994. Originally

e1 by rolling or filing after slitting.

published as F 256 – 51 T. Last previous edition F 256 – 72 (1989) . Consolidated

Discussion—Cold-finished product 0.005 in. (0.13 mm) in

with F 257 in 1972.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

thickness and under 24 in. (609.6 mm) in width is sometimes

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

identified as foil.

Standards volume information, refer to the standard’s Document Summary page on

3.1.7 wire:

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

F 256 – 94 (1999)

3.1.7.1 cold finished only, round or square, ⁄2 in. (12.7 mm) 7.2.2 Cold drawn (wire and bar),

and under in diameter or size. 7.2.3 Centerless ground (wire and bar), or

3.1.7.2 cold finished only, flat wire of ⁄16 in. (1.6 mm) to 7.2.4 Cold rolled (strip).

under ⁄8 in. (9.5 mm) in width and 0.010 in. (0.25 mm) to

8. Chemical Composition

under ⁄16 in. (4.8 mm) in thickness.

8.1 The material shall conform to the chemical composition

4. Classification

specified in Table 1.

4.1 The alloys covered by this specification are classified by

nominal chemical composition, specifically by chromium con-

TABLE 1 Chemical Requirements

tent, in two types:

4.1.1 Type I—18 % chromium (UNS K91800) and

NOTE 1—Round observed or calculated values to the nearest unit in the

4.1.2 Type II—28 % chromium (UNS K92801). last right-hand place of figures used in expressing the limiting value, in

accordance with the rounding-off method of PracticeE29.

5. Ordering Information

Composition, %

Element

5.1 Orders for material under this specification shall include Type I Type II

the following information:

Carbon, max 0.08 0.12

Manganese, max 1.00 1.00

5.1.1 Quantity (weight (Note 1) or number of pieces),

Silicon, max 0.75 0.75

5.1.2 Name of material (chromium-iron alloy),

Phosphorus, max 0.040 0.040

5.1.3 Type (Section 4),

Sulfur, max 0.030 0.030

Chromium, nominal 18.0 28.0

5.1.4 Form (Section 3),

Nickel, max 0.50 0.50

5.1.5 Temper and finish (Section 7),

Nitrogen, max . 0.20

A

5.1.6 Permissible variations in dimensions for rod (Section

Titanium .

Iron remainder remainder

13),

A

Five times the carbon content, minimum, and 0.60, max.

5.1.7 Certification if required (Section 21),

5.1.8 Packaging required (Section 22),

5.1.9 Dimensions (width, thickness, diameter, etc.),

8.2 Ladle Analysis—A ladle analysis of each heat of steel

5.1.10 ASTM designation: F 256, and

shall be made by the manufacturer to determine the percent-

5.1.11 Exceptions to the specification or special require-

ages of the elements specified in Table 1. The analysis shall be

ments.

made from test castings made during the pouring of the heat.

NOTE 1—The term “weight” is temporarily used in this standard

The chemical composition thus determined shall conform to

because of established trade usage.The word is used to mean both “force”

the requirements specified in Table 1.

and“ mass,” and care must be taken to determine which is meant in each

8.3 Check Analysis—If check analysis is made by the

case (SI unit for force = newton and for mass = kilogram).

purchaser, the chemical composition thus determined shall

5.2 If possible, the intended end use of the item should be

conform to the requirements specified in Table 1 subject to the

givenonthepurchaseorderespeciallywhentheitemisordered

permissible tolerances of Table 2.

for a specific end use or uses. Such information will enable the

manufacturer to produce a material more satisfactory for the

purchaser’s process and product.

TABLE 2 Check Analysis Tolerances

Tolerances over maxi-

NOTE 2—A typical ordering description is as follows: 2000 kg,

Element mum or under minimum

chromium-iron alloy. Type II, wire, annealed, cold drawn, commercial

limits, percentage points

packaging, ⁄4 in. (6.4 mm) round by coil, ASTM F 256, end use-redraw.

Carbon 0.01

Manganese 0.03

6. Process

Phosphorus 0.005

Sulfur 0.005

6.1 The purchaser shall specify that the alloy be made by

Silicon 0.05

one or more of the following processes: electric-arc, electric-

Nickel 0.03

induction, or other process approved by the purchaser.

Nitrogen 0.01

Titanium 0.05

7. Temper and Finish

7.1 The desired temper of the material shall be specified on

the purchase order as follows:

9. Chemical Analysis

7.1.1 Annealed for forming (strip),

9.1 Chemical analysis shall be made in accordance with

7.1.2 Annealed for deep drawing (strip),

MethodE38 or equivalent methods.

7.1.3 Cold rolled or cold drawn to a specified mechanical

property level, or

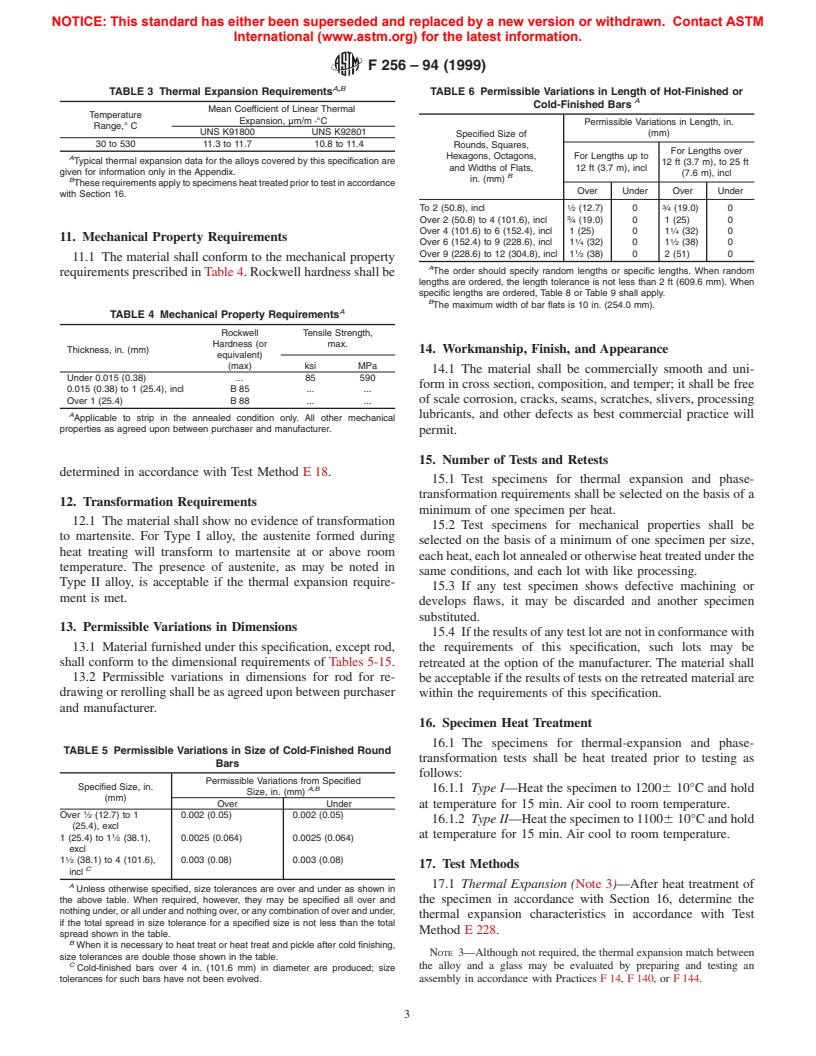

10. Thermal Expansion Requirements Thermal Expansion

7.1.4 As hot rolled.

Requirements

7.2 The desired surface of the material shall be specified on

the purchase order as follows: 10.1 The material shall conform to the thermal expansion

7.2.1 Pickled, requirements prescribed in Table 3.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

F 256 – 94 (1999)

A,B

TABLE 3 Thermal Expansion Requirements TABLE 6 Permissible Variations in Length of Hot-Finished or

A

Cold-Finished Bars

Mean Coefficient of Linear Thermal

Temperature

Expansion, µm/m ·°C

Permissible Variations in Length, in.

Range,° C

UNS K91800 UNS K92801

Specified Size of (mm)

30 to 530 11.3 to 11.7 10.8 to 11.4

Rounds, Squares,

For Lengths over

A Hexagons, Octagons, For Lengths up to

Typical thermal expansion data for the alloys covered by this specification are

12 ft (3.7 m), to 25 ft

and Widths of Flats, 12 ft (3.7 m), incl

given for information only in the Appendix.

(7.6 m), incl

B

B in. (mm)

These requirements apply to specimens heat treated prior to test in accordance

Over Under Over Under

with Section 16.

1 3

To 2 (50.8), incl ⁄2 (12.7) 0 ⁄4 (19.0) 0

Over 2 (50.8) to 4 (101.6), incl ⁄4 (19.0) 0 1 (25) 0

Over 4 (101.6) to 6 (152.4), incl 1 (25) 0 1 ⁄4 (32) 0

11. Mechanical Property Requirements

1 1

Over 6 (152.4) to 9 (228.6), incl 1 ⁄4 (32) 0 1 ⁄2 (38) 0

Over 9 (228.6) to 12 (304.8), incl 1 ⁄2 (38) 0 2 (51) 0

11.1 The material shall conform to the mechanical property

A

The order should specify random lengths or specific lengths. When random

requirements prescribed inTable 4. Rockwell hardness shall be

lengths are ordered, the length tolerance is not less than 2 ft (609.6 mm). When

specific lengths are ordered, Table 8 or Table 9 shall apply.

B

The maximum width of bar flats is 10 in. (254.0 mm).

A

TABLE 4 Mechanical Property Requirements

Rockwell Tensile Strength,

Hardness (or max.

Thickness, in. (mm) 14. Workmanship, Finish, and Appearance

equivalent)

(max) ksi MPa

14.1 The material shall be commercially smooth and uni-

Under 0.015 (0.38) . 85 590

form in cross section, composition, and temper; it shall be free

0.015 (0.38) to 1 (25.4), incl B 85 . .

Over 1 (25.4) B 88 . . of scale corrosion, cracks, seams, scratches, slivers, processing

A

lubricants, and other defects as best commercial practice will

Applicable to strip in the annealed condition only. All other mechanical

properties as agreed upon between purchaser and manufacturer.

permit.

15. Number of Tests and Retests

determined in accordance with Test MethodE18.

15.1 Test specimens for thermal expansion and phase-

transformation requirements shall be selected on the basis of a

12. Transformation Requirements

minimum of one specimen per heat.

12.1 The material shall show no evidence of transformation

15.2 Test specimens for mechanical properties shall be

to martensite. For Type I alloy, the austenite formed during

selected on the basis of a minimum of one specimen per size,

heat treating will transform to martensite at or above room

each heat, each lot annealed or otherwise heat treated under the

temperature. The presence of austenite, as may be noted in

same conditions, and each lot with like processing.

Type II alloy, is acceptable if the thermal expansion require-

15.3 If any test specimen shows defective machining or

ment is met.

develops flaws, it may be discarded and another specimen

substituted.

13. Permissible Variations in Dimensions

15.4 Iftheresultsofanytestlotarenotinconformancewith

13.1 Material furnished under this specification, except rod,

the requirements of this specification, such lots may be

shall conform to the dimensional requirements of Tables 5-15. retreated at the option of the manufacturer. The material shall

13.2 Permissible variations in dimensions for rod for re-

be acceptable if the results of tests on the retreated material are

drawingorrerollingshallbeasagreeduponbetweenpurchaser within the requirements of this specification.

and manufacturer.

16. Specimen Heat Treatment

16.1 The specimens for thermal-expansion and phase-

TABLE 5 Permissible Variations in Size of Cold-Finished Round

transformation tests shall be heat treated prior to testing as

Bars

follows:

Permissible Variations from Specified

Specified Size, in.

A,B

16.1.1 Type I—Heat the specimen to 12006 10°C and hold

Size, in. (mm)

(mm)

Over Under

at temperature for 15 min. Air cool to room temperature.

Over ⁄2 (12.7) to 1 0.002 (0.05) 0.002 (0.05)

16.1.2 Type II—Heat the specimen to 11006 10°C and hold

(25.4), excl

1 at temperature for 15 min. Air cool to room temperature.

1 (25.4) to 1 ⁄2 (38.1), 0.0025 (0.064) 0.0025 (0.064)

excl

1 ⁄2 (38.1) to 4 (101.6), 0.003 (0.08) 0.003 (0.08)

17. Test Methods

C

incl

17.1 Thermal Expansion (Note 3)—After heat treatment of

A

Unless otherwise specified, size tolerances are over and under as shown in

the above table. When required, however, they may be specified all over and the specimen in accordance with Section 16, determine the

nothing under, or all under and nothing over, or any combination of over and under,

thermal expansion characteristics in accordance with Test

if the total spread in size tolerance for a specified size is not less than the total

Method E 228.

spread shown in the table.

B

When it is necessary to heat treat or heat treat and pickle after cold finishing,

NOTE 3—Although not required, the thermal expansion match between

size tolerances are double those shown in the table.

C

the alloy and a glass may be evaluated by preparing and testing an

Cold-finished bars over 4 in. (101.6 mm) in diameter are produced; size

tolerances for such bars have not been evolved. assembly in accordance with PracticesF14, F 140,or F 144.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

F 256 – 94 (1999)

TABLE 7 Permissible Variations in Straightness of Machine-Straightened Hot-Finished or Cold-Fin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.