ASTM F1162-88(1999)

(Specification)Standard Specification for Pole Vault Landing Pits

Standard Specification for Pole Vault Landing Pits

SCOPE

1.1 This specification covers minimum requirements of size, physical characteristics of materials, standard testing procedures, labeling and identification of pole vault landing pits.

1.2 The values as stated in inch-pound units are to be regarded as the standard. The values in parentheses are given for information only.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification: This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1162 – 88 (Reapproved 1999)

Standard Specification for

Pole Vault Landing Pits

This standard is issued under the fixed designation F 1162; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers minimum requirements of

size, physical characteristics of materials, standard testing

procedures, labeling and identification of pole vault landing

pits.

1.2 The values as stated in inch-pound units are to be

regarded as the standard. The values in parentheses are given

for information only.

1.3 The following safety hazards caveat pertains only to the

test methods portion, Section 8, of this specification: This

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

tions prior to use.

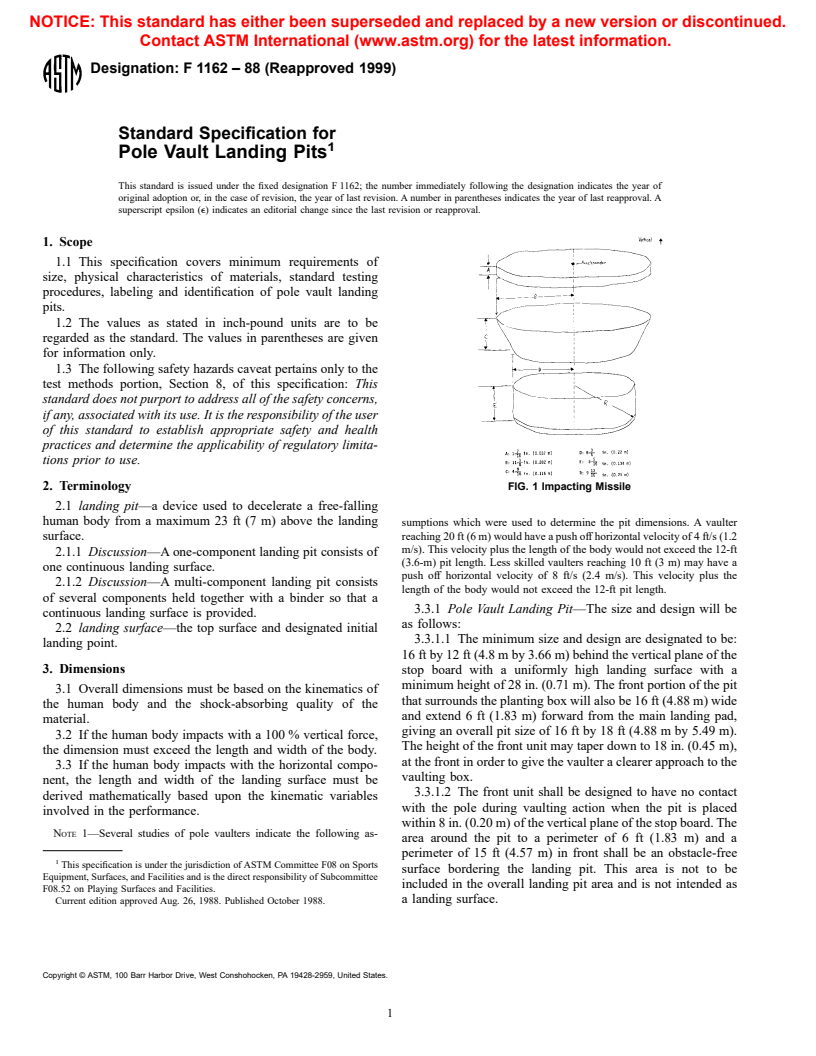

2. Terminology FIG. 1 Impacting Missile

2.1 landing pit—a device used to decelerate a free-falling

human body from a maximum 23 ft (7 m) above the landing

sumptions which were used to determine the pit dimensions. A vaulter

reaching 20 ft (6 m) would have a push off horizontal velocity of 4 ft/s (1.2

surface.

m/s). This velocity plus the length of the body would not exceed the 12-ft

2.1.1 Discussion—A one-component landing pit consists of

(3.6-m) pit length. Less skilled vaulters reaching 10 ft (3 m) may have a

one continuous landing surface.

push off horizontal velocity of 8 ft/s (2.4 m/s). This velocity plus the

2.1.2 Discussion—A multi-component landing pit consists

length of the body would not exceed the 12-ft pit length.

of several components held together with a binder so that a

3.3.1 Pole Vault Landing Pit—The size and design will be

continuous landing surface is provided.

as follows:

2.2 landing surface—the top surface and designated initial

3.3.1.1 The minimum size and design are designated to be:

landing point.

16 ft by 12 ft (4.8 m by 3.66 m) behind the vertical plane of the

3. Dimensions stop board with a uniformly high landing surface with a

minimum height of 28 in. (0.71 m). The front portion of the pit

3.1 Overall dimensions must be based on the kinematics of

that surrounds the planting box will also be 16 ft (4.88 m) wide

the human body and the shock-absorbing quality of the

and extend 6 ft (1.83 m) forward from the main landing pad,

material.

giving an overall pit size of 16 ft by 18 ft (4.88 m by 5.49 m).

3.2 If the human body impacts with a 100 % vertical force,

The height of the front unit may taper down to 18 in. (0.45 m),

the dimension must exceed the length and width of the body.

at the front in order to give the vaulter a clearer approach to the

3.3 If the human body impacts with the horizontal compo-

vaulting box.

nent, the length and width of the landing surface must be

3.3.1.2 The front unit shall be designed to have no contact

derived mathematically based upon the kinematic variables

with the pole during vaulting action when the pit is placed

involved in the performance.

within 8 in. (0.20 m) of the vertical plane of the stop board. The

NOTE 1—Several studies of pole vaulters indicate the following as-

area around the pit to a perimeter of 6 ft (1.83 m) and a

perimeter of 15 ft (4.57 m) in front shall be an obstacle-free

This specification is under the jurisdiction of ASTM Committee F08 on Sports

surface bordering the landing pit. This area is not to be

Equipment, Surfaces, and Facilities and is the direct responsibility of Subcommittee

included in the overall landing pit area and is not intended as

F08.52 on Playing Surfaces and Facilities.

Current edition approved Aug. 26, 1988. Published October 1988. a landing surface.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1162

4. Physical Characteristics of Material and Performance

Specifications

4.1 The landing pit will be made of a material which will

cause deceleration of the missile by landing pit deformation

less than 75 % of the pit thickness during impact testing

conducted in accordance with Section 10.

4.2 When impact testing is performed in accordance with

Section 10 missile rebound shall not exceed 1.48 ft (0.45 m)

above the surface of the nondeformed landing pit.

4.3 Rebound and deformation characteristics shall be6

10 % throughout the 16 ft by 18 ft (4.88 m by 5.49 m) area to

within 1 ft (0.304 m) of the edges.

4.4 Peak deceleration shall not exceed 20 g’s when a

landing pit is tested in accordance with Section 10.

5. Significance and Use

5.1 The dynamic data obtained with the procedures given in

this specification measure the cushioning properties of the

landing pits tested.

5.2 The size of the pole vault landing pit is specified with

respect to the kinematics of body movement.

6. Testing Apparatus

6.1 Testing Machine—Any type of dynamic testing appara-

NOTE 1—The Landing Pit cutout which surrounds the planting box

tus that impacts the specimen on a solid, rigid surface (typical

should be tapered in such a way as to not interfere with the action of the

of service conditions) with the prescribed missile at the

pole.

prescribed impact velocity and monitors and records impact

FIG. 2 Landing Pit

deceleration-time histories.

6.2 The missile described in 8.1 is constructed in three

velocity to an accuracy of 65 % of the true value. Any velocity

sections and is more clearly defined as follows: (see Fig. 2).

measurement method that does not physically interfere with

NOTE 2—The missile constructed for initial testing was of marine grade

impact conditions is acceptable.

plywood. The missile could be made of various materials and methods

6.5 Displacement-Time—Displacement-time history shall

provided it maintains the specific dimensions and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.