ASTM D565-99(2005)

(Test Method)Standard Test Method for Carbonizable Substances in White Mineral Oil

Standard Test Method for Carbonizable Substances in White Mineral Oil

SIGNIFICANCE AND USE

This test method is a means for ascertaining whether pharmaceutical mineral oil conforms to the standards of the United States Pharmacopeia, the National Formulary, and the Food and Drug Administration.

SCOPE

1.1 This test method covers white mineral oil (Mineral Oil USP and Light Mineral Oil NF) to determine whether it conforms to the standard of quality required for pharmaceutical use as defined by the United States Pharmacopeia and the National Formulary, or the Food and Drug Administration.

1.2 The values stated in SI units are to be regarded as the standard.

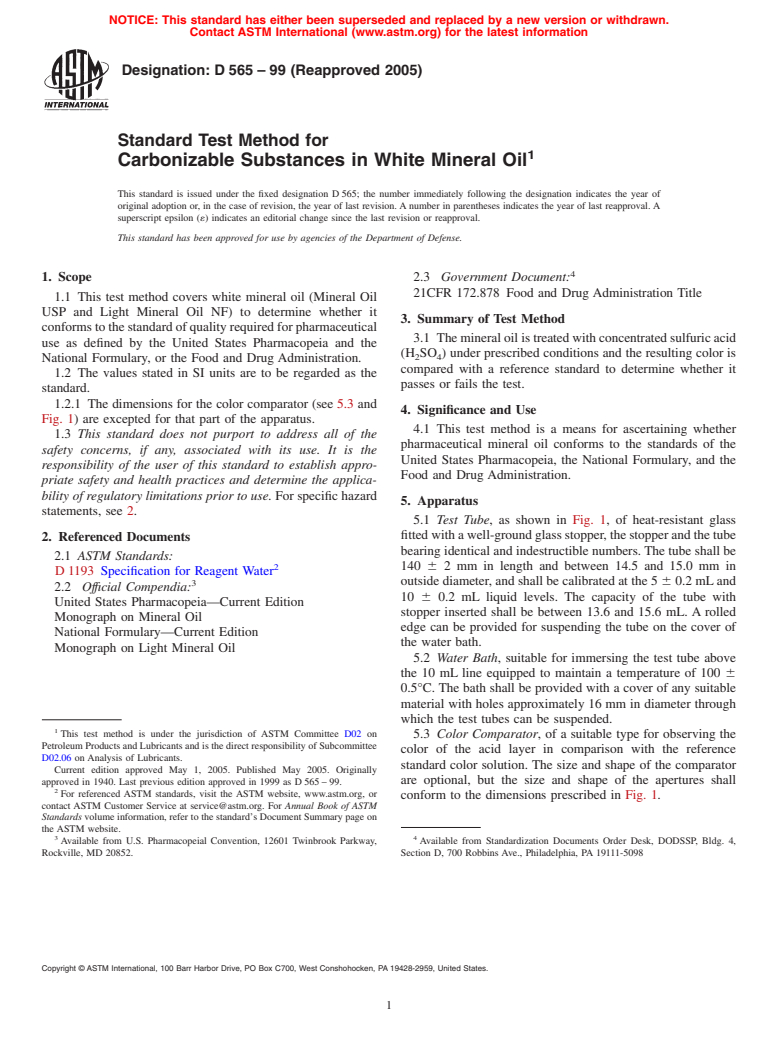

1.2.1 The dimensions for the color comparator (see 5.3 and Fig. 1) are excepted for that part of the apparatus.

1.3This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D565–99 (Reapproved 2005)

Standard Test Method for

Carbonizable Substances in White Mineral Oil

This standard is issued under the fixed designation D 565; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.3 Government Document:

21CFR 172.878 Food and Drug Administration Title

1.1 This test method covers white mineral oil (Mineral Oil

USP and Light Mineral Oil NF) to determine whether it

3. Summary of Test Method

conformstothestandardofqualityrequiredforpharmaceutical

3.1 Themineraloilistreatedwithconcentratedsulfuricacid

use as defined by the United States Pharmacopeia and the

(H SO ) under prescribed conditions and the resulting color is

2 4

National Formulary, or the Food and Drug Administration.

compared with a reference standard to determine whether it

1.2 The values stated in SI units are to be regarded as the

passes or fails the test.

standard.

1.2.1 The dimensions for the color comparator (see 5.3 and

4. Significance and Use

Fig. 1) are excepted for that part of the apparatus.

4.1 This test method is a means for ascertaining whether

1.3 This standard does not purport to address all of the

pharmaceutical mineral oil conforms to the standards of the

safety concerns, if any, associated with its use. It is the

United States Pharmacopeia, the National Formulary, and the

responsibility of the user of this standard to establish appro-

Food and Drug Administration.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific hazard

5. Apparatus

statements, see 2.

5.1 Test Tube, as shown in Fig. 1, of heat-resistant glass

fittedwithawell-groundglassstopper,thestopperandthetube

2. Referenced Documents

bearing identical and indestructible numbers. The tube shall be

2.1 ASTM Standards:

2 140 6 2 mm in length and between 14.5 and 15.0 mm in

D 1193 Specification for Reagent Water

3 outside diameter, and shall be calibrated at the 5 6 0.2 mLand

2.2 Offıcial Compendia:

10 6 0.2 mL liquid levels. The capacity of the tube with

United States Pharmacopeia—Current Edition

stopper inserted shall be between 13.6 and 15.6 mL. A rolled

Monograph on Mineral Oil

edge can be provided for suspending the tube on the cover of

National Formulary—Current Edition

the water bath.

Monograph on Light Mineral Oil

5.2 Water Bath, suitable for immersing the test tube above

the 10 mL line equipped to maintain a temperature of 100 6

0.5°C. The bath shall be provided with a cover of any suitable

material with holes approximately 16 mm in diameter through

which the test tubes can be suspended.

This test method is under the jurisdiction of ASTM Committee D02 on

5.3 Color Comparator, of a suitable type for observing the

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

color of the acid layer in comparison with the reference

D02.06 on Analysis of Lubricants.

standard color solution. The size and shape of the comparator

Current edition approved May 1, 2005. Published May 2005. Originally

are optional, but the size and shape of the apertures shall

approved in 1940. Last previous edition approved in 1999 as D 565 – 99.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

conform to the dimensions prescribed in Fig. 1.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available from U.S. Pharmacopeial Convention, 12601 Twinbrook Parkway, Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Rockville, MD 20852. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D565–99 (2005)

FIG. 1 Color Comparator for Carbonizable Substances in Liquid Petrolatum

6. Reagents thiosulfate (Na S O ) solution, using starch solution as an

2 2 3

indicator. Each millilitre of Na S O solution is equivalent to

2 2 3

6.1 Purity of Reagents—Reagent grade chemicals shall be

0.0238 g of CoCl ·6H O. Adjust the final volume of CoCl

used in all tests. Unless otherwise indicated, it is intended that 2 2 2

solution by the addition of HCl solution so that 1 mL contains

all reagents shall conform to the specifications of the Commit-

59.5 mg of CoCl ·6H O.

tee onAnalytical Reagents of theAmerican Chemical Society, 2 2

where such specifications are available. Other grades may be

NOTE 1—This freshly prepared H SO solution will be hot. Allow to

2 4

used, provided it is first ascertained that the reagent is of

cool before continuing.

sufficiently high purity to permit its use without lessening the

6.4 Cupric Sulfate Solution (0.25 M)—Prepare a solution of

accuracy of the determination.

HCl (Warning—see 6.3) by mixing 30 mL of concentrated

6.2 Purity of Water—Unless otherwise indicated, references

HCl with 1170 mL of water. Slowly add the acid to the water.

to water shall be understood to mean distilled water or water of

equal purity conforming to Type III of Specification D 1193. Dissolve 65 6 1 g of cupric sulfate pentahydrate

6.3 Cobaltous Chloride Solution (0.25 M)—Prepare a solu- (CuSO ·5H O) in enough HCl solution to make 1000 mL of

4 2

tion of hydrochloric acid (HCl) (Warning—Causes burns. solution. Using a pipet, transfer 10 mL of the solution to a

Vapor extremely irritating.) by mixing 30 mL of concentrated 250-mL iodine flask, add 40 mL of water. Prepare a 6M acetic

HCl with 1170 mL of water. Slowly add the acid to the water.

acid (CH COOH) (Warning—Corrosive. Combustible. Vapor

Dissolve 65 6 1 g of cobaltous chloride hexahydrate

irritating.) solution by mixing 353 mL of concentrated

(CoCl ·6H O) in the HCl solution to make 1000 mL of

CH COOH with 1000 mL of water. Slowly add the acid to the

2 2

solution. Using a pipet, transfer 5 mL of this solution to a 250

water.Add 4 mLof 6M CH COOH,3gofKland5mLofHCl

mL iodine flask. Prepare a solution of sodium hydroxide

to the flask. Titrate the liberated iodine with 0.100 M Na S O

2 2 3

(NaOH) (Warning—Corrosive. Can cause severe burns or

solution,usingstarchsolutionasanindicator.Eachmillilitreof

blindness. Evolution o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.