ASTM D229-96

(Test Method)Standard Test Methods for Rigid Sheet and Plate Materials Used for Electrical Insulation

Standard Test Methods for Rigid Sheet and Plate Materials Used for Electrical Insulation

SCOPE

1.1 These test methods cover procedures for testing rigid electrical insulation normally manufactured in flat sheet or plate form. They are generally used as terminal boards, spacers, voltage barriers, and circuit boards.

Note 1—For tests applying to vulcanized fibre reference should be made to Test Methods D 619. Note 2—This standard resembles IEC 60893-2, Specification for Rigid Industrial Laminated Sheets Based On Thermosetting Resins for Electrical Purpose, Methods of Tests.

1.2 The test methods appear in the following sections:TestSectionsASTMTestMethodAcetone extractable matter 83 to 84D 494Arc resistance47 D 495Ash56 to 60 ...Bonding strength49 to 54...Burning rate and flame resistance61 to 75...Compressive strength25 D 695Conditioning4 D 6054Dissipation factor34 to 40D 669Dielectric strength28 to 33D 149Expansion (linear thermal)76D 696Flexural properties12 to 24D 790Hardness (Rockwell)55 D 785Insulation resistance and resistivity41 to 46D 257Permittivity34 to 40D 150Resistance to impact26 D 256Tensile properties7 to 11D 638Thickness5 to 6D 374Tracking resistance48 D 2132Warp or twist77 to 82...Water absorption27 D 570

1.3 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units given in these test methods may be approximate.

1.4 This is a fire-test-response standard. See Sections 61 through 75, which are the procedures for burning rate and flame resistance.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 31.1 and 61.5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 229 – 96 An American National Standard

Standard Test Methods for

Rigid Sheet and Plate Materials Used for Electrical

Insulation

This standard is issued under the fixed designation D 229; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope tionary statements are given in Note 5 and 61.5.

1.1 These test methods cover procedures for testing rigid

2. Referenced Documents

electrical insulation normally manufactured in flat sheet or

2.1 ASTM Standards:

plate form. They are generally used as terminal boards, spacers,

D 149 Test Method for Dielectric Breakdown Voltage and

voltage barriers, and circuit boards.

Dielectric Strength of Solid Electrical Insulating Materials

NOTE 1—For tests applying to vulcanized fibre reference should be

at Commercial Power Frequencies

made to Test Methods D 619.

D 150 Test Methods for A-C Loss Characteristics and

1.2 The test methods appear in the following sections:

Permittivity (Dielectric Constant) of Solid Electrical Insu-

ASTM lating Materials

Test

D 256 Test Method for Determining the Pendulum Impact

Test Sections Method

Resistance of Notched Specimens of Plastics

Acetone extractable matter 83 to 84 D 494

Arc resistance 47 D 495 D 257 Test Methods for D-C Resistance or Conductance of

Ash 56 to 60 .

Insulating Materials

Bonding strength 49 to 54 .

D 374 Test Methods for Thickness of Solid Electrical Insu-

Burning rate and flame resistance 61 to 75 .

Compressive strength 25 D 695

lation

Conditioning 4 D 618

D 494 Test Method for Acetone Extraction of Phenolic

Dissipation factor 34 to 40 D 669

Molded or Laminated Products

Dielectric strength 28 to 33 D 149

Expansion (linear thermal) 76 D 696 D 495 Test Method for High-Voltage, Low-Current, Dry

Flexural properties 12 to 24 D 790 2

Arc Resistance of Solid Electrical Insulation

Hardness (Rockwell) 55 D 785

D 570 Test Method for Water Absorption of Plastics

Insulation resistance and resistivity 41 to 46 D 257

Permittivity 34 to 40 D 150

D 617 Test Method for Punching Quality of Phenolic Lami-

Resistance to impact 26 D 256 2

nated Sheets

Tensile properties 7 to 11 D 638

D 618 Practice for Conditioning Plastics and Electrical

Thickness 5 to 6 D 374

Tracking resistance 48 D 2132

Insulating Materials for Testing

Warp or twist 77 to 82 .

D 619 Test Methods for Vulcanized Fibre Used for Electri-

Water absorption 27 D 570

cal Insulation

1.3 The values stated in inch-pound units are to be regarded

D 638 Test Method for Tensile Properties of Plastics

as the standard. The metric equivalents of inch-pound units

D 669 Test Method for Dissipation Factor and Permittivity

given in these test methods may be approximate.

Parallel with Laminations of Laminated Sheet and Plate

1.4 This is a fire-test-response standard. See Sections 61

Materials

through 75, which are the procedures for burning rate and

D 695 Test Method for Compressive Properties of Rigid

flame resistance.

Plastics

1.5 This standard does not purport to address all of the

D 696 Test Method for Coefficient of Linear Thermal Ex-

safety concerns, if any, associated with its use. It is the

pansion of Plastics

responsibility of the user of this standard to establish appro-

D 785 Test Method for Rockwell Hardness of Plastics and

priate safety and health practices and determine the applica-

Electrical Insulating Materials

bility of regulatory limitations prior to use. Specific precau-

D 790 Test Methods for Flexural Properties of Unreinforced

and Reinforced Plastics and Electrical Insulating Materi-

als

These test methods are under the jurisdiction of ASTM Committee D-9 on

Electrical and Electronic Insulating Materials and are the direct responsibility of

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

Current edition approved March 10, 1996. Published May 1996. Originally Annual Book of ASTM Standards, Vol 10.01.

published as D 229 – 25 T. Last previous edition D 229 – 91. Annual Book of ASTM Standards, Vol 08.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 229

D 792 Test Methods for Density and Specific Gravity (Rela- perature and humidity exposure is undertaken to: (1) obtain

tive Density) of Plastics by Displacement satisfactory test precision, or (2) study the behavior of the

D 883 Terminology Relating to Plastics material as influenced by specific temperature and humidity

D 1674 Methods of Testing Polymerizable Embedding conditions.

Compounds Used for Electrical Insulation 4.2 Unless otherwise specified in these test methods or by a

D 1711 Terminology Relating to Electrical Insulation specific ASTM material specification, or unless material be-

D 1825 Practice for Etching and Cleaning Copper-Clad havior at a specific exposure is desired, condition test speci-

Electrical Insulating Materials and Thermosetting Lami- mens in accordance with Procedure A of Practice D 618 and

nates for Electrical Testing test in the Standard Laboratory Atmosphere (23 6 1.1°C, 50 6

D 2132 Test Method for Dust-and-Fog Tracking and Ero- 2 % relative humidity).

sion Resistance of Electrical Insulating Materials

THICKNESS

D 2303 Test Method for Liquid-Contaminant, Inclined-

Plane Tracking and Erosion of Insulating Materials

5. Apparatus and Procedure

D 3487 Specification for Mineral Insulating Oil Used in

5.1 Measure thickness in accordance with Test Methods

Electrical Apparatus

D 374.

D 5032 Practice for Maintaining Constant Relative Humid-

5.2 On test specimens, the use of a machinist’s micrometer

ity by Means of Aqueous Glycerin Solutions

as specified in Method B is satisfactory for the determination of

E 197 Specification for Enclosures and Servicing Units for

thickness for all of the test methods that follow. Where it is

Tests Above and Below Room Temperature

convenient, the deadweight dial micrometer, Method C, may

3. Terminology

be used.

5.3 On large sheets, use Method B. Choose a micrometer

3.1 Definitions—Rigid electrical insulating materials are

with a yoke of sufficient size and rigidity to permit accurate

defined in these test methods in accordance with Terminology

measurements in the center of the sheet.

D 883. The terminology applied to materials in these test

methods shall be in accordance with the terms appearing in

6. Precision and Bias

Terminologies D 883 and D 1711.

3.2 Definitions of Terms Specific to This Standard: 6.1 Results of comparative tests in several factories, mea-

3.2.1 In referring to the cutting, application, and loading of suring 36-in. (914-mm) square sheets by a variety of such

the specimens the following terms apply: devices, indicate that the trade is able to measure sheets ⁄32 and

3.2.1.1 crosswise (CW), adj—in the direction of the sheet at ⁄8 in. (1 and 3 mm) in thickness to bias of 0.0015 in. (0.0381

90° to the lengthwise direction. This is normally the weakest mm). (In the tests, s, or root mean square deviations, of 0.0005

direction in flexure. For some materials, including the raw in. (0.0127 mm) were obtained.)

materials used for manufacture of materials considered herein,

TENSILE PROPERTIES

this direction may be designated as the cross-machine direction

or the weft direction.

7. Test Specimens

3.2.1.2 edgewise loading, n—mechanical force applied in

7.1 Machine the test specimens from sample material to

the plane of the original sheet or plate.

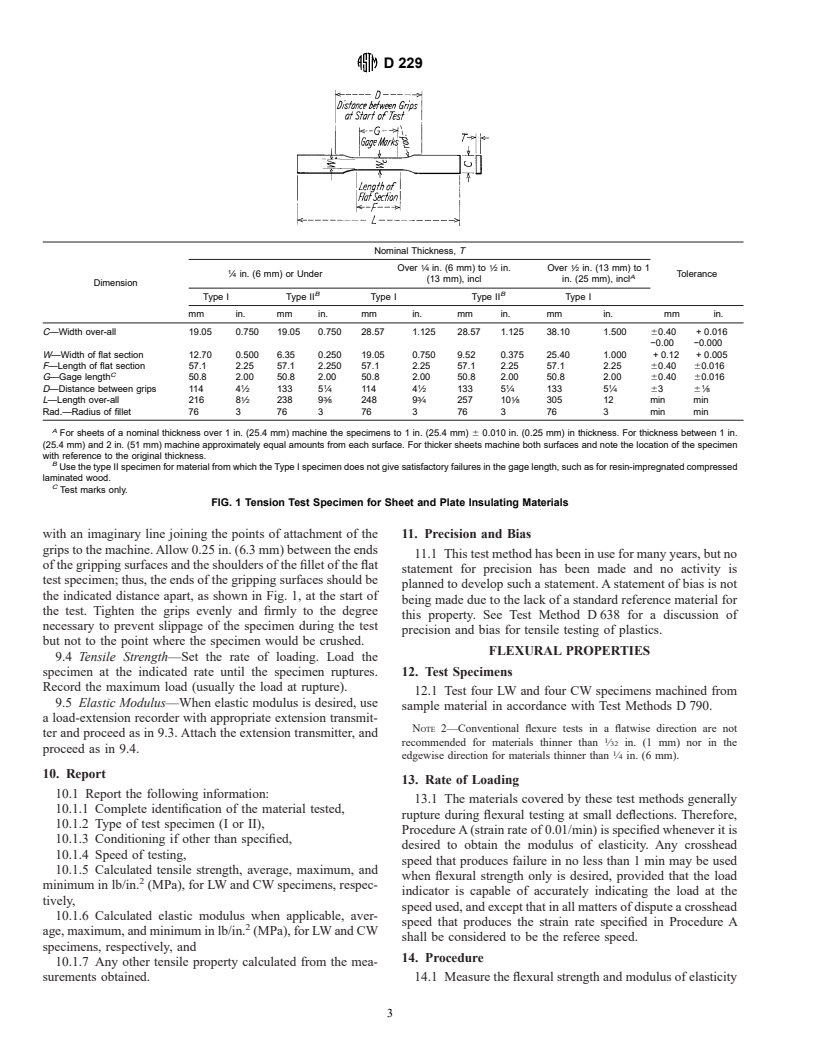

conform to the dimensions of sheet and plate materials in Fig.

3.2.1.3 flatwise loading, n—mechanical force applied nor-

1.

mal to the surfaces of the original sheet or plate.

7.2 Prepare four LW and four CW specimens.

3.2.1.4 lengthwise (LW), adj—in the direction of the sheet

which is strongest in flexure. For some materials, including the

8. Rate of Loading

raw materials used for the manufacture of materials considered

8.1 The materials covered by these test methods generally

herein, this direction may be designated as the machine

exhibit high elastic modulus. Use any crosshead speed pro-

direction or the warp direction.

vided that the load and strain indicators are capable of accurate

3.2.2 In referring to bonding strength the following term

measurement at the speed used, except use 0.05 in./min (1

applies:

mm/min) in matters of dispute.

3.2.2.1 bonding strength, n—the force required to split a

prescribed specimen under the test conditions specified herein.

9. Procedure

4. Conditioning

9.1 Measure the tensile strength and elastic modulus in

accordance with Test Method D 638 except as modified in the

4.1 The properties of the materials described in these test

methods are affected by the temperature and moisture exposure following paragraphs.

9.2 Measure the width and thickness of the specimen to the

of the materials to a greater or lesser extent, depending on the

particular material and the specific property. Control of tem- nearest 0.001 in. (0.025 mm) at several points along the length

of the flat section, which is indicated as Dimension F in Fig. 1.

Record the minimum values of cross-sectional area so deter-

Discontinued; see 1991 Annual Book of ASTM Standards, Vol 10.01.

mined.

Annual Book of ASTM Standards, Vol 10.03.

9.3 Place the specimen in the grips of the testing machine,

Annual Book of ASTM Standards, Vol 10.02.

Discontinued; see 1979 Annual Book of ASTM Standards, Part 40. taking care to align the long axis of the specimen and the grips

D 229

Nominal Thickness, T

1 1 1

Over ⁄4 in. (6 mm) to ⁄2 in. Over ⁄2 in. (13 mm) to 1

⁄4 in. (6 mm) or Under Tolerance

A

(13 mm), incl in. (25 mm), incl

Dimension

B B

Type I Type II Type I Type II Type I

mm in. mm in. mm in. mm in. mm in. mm in.

C—Width over-all 19.05 0.750 19.05 0.750 28.57 1.125 28.57 1.125 38.10 1.500 60.40 + 0.016

−0.00 −0.000

W—Width of flat section 12.70 0.500 6.35 0.250 19.05 0.750 9.52 0.375 25.40 1.000 + 0.12 + 0.005

F—Length of flat section 57.1 2.25 57.1 2.250 57.1 2.25 57.1 2.25 57.1 2.25 60.40 60.016

C

G—Gage length 50.8 2.00 50.8 2.00 50.8 2.00 50.8 2.00 50.8 2.00 60.40 60.016

1 1 1 1 1 1

D—Distance between grips 114 4 ⁄2 133 5 ⁄4 114 4 ⁄2 133 5 ⁄4 133 5 ⁄4 63 6 ⁄8

1 3 3 1

L—Length over-all 216 8 ⁄2 238 9 ⁄8 248 9 ⁄4 257 10 ⁄8 305 12 min min

Rad.—Radius of fillet 76 3 76 3 76 3 76 3 76 3 min min

A

For sheets of a nominal thickness over 1 in. (25.4 mm) machine the specimens to 1 in. (25.4 mm) 6 0.010 in. (0.25 mm) in thickness. For thickness between 1 in.

(25.4 mm) and 2 in. (51 mm) machine approximately equal amounts from each surface. For thicker sheets machine both surfaces and note the location of the specimen

with reference to the original thickness.

B

Use the type II specimen for material from which the Type I specimen does not give satisfactory failures in the gage length, such as for resin-impregnated compressed

laminated wood.

C

Test marks only.

FIG. 1 Tension Test Specimen for Sheet and Plate Insulating Materials

with an imaginary line joining the points of attachment of the 11. Precision and Bias

grips to the machine. Allow 0.25 in. (6.3 mm) between the ends

11.1 This test method has been in use for many years, but no

of the gripping surfaces and the shoulders of the fillet of the flat

statement for precision has been made and no activity is

test specimen; thus, the ends of the gripping surfaces should be

planned to develop such a statement. A statement of bias is not

the indicated distance apart, as shown in Fig. 1, at the start of

being made due to the lack of a standard reference material for

the test. Tighten the grips evenly and firmly to the degree

this property. See Test Method D 638 for a discussion of

necessary to prevent slippage of the specimen during the test

precision and bias for tensile testing of plastics.

but not to the point where the specimen would be crushed.

FLEXURAL PROPERTIES

9.4 Tensile Strength—Set the rate of loading. Load the

12. Test Specimens

specimen at the indicated rate until the specimen ruptures.

Record the maximum load (usually the load at rupture).

12.1 Test four LW and four CW specimens machined from

9.5 Elastic Modulus—When elastic modulus is desired, use

sample material in accordance with Test Methods D 790.

a load-extension recorder with appropriate extension transmit-

NOTE 2—Conventional flexure tests in a flatwise direction are not

ter and proceed as in 9.3. Attach the extension transmitter, and

recommended for materials thinner than ⁄32 in. (1 mm) nor in the

proceed as in 9.4.

edgewise direction for materials thinner than ⁄4 in. (6 mm).

10. Report

13. Rate of Loading

10.1 Report the following information:

13.1 The materials covered by these test methods generally

10.1.1 Complete identification of the material tested,

rupture during flexural testing at small deflections. Therefore,

10.1.2 Type of test specimen (I or II),

Procedure A (strain rate of 0.01/min) is specified whenever it is

10.1.3 Conditioning if other than specified,

desired to obtain the modulus of elasticity. Any crosshead

10.1.4 Speed of testing,

speed that produces failure in no less than 1 min may be used

10.1.5 Calculated tensile strength, average, maximum, and

when flexural strength only is desired, provided that the load

minimum in lb/in. (MPa), for LW and CW specimens, respec-

indicator is capable of accurately indicating the load at the

tively,

speed used, and except that in all matters of dispute a crosshead

10.1.6 Calculated elastic modulus when applicable, aver-

speed that produces the strain rate specified in Procedure A

age, maximum, and minimum in lb/in. (MPa), for LW and CW

shall be considered to be the referee speed.

specimens, respectively, and

14. Procedure

10.1.7 Any other tensile property calculated from the mea-

surements obtained. 14.1 Measure the flexural strength and modulus of elasticity

D 229

in accordance with Procedure A of Test Methods D 790, except The oven shall conform to the requirements for Type I, Grade

that where modulus of elasticity is desired use a load-deflection A, units of Specification E 197, except with respect to the time

recorder with appropriate deflection transmitter. constant.

19.4 Specimen Transfer Device—A means of transferring

15. Report

the test specimens from the heat-aging oven to the test

15.1 Report the following information: enclosure when testing specimens exposed to elevated tem-

perature for periods of more than 1 h. The specimens may be

15.1.1 Complete identification of the material tested,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.