ASTM B895-05

(Test Method)Test Methods for Evaluating the Corrosion Resistance of Stainless Steel Powder Metallurgy (P/M) Parts/Specimens by Immersion in a Sodium Chloride Solution

Test Methods for Evaluating the Corrosion Resistance of Stainless Steel Powder Metallurgy (P/M) Parts/Specimens by Immersion in a Sodium Chloride Solution

SIGNIFICANCE AND USE

The ability of sintered powder metallurgy stainless steel parts/specimens to resist corrosion when immersed in sodium chloride solution is important to their end use. Causes of unacceptable corrosion may be incorrect alloy, contamination of the parts by iron or some other corrosion-promoting material or improper sintering of the parts (for example, undesirable carbide and nitride formations caused by poor lubricant burnoff or improper sintering atmosphere).

This standard may be part of a purchase agreement between the P/M parts producer (seller) and the user of the parts (purchaser) (Method 1). It may also be used to optimize part or specimen production parameters (Method 2).

SCOPE

1.1 These test methods cover a procedure for evaluating the ability of sintered P/M stainless steel parts/specimens to resist corrosion when immersed in a sodium chloride (NaCl) solution.

1.2 Corrosion resistance is evaluated by one of two methods. In Method 1, the stainless steel parts/specimens are examined periodically and the time to the first appearance of staining or rust is used to indicate the end point. In Method 2, continued exposure to the sodium chloride solution is used to monitor the extent of corrosion as a function of time.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:B895–05

Standard Test Methods for

Evaluating the Corrosion Resistance of Stainless Steel

Powder Metallurgy (P/M) Parts/Specimens by Immersion in a

1

Sodium Chloride Solution

This standard is issued under the fixed designation B895; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G1 Practice for Preparing, Cleaning, and Evaluating Corro-

sion Test Specimens

1.1 These test methods cover a procedure for evaluating the

G48 Test Methods for Pitting and Crevice Corrosion Resis-

ability of sintered P/M stainless steel parts/specimens to resist

tance of Stainless Steels and Related Alloys by Use of

corrosion when immersed in a sodium chloride (NaCl) solu-

Ferric Chloride Solution

tion.

1.2 Corrosion resistance is evaluated by one of two meth-

3. Terminology

ods. In Method 1, the stainless steel parts/specimens are

3.1 Definitions—Useful definitions of terms for metal pow-

examined periodically and the time to the first appearance of

ders and powder metallurgy are found in Terminology B243.

staining or rust is used to indicate the end point. In Method 2,

continued exposure to the sodium chloride solution is used to

4. Summary of Test Method

monitor the extent of corrosion as a function of time.

4.1 Method 1 is recommended for evaluating the corrosion

1.3 This standard does not purport to address the safety

resistance of stainless steel powder metallurgy parts/specimens

concerns, if any, associated with its use. It is the responsibility

and to verify that proper materials and processing conditions

of the user of this standard to establish appropriate safety and

were used.

health practices and determine the applicability of regulatory

4.1.1 In this method, parts/specimens are immersed in 5 %

limitations prior to use.

(by mass) NaCl solution and examined periodically until the

first appearance of staining or rust. A part or specimen is

2. Referenced Documents

2 considered to have reached the end point when the first sign of

2.1 ASTM Standards:

corrosion occurs.

A380 Practice for Cleaning, Descaling, and Passivation of

4.2 Method 2 is recommended for evaluating the processing

Stainless Steel Parts, Equipment, and Systems

variables used in producing parts/specimens.

B243 Terminology of Powder Metallurgy

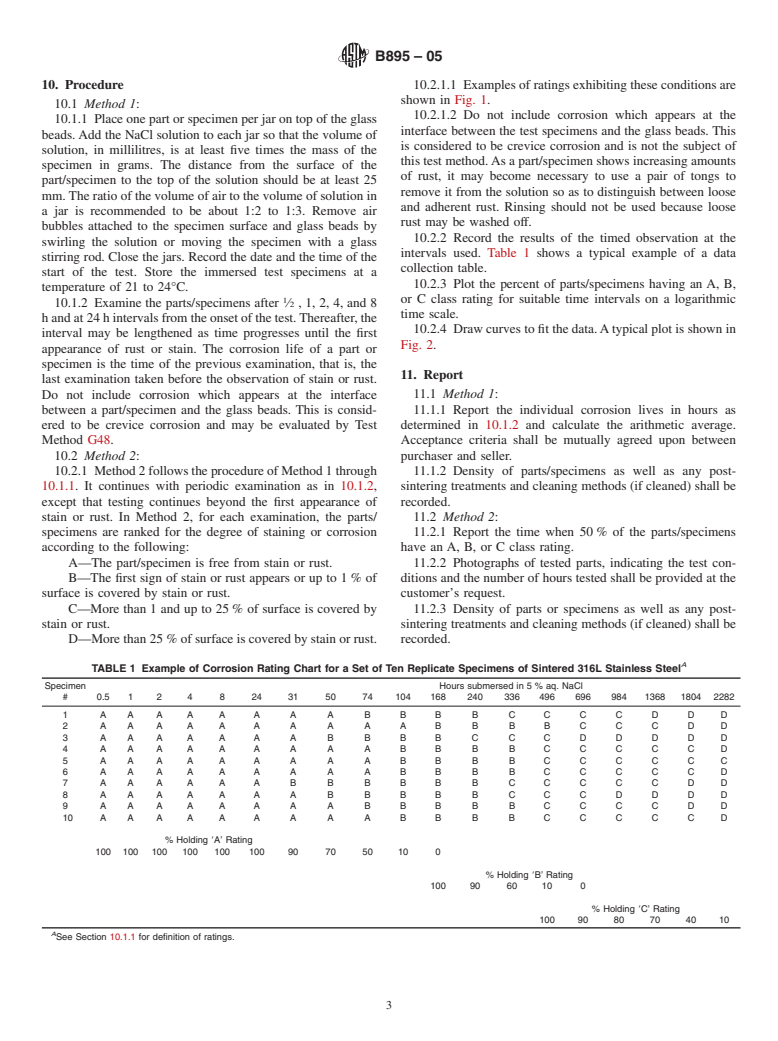

4.2.1 In this method, parts/specimens are exposed further to

B528 Test Method for Transverse Rupture Strength of

the NaCL solution and periodically rated as either A, B, C, or

Metal Powder Specimens

D (A-no corrosion; D-high or extreme corrosion) by compari-

D610 Practice for Evaluating Degree of Rusting on Painted

son with Fig. 1, a photograph of corroded specimens which

Steel Surfaces

serves as a standard. Additional examples of quantitative

D1193 Specification for Reagent Water

ratings may be found inTest Method D610. Method 2 has been

found useful in alloy screening and process optimization

1

These test methods are under the jurisdiction of Committee B09 on Metal

studies.

Powders and Metal Powder Products and is the direct responsibility of Subcom-

mittee B09.05 on Structural Parts.

5. Significance and Use

Current edition approved March 1, 2005. Published March 2005. Originally

5.1 The ability of sintered powder metallurgy stainless steel

approved in 1999. Last previous edition approved in 1999 as B895 – 99. DOI:

10.1520/B0895-05.

parts/specimens to resist corrosion when immersed in sodium

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

chloride solution is important to their end use. Causes of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

unacceptable corrosion may be incorrect alloy, contamination

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ofthepartsbyironorsomeothercorrosion-promotingmaterial

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B895–05

FIG. 1 Examples of Ratings for Various Amounts of Rust or Stain (Immersion in Aqueous Solution of 5% NaCl)

or improper sintering of the parts (for example, undesirable 8. Test Specimen

carbideandnitrideformationscausedbypoorlubricantburnoff

8.1 Usuallytestpartsaresinteredparts,buttheymayalsobe

or improper sintering atmosphere).

standard transverse rupture bars as defined in Test Method

5.2 This standard may be part of a purchase agreement

B528. A minimum of five parts/specimens shall be used for

between the P/M parts producer (seller) and the user of the

each test.

parts (purchaser) (Method 1). It may also be used to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.