ASTM D5325-03(2008)e1

(Test Method)Standard Test Method for Determination of Weight Percent Volatile Content of Water-Borne Aerosol Paints

Standard Test Method for Determination of Weight Percent Volatile Content of Water-Borne Aerosol Paints

SIGNIFICANCE AND USE

Calculation of the weight percent volatile organic content of water-borne paints, requires that the water content be known. This test method provides a direct way to determine the weight percent volatile organic matter of water-borne aerosol paints minus the matter content. This test method is modeled after Method 36.

SCOPE

1.1 This test method is for the determination of the weight percent volatile content of water-borne paints in aerosols.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D5325 − 03 (Reapproved2008)

Standard Test Method for

Determination of Weight Percent Volatile Content of Water-

Borne Aerosol Paints

This standard is issued under the fixed designation D5325; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—The units statement in subsection 1.2 was corrected editorially in November 2008.

1. Scope 3. Summary of Test Method

3.1 The propellant is released from the can and the content

1.1 This test method is for the determination of the weight

remaining is tested for percent water and nonvolatiles.

percent volatile content of water-borne paints in aerosols.

4. Significance and Use

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4.1 Calculation of the weight percent volatile organic con-

standard.

tent of water-borne paints, requires that the water content be

known.Thistestmethodprovidesadirectwaytodeterminethe

1.3 This standard does not purport to address all of the

weight percent volatile organic matter of water-borne aerosol

safety concerns, if any, associated with its use. It is the

paints minus the matter content. This test method is modeled

responsibility of the user of this standard to establish appro-

after Method36.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Apparatus

5.1 Freezer.

2. Referenced Documents

5.2 Ice Pick.

2.1 ASTM Standards:

5.3 Hammer.

D2369Test Method for Volatile Content of Coatings

D3792TestMethodforWaterContentofCoatingsbyDirect

5.4 Applicator Sticks.

Injection Into a Gas Chromatograph

5.5 Masking Tape.

D4017Test Method for Water in Paints and Paint Materials

5.6 Tin Snips or Metal Cutter.

by Karl Fischer Method

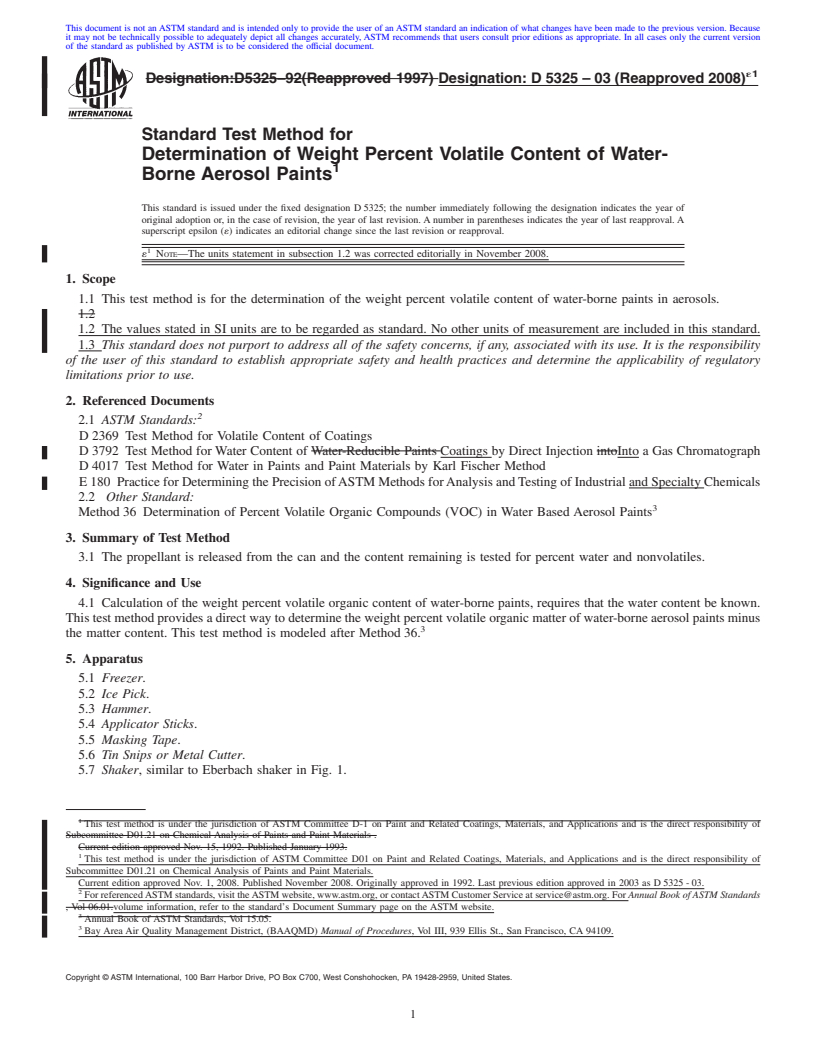

E180Practice for Determining the Precision of ASTM 5.7 Shaker, similar to Eberbach shaker in Fig. 1.

Methods for Analysis and Testing of Industrial and Spe-

6. Procedure

cialty Chemicals (Withdrawn 2009)

6.1 Preparation of Aerosol Contents for Analysis:

2.2 Other Standard:

6.1.1 Mix the aerosol paint container thoroughly for about

Method36 DeterminationofPercentVolatileOrganicCom-

4 15min,usingashakersimilartotheEberbachshakershownin

pounds (VOC) in Water Based Aerosol Paints

Fig. 1, at the low speed setting. It is essential that the samples

be well mixed to obtain valid results.

6.1.2 Removethecapandactuatorfromthecan.Putthecap

This test method is under the jurisdiction of ASTM Committee D01 on Paint

on the can and weigh the can to 0.01 g.

and Related Coatings, Materials, andApplications and is the direct responsibility of

6.1.3 Place the can in an upside down position in a freezer

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

for2hata temperature that is 0°C.

Current edition approved Nov. 1, 2008. Published November 2008. Originally

approved in 1992. Last previous edition approved in 2003 as D5325-03. DOI:

6.1.4 Put the can upside down in a fume hood. Puncture the

10.1520/D5325-03R08E01.

bottom of the can near the edge with a very sharp ice pick.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Slowly remove the ice pick from the hole. Leave the hole

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

uncovered for about 12 to 16 h to allow most of the propellant

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

to escape.

The last approved version of this historical standard is referenced on

6.1.5 Enlarge the hole slightly by tapping the ice pick

www.astm.org.

further into the can. Swirl the can gently for 1 to 2 min to

Bay Area Air Quality Management District, (BAAQMD) Manual of

Procedures, Vol III, 939 Ellis St., San Francisco, CA 94109. remove any remaining propellant.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D5325–92(Reapproved 1997) Designation:D5325–03(Reapproved2008)

Standard Test Method for

Determination of Weight Percent Volatile Content of Water-

Borne Aerosol Paints

This standard is issued under the fixed designation D5325; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—The units statement in subsection 1.2 was corrected editorially in November 2008.

1. Scope

1.1 This test method is for the determination of the weight percent volatile content of water-borne paints in aerosols.

1.2

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D2369 Test Method for Volatile Content of Coatings

D3792 Test Method for Water Content of Water-Reducible Paints Coatings by Direct Injection intoInto a Gas Chromatograph

D4017 Test Method for Water in Paints and Paint Materials by Karl Fischer Method

E180 PracticeforDeterminingthePrecisionofASTMMethodsforAnalysisandTestingofIndustrialandSpecialtyChemicals

2.2 Other Standard:

Method36 Determination of Percent Volatile Organic Compounds (VOC) in Water Based Aerosol Paints

3. Summary of Test Method

3.1 The propellant is released from the can and the content remaining is tested for percent water and nonvolatiles.

4. Significance and Use

4.1 Calculation of the weight percent volatile organic content of water-borne paints, requires that the water content be known.

Thistestmethodprovidesadirectwaytodeterminetheweightpercentvolatileorganicmatterofwater-borneaerosolpaintsminus

the matter content. This test method is modeled after Method36.

5. Apparatus

5.1 Freezer.

5.2 Ice Pick.

5.3 Hammer.

5.4 Applicator Sticks.

5.5 Masking Tape.

5.6 Tin Snips or Metal Cutter.

5.7 Shaker, similar to Eberbach shaker in Fig. 1.

This test method is under the jurisdiction of ASTM Committee D-1 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials .

Current edition approved Nov. 15, 1992. Published January 1993.

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

Current edition approved Nov. 1, 2008. Published November 2008. Originally approved in 1992. Last previous edition approved in 2003 as D5325-03.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

, Vol 06.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 15.05.

Bay Area Air Quality Management District, (BAAQMD) Manual of Procedures, Vol III, 939 Ellis St., San Francisco, CA 94109.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D5325–03 (2008)

FIG. 1 Aerosol Can on Eberbach Shaker

6. Procedure

6.1 Preparation of Aerosol Contents for Analysis:

6.1.1 Mix the aerosol paint container thoroughly for about 15 min, using a shaker similar to the Eberbach shaker shown in Fig.

1, at the low speed setting. It is essential that the samples be well mixed to obtain valid results.

6.1.2 Remove the cap and actuator from the can. Put the cap on the can and weigh the can to 0.01 g.

6.1.3 Place the can in an upside down position in a freezer for2hata temperature that is 0°C.

6.1.4 Put the can upside down in a fume hood. Puncture the bottom of the can near the edge

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.