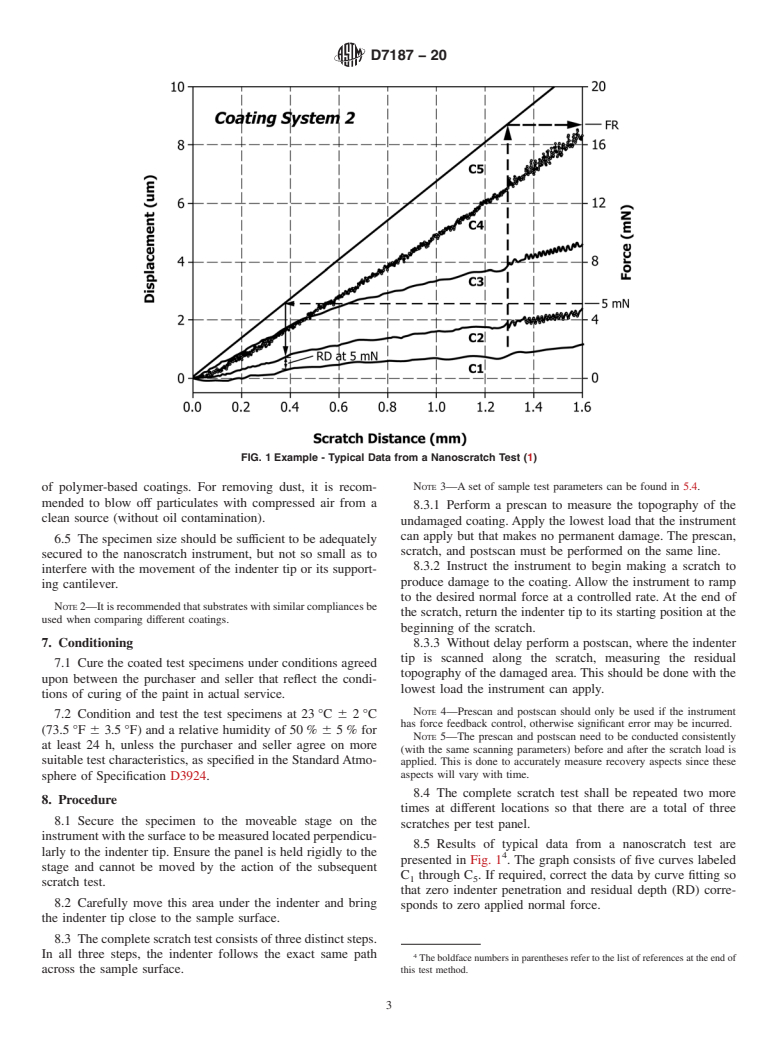

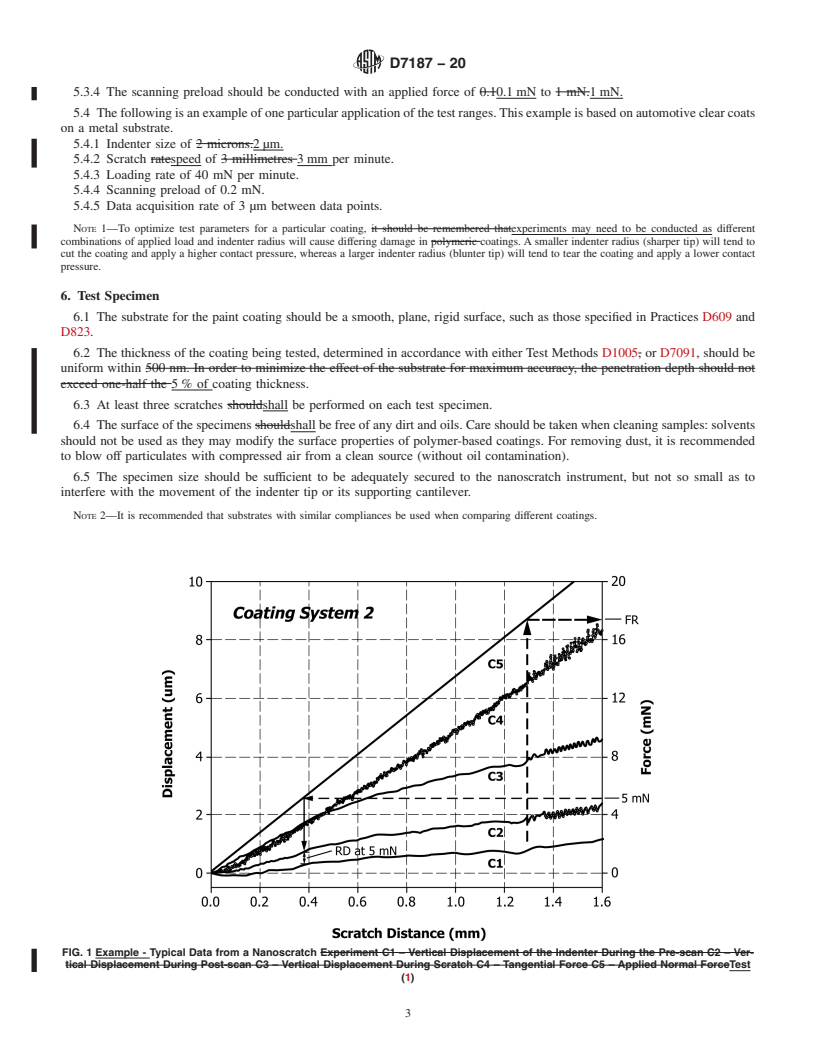

ASTM D7187-20

(Test Method)Standard Test Method for Measuring Mechanistic Aspects of Scratch/Mar Behavior of Paint Coatings by Nanoscratching

Standard Test Method for Measuring Mechanistic Aspects of Scratch/Mar Behavior of Paint Coatings by Nanoscratching

SIGNIFICANCE AND USE

4.1 This test addresses two limitations in existing mar tests such as Test Methods D1044, D3363, D5178, D6037, and D6279, namely:

4.1.1 Measured damage is caused by hundreds of contacts with differing contact geometries making it difficult or impossible for mechanical quantities (force, displacement) at the contact points to be reliably determined.

4.1.2 The damage is evaluated using subjective visual assessments, which provide only a qualitative sense of wear with little information about mar mechanisms.

4.2 This test provides a quantitative assessment of a paint coating’s mechanistic aspects of scratch/mar behavior in various conditions. The ability to control testing variables such as loading rate, speed, and temperature allow the study of the scratch/mar behavior in a variety of environments.

4.3 This test method is particularly suitable for measurement of paint coatings on laboratory test panels.

4.4 The accuracy and precision of scratch/mar performance may be significantly influenced by coating surface non-uniformity and irregularities.

4.5 A correlation has been observed between good mar resistance in field studies and a combination of high plastic resistance and high fracture resistance. When coatings have had either high plastic resistance and low fracture resistance, or low plastic resistance and high fracture resistance, there have been contradictory results in field studies.

4.6 Mar resistance characterizes the ability of the coating to resist light damage. The difference between mar and scratch resistance is that mar is related to only the relatively fine surface scratches which spoil the appearance of the coating. The mechanistic aspects of mar resistance depend on a complex interplay between visco-elastic and thermal recovery, yield or plastic flow, and micro-fracture. Polymers are challenging because they exhibit a range of mechanical properties from near liquid through rubber materials to brittle solids. The mechanical propertie...

SCOPE

1.1 This test method covers a nanoscratch method for determining the resistance of paint coatings on smooth flat surfaces to scratch/mar.

1.2 Other methods used in scratch/mar evaluation physically scratch or mar a sample’s surface with single or multiple contact cutting, and then use visual inspection to assign a ranking. It has been recognized that loss of appearance is mainly due to surface damage created. This method quantitatively and objectively measures scratch/mar behavior by making the evaluation process two steps with emphasis on surface damage. Step one is to find the relationship between damage shape and size and external input (such as forces, contact geometry, and deformation). Step two is to relate damage shape and size to visual loss of luster. The first step is covered by this method; in addition, a survey in the appendix provides an example of an experiment to relate the damage to the change in luster.

1.3 There are three elementary deformation mechanisms: elastic deformation, plastic deformation and fracture; only the latter two contribute significantly to mar. This method evaluates scratch/mar based on the latter two damage mechanisms.

1.4 Although this standard was developed for paint coatings, it can also be applied to other types of similar polymer-based coatings, for example, lacquers, varnishes, glazes and other decorative and protective layers deposited on hard substrates.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally rec...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7187 − 20

Standard Test Method for

Measuring Mechanistic Aspects of Scratch/Mar Behavior of

1

Paint Coatings by Nanoscratching

This standard is issued under the fixed designation D7187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This test method covers a nanoscratch method for

ization established in the Decision on Principles for the

determining the resistance of paint coatings on smooth flat

Development of International Standards, Guides and Recom-

surfaces to scratch/mar.

mendations issued by the World Trade Organization Technical

1.2 Other methods used in scratch/mar evaluation physi-

Barriers to Trade (TBT) Committee.

cally scratch or mar a sample’s surface with single or multiple

2. Referenced Documents

contact cutting, and then use visual inspection to assign a

2

ranking. It has been recognized that loss of appearance is

2.1 ASTM Standards:

mainly due to surface damage created. This method quantita-

D609Practice for Preparation of Cold-Rolled Steel Panels

tively and objectively measures scratch/mar behavior by mak-

for Testing Paint, Varnish, Conversion Coatings, and

ing the evaluation process two steps with emphasis on surface

Related Coating Products

damage. Step one is to find the relationship between damage

D823Practices for Producing Films of Uniform Thickness

shape and size and external input (such as forces, contact

of Paint, Coatings and Related Products on Test Panels

geometry,anddeformation).Steptwoistorelatedamageshape

D1005Test Method for Measurement of Dry-Film Thick-

andsizetovisuallossofluster.Thefirststepiscoveredbythis

ness of Organic Coatings Using Micrometers

method; in addition, a survey in the appendix provides an

D1044TestMethodforResistanceofTransparentPlasticsto

exampleofanexperimenttorelatethedamagetothechangein

Surface Abrasion by the Taber Abraser

luster.

D3363Test Method for Film Hardness by Pencil Test

3

(Withdrawn 2020)

1.3 There are three elementary deformation mechanisms:

D3924Specification for Standard Environment for Condi-

elastic deformation, plastic deformation and fracture; only the

tioning and Testing Paint, Varnish, Lacquer, and Related

latter two contribute significantly to mar. This method evalu-

Materials

ates scratch/mar based on the latter two damage mechanisms.

D5178TestMethodforMarResistanceofOrganicCoatings

1.4 Although this standard was developed for paint

D6037Test Methods for Dry Abrasion Mar Resistance of

coatings, it can also be applied to other types of similar

High Gloss Coatings

polymer-based coatings, for example, lacquers, varnishes,

D6279Test Method for Rub Abrasion Mar Resistance of

glazes and other decorative and protective layers deposited on

High Gloss Coatings

hard substrates.

D7027Test Method for Evaluation of Scratch Resistance of

1.5 The values stated in SI units are to be regarded as the

Polymeric Coatings and Plastics Using an Instrumented

standard. The values given in parentheses are for information

Scratch Machine

only.

D7091Practice for Nondestructive Measurement of Dry

Film Thickness of Nonmagnetic Coatings Applied to

1.6 This standard does not purport to address all of the

Ferrous Metals and Nonmagnetic, Nonconductive Coat-

safety concerns, if any, associated with its use. It is the

ings Applied to Non-Ferrous Metals

responsibility of the user of this standard to establish appro-

G171Test Method for Scratch Hardness of Materials Using

priate safety, health, and environmental practices and deter-

a Diamond Stylus

mine the applicability of regulatory limitations prior to use.

1 2

This test method is under the jurisdiction of ASTM Committee D01 on Paint For referenced ASTM standards, visit the ASTM website, www.astm.org, or

andRelatedCoatings,Materials,andApplicationsandisthedirectresponsibilityof contact ASTM Customer Service at service@astm.org. For ASTM Book of ASTM

Subcommittee D01.23 on Physical Properties of Applied Paint Films. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved June 1, 2020. Published June 2020. Originally the ASTM website.

3

approved in 2005. Last previous edition approved in 2015 as D7187 –15. DOI: The last approved version of this historical standard is referenced on

10.1520/D7187-20. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7187 − 15 D7187 − 20

Standard Test Method for

Measuring Mechanistic Aspects of Scratch/Mar Behavior of

1

Paint Coatings by Nanoscratching

This standard is issued under the fixed designation D7187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers thea nanoscratch method for determining the resistance of paint coatings on smooth flat surfaces

to scratch/mar.

1.2 PreviousOther methods used in scratch/mar evaluation first physically scratch or mar a sample’s surface with single or

multiple contact cutting, and then use visual inspection to assign a ranking. It has been recognized that loss of appearance is mainly

due to surface damages created. The philosophy of this method is to damage created. This method quantitatively and objectively

measuremeasures scratch/mar behavior by making the evaluation process two steps with emphasis on surface damages.damage.

Step one is to find the relationship between damage shape and size and external input (such as forces, contact geometry, and

deformation). Step two is to relate damage shape and size to visual loss of luster. The first step is covered by this method; in

addition, a survey in the appendix provides an example of an experiment to relate the damage to the change in luster.

1.3 There are three elementary deformation mechanisms: elastic deformation, plastic deformation and fracture; only the latter

two both contribute significantly to mar. This method evaluates scratch/mar based on the latter two damage mechanisms.

1.4 Although this standard was developed for paint coatings, it can also be applied to other types of similar polymer-based

coatings, for example, lacquers, varnishes, glazes and other decorative and protective layers deposited on hard substrates.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety problems,concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and

determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D609 Practice for Preparation of Cold-Rolled Steel Panels for Testing Paint, Varnish, Conversion Coatings, and Related Coating

Products

D823 Practices for Producing Films of Uniform Thickness of Paint, Coatings and Related Products on Test Panels

D1005 Test Method for Measurement of Dry-Film Thickness of Organic Coatings Using Micrometers

D1044 Test Method for Resistance of Transparent Plastics to Surface Abrasion by the Taber Abraser

3

D3363 Test Method for Film Hardness by Pencil Test (Withdrawn 2020)

D3924 Specification for Standard Environment for Conditioning and Testing Paint, Varnish, Lacquer, and Related Materials

D5178 Test Method for Mar Resistance of Organic Coatings

D6037 Test Methods for Dry Abrasion Mar Resistance of High Gloss Coatings

D6279 Test Method for Rub Abrasion Mar Resistance of High Gloss Coatings

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

Current edition approved Feb. 1, 2015June 1, 2020. Published April 2015June 2020. Originally approved in 2005. Last previous edition approved in 20102015 as D7187

– 10.– 15. DOI: 10.1520/D7187-15.10.1520/D7187-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For ASTM Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.