ASTM D6980-04

(Test Method)Test Method for Determination of Moisture in Plastics by Loss in Weight

Test Method for Determination of Moisture in Plastics by Loss in Weight

SIGNIFICANCE AND USE

This test method is intended for use as a control, acceptance, and assessment test.

Moisture can seriously affect the processability of plastics. It is possible that high moisture content will cause surface imperfections (that is, splay or bubbling) or degradation by hydrolysis. Low moisture (with high temperature) has been known to cause solid phase polymerization.

The physical properties of some plastics are greatly affected by the moisture content.

SCOPE

1.1 This test method covers the quantitative determination of moisture by means of loss in weight technology down to 50 ppm as it applies to most plastics.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 Specimens tested in this method can reach or exceed 250C, use caution when handling them after testing has been completed.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 1

There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6980–04

Standard Test Method for

Determination of Moisture in Plastics by Loss in Weight

This standard is issued under the fixed designation D 6980; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1.1 Discussion—The effects of lift are compensated for

in different ways by different manufacturers.

1.1 This test method covers the quantitative determination

3.1.2 tempering—a process that re-defines the molecular

of moisture by means of loss in weight technology down to 50

structure of a metal to enhance its performance.

ppm as it applies to most plastics.

1.2 The values stated in SI units are to be regarded as the

4. Summary of Test Method

standard.

4.1 The specimen is spread onto a sample pan that is

1.3 Specimens tested in this method can reach or exceed

supported on a balance in a heating chamber that has been

250°C, use caution when handling them after testing has been

preheated and equilibrated to the specified idle temperature. It

completed.

is then heated to vaporize the moisture. The analysis is

1.4 This standard does not purport to address all of the

completed when the indicated weight loss falls below a rate

safety concerns, if any, associated with its use. It is the

specified in the test conditions. The total loss of weight is

responsibility of the user of this standard to establish appro-

integrated and displayed as the percent of moisture. Both the

priate safety and health practices and determine the applica-

analyzer’s balance and heater are calibrated to NIST standards

bility of regulatory limitations prior to use.

to achieve precise and accurate results.

NOTE 1—There is no similar or equivalent ISO standard.

4.2 Through adjustment of the analyzer’s parameter set-

tings, a set of conditions is developed to measure moisture.

2. Referenced Documents

2.1 ASTM Standards:

5. Significance and Use

D 883 Terminology Relating to Plastics

5.1 This test method is intended for use as a control,

D 1600 Terminology for Abbreviated Terms Relating to

acceptance, and assessment test.

Plastics

5.2 Moisture can seriously affect the processability of plas-

D 6869 Test Method for Coulometric and Volumetric De-

tics. It is possible that high moisture content will cause surface

termination of Moisture in Plastics Using the Karl Fischer

imperfections (that is, splay or bubbling) or degradation by

Reaction (the Reaction of Iodine with Water)

hydrolysis. Low moisture (with high temperature) has been

known to cause solid phase polymerization.

3. Terminology

5.3 The physical properties of some plastics are greatly

3.1 Definitions—The definitions used in this test method are

affected by the moisture content.

in accordance with Terminologies D 883 and D 1600.

3.1.1 lift—the result of convection currents created during 6. Interferences

the heating of the specimen raising the sample pan off of its

6.1 When testing plastic materials for moisture by a loss in

support falsely indicating a moisture loss.

weight technique, the possibility exists for volatiles other than

water to be evolved and cause a biased high result if the

1 material has not been dried to remove excess moisture and low

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods. boiling volatiles. It is important to have a working knowledge

Current edition approved July 1, 2004. Published August 2004.

of the material that is being tested and to remain below any

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

melting or decomposition temperatures that would unnecessar-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ily cause the emission of volatiles which can be harmful.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

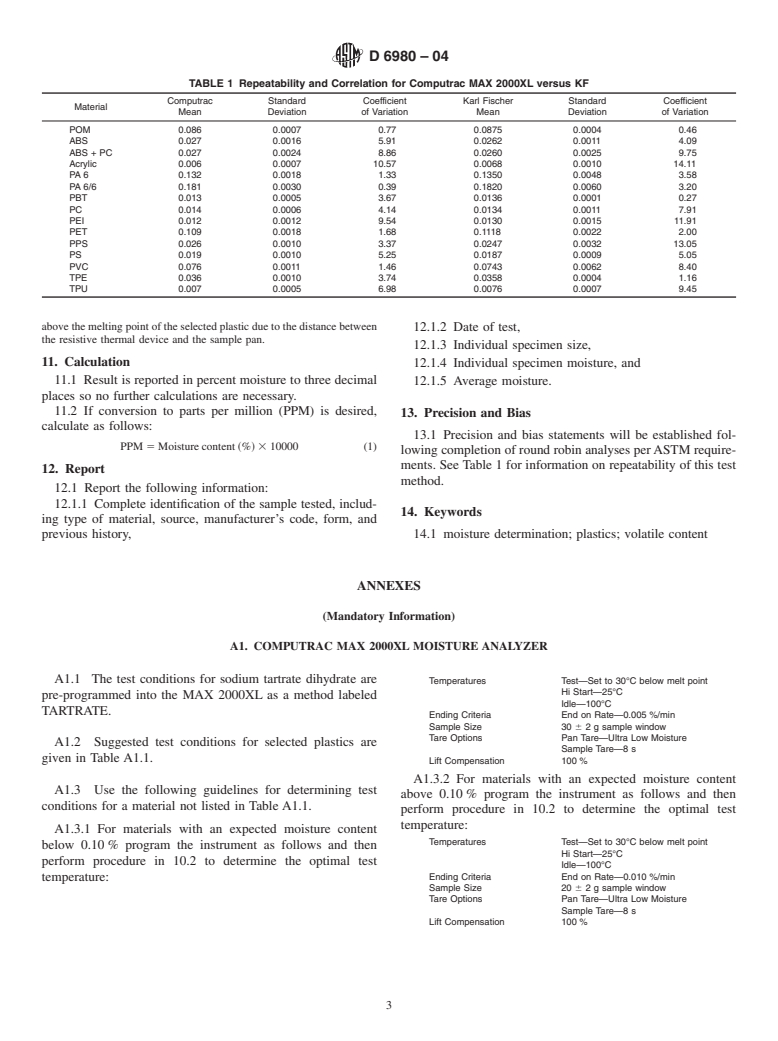

D6980–04

7. Apparatus 10. Procedure

7.1 Moisture Analyzer, containing: 10.1 Sample Analysis:

7.1.1 The capability of the oven shall be selected based 10.1.1 Place the analyzer on a flat, level surface.

upon the specific material being tested. Suggested test tem- 10.1.2 Turn the analyzer on and allow equilibration at the

peratures for specific plastics are shown in Tables A1.1 and programmed idle temperature for 15 min.

A2.1. 10.1.3 Program the analyzer with the suggested test condi-

tions listed in Annex A1 or Annex A2.

NOTE 2—It will be necessary to contact the analyzer manufacturer for

suggested test temperatures for materials not listed in Tables A1.1 and

NOTE 3—IftestconditionsforaspecificmaterialarenotlistedinAnnex

A2.1.

A1 or Annex A2, they will have to be determined experimentally or by

contacting the analyzer manufacturer.

7.1.2 A balance capable of measuring to 0.0001 g.

7.1.3 An electronic or mechanical means of compensating 10.1.4 Begin the program and follow the prompts for

for lift caused by convection currents created during testing. placing the sample on the sample pan.

7.1.4 A processor that is capable of converting the loss of 10.1.5 At the end of the test allow the analyzer to cool and

weight to digital data. remove the sample pan.

7.1.5 Digital display for presenting the digital data as 10.1.6 Record the result as displayed in percent moisture.

percent moisture. 10.1.7 Place a clean sample pan in the analyzer and allow

7.1.6 Sample Pans, made from “0” temper,Aluminum 3003 equilibration prior to beginning subsequent tests.

or other nonreactive material. 10.2 Determination of Optimal Test Conditions:

NOTE 4—When determining the optimal test conditions for a material,

8. Test Specimen and Sample

it is useful to have a Karl Fischer apparatus available and test in

8.1 Due to the small specimen size, exercise care to ensure accordancewithTestMethodD 6869orcontacttheanalyzermanufacturer

who in some cases will provide this service for you.

that the specimen is representative of the sample.

8.2 Due to the hygroscopic nature of many plastics, samples

10.2.1 Program the analyzer in accordance with the condi-

shall be stored in airtight containers made of glass or other

tions listed in Annex A1 or Annex A2.

qualified or suitable material.

10.2.2 To determine the optimum test temperature for a

8.3 Samples that have been heated to remove moisture prior

material, run a single test which includes several consecutive

to processing and testing shall be allowed to cool to room

programs that have been linked together. Each program is

temperature in a sealed container prior to determination.

identical in its parameters except the temperature is increased

8.4 Test specimens in the form of powders, pellets, or

5°.

ground material.

NOTE 5—When increasing the test temperature, do not exceed a

temperature where the potential exists for the emission of harmful fumes.

9. Calibration and Standardization

NOTE 6—Ensure that the program selected to run first is the lowest

9.1 To maintain the integrity of the test results the balance

temperature.

and heater shall both be calibrated using NIST-traceable

10.2.3 After the tests have completed, plot the result versus

weights and an NIST-traceable temperature calibration inter-

temperature to make a curve as in Fig. 1.

face.

10.2.3.1 Most of the moisture is vaporized in temperature

9.2 The calibration is validated by way of using sodium

range from points 1 to 3.

tartratedihydrate exhibitingatheoreticalcrystalwatercontent

10.2.3.2 Between points 3 and 5 the moisture result is very

of15.66 %withanacceptableresultrangeof15.61to15.71 %.

low and constant. Choose a temperature in this range as the

Other materials with known theoretical water content are

optimum test temperature.

acceptable for validation.

10.2.3.3 Above point 5 the moisture result begins to in-

9.3 Prepare the analyzer for use and perform the analysis as

crease. This is likely caused by the generation of water due to

described in 10.1.

decomposition or solid phase polymerization of the sample.

9.4 If the result is not within the acceptable range, return to

NOTE 7—It is not uncommon for the optimal test temperature to be

9.3 for re-analysis.

9.5 If results are still not within the acceptable range, first

perform a temperature calibrati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.