ASTM D6728-11

(Test Method)Standard Test Method for Determination of Contaminants in Gas Turbine and Diesel Engine Fuel by Rotating Disc Electrode Atomic Emission Spectrometry

Standard Test Method for Determination of Contaminants in Gas Turbine and Diesel Engine Fuel by Rotating Disc Electrode Atomic Emission Spectrometry

SIGNIFICANCE AND USE

Operating experience of gas turbines and diesel engines has shown that some of the ash-forming substances present in a fuel can lead to high temperature corrosion, ash deposition, and fuel system fouling. Ash-forming materials may be in a fuel as oil-soluble metallo-organic compounds as water-soluble salts or as solid foreign contamination. Their presence and concentration varies with the geographical source of a crude oil and they are concentrated in the residual fractions during the refining process. Although distillate fuel oils are typically contaminant free, ash-forming materials may be introduced later in the form of salt-bearing water or by contact with other petroleum products during transportation and storage. Specifications of gas turbine and diesel engine fuels and the significance of contamination and trace metals are detailed in Specifications D2880 and D975.

Pre-conditioning of the fuel before it reaches the gas turbine or diesel engine has become a prerequisite for installations that use heavy petroleum fuel, and also for sites that use light distillate fuel oils. On-site fuel analysis to determine the extent of contamination is an integral part of a fuel quality management program. It is used first to determine the extent of the required treatment, and later, the effectiveness of the treatment. It starts with the delivery of the fuel, continues throughout fuel handling and ends only as the fuel is injected into the turbine or engine.

Fuel contamination specifications vary among the different gas turbine manufacturers. However, without exception, each requires that contaminants must be as low as possible. In most power generation installations, it is the owner who has the responsibility of verifying fuel cleanliness in compliance with the turbine manufacturer's warranty specifications. This leads to an on-site analytical instrument performance requirement of below 1.0 mg/kg for several elements.

SCOPE

1.1 This test method covers the determination of contaminants and materials as a result of corrosion in gas turbine or diesel engine fuels by rotating disc electrode atomic emission spectroscopy (RDE-AES).

1.1.1 The test method is applicable to ASTM Grades 0-GT, 1-GT, 2-GT, 3-GT, and 4-GT gas turbine fuels and Grades Low Sulfur No. 1-D, Low Sulfur No. 2-D, No. 1-D, No. 2-D, and No. 4-D diesel fuel oils.

1.1.2 This test method provides a rapid at-site determination of contamination and corrosive elements ranging from fractions of mg/kg to hundreds of mg/kg in gas turbine and diesel engine fuels so the fuel quality and level of required treatment can be determined.

1.1.3 This test method uses oil-soluble metals for calibration and does not purport to quantitatively determine or detect insoluble particles.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. The preferred units are mg/kg (ppm by mass).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6728 − 11

StandardTest Method for

Determination of Contaminants in Gas Turbine and Diesel

Engine Fuel by Rotating Disc Electrode Atomic Emission

1

Spectrometry

This standard is issued under the fixed designation D6728; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

1.1 This test method covers the determination of contami-

D5854 Practice for Mixing and Handling of Liquid Samples

nants and materials as a result of corrosion in gas turbine or

of Petroleum and Petroleum Products

diesel engine fuels by rotating disc electrode atomic emission

D6299 Practice for Applying Statistical Quality Assurance

spectroscopy (RDE-AES).

and Control Charting Techniques to Evaluate Analytical

1.1.1 The test method is applicable to ASTM Grades 0-GT,

Measurement System Performance

1-GT,2-GT,3-GT,and4-GTgasturbinefuelsandGradesLow

Sulfur No. 1-D, Low Sulfur No. 2-D, No. 1-D, No. 2-D, and

3. Terminology

No. 4-D diesel fuel oils.

1.1.2 Thistestmethodprovidesarapidat-sitedetermination

3.1 Definitions:

of contamination and corrosive elements ranging from frac- 3.1.1 burn, vt—in emission spectroscopy, to vaporize and

tions of mg/kg to hundreds of mg/kg in gas turbine and diesel

excite a specimen with sufficient energy to generate spectral

engine fuels so the fuel quality and level of required treatment radiation.

can be determined.

3.1.2 calibration, n—the determination of the values of the

1.1.3 This test method uses oil-soluble metals for calibra-

significant parameters by comparison with values indicated by

tion and does not purport to quantitatively determine or detect

a set of reference standards.

insoluble particles.

3.1.3 calibration curve, n—the graphical or mathematical

1.2 The values stated in SI units are to be regarded as

representation of a relationship between the assigned (known)

standard. No other units of measurement are included in this

values of standards and the measured responses from the

standard. The preferred units are mg/kg (ppm by mass).

measurement system.

1.3 This standard does not purport to address all of the

3.1.4 calibration standard, n—a standard having an ac-

safety concerns, if any, associated with its use. It is the

cepted value (reference value) for use in calibrating a measure-

responsibility of the user of this standard to establish appro-

ment instrument or system.

priate safety and health practices and determine the applica-

3.1.5 detection limit, n—the smallest concentration of an

bility of regulatory limitations prior to use.

element that can be measured for specific analysis conditions

and data collection periods.

2. Referenced Documents

2 3.1.6 emission spectroscopy, n—measurement of energy

2.1 ASTM Standards:

spectrum emitted by or from an object under some form of

D975 Specification for Diesel Fuel Oils

energetic stimulation; for example, light, electrical discharge,

D2880 Specification for Gas Turbine Fuel Oils

and so forth.

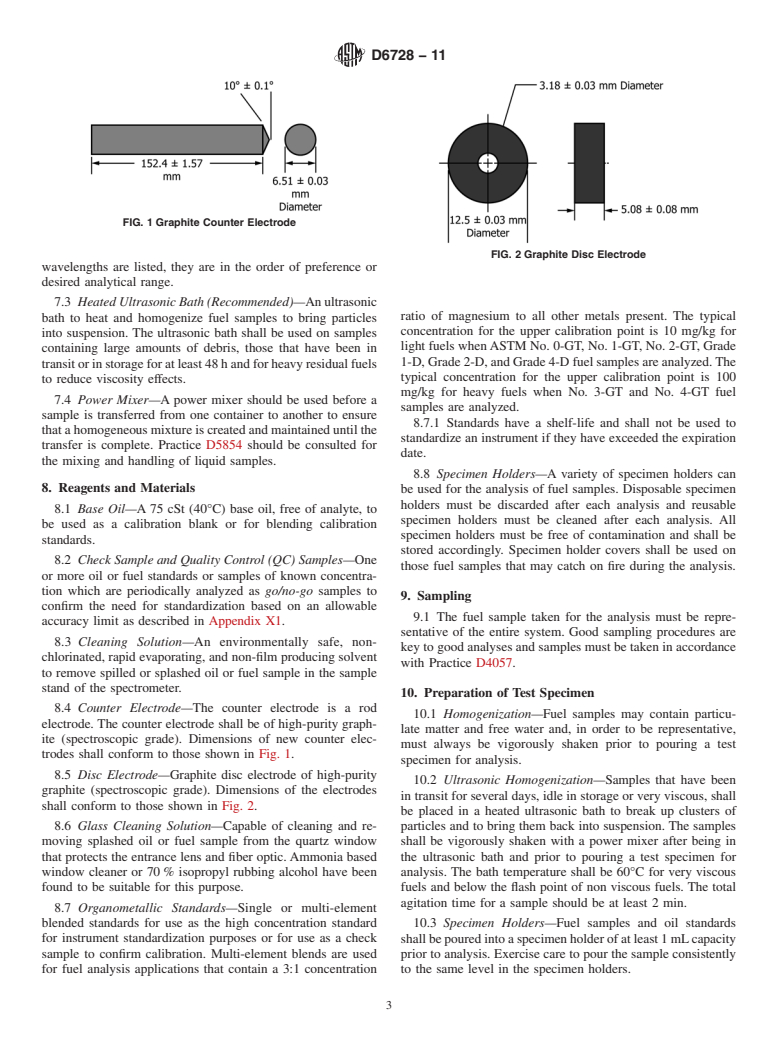

3.2 Definitions of Terms Specific to This Standard:

3.2.1 arc discharge, n—a self-sustaining, high current

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of density, high temperature discharge uniquely characterized by

Subcommittee D02.03 on Elemental Analysis.

a cathode fall nearly equal to the ionization potential of the gas

Current edition approved Oct. 1, 2011. Published November 2011. Originally

or vapor in which it exists.

approved in 2001. Last previous edition approved in 2006 as D6728–01(2006).

DOI: 10.1520/D6728-11.

3.2.2 check sample, n—a reference material usually pre-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

pared by a single laboratory for its own use as a measurement

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

control standard, or for the qualification of a measurement

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. method.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6728 − 11

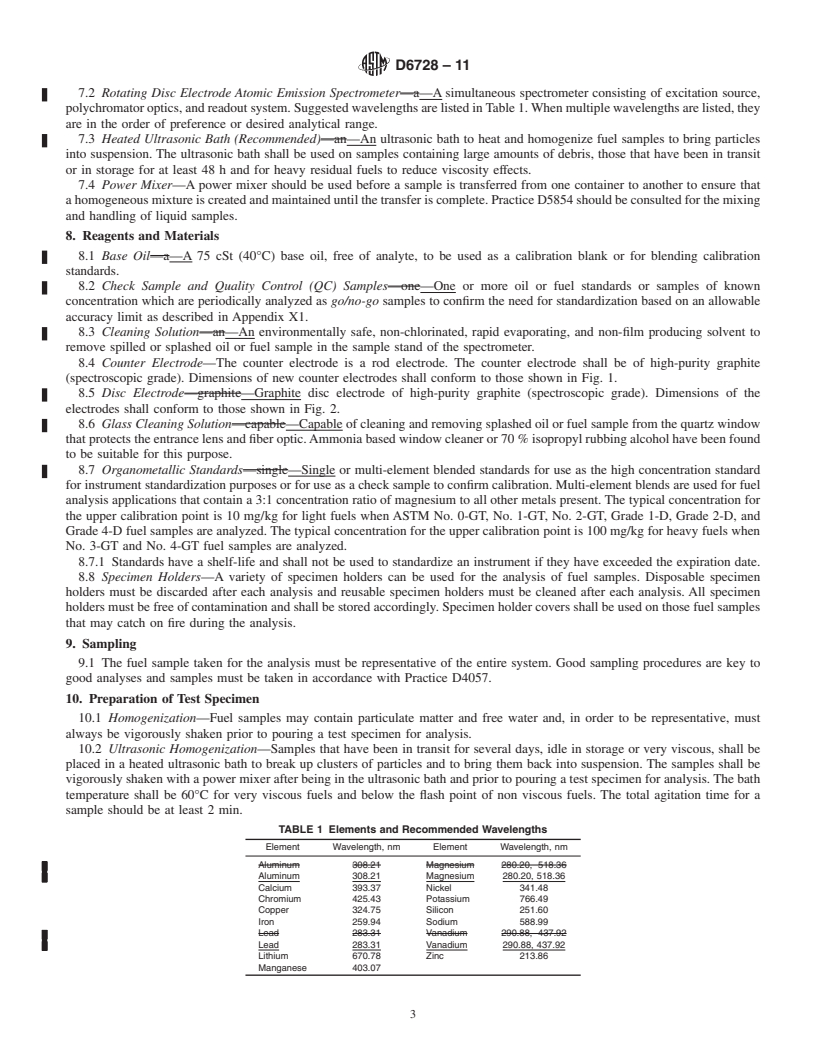

TABLE 1 Elements and Recommended Wavelengths

3.2.3 contaminant, n—material in a fuel sample that may

cause ash deposition or high temperature corrosion. Element Wavelength, Element Wavelength, nm

nm

3.2.4 graphite disc electrode, n—a soft form of the element

Aluminum 308.21 Mag

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6728–01 (Reapproved 2006) Designation:D6728–11

Standard Test Method for

Determination of Contaminants in Gas Turbine and Diesel

Engine Fuel by Rotating Disc Electrode Atomic Emission

1

Spectrometry

This standard is issued under the fixed designation D6728; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of contaminants and materials as a result of corrosion in gas turbine or diesel

engine fuels by rotating disc electrode atomic emission spectroscopy (RDE-AES).

1.1.1 The test method is applicable to ASTM Grades 0-GT, 1-GT, 2-GT, 3-GT, and 4-GT gas turbine fuels and Grades Low

Sulfur No. 1-D, Low Sulfur No. 2-D, No. 1-D, No. 2-D, and No. 4-D diesel fuel oils.

1.1.2 This test method provides a rapid at-site determination of contamination and corrosive elements ranging from fractions

of mg/kg to hundreds of mg/kg in gas turbine and diesel engine fuels so the fuel quality and level of required treatment can be

determined.

1.1.3 Thistestmethodusesoil-solublemetalsforcalibrationanddoesnotpurporttoquantitativelydetermineordetectinsoluble

particles.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parenthesesNo other units of

measurement are for information only.included in this standard. The preferred units are mg/kg (ppm by mass).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D975 Specification for Diesel Fuel Oils

D2880 Specification for Gas Turbine Fuel Oils

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D5854 Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical

Measurement System Performance

3. Terminology

3.1 Definitions:

3.1.1 burn, vt—in emission spectroscopy,tovaporizeandexciteaspecimenwithsufficientenergytogeneratespectralradiation.

3.1.2 calibration, n—the determination of the values of the significant parameters by comparison with values indicated by a set

of reference standards.

3.1.3 calibration curve, n—the graphical or mathematical representation of a relationship between the assigned (known) values

of standards and the measured responses from the measurement system.

3.1.4 calibration standard, n—a standard having an accepted value (reference value) for use in calibrating a measurement

instrument or system.

3.1.5 detection limit, n—the smallest concentration of an element that can be measured for specific analysis conditions and data

collection periods.

3.1.6 emission spectroscopy, n—measurement of energy spectrum emitted by or from an object under some form of energetic

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.03 on

Elemental Analysis.

Current edition approved MayOct. 1, 2006.2011. Published June 2006.November 2011. Originally approved in 2001. Last previous edition approved in 20012006 as

D6728–01.D6728–01(2006). DOI: 10.1520/D6728-01R06.10.1520/D6728-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6728–11

stimulation; for example, light, electrical discharge, and so forth.

3.2 DescriptionDefinitions of Terms Specific to This Standard:

3.2.1 arc discharge, n—a self-sustaining, high current density, high temperature discharge uniquely characterized by a cathode

fall nearly equal to the ionization potential of the gas or vapor in which it exists.

3.2.2 check sample, n—a reference material usually prepared by a single labo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.