ASTM F1956-99(2005)

(Specification)Standard Specification for Rescue Carabiners

Standard Specification for Rescue Carabiners

ABSTRACT

This specification covers six mechanical tests, one corrosion resistance test, and the minimum performance requirements for these tests. This specification applies to carabiners designed specifically for use by rescue personnel during both training exercises and actual rescue operations. Two different types of carabiners are defined, a heavy-duty rescue carabiner and a light-duty rescue carabiner. The mechanical tests are: gate function test, gate locking mechanism function load test, major axis gate closed function load test, major axis gate closed ultimate strength test, major axis gate open ultimate strength test, and minor axis gate closed ultimate strength test. Carabiners may disengage or eject parts from the test fixture. Use a safety screen and wear safety glasses while testing.

SCOPE

1.1 This specification covers six mechanical tests, one corrosion resistance test, and the minimum performance requirements for these tests. This specification applies to carabiners designed specifically for use by rescue personnel during both training exercises and actual rescue operations. This specification does not apply to recreational use carabiners.

1.2 Two different types of carabiners are defined in this specification, a heavy-duty rescue carabiner and a light-duty rescue carabiner.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 Tests contained herein are destructive in nature. Carabiners subjected to any of these tests shall not be used in any way after testing except in evaluation the results of such testing.

1.5 This specification does not imply approval of any method of use of rescue carabiners. In addition, the tests described are laboratory tests and do not duplicate field conditions. Furthermore, the test load values contained herein are not to be interpreted as the forces which a rescue carabiner may be subjected to, or may be expected to sustain, in actual field use.

1.6 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1956 −99(Reapproved 2005)

Standard Specification for

Rescue Carabiners

This standard is issued under the fixed designation F1956; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E4 Practices for Force Verification of Testing Machines

1.1 This specification covers six mechanical tests, one

3. Terminology

corrosion resistance test, and the minimum performance re-

3.1 Definitions:

quirements for these tests. This specification applies to cara-

3.1.1 carabiner—a load-bearing, connective device with a

biners designed specifically for use by rescue personnel during

self-closing gate.

both training exercises and actual rescue operations. This

3.1.2 heavy-duty rescue carabiner—a carabiner that meets

specification does not apply to recreational use carabiners.

the specifications for a heavy-duty rescue carabiner as defined

1.2 Two different types of carabiners are defined in this

in Section 8.

specification, a heavy-duty rescue carabiner and a light-duty

3.1.3 light-duty rescue carabiner—a carabiner that meets

rescue carabiner.

the specifications for a light-duty rescue carabiner as defined in

1.3 The values stated in SI units are to be regarded as the

Section 8.

standard.

3.1.4 locking carabiner—a carabiner with a locking mecha-

1.4 Tests contained herein are destructive in nature. Cara-

nism which reduces the possibility of a gate being opened

biners subjected to any of these tests shall not be used in any

inadvertently. A locking mechanism requires at least two

way after testing except in evaluation the results of such

different consecutive manual actions to open the gate (see

testing.

Appendix X2).

1.5 This specification does not imply approval of any

3.1.5 non-locking carabiner—any carabiner that does not

method of use of rescue carabiners. In addition, the tests

have a locking mechanism that reduces the possibility of a gate

described are laboratory tests and do not duplicate field

being opened inadvertently.

conditions. Furthermore, the test load values contained herein

3.1.6 rescue carabiner—a carabiner intended for life sup-

are not to be interpreted as the forces which a rescue carabiner

port in rescue systems. It may be classified as heavy-type or

may be subjected to, or may be expected to sustain, in actual

light duty.

field use.

3.1.7 ultimate strength—the maximum force sustained by a

1.6 This standard may involve hazardous materials,

carabiner during an ultimate force test, prior to failure.

operations, and equipment. This standard does not purport to

3.1.7.1 failure—the point at which some part of the cara-

address all of the safety concerns, if any, associated with its

biner physically breaks or distorts to an extent that the test

use. It is the responsibility of the user of this standard to

members are released.

establish appropriate safety and health practices and deter-

mine the applicability of regulatory limitations prior to use.

4. Significance and Use

2. Referenced Documents 4.1 Gate Function Load Test—This test verifies that the gate

2 can be opened (with the gate locking mechanism in the

2.1 ASTM Standards:

unlocked position) and that the gate can not be opened (with

B117 Practice for Operating Salt Spray (Fog) Apparatus

the gate locking mechanism in the locked position) while

loaded with Function Test Force #1 along the major axis.

This specification is under the jurisdiction ofASTM Committee F32 on Search

4.2 Gate Locking Mechanism Function Load Test—This test

and Rescue and is the direct responsibility of Subcommittee F32.01 on Equipment,

Testing, and Maintenance.

verifies that the gate locking mechanism can be unlocked, after

Current edition approved April 1, 2005. Published April 2005. Originally

Function Test Force #2 has been applied along the major axis

approved in 1999. Last previous edition approved in 1999 as F1956 - 99. DOI:

and released.

10.1520/F1956-99R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.3 Major Axis Gate Closed Function Load Test—This test

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

verifies that the gate functions as originally intended, after

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Function Test Force #3 has been applied and released.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1956−99 (2005)

4.4 Major Axis Gate Closed Ultimate Strength Test—This

test is intended to show the ultimate strength of the carabiner

in the major axis with the gate closed.

4.5 Major Axis Gate Open Ultimate Strength Test—This test

is intended to show the ultimate strength of the carabiner in the

major axis with the gate open.

4.6 Minor Axis Gate Closed Ultimate Strength Test—This

test is intended to show the ultimate strength of the carabiner

in the minor axis with the gate closed.

4.7 Corrosion Test—This test is intended to verify that the

carabiner is produced from a corrosion-resistant material, or

adequately covered with a protective coating.

5. Apparatus and Conditions

5.1 Tensile Test Machine—Thetensiontestingmachineshall

be maintained in good operation condition, used only in the

proper loading range, and calibrated periodically in accordance

with the latest revision of Practices E4.

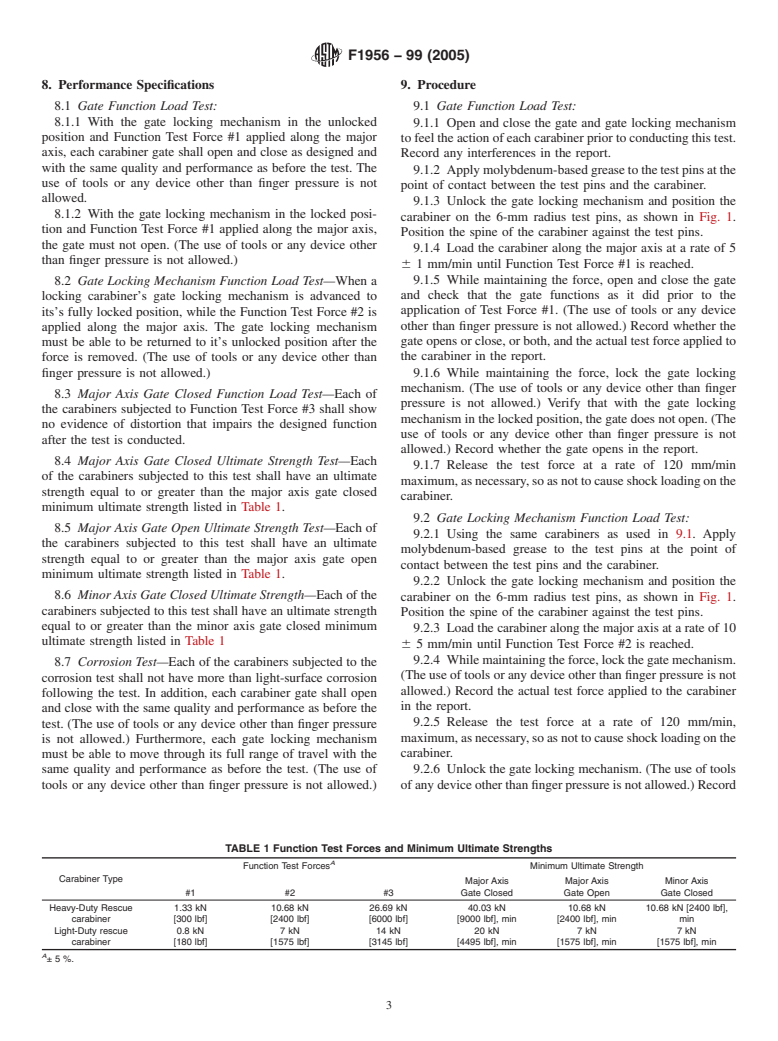

FIG. 2Test Fixture

5.2 Test Fixtures and Supplies:

5.2.1 There are four test pins required, two test pins with 6

6 0.05-mm radii and two test pins with 5 6 0.05-mm radii.

NOTE 1—Test pin cross section is not required to be round. Any cross

Test pins must be AISI SAE Type 01 Tool Steel (commonly

section necessary to prevent test pin failure or any design to prevent test

purchased as 01 Drill Rod) heat treated to a minimum

pin rotation is acceptable, as long as the contact point (between test pin

Rockwell hardness, C scale 60. The mean surface roughness,

and carabiner) of the test pin has the specified radius, material type,

Ra must not exceed 0.8 µm and the peak to valley height.

hardness, and surface roughness.

Rmax, must not exceed 6.3 µm. The fixture must be designed

5.2.2 Molybdenum-Based Grease.

to prevent the test pins from rotating and so that the carabiner

5.3 Test Conditions:

isfreetolocateitselfonthetestpinswhenforceisapplied.See

5.3.1 The ambient temperature, test samples, test fixture,

Figs. 1 and 2.

and supplies shall be between 15 and 23°C [59 and 73°F].

5.3.2 All six mechanical tests must be conducted with the

force applied parallel to the gravitational pull of the earth.

6. Hazards

Carabiners may disengage or eject parts from the test fixture.

Use a safety screen and wear safety glasses while testing.

Do not perform these tests alone.

7. Sampling

7.1 Sample Selection—Randomly select the carabiners in

accordance with 7.2.2. Each user of this test method may

specify the lot size from which the carabiners are to be

selected.

7.2 Number of Samples:

7.2.1 The same number of carabiners must be used for each

of the tests in this specification.

7.2.2 A minimum of five carabiners will be used, in

sequence, for the Gate Function Load Test, Gate Locking

Mechanism Function Load Test, Major Axis Gate Closed

Function Load Test, and Major Axis Gate Closed Ultimate

Strength Test. A minimum of five carabiners will be used for

the MajorAxis Gate Open Ultimate Strength Test.Aminimum

of five carabiners will be used for the MinorAxis Gate Closed

Ultimate Strength Test. A minimum of five carabiners will be

used for the Corrosion Test.

7.2.3 Label the randomly selected carabiners 1 through X

FIG. 1Major Axis Test Setup (X being the total number of carabiners selected).

F1956−99 (2005)

8. Performance Specifications 9. Procedure

8.1 Gate Function Load Test:

9.1 Gate Function Load Test:

8.1.1 With the gate locking mechanism in the unlocked

9.1.1 Open and close the gate and gate locking mechanism

position and Function Test Force #1 applied along the major to feel the action of each carabiner prior to conducting this test.

axis, each carabiner gate shall open and close as designed and

Record any interferences in the report.

with the same quality and performance as before the test. The

9.1.2 Applymolybdenum-basedgreasetothetestpinsatthe

use of tools or any device other than finger pressure is not

point of contact between the test pins and the carabiner.

allowed.

9.1.3 Unlock the gate locking mechanism and position the

8.1.2 With the gate locking mechanism in the locked posi-

carabiner on the 6-mm radius test pins, as shown in Fig. 1.

tion and Function Test Force #1 applied along the major axis,

Position the spine of the carabiner against the test pins.

the gate must not open. (The use of tools or any device other

9.1.4 Load the carabiner along the major axis at a rate of 5

than finger pressure is not allowed.)

6 1 mm/min until Function Test Force #1 is reached.

9.1.5 While maintaining the force, open and close the gate

8.2 Gate Locking Mechanism Function Load Test—When a

and check that the gate functions as it did prior to the

locking carabiner’s gate locking mechanism is advanced to

application of Test Force #1. (The use of tools or any device

its’s fully locked position, while the Function Test Force #2 is

other than finger pressure is not allowed.) Record whether the

applied along the major axis. The gate locking mechanism

gate opens or close, or both, and the actual test force applied to

must be able to be returned to it’s unlocked position after the

the carabiner in the report.

force is removed. (The use of tools or any device other than

finger pressure is not allowed.) 9.1.6 While maintaining the force, lock the gate locking

mechanism. (The use of tools or any device other than finger

8.3 Major Axis Gate Closed Function Load Test—Each of

pressure is not allowed.) Verify that with the gate locking

the carabiners subjected to Function Test Force #3 shall show

mechanism in the locked position, the gate does not open. (The

no evidence of distortion that impairs the designed function

use of tools or any device other than finger pressure is not

after the test is conducted.

allowed.) Record whether the gate opens in the report.

8.4 Major Axis Gate Closed Ultimate Strength Test—Each

9.1.7 Release the test force at a rate of 120 mm/min

of the carabiners subjected to this test shall have an ultimate

maximum,asnecessary,soasnottocauseshockloadingonthe

strength equal to or greater than the major axis gate closed

carabiner.

minimum ultimate strength listed in Table 1.

9.2 Gate Locking Mechanism Function Load Test:

8.5 Major Axis Gate Open Ultimate Strength Test—Each of

9.2.1 Using the same carabiners as used in 9.1. Apply

the carabiners subjected to this test shall have an ultimate

molybdenum-based grease to the test pins at the point of

strength equal to or greater than the major axis gate open

contact between the test pins and the carabiner.

minimum ultimate strength listed in Table 1.

9.2.2 Unlock the gate locking mechanism and position the

8.6 Minor Axis Gate Closed Ultimate Strength—Each of the

carabiner on the 6-mm radius test pins, as shown in Fig. 1.

carabiners subjected to this test shall have an ultimate strength

Position the spine of the carabiner against the test pins.

equal to or greater than the minor axis gate closed minimum

9.2.3 Load the carabiner along the major axis at a rate of 10

ultimate strength listed in Table 1

6 5 mm/min until Function Test Force #2 is reached.

9.2.4 Whilemaintainingtheforce,lockthegatemechanism.

8.7 Corrosion Test—Each of the carabiners subjected to the

(The use of tools or any device other than finger pressure is not

corrosion test shall not have more than light-surface corrosion

allowed.) Record the actual test force applied to the carabiner

following the test. In addition, each carabiner gate shall open

in the report.

and close with the same quality and performance as before the

9.2.5 Release the test force at a rate of 120 mm/min,

test. (The use of tools or any device other than finger pressure

maximum,asnecessary,soasnottocauseshockloadingonthe

is not allowed.) Furthermore, each gate locking mechanism

carabiner.

must be able to move through its full range of travel with the

same quality and performance as before the test. (The use of 9.2.6 Unlock the gate locking mechanism. (The use of tools

tools or any device other than finger pressure is not allowed.) ofanydeviceotherthanfingerpressureisnotallowed.)Record

TABLE 1 Function Test Forces and Minimum Ultimate Strengths

A

Function Test Forces Minimum Ultimate Strength

Carabiner Type

Major Axis Major Axis Minor Axis

#1 #2 #3 Gate Closed Gate Open Gate Closed

Heavy-Duty Rescue 1.33 kN 10.68 kN 26.69 kN 40.03 kN 10.68 kN 10.68 kN [2400 lbf],

carabiner [300 lbf] [2400 lbf] [6000 lbf] [9000 lbf], min [2400 lbf], min min

Light-Duty rescue 0.8 kN 7kN 14 kN 20 kN 7kN 7kN

carabiner [180 lbf] [1575 lbf] [3145 lbf] [4495 lbf], min [1575 lbf], min [1575 lbf], min

A

±5%.

F1956−99 (2005)

whether the gate locking mechanism can be returned to it’s 9.7.1 Verifythatthegatelockingmechanismisinthelocked

unlocked position in the report. position. Conduct a 50-h salt spray test in accordance with

Practice B117.

9.3 Major Axis Gate Closed Function Load Test:

9.7.2 After the test, visually inspect the carabiner for signs

9.3.1 Using the same carabiners as used in 9.1 and 9.2,

of corrosion. Open and close the gate and check that the gate

apply molybdenum-based grease to the test pins at the point of

functions as it did prior to the salt spray test. Move the gate

contact between the test pins and the carabiner.

locking mechanism from it’s locked position to its fully

9.3.2 Unlock the gate locking mechanism and position the

unlocked position and check that the gate locking mechanism

carabiner on the 6-mm radius test pins, as shown in Fig. 1.

functions as it did prior to the sale spray test.

Position the spine of the carabiner against the test pins.

9.7.3 Record whether there is light surface-type corrosion,

9.3.3 Load the carabiner along the major axis at a rate of 20

whether the gate functions as it did prior to the salt spray test,

6 5 mm/min until Function Test Force #3 is reached.

and whether the gate locking mechanism functions as it did

9.3.4 Release the test force at a rate of 120 mm/min,

prior to the salt spray test in the report.

maximum,asnecessary,soasnottocauseshockloadingonthe

carabiner.

10. Certification

9.3.5 Open and close the gate and check the carabiner for

10.1 When specified in th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.