ASTM D7961-17

(Practice)Standard Practice for Calibrating U-tube Density Cells over Large Ranges of Temperature and Pressure

Standard Practice for Calibrating U-tube Density Cells over Large Ranges of Temperature and Pressure

SIGNIFICANCE AND USE

5.1 This practice covers a series of methods offered to aid users in calibrating U-tube density meters to provide a measure of density and an associated expanded uncertainty. The reference density, as obtained from either an equation of state (EOS) or CRM has an uncertainty that arises from the uncertainty of the measurements of temperature, pressure, and also the chemical purity of the substance studied (origin) or for that matter of the certified reference material. This uncertainty results in an additional uncertainty for the density of these samples. Because the measurements made with U-tube density meters are not absolute, the uncertainty with which the instrument calibration is determined is directly related to the uncertainty of the density obtained.

SCOPE

1.1 This practice outlines procedures for the calibration of U-tube density cells. It is applicable to instruments capable of determining fluid density at temperatures in the range –10 °C to 200 °C and pressures from just greater than the saturation pressure to 140 MPa. The practice refers to density cells as they are utilized to make measurements of fluids primarily in the compressed-liquid state. Examples of substances for which the density can be determined with a calibrated U-tube density meter include: crude oils, gasoline and gasoline-oxygenate blends, diesel and jet fuels, hydraulic fluids, and lubricating oils.

1.2 This practice specifies a procedure for the determination of the expanded uncertainty of the density measurement.

1.3 This practice pertains to fluids with viscosities

1.4 4 The values listed in SI units are regarded as the standard, unless otherwise stated. The SI unit for mass density is kilograms per cubic metre (kg·m-3) and can be given as grams per cubic centimetre (g·cm-3).

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7961 − 17

Standard Practice for

Calibrating U-tube Density Cells over Large Ranges of

1

Temperature and Pressure

This standard is issued under the fixed designation D7961; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This practice outlines procedures for the calibration of 2.1 ASTM Standards:

U-tube density cells. It is applicable to instruments capable of D1193 Specification for Reagent Water

determining fluid density at temperatures in the range –10 °C D4052 Test Method for Density, Relative Density, and API

to 200 °C and pressures from just greater than the saturation Gravity of Liquids by Digital Density Meter

pressure to 140 MPa. The practice refers to density cells as D5002 Test Method for Density and Relative Density of

they are utilized to make measurements of fluids primarily in Crude Oils by Digital Density Analyzer

the compressed-liquid state. Examples of substances for which D6792 Practice for Quality Management Systems in Petro-

the density can be determined with a calibrated U-tube density leum Products, Liquid Fuels, and Lubricants Testing

meter include: crude oils, gasoline and gasoline-oxygenate Laboratories

blends, diesel and jet fuels, hydraulic fluids, and lubricating D7483 TestMethodforDeterminationofDynamicViscosity

oils. and Derived Kinematic Viscosity of Liquids by Oscillat-

ing Piston Viscometer

1.2 This practice specifies a procedure for the determination

D7578 Guide for Calibration Requirements for Elemental

of the expanded uncertainty of the density measurement.

Analysis of Petroleum Products and Lubricants

1.3 This practice pertains to fluids with viscosities < 1 Pa·s

D7740 Practice for Optimization, Calibration, and Valida-

(1000 centipoise) at ambient conditions.

tion ofAtomicAbsorption Spectrometry for MetalAnaly-

sis of Petroleum Products and Lubricants

1.4 4 The values listed in SI units are regarded as the

standard, unless otherwise stated. The SI unit for mass density

-3 3. Terminology

is kilograms per cubic metre (kg·m ) and can be given as

-3

grams per cubic centimetre (g·cm ). 3.1 Definitions:

3.1.1 calibration, n—set of operations that establishes the

1.5 This standard does not purport to address all of the

relationship between the reference density of standards and the

safety concerns, if any, associated with its use. It is the

corresponding density reading of the instrument. D4052

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1.2 certified reference material (CRM), n—reference ma-

bility of regulatory limitations prior to use. terial one or more of whose property values are certified by a

1.6 This international standard was developed in accor- technically valid procedure, accompanied by a traceable cer-

dance with internationally recognized principles on standard- tificate or other documentation that is issued by a certifying

ization established in the Decision on Principles for the body. [D02.94] D6792, [D02.03] D7578

Development of International Standards, Guides and Recom-

3.1.3 density (ρ), n—mass per unit volume at a specified

mendations issued by the World Trade Organization Technical

temperature. [D02.07] D7483

Barriers to Trade (TBT) Committee.

3.1.4 standard reference material (SRM), n—trademark for

reference materials certified by NIST. [D02.03] D7740

1

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

2

mittee D02.04.0D on Physical and Chemical Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2017. Published January 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2015. Last previous edition approved in 2015 as D7961 – 15. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7961-17. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

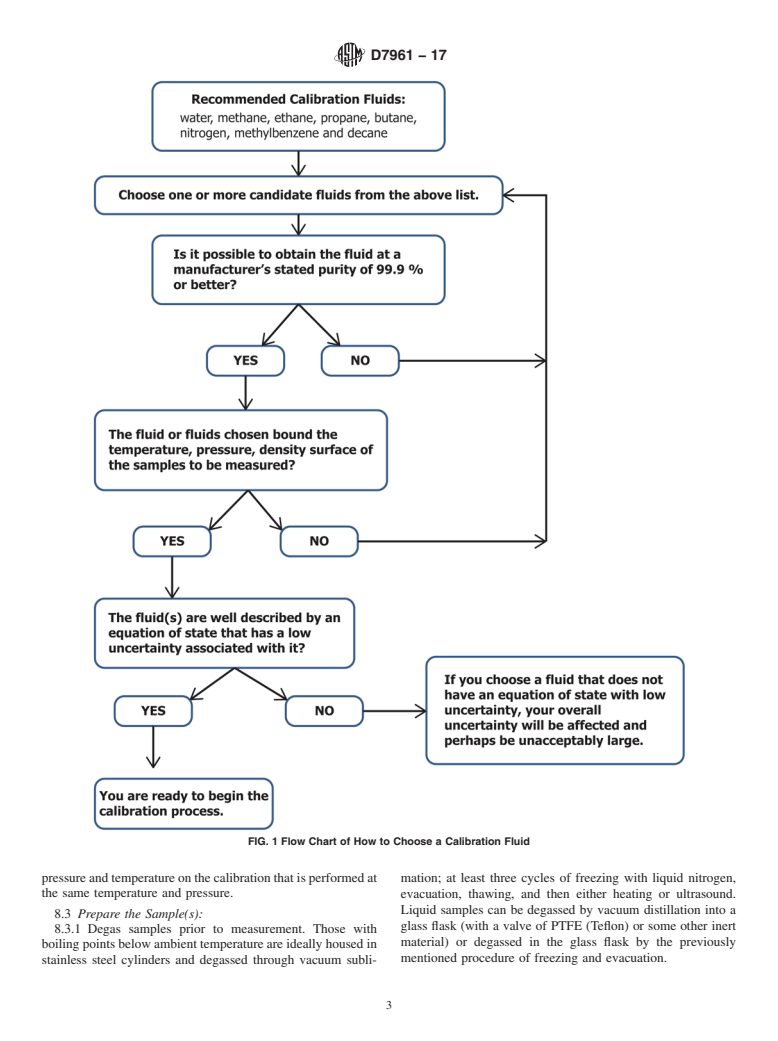

D7961 − 17

4. Summary of Practice 7. Reagents

7.1 The best calibration fluids are those referred to as

4.1 This practice details the considerations and procedures

Certified Reference Materials (CRM) which have correlations

necessaryinordertocompleteacalibrationofaU-tubedensity

for density over the temperature and pressure range

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7961 − 15 D7961 − 17

Standard Practice for

Calibrating U-tube Density Cells over Large Ranges of

1

Temperature and Pressure

This standard is issued under the fixed designation D7961; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice outlines procedures for the calibration of U-tube density cells. It is applicable to instruments capable of

determining fluid density at temperatures in the range –10 °C to 200 °C and pressures from just greater than the saturation pressure

to 140 MPa. The practice refers to density cells as they are utilized to make measurements of fluids primarily in the

compressed-liquid state. Examples of substances for which the density can be determined with a calibrated U-tube density meter

include: crude oils, gasoline and gasoline-oxygenate blends, diesel and jet fuels, hydraulic fluids, and lubricating oils.

1.2 This practice specifies a procedure for the determination of the expanded uncertainty of the density measurement.

1.3 This practice pertains to fluids with viscosities < 1 Pa·s (1000 centipoise) at ambient conditions.

1.4 4 The values listed in SI units are regarded as the standard, unless otherwise stated. The SI unit for mass density is kilograms

-3 -3

per cubic metre (kg·m ) and can be given as grams per cubic centimetre (g·cm ).

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

D5002 Test Method for Density and Relative Density of Crude Oils by Digital Density Analyzer

D6792 Practice for Quality System in Petroleum Products and Lubricants Testing Laboratories

D7483 Test Method for Determination of Dynamic Viscosity and Derived Kinematic Viscosity of Liquids by Oscillating Piston

Viscometer

D7578 Guide for Calibration Requirements for Elemental Analysis of Petroleum Products and Lubricants

D7740 Practice for Optimization, Calibration, and Validation of Atomic Absorption Spectrometry for Metal Analysis of

Petroleum Products and Lubricants

3. Terminology

3.1 Definitions:

3.1.1 calibration, n—set of operations that establishes the relationship between the reference density of standards and the

corresponding density reading of the instrument. D4052

3.1.2 certified reference material (CRM), n—reference material one or more of whose property values are certified by a

technically valid procedure, accompanied by a traceable certificate or other documentation that is issued by a certifying body.

[D02.94] D6792, [D02.03] D7578

3.1.3 density (ρ), n—mass per unit volume at a specified temperature. [D02.07] D7483

3.1.4 standard reference material (SRM), n—trademark for reference materials certified by NIST. [D02.03] D7740

1

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.04 on Hydrocarbon Analysis.

Current edition approved Dec. 1, 2015Jan. 1, 2017. Published February 2016January 2017. Originally approved in 2015. Last previous edition approved in 2015 as

D7961 – 15. DOI: 10.1520/D7961-15.10.1520/D7961-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

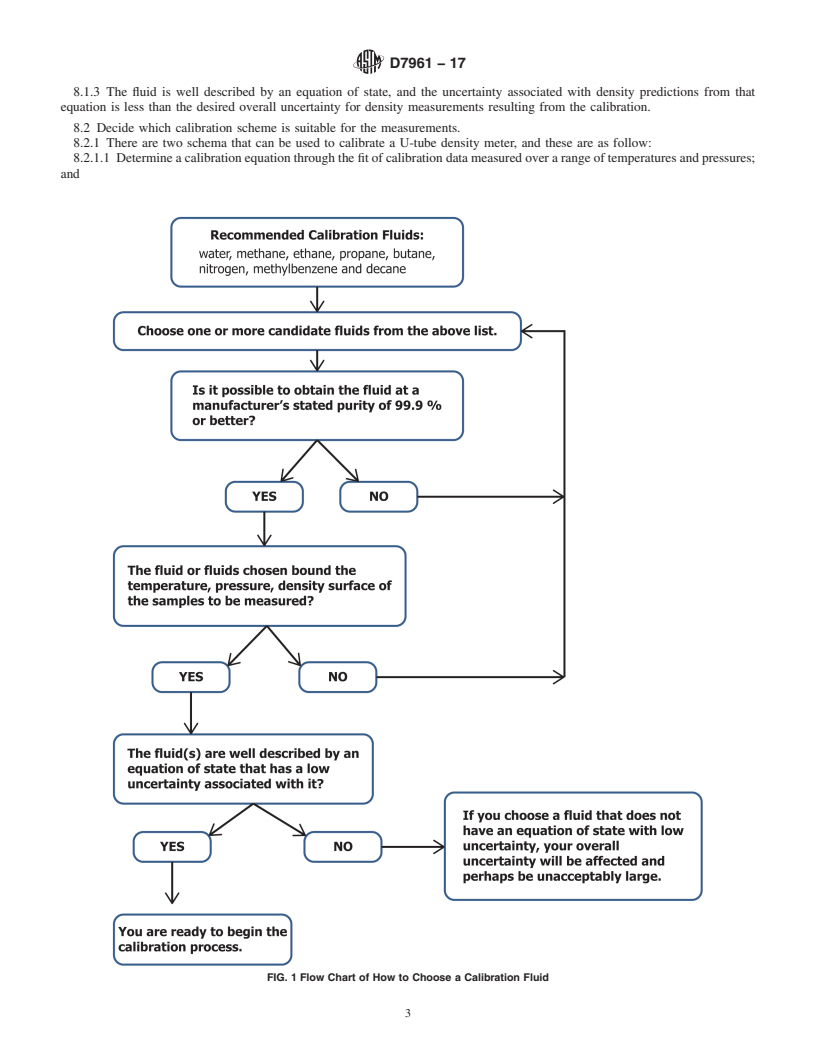

D7961 − 17

4. Summary of Practice

4.1 This practice details the considerations and procedures necessary in order to complete a calibration of a U-tube density meter

and an associated uncertainty analysis. The principal objective of this practice is to provide the user with information as to how

different aspects of the calibration procedure contribute to the over

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.