ASTM F390-98

(Test Method)Standard Test Method for Sheet Resistance of Thin Metallic Films With a Collinear Four-Probe Array

Standard Test Method for Sheet Resistance of Thin Metallic Films With a Collinear Four-Probe Array

SCOPE

1.1 This test method covers the measurement of the sheet resistance of metallic thin films with a collinear four-probe array. It is intended for use with rectangular metallic films between 0.01 and 100 [mu]m thick, formed by deposition of a material or by a thinning process and supported by an insulating substrate, in the sheet resistance range from 10 to 10 [omega]/[open-box] (see 3.1.3).

1.2 This test method is suitable for referee measurement purposes as well as for routine acceptance measurements.

1.3 The values stated in Si units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: F 390 – 98

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Sheet Resistance of Thin Metallic Films With a Collinear

1

Four-Probe Array

This standard is issued under the fixed designation F 390; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope film, the quotient of the resistance, measured along the length

of the film, divided by the length, l, to width, w, ratio. The ratio

1.1 This test method covers the measurement of the sheet

l/w is the number of squares.

resistance of metallic thin films with a collinear four-probe

array. It is intended for use with rectangular metallic films

4. Summary of Test Method

between 0.01 and 100 μm thick, formed by deposition of a

4.1 A collinear four-probe array is used to determine the

material or by a thinning process and supported by an

−2

sheet resistance by passing a measured direct current through

insulating substrate, in the sheet resistance range from 10 to

4 the specimen between the outer probes and measuring the

10 V/h (see 3.1.3).

resulting potential difference between the inner probes. The

1.2 This test method is suitable for referee measurement

sheet resistance is calculated from the measured current and

purposes as well as for routine acceptance measurements.

potential values using correction factors associated with the

1.3 The values stated in Si units are to be regarded as the

geometry of the specimen and the probe spacing.

standard. The values given in parentheses are for information

4.2 This test method includes procedures for checking both

only.

the probe assembly and the electrical measuring apparatus.

1.4 This standard does not purport to address the safety

4.2.1 The spacings between the four probe tips are deter-

concerns, if any, associated with its use. It is the responsibility

mined from measurements of indentations made by the tips in

of whoever uses this standard to consult and establish appro-

a suitable surface. This test also is used to determine the

priate safety and health practices and determine the applica-

condition of the tips.

bility of regulatory limitations prior to use.

4.2.2 The accuracy of the electrical measuring equipment is

2. Referenced Documents tested by means of an analog circuit containing a known

standard resistor together with other resistors which simulate

2.1 ASTM Standards:

2

the resistance at the contacts between the probe tips and the

E 1 Specification for ASTM Thermometers

film surface.

F 388 Method for Measurement of Oxide Thickness on

Silicon Wafers and Metallization Thickness by Multiple-

5. Apparatus

3

Beam Interference (Tolansky Method)

5.1 Probe Assembly:

3. Terminology 5.1.1 Probes—The probe shaft and tip shall be constructed

of tungsten carbide, Monel, hardened tool steel, or hard copper

3.1 Definitions:

and have a conical tip with included angle of 45 to 90°.

3.1.1 thin film—a film having a thickness much smaller than

Alternatively, the tip may be formed from a platinum-

any lateral dimension, formed by deposition of a material or by

palladium alloy and resistance welded to the shaft. The tip shall

a thinning process.

have a nominal initial radius of 25 to 50 μm. In all cases all of

3.1.2 thin metallic film—a thin film composed of a material

−8

the four paths from the electrical measurement equipment

or materials with resistivity in the range from 10 to

−3

inputs to the film surface must be identical.

10 V·cm.

5.1.2 Probe Force—The probes shall be uniformly loaded

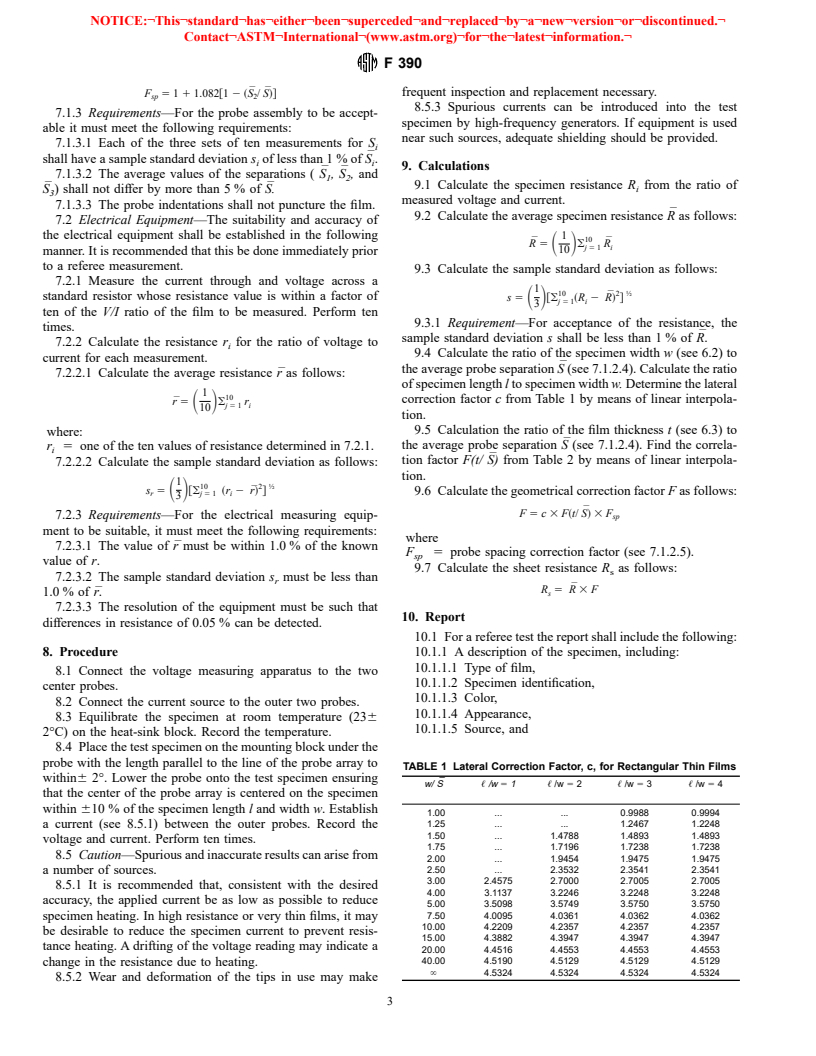

3.1.3 sheet resistance, R [V/h]—in a thin film, the ratio of

s

to exert a force sufficient to deform the metal film but

the potential gradient parallel to the current to the product of

insufficient to puncture the film. A rough guide for loading is a

the current density and the film thickness; in a rectangular thin

load of 20 g/Mohs (unit of hardness) of the film material on

each probe.

1

This test method is under the jurisdiction of ASTM Committee F-1 on

5.1.3 Probe Characteristics—The probes shall be mounted

Electronics and is the direct responsibility of Subcommittee F01.17 on Sputtered

in an insulating fixture such as a sapphire bearing in a methyl

Thin Films.

Current edition approved May 10, 1998. Published October 1998. Originally

methacrylate or hardened polystyrene block in an equally

published as F 390 – 73 T. Last previous edition F 390 – 97.

spaced linear array. The electrical insulation between adjacent

2

Annual Book of ASTM Standards, Vol 14.03.

5

3 probe points shall be at least 10 times gre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.