ASTM D4225-97

(Specification)Standard Specification for Styrene-Butadiene Sheeting

Standard Specification for Styrene-Butadiene Sheeting

SCOPE

1.1 This specification covers styrene-butadiene sheeting in thicknesses of 0.25 mm (0.01 in.) and greater. Sheeting conforming to this specification is intended for use in instrument housings and applications requiring resistance to impact. Methods of fabrication may require that the sheet be drawn or bent.

1.2 This specification covers natural and colored sheeting.

1.3 This specification covers quality requirements that include degree of orientation, amount of warpage or twist, dimensions, tolerances, and workmanship.

1.4 The values stated in SI units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.5 The following precautionary statement pertains to the test method portion only, Section 12, of this specification: This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4225 – 97

Standard Specification for

Styrene-Butadiene Sheeting

This standard is issued under the fixed designation D 4225; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 1525 Test Method for Vicat Softening Temperature of

Plastics

1.1 This specification covers styrene-butadiene sheeting in

D 1898 Practice for Sampling of Plastics

thicknesses of 0.25 mm (0.01 in.) and greater. Sheeting

D 2732 Test Method for Unrestrained Linear Thermal

conforming to this specification is intended for use in instru-

Shrinkage of Plastic Film and Sheeting

ment housings and applications requiring resistance to impact.

D 3892 Practice for Packaging/Packing of Plastics

Methods of fabrication may require that the sheet be drawn or

D 4549 Specification for Polystyrene Molding and Extru-

bent.

sion Materials (PS)

1.2 This specification covers natural and colored sheeting.

D 5033 Guide for the Development of Standards Relating to

1.3 This specification covers quality requirements that in-

the Proper Use of Recycled Plastics

clude degree of orientation, amount of warpage or twist,

2.2 Federal Standard:

dimensions, tolerances, and workmanship.

Fed. Std. No. 406, Plastics: Methods of Testing

1.4 The values stated in SI units are to be regarded as the

(Method 6051, Warpage)

standard. The SI units given in parentheses are for information

2.3 Military Standard:

only.

MIL-STD-105 Sampling Procedures and Tables for Inspec-

1.5 This specification allows for the use of recycled plastics

tion by Attributes

as defined in Guide D 5033.

1.6 The following precautionary statement pertains to the

3. Terminology

test method portion only, Section 12, of this specification: This

3.1 Definitions: Unless otherwise indicated, the terminology

standard does not purport to address the safety concerns, if

used in this specification is in accordance with definitions

any, associated with its use. It is the responsibility of the user

given in Terminology D 883.

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

4. Classification

tions prior to use.

4.1 The styrene-butadiene sheeting in accordance with this

NOTE 1—There is no similar or equivalent ISO standard.

specification is classified by Type (see Table 1) as follows:

4.1.1 Type I—Low shrinkage.

2. Referenced Documents

4.1.2 Type II—Intermediate shrinkage.

2.1 ASTM Standards:

4.1.3 Type III—High shrinkage.

D 256 Test Methods for Impact Resistance of Plastics and

4.2 The styrene-butadiene sheeting is further divided into

Electrical Insulating Materials

classes as follows:

D 618 Practice for Conditioning Plastics and Electrical

4.2.1 Class 1 - Natural

Insulating Materials for Testing

4.2.2 Class 2 - As specified by user

D 638 Test Method for Tensile Properties of Plastics

4.3 Sizes

D 883 Terminology Relating to Plastics

4.3.1 Size A: .05 by 1m.

D 1238 Test Method for Flow Rates of Thermoplastics by

4.3.2 Size B: as specified by user.

Extrusion Plastometer

4.4 The sheeting covered by this specification shall be

1 3

This specification is under the jurisdiction of ASTM Committee D-20 on Annual Book of ASTM Standards, Vol 08.02.

Plastics and is the direct responsibility of Subcommittee D20.19 on Film and Annual Book of ASTM Standards, Vol 08.03.

Sheeting. Available from Superintendent of Documents, U.S. Government Printing

Current edition approved July 10, 1997. Published April 1998. Originally Office, North Capital and H Sts., NW, Washington, DC 20401.

published as D 4225 – 83. Last previous edition D 5225 – 90. Available from Standardization Documents, Order Desk, Bldg. 4 Section D,

Annual Book of ASTM Standards, Vol 08.01. 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4225

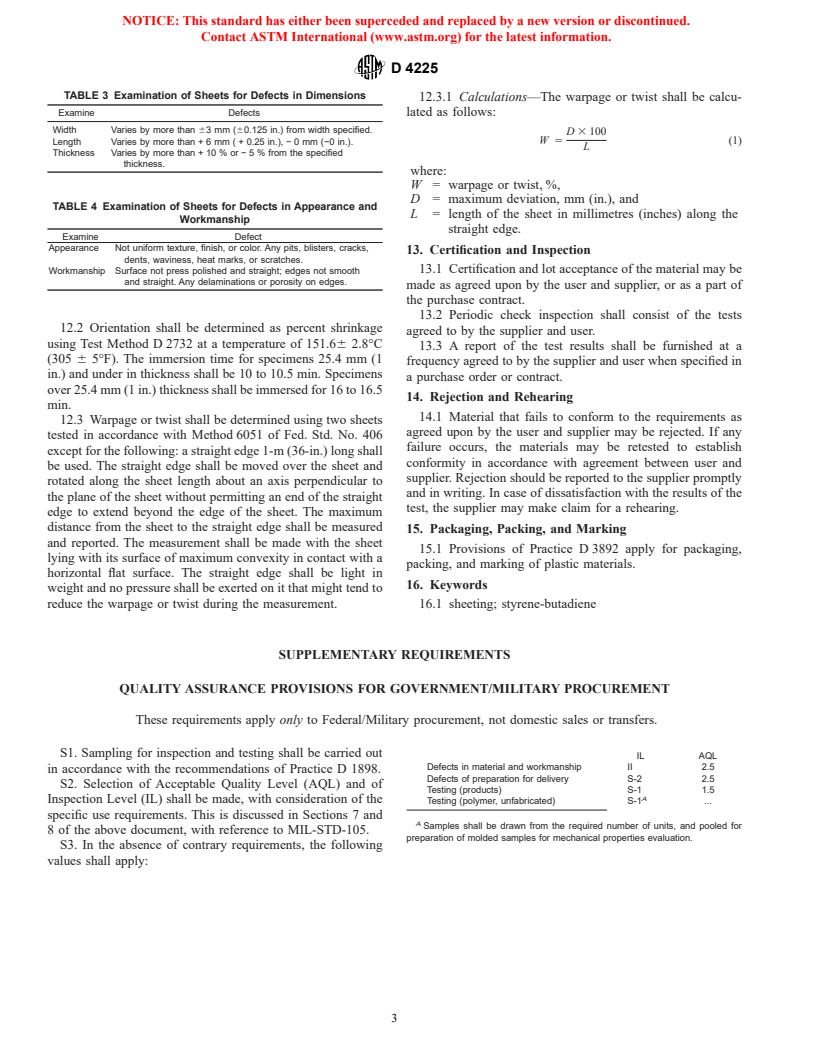

A

TABLE 1 Orientation (Percent Shrinkage)

7. Specific Requirements

Sheet Thickness Type 1 Type II Type III

7.1 Form—The material shall be furnished in the form of

mm (in.) % % %

flat rectangular sheeting of the dimensions specified.

0.25 to 0.50 less than 30 30 to 60 greater than 60

7.2 Orientation—The sheeting, when tested as specified in

(0.01 to 0.019)

12.2, shall conform to the requirements of Table 1.

0.50 to 1.0 less than 20 20 to 50 greater than 50

(0.020 to 0.039)

7.3 Warpage or Twist—Applicable only to sheets having

1.0 to 1.50 less than 20 20 to 40 greater than 40

diagonals of 1 m (36 in.) or more in length. Warpage or twist

(0.040 to 0.059)

shall not exceed the values shown in Table 2, when measured

1.50 to 2.00 less than 10 10 to 30 greater than 30

(0.060 to 0.079)

in accordance with 12.3.

2.00 to 2.54 less than 5 5 to 20 greater than 20

7.4 Color—The color shall be as specified by the user.

(0.080 to 0.10)

7.5 Dimensions and Tolerances—Unless otherwise speci-

A

Shrinkage in the sheets is an indication of orientation. The higher the

fied, the standard size of sheets shall be 0.5 by 1 m (20 by 40

shrinkage, the higher the orientation.

in.), and the tolerances on the width, length and thickness shall

identified by a document-based part numbering system as be as shown in Table 3.

follows: 7.6 Workmanship:

7.6.1 Uniformity—All sheets in the lot shall, when sub-

jected to visual examination, satisfy the color and surface finish

requirements of this specification.

7.6.2 Surface Finish—The surface shall be free from de-

fects as described in Table 4.

7.6.3 Internal Defects—The edges and cut sections shall

show none of the defects as described in Table 4.

8. Sampling

8.1 Unless otherwise agreed upon between the user and the

supplier, the materials shall be sampled in accordance with the

where:

sampling procedure prescribed in Practice D 1898. Adequate

I = Type I (low shrinkage),

statistical sampling shall be considered an acceptable alterna-

A = Size (0.5 by 1 m),

tive. A lot should consist of all items of one type, size, and class

1 = Class (natural color), and

D 4225 = ASTM standard designation number. offered for delivery at one time on one contract or order.

5. Ordering Information

9. Testing

5.1 Purchasers should select the preferred options permitted

9.1 The sheet shall be tested for the applicable characteris-

herein and include the following information in the purchase

tics listed in Table 1 and Table 2 in accordance with the test

contract.

methods specified herein, for each lot submitted for inspection.

5.1.1 Title, number, and date of this specification.

10. Specimen Preparation

5.1.2 Classification according to Specification D 4549 of the

material to be used to manufacture the sheet (see 6.1). 10.1 Test specimens shall be molded as specified in the test

5.1.3 Lengt

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.