ASTM D6364-06(2011)

(Test Method)Standard Test Method for Determining Short-Term Compression Behavior of Geosynthetics

Standard Test Method for Determining Short-Term Compression Behavior of Geosynthetics

SIGNIFICANCE AND USE

The compression behavior test for geosynthetics is intended to be an index test. It is anticipated that the results of the compression behavior test will be used to evaluate product. The results of the analyses may also be used to compare the relative compressive yield points of materials that exhibit a detectable compressive yield point. It is anticipated that this test will be used for quality control testing to evaluate uniformity and consistency within a lot or between lots where sample geometry factors (for example, thickness) or materials may have changed.

Note 1—This is a one-dimensional test for compressive loading of a geosynthetic(s) in one plane.

The compressive yield point of geosynthetics may be evaluated from the stress/strain relationship. Many materials exhibit compressive deformation but may not show a distinct compressive yield point.

This test method can be used to evaluate the short-term stress/strain behavior of geosynthetics under compressive stress while loaded at a constant rate of deformation.

This test method may be used for acceptance testing of commercial shipments of geosynthetics but caution is advised because interlab testing is incomplete.

In the case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, two parties should take a group of test specimens from material shipped to the project. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using the Student's t-test for unpaired data and an acceptable probability level chosen by the two parties before the testing is begun. If bias is found, either its ca...

SCOPE

1.1 This test method covers the procedures for evaluation of the deformations of a geosynthetic or combination of geosynthetics (that is, geocomposite (excluding geotextiles, geomembranes, and geosynthetic clay liners)) under short-term compressive loading. This test method is strictly an index test method to be used to verify the compressive strength consistency of a given manufactured geosynthetic(s). Results from this test method should not be considered as an indication of actual or long-term performance of the geosynthetic(s) in field applications.

1.2 Since these geosynthetics may experience muti-directional compressive loadings in the field, this test method will not show actual field performance and should not be used for this specific objective. The evaluator of the results should also recognize that the determination of the short-term single plane compressive behavior of geosynthetics does not reflect the installed performance of synthetic drainage systems and, therefore, should not be used as the only method of product specification or performance with respect to synthetic drainage systems.

1.3 This standard does not purport to address all the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate health and safety practices and to determine the applicability of regulatory limitations prior to use.

1.4 The values in SI units are to be regarded as the standard. Values in inch-pound units are provided in parentheses for information.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6364 − 06 (Reapproved 2011)

Standard Test Method for

Determining Short-Term Compression Behavior of

Geosynthetics

This standard is issued under the fixed designation D6364; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4354Practice for Sampling of Geosynthetics and Rolled

Erosion Control Products(RECPs) for Testing

1.1 Thistestmethodcoverstheproceduresforevaluationof

D4439Terminology for Geosynthetics

the deformations of a geosynthetic or combination of geosyn-

D5199Test Method for Measuring the Nominal Thickness

thetics (that is, geocomposite (excluding geotextiles,

of Geosynthetics

geomembranes,andgeosyntheticclayliners))undershort-term

D7001Specification for Geocomposites for Pavement Edge

compressive loading. This test method is strictly an index test

Drains and Other High-Flow Applications

method to be used to verify the compressive strength consis-

tency of a given manufactured geosynthetic(s). Results from

3. Terminology

this test method should not be considered as an indication of

actual or long-term performance of the geosynthetic(s) in field

3.1 Definitions:

applications.

3.1.1 compressive deformation, [L], n—thedecreaseingage

length produced in the test specimen by a compressive load.

1.2 Since these geosynthetics may experience muti-

directional compressive loadings in the field, this test method

3.1.2 compressive strain, [nd], n—the ratio of compressive

will not show actual field performance and should not be used

deformation to the gage length of the test specimen.

for this specific objective. The evaluator of the results should

3.1.3 gage length, [L], n—in compression testing, the mea-

also recognize that the determination of the short-term single

sured thickness of the test specimen under specified compres-

plane compressive behavior of geosynthetics does not reflect

sional force, expressed in units of length prior to compressive

the installed performance of synthetic drainage systems and,

loading. (D5199)

therefore, should not be used as the only method of product

specification or performance with respect to synthetic drainage

3.1.4 geocomposite, n—a product fabricated from any com-

systems.

bination of geosynthetics with geotechnical materials or other

1.3 This standard does not purport to address all the safety synthetics that is used in a geotechnical application.

concerns, if any, associated with its use. It is the responsibility

3.1.5 geosynthetic, n—a planar product manufactured from

of the user of this standard to establish appropriate health and

polymeric material used with foundation, soil, rock, earth, or

safety practices and to determine the applicability of regula-

any other geotechnical engineering-related material as an

tory limitations prior to use.

integral part of a man-made project, structure, or system.

1.4 ThevaluesinSIunitsaretoberegardedasthestandard.

(D4439)

Values in inch-pound units are provided in parentheses for

3.1.6 index test, n—a test procedure that may contain a

information.

known bias but that may be used to establish an order for a set

2. Referenced Documents of specimens with respect to the property of interest. (D4439)

2.1 ASTM Standards:

3.1.7 yield point, n—the first point on the load-deformation

curve at which an increase in deformation occurs without a

corresponding increase in load.

This test method is under the jurisdiction of ASTM Committee D35 on

3.1.7.1 Discussion—Some geosynthetics do not exhibit an

GeosyntheticsandisthedirectresponsibilityofSubcommitteeD35.01onMechani-

cal Properties. exact yield point. The tested geosynthetic may exhibit a less

Current edition approved Oct. 1, 2011. Published October 2011. Originally

steep slope at yield. In addition, it should be stated that the

approved in 1999. Last previous edition approved in 2006 as D6364-06. DOI:

yield point may also be the ultimate strength of the geosyn-

10.1520/D6364-06R11.

2 thetic.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.8 Fordefinitionsoftermsrelatingtogeotextiles,referto

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Terminology D4439

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6364 − 06 (2011)

NOTE 2—Some loading mechanisms, especially the older models, do

4. Summary of Test Method

not have the capability of adjusting the rate of deformation to the specific

4.1 Specimensaremountedbetweenparallelplatesinaload

rate required. For these instruments, the user and producer should

frame. Compressive loads are applied at a constant rate of

establish mutually agreed upon testing rates. However, the rate of

deformation selected should not be greater than 10% on the nominal

crosshead movement. The deformations are recorded as a

thickness of the test specimen per minute or 1 mm/min, whichever is

function of load. The compressive stress and strain are evalu-

greater.

atedandplotted.Thecompressiveyieldpointisevaluatedfrom

6.2 Fixed Plate—The fixed plate shall be larger than the

the stress/strain relationship for those materials that exhibit a

specimen to be tested. It shall also be flat, smooth, and

detectable compressive yield point.

completely and uniformly supported.

5. Significance and Use

NOTE 3—It is recommended that the minimum fixed plate width be

equaltothesamplewidthplustwicethethicknessofthetestsample.This

5.1 The compression behavior test for geosynthetics is

should support the sample through the range of deformation and prevent

intended to be an index test. It is anticipated that the results of

draping or flexing displacement.

thecompressionbehaviortestwillbeusedtoevaluateproduct.

6.3 Movable Plate—Themovableplateshallbeofsufficient

The results of the analyses may also be used to compare the

thicknessandstrengthtoprecludeanybendingduringloading.

relative compressive yield points of materials that exhibit a

It shall be parallel to the fixed plate and attached to the

detectable compressive yield point. It is anticipated that this

compression mechanism. A spherical loading block of the

test will be used for quality control testing to evaluate

suspended,self-aligningtypeisrecommended.Thedimensions

uniformity and consistency within a lot or between lots where

and shape of the movable plate shall depend on the specimen

sample geometry factors (for example, thickness) or materials

dimensions and geometry. In general, both length and width of

may have changed.

themovableplateshouldeachbeatleast20%greaterthanthe

NOTE 1—This is a one-dimensional test for compressive loading of a

length and width of the specimens.

geosynthetic(s) in one plane.

NOTE 4—Where the sample exhibits excessive surface irregularities or

5.1.1 The compressive yield point of geosynthetics may be

variationinthickness,theplatesmaybemodifiedtoaccommodatesurface

evaluated from the stress/strain relationship. Many materials

irregularities and thickness variations. This can be achieved by the

exhibit compressive deformation but may not show a distinct

insertion of a layer of hardening paste between the specimen and the

compressive yield point.

plates. The surface of the specimen may require covering with a flexible

film to inhibit the intrusion of the paste into the specimen. The hardened

5.2 This test method can be used to evaluate the short-term

paste, when fully cured, must be well adhered to the loading plates and

stress/strain behavior of geosynthetics under compressive

have compressive and shear strength properties at least a magnitude

stress while loaded at a constant rate of deformation. greater than the specimen to be tested.

6.4 Variable Plates (Required for High-Flow Products per

5.3 This test method may be used for acceptance testing of

commercial shipments of geosynthetics but caution is advised Specification D7001)— Variable inclined plates or set angled

blocks should be used to test the specimen under non-axial

because interlab testing is incomplete.

conditions. The test apparatus shall have one fixed plate and

5.3.1 In the case of a dispute arising from differences in

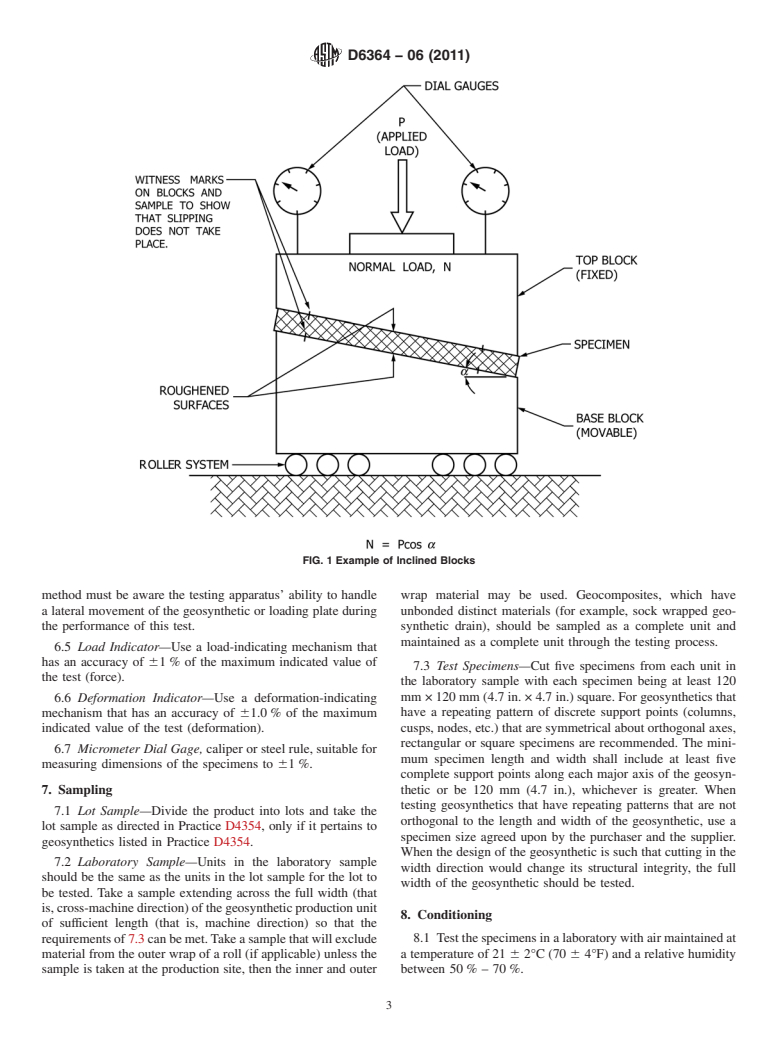

one movable plate. Fig. 1 shows set angled blocks with a

reportedtestresultswhenusingthistestmethodforacceptance

movable base block with a roller system to allow lateral

testing of commercial shipments, the purchaser and the sup-

movement of the block during deformation (see 6.4.1). The

plier should conduct comparative tests to determine if there is

baseandtopinclinedplatescanbeadjustableangleplates.The

statisticalbiasbetweentheirlaboratories.Competentstatistical

assistance is recommended for the investigation of bias. As a inclinedplatesorsetangledblocksmustmeettherequirements

as stated in 6.3 of this test method. The base and top inclined

minimum, two parties should take a group of test specimens

frommaterialshippedtotheproject.Thetestspecimensshould plates or blocks must have a matched set of angles that differ

by no more than 0.5 degrees.The incline plates or blocks shall

thenberandomlyassignedinequalnumberstoeachlaboratory

for testing. The average results from the two laboratories be roughened or ribbed to keep specimen from sliding down

the fixed plate or block during the test. The samples should be

shouldbecomparedusingtheStudent’s t-testforunpaireddata

and an acceptable probability level chosen by the two parties marked in regards to plates or blocks to check for slippage

during the test. If mutual agreement is obtained between the

before the testing is begun. If bias is found, either its cause

mustbefoundandcorrectedorthepurchaserandsuppliermust manufactureranduser,otherfacingstotheplatesorblockscan

be used. Allowable percent reduction in strength based on the

agree to interpret future test results in the light of the known

bias. load angle should also be agreed upon.

NOTE 5—The use of inclined plates or blocks may assist the manufac-

6. Apparatus

turer or user to evaluate the deformation of the geosynthetic(s) under

loading at various angles. The use of inclined plates may not reflect the

6.1 Loading Mechanism—The loading mechanism shall be

in-service performance of synthetic drainage systems.

capable of applying com

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.