ASTM A532/A532M-93a(2008)

(Specification)Standard Specification for Abrasion-Resistant Cast Irons

Standard Specification for Abrasion-Resistant Cast Irons

ABSTRACT

This specification deals with abrasion-resistant cast irons used for mining, milling, earth-handling, and manufacturing industries. These alloys may be made by melting process and shall have microstructures that consist of carbides, martensite, bainite, austenite, and in exceptional cases, minor amounts of graphite or pearlite. The following conditions for casting will be supplied: as-cast, as-cast and stress relieved, hardened, hardened and stress relieved, or softened for machining. Heat treatment shall be done. The chemical composition of a class and type (that is, Class I, Type A) shall conform to the range of values specified for carbon, manganese, silicon, nickel, chromium, molybdenum, copper, phosphorus, and sulfur. Hardness test shall also be made.

SCOPE

1.1 This specification covers a group of white cast irons that have been alloyed to secure high resistance to abrasive wear in the applications of the mining, milling, earth-handling, and manufacturing industries.

1.2 Simple and low-alloy white cast irons that consist essentially of iron carbides and pearlite are specifically excluded from this specification.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A532/A532M – 93a (Reapproved 2008)

Standard Specification for

Abrasion-Resistant Cast Irons

This standard is issued under the fixed designationA532/A532M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.1 Quantity,

3.1.2 Specification number, class, and type,

1.1 This specification covers a group of white cast irons that

3.1.3 Descriptionofthecasting,patternnumber,ordrawing,

have been alloyed to secure high resistance to abrasive wear in

3.1.4 Chilling of the casting, if required (see 4.2),

the applications of the mining, milling, earth-handling, and

3.1.5 Heat treat condition (see 5.1),

manufacturing industries.

3.1.6 Hardness level, if supplied hardened or hardened and

1.2 Simple and low-alloy white cast irons that consist

stress relieved, and

essentially of iron carbides and pearlite are specifically ex-

3.1.7 Hardness method, Brinell, Rockwell, Vickers (see

cluded from this specification.

Section 9). If the hardness method is not specified, it shall be

1.3 The values stated in either SI units or inch-pound units

at the manufacturer’s option.

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each

4. Method of Manufacture

system shall be used independently of the other. Combining

4.1 These alloys may be made by any suitable melting

values from the two systems may result in non-conformance

process.

with the standard.

4.2 If the casting is to be chilled or otherwise specially

2. Referenced Documents treated on any portion, the inquiries and the purchase order

shallsostateandaproperlymarkeddrawingofthecastingwill

2.1 ASTM Standards:

accompany both the inquiry and the purchase order.

E10 Test Method for Brinell Hardness of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Ma-

5. Heat Treatment

terials

5.1 The casting will be supplied in one of the following

E92 Test Method for Vickers Hardness of Metallic Materi-

conditions:

als

5.1.1 As-cast,

E350 Test Methods for ChemicalAnalysis of Carbon Steel,

5.1.2 As-cast and stress relieved,

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and

5.1.3 Hardened,

Wrought Iron

5.1.4 Hardened and stress relieved, or

E351 Test Methods for Chemical Analysis of Cast Iron—

5.1.5 Softened for machining.

All Types

5.2 Unless otherwise specified by the purchaser, the manu-

3. Ordering Information facturer shall supply the castings in the heat treatment he

deems best for the application.

3.1 Orders for material in this specification should include

5.3 If the heat treatment specified for delivered condition is

the following information:

not that of final use, it shall be the responsibility of the

purchaser to provide the additional heat treatment.

This specification is under the jurisdiction of ASTM Committee A04 on Iron

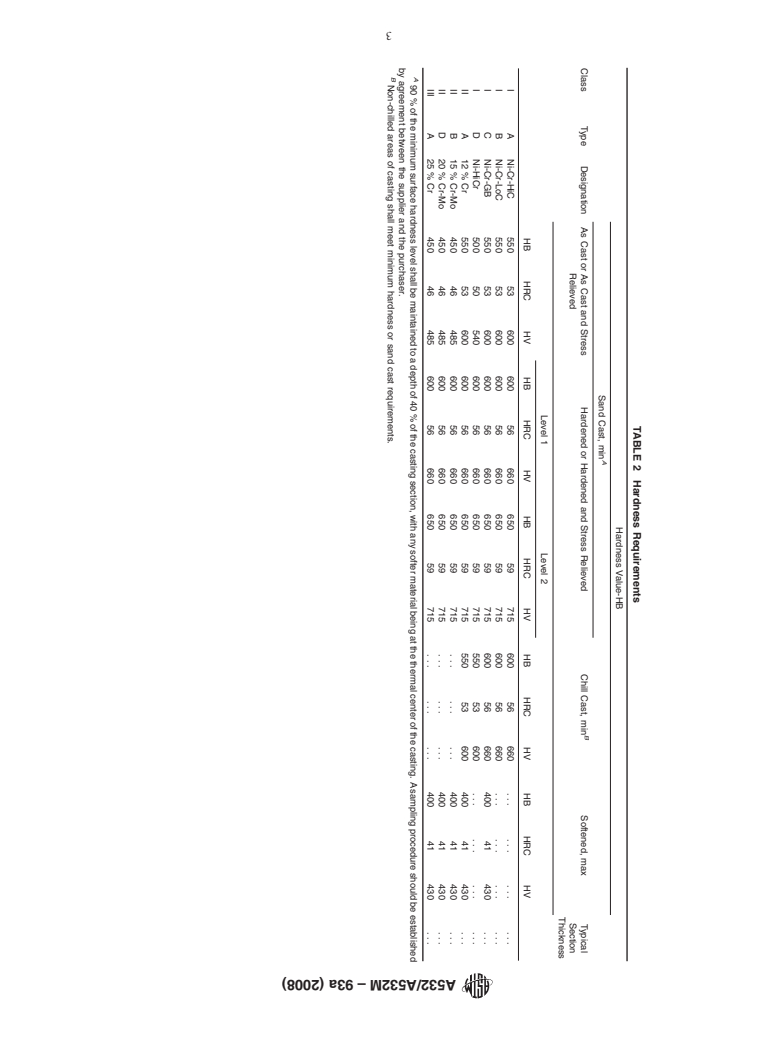

5.4 ClassIIandClassIIIalloysarefrequentlyorderedinthe

CastingsandisthedirectresponsibilityofSubcommitteeA04.01onGreyandWhite

annealedconditionwithamaximumhardnessof400HB.After

Iron Castings.

machining operations are performed the castings may then be

Current edition approved Oct. 1, 2008. Published November 2008. Originally

approved in 1965. Last previous edition approved in 2003 as A532/A532M – 93a

hardened. If both annealing and machining are to be performed

(2003). DOI: 10.1520/A0532_A0532M-93AR08.

by the manufacturer, as specified in the inquiry, contract, or

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

order, the purchaser may then specify delivery in the hardened

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on condition. If the purchaser specifies delivery in the annealed

the ASTM website.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

A532/A532M – 93a (2008)

condition, subsequent hardening (and stress-relief, if it is 6.3.2 The following is in accordance with Test Methods

desired) is the responsibility of the purchaser. E350:

6.3.2.1 Molybdenum by the Photometric Method.

6. Chemical Composition

7. Microstructure

6.1 The composition of the metal of a class and type

7.1 The alloys covered by this specification are expected to

produced under this specification shall fall within the ranges

have microstructures that consist essentially of carbides, mar-

prescribed in Table 1 for that class and type.

tensite, bainite, austenite; and in exceptional cases minor

6.2 Spectrographic, X-ray, or wet chemical laboratory tech-

amounts of graphite or pearlite.

niques are acceptable for routine and control determinations,

7.2 The microstructu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.