ASTM A571/A571M-01(2023)e1

(Specification)Standard Specification for Austenitic Ductile Iron Castings for Pressure-Containing Parts Suitable for Low-Temperature Service

Standard Specification for Austenitic Ductile Iron Castings for Pressure-Containing Parts Suitable for Low-Temperature Service

ABSTRACT

This specification covers austenitic ductile iron castings for compressors, expanders, pumps, valves, and other pressure-containing parts intended primarily for low-temperature service. The castings covered here are Type D-2M, Class 1, Class 2, Class 3, and Class 4. The castings shall be made in the electric-arc furnace, induction furnace, cupola, or any other furnace which is capable of producing castings. Heat and product analyses shall be performed wherein specimens shall conform to required chemical composition of carbon, silicon, manganese, nickel, chromium, and phosphorus. The castings shall undergo tension tests and impact tests, and shall conform to the following mechanical requirements: tensile strength, yield strength, elongation, Brinell hardness, and Charpy V-notch.

SCOPE

1.1 This specification2 covers austenitic ductile iron, Type D-2M, Classes 1 and 2, for compressors, expanders, pumps, valves, and other pressure-containing parts intended primarily for low-temperature service.

1.2 These grades of austenitic ductile iron are characterized by having their graphite substantially in a spheroidal form and free of flake graphite. They are essentially free of carbides and contain sufficient alloy content to produce a stable austenitic matrix down to −423 °F [−252 °C] (liquid hydrogen).

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3.1 Within the text, the SI units are shown in brackets.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: A571/A571M − 01 (Reapproved 2023)

Standard Specification for

Austenitic Ductile Iron Castings for Pressure-Containing

Parts Suitable for Low-Temperature Service

This standard is issued under the fixed designation A571/A571M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—A typo in X1.1 was editorially corrected in November 2023.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers austenitic ductile iron, Type

A941 Terminology Relating to Steel, Stainless Steel, Related

D-2M, Classes 1 and 2, for compressors, expanders, pumps,

Alloys, and Ferroalloys

valves, and other pressure-containing parts intended primarily

E8/E8M Test Methods for Tension Testing of Metallic Ma-

for low-temperature service.

terials

1.2 These grades of austenitic ductile iron are characterized

E23 Test Methods for Notched Bar Impact Testing of Me-

by having their graphite substantially in a spheroidal form and

tallic Materials

free of flake graphite. They are essentially free of carbides and

E30 Test Methods for Chemical Analysis of Steel, Cast Iron,

contain sufficient alloy content to produce a stable austenitic

Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

matrix down to −423 °F [−252 °C] (liquid hydrogen).

E59 Practice for Sampling Steel and Iron for Determination

of Chemical Composition (Withdrawn 1996)

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3. Ordering Information

each system may not be exact equivalents; therefore, each

3.1 Orders for material under this specification shall include

system shall be used independently of the other. Combining

the following information:

values from the two systems may result in nonconformance

3.1.1 Quantity (weight or number of pieces),

with the standard.

3.1.2 ASTM designation and year of issue,

1.3.1 Within the text, the SI units are shown in brackets.

3.1.3 Material class (Table 1),

1.4 The following precautionary caveat pertains only to the

3.1.4 Impact test temperature requirement (Section 11),

test methods portion, Section 11, of this specification: This

3.1.5 Place of inspection (Section 13), and

standard does not purport to address all of the safety concerns,

3.1.6 Certification requirements (Section 14).

if any, associated with its use. It is the responsibility of the user

4. Materials and Manufacture

of this standard to establish appropriate safety, health, and

environmental practices and determine the applicability of

4.1 Material—The iron shall be made in the electric-arc

regulatory limitations prior to use.

furnace, induction furnace, cupola, or any other furnace which

1.5 This international standard was developed in accor-

is capable of producing castings meeting the chemical compo-

dance with internationally recognized principles on standard-

sitions and mechanical properties in this specification.

ization established in the Decision on Principles for the

4.2 Heat Treatment:

Development of International Standards, Guides and Recom-

4.2.1 All castings shall be heat treated.

mendations issued by the World Trade Organization Technical

4.2.2 Heat treatment shall be performed before machining

Barriers to Trade (TBT) Committee.

except in instances when reheat treating is necessary.

4.2.3 Heat treatment shall consist of annealing. The proce-

dure for this type of treatment shall consist of heating the

This specification is under the jurisdiction of the ASTM Committee A04 on

Iron Castings and is the direct responsibility of Subcommittee A04.02 on Malleable

and Ductile Iron Castings. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2023. Published November 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1966. Last previous edition approved in 2019 as A571/ Standards volume information, refer to the standard’s Document Summary page on

A571M – 01 (2019). DOI: 10.1520/A0571_A0571M-01R23E01. the ASTM website.

2 4

For ASME Boiler and Pressure Vessel Code applications, see related Specifi- The last approved version of this historical standard is referenced on

cation SA-571 in Section II of that code. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A571/A571M − 01 (2023)

A

TABLE 1 Mechanical Property Requirements

Class 1 Class 2 Class 3 Class 4

Tensile Strength, min, ksi [mPa] 65 60 [450] [415]

B

Yield Strength 0.2 % (offset), min, ksi [mPa] 30 25 [205] [170]

Elongation, min, % 30 25 30 25

Brinell Hardness, 3000 kg [kgf] 121–171 111–171 121–171 111–171

Charpy V-notch, ft·lbf [J]

min, average 3 tests 15 20 [20] [27]

C

min, individual test 12 15 [16] [20]

A

Heat-treated condition.

B

Yield Strength shall be determined at 0.2 % offset by the offset method, see Test Methods E8/E8M. Other methods may be agreed upon by mutual consent of

manufacturer and purchaser.

C

Not more than one test in a set of three may be below the minimum average required for the set of three.

casting to a minimum of 1600 °F [870 °C] but not greater than 7. Workmanship, Finish, and Appearance

1800 °F [980 °C], holding at that temperature not less than

7.1 The castings shall conform to the dimensions and

1 h ⁄in. [1 h ⁄25 mm] of section, and furnace cooling. (See

tolerances on the drawings furnished by the purchaser, or if no

Terminology A941.)

drawing has been provided, to the dimensions predicated by

the pattern supplied by the purchaser. The castings shall be free

5. Chemical Requirements

from injurious defects. Surfaces of the castings shall be free of

5.1 Drillings taken from test coupons, broken test

burnt-on sand and shall be reasonably smooth. Runners, risers,

specimens, or castings shall conform to the requirements as to fins, and other useless cast-on pieces shall be removed. In other

chemical composition prescribed in Table 2.

respects, the castings shall conform to whatever points may be

specifically agreed upon between the manufacturer and the

5.2 The chemical analysis for total carbon shall be made on

purchaser.

either chilled cast pencil-type specimens or thin wafers ap-

proximately ⁄32 in. [0.8 mm] thick cut from test coupons.

8. Sampling

Drillings shall not be used because of attendant loss of

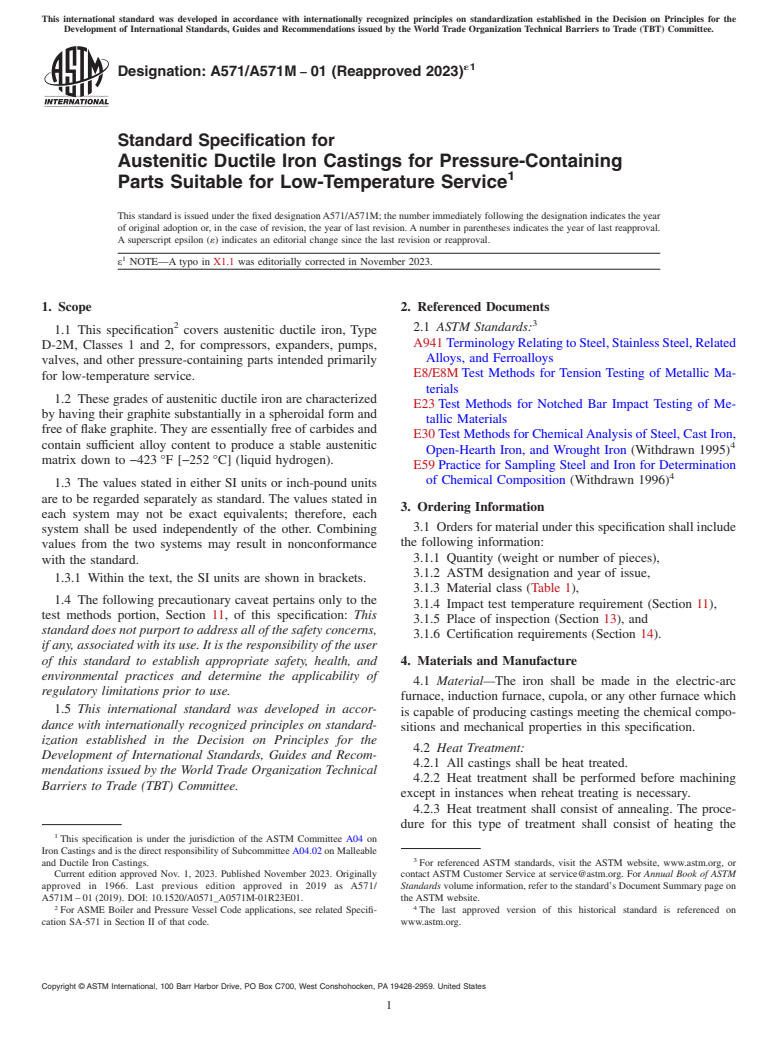

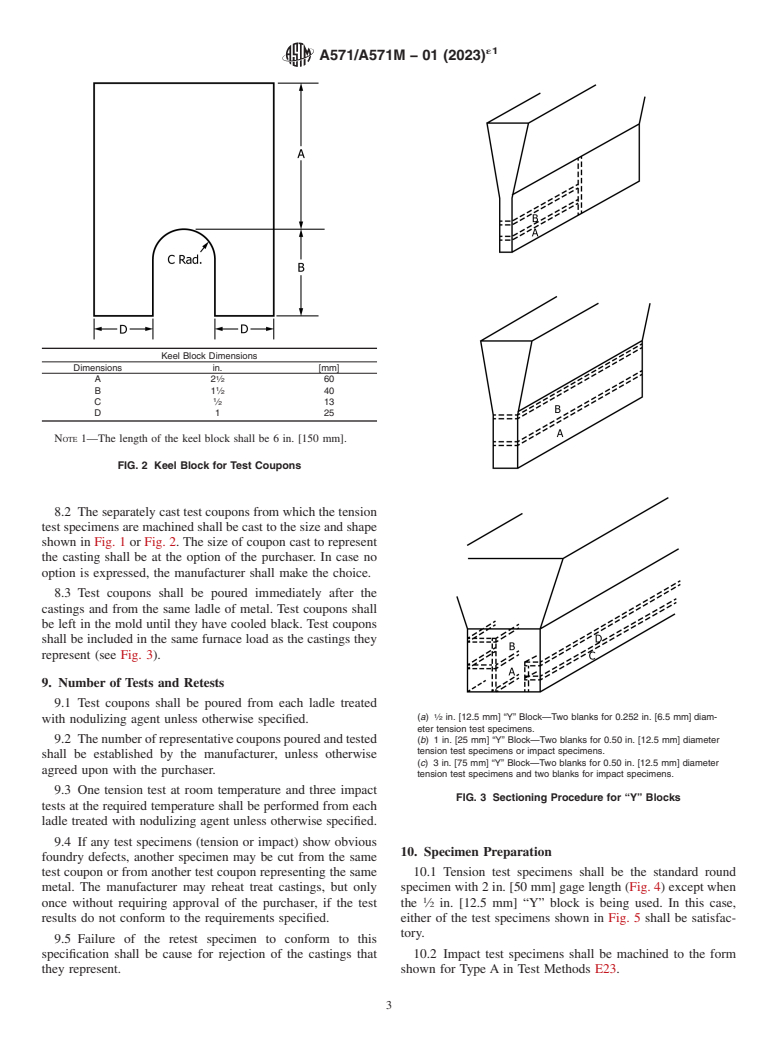

graphite. 8.1 The standard test coupons shall be the 1 in. [25 mm] “Y”

block and 1 in. [25 mm] keel block as shown in Fig. 1 and Fig.

6. Physical Property Requirements

2, respectively.

6.1 Tensile Properties—The room temperature mechanical

properties of the two classes of ductile iron used for the casting

shall conform to the requirements for the heat-treated condition

shown in Table 1.

6.2 Impact Properties—The notched-bar impact properties

of the materials shall be determined by testing a set of three

Charpy V-notch impact specimens to the energy absorption

requirements shown in Table 1. The test temperature shall be

agreed upon by the manufacturer and the purchaser. The energy

absorption values shown in Table 1 are applicable at tempera-

tures down to and including −320 °F [−195 °C].

6.3 Brinell Hardness—The room temperature hardness of

test bars and castings shall conform to the requirements of

Table 1.

“Y” Block Size

For Castings For Castings For Castings

of Thickness of Thickness of Thickness

Dimensions

1 1 1 1

Less Than ⁄2 ⁄2 to 1 ⁄2 in. of 1 ⁄2 in. [40 mm]

in. [12.5 mm] [12.5 to 40 mm] and Over

TABLE 2 Chemical Requirements

in. [mm] in. [mm] in. [mm]

Element Composition, %

A ⁄2 [12.5] 1 [25] 3 [75]

A

Total carbon 2.2–2.7 1

B 1 [25] 2 ⁄8 [55] 5 [125]

Silicon 1.5–2.50

C 2 [50] 3 [75] 4 [100]

Manganese 3.75–4.5

D 4 [100] 6 [150] 8 [200]

Nickel 21.0–24.0

E 7 [175] 7 [175] 7 [175]

B

Chromium 0.20 max

approx approx approx

Phosphorus 0.08 max 9 1 1

F ⁄16 [14] 1 ⁄16 [27] 3 ⁄16 [78]

1 1 1

A

1 G 7 ⁄8 [180] 7 ⁄8 [180] 7 ⁄8 [180]

For castings with sections under ⁄4 in. [6 mm], it may be desirable to adjust the

approx approx approx

carbon upwards to a maximum of 2.90 %.

B

Not intentionally added.

FIG. 1 “Y” Blocks for Test Coupons

---------------------- Page

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.