ASTM F42-93(1997)

(Test Method)Standard Test Methods for Conductivity Type of Extrinsic Semiconducting Materials

Standard Test Methods for Conductivity Type of Extrinsic Semiconducting Materials

SCOPE

1.1 These test methods cover the determination of the conductivity type of extrinsic semiconductors. While explicit details are given for germanium and silicon, inclusion of other extrinsic materials such as gallium arsenide and indium antimonide should be feasible. For the latter compounds, however, applicability has not been formally verified by round-robin tests. Determinations can be made most reliably on homogeneous bulk material, but these test methods may also be used to map regions of different conductivity type on the surfaces of inhomogeneous specimens. These test methods have not been tested on layered structures such as epitaxial layers. Measurements on these structures may give erroneous indications of conductivity type.

1.2 Four test methods are described:

1.2.1 Test Method A -Hot-Probe Thermal EMF Conductivity-Type Test.

1.2.2 Test Method B -Cold-Probe Thermal EMF Conductivity-Type Test.

1.2.3 Test Method C -Point-Contact Rectification Conductivity-Type Test.

1.2.4 Test Method D -Type-All system operating in two modes:

1.2.4.1 Rectification Conductivity-Type Test.

1.2.4.2 Thermal EMF Conductivity-Type Test.

1.3 Experience has shown that Test Method A (hot-probe) gives dependable results in n- and p-type silicon having a room-temperature resistivity up to 1000 [omega][dot]cm. Note 1-Resistivity of germanium specimens may be measured in accordance with Test Methods F43 and resistivity of silicon slices may be measured in accordance with Test Methods F43 or Test Method F84.

1.4 Test Method B (cold-probe) gives dependable results for n- and p-type germanium having a room-temperature resistivity of 20 [omega][dot]cm or less and for n- and p-type silicon having a resistivity up to 1000 [omega][dot]cm (Note 1). This technique has the advantage over the hot-probe test method in that the signal amplitude can be increased by developing a greater temperature difference between the two probes.

1.5 Test Method C (rectification) is a simple convenient technique which gives dependable results for n- and p-type silicon with room-temperature resistivity between 1 and 1000 [omega][dot]cm. This test method is not recommended for germanium (Note 1).

1.6 Test Method D (type-all rectification mode) is appropriate for use on n- and p-type silicon having a room-temperature resistivity between 0.1 and 1000 [omega][dot]cm, inclusive (Note 1).

1.7 Test Method D (type-all thermal emf mode) is appropriate for use on n- and p-type silicon having a room-temperature resistivity between 0.002 and 0.1 [omega][dot]cm, inclusive (Note 1).

1.8 These test methods may apply outside the limits given above, but their suitability outside these limits has not been verified experimentally.

1.9 It is recommended that if satisfactory results can not be obtained with the use of these test methods that conductivity type be determined from Hall-effect measurements as described in Test Methods F76. Note 2-DIN 50432 covers technical equivalents to Test Methods A and C of these test methods, but does not include Test Methods B and D.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Please

contact ASTM International (www.astm.org) for the latest information.

DIN 50432

Designation: F 42 – 93 (Reapproved 1997)

Standard Test Methods for

Conductivity Type of Extrinsic Semiconducting Materials

ThisstandardisissuedunderthefixeddesignationF42;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 TestMethodB(cold-probe)givesdependableresultsfor

n- and p-type germanium having a room-temperature resistiv-

1.1 These test methods cover the determination of the

ity of 20 V·cm or less and for n- and p-type silicon having a

conductivity type of extrinsic semiconductors. While explicit

resistivity up to 1000 V·cm (Note 1). This technique has the

details are given for germanium and silicon, inclusion of other

advantage over the hot-probe test method in that the signal

extrinsic materials such as gallium arsenide and indium anti-

amplitude can be increased by developing a greater tempera-

monideshouldbefeasible.Forthelattercompounds,however,

ture difference between the two probes.

applicability has not been formally verified by round-robin

1.5 Test Method C (rectification) is a simple convenient

tests. Determinations can be made most reliably on homoge-

technique which gives dependable results for n- and p-type

neousbulkmaterial,butthesetestmethodsmayalsobeusedto

silicon with room-temperature resistivity between 1 and 1000

map regions of different conductivity type on the surfaces of

V·cm. This test method is not recommended for germanium

inhomogeneous specimens. These test methods have not been

(Note 1).

tested on layered structures such as epitaxial layers. Measure-

1.6 Test Method D (type-all rectification mode) is appropri-

ments on these structures may give erroneous indications of

ate for use on n- and p-type silicon having a room-temperature

conductivity type.

resistivity between 0.1 and 1000 V·cm, inclusive (Note 1).

1.2 Four test methods are described:

1.7 Test Method D (type-all thermal emf mode) is appro-

1.2.1 Test Method A—Hot-Probe Thermal EMF

priate for use on n- and p-type silicon having a room-

Conductivity-Type Test.

temperature resistivity between 0.002 and 0.1 V·cm, inclusive

1.2.2 Test Method B—Cold-Probe Thermal EMF

(Note 1).

Conductivity-Type Test.

1.8 These test methods may apply outside the limits given

1.2.3 Test Method C—Point-Contact Rectification

above, but their suitability outside these limits has not been

Conductivity-Type Test.

verified experimentally.

1.2.4 Test Method D—Type-All system operating in two

1.9 It is recommended that if satisfactory results can not be

modes:

obtained with the use of these test methods that conductivity

1.2.4.1 Rectification Conductivity-Type Test.

type be determined from Hall-effect measurements as de-

1.2.4.2 Thermal EMF Conductivity-Type Test.

scribed in Test MethodsF76.

1.3 Experience has shown that Test Method A (hot-probe)

gives dependable results in n- and p-type silicon having a

NOTE 2—DIN 50432 covers technical equivalents to Test Methods A

room-temperature resistivity up to 1000 V·cm. and C of these test methods, but does not include Test Methods B and D.

1.10 This standard does not purport to address all of the

NOTE 1—Resistivity of germanium specimens may be measured in

accordancewithTestMethodsF43andresistivityofsiliconslicesmaybe

safety concerns, if any, associated with its use. It is the

measured in accordance with Test MethodsF43 or Test MethodF84.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

These test methods are under the jurisdiction of ASTM Committee F-1 on

2. Referenced Documents

Electronics, and are the direct responsibility of Subcommittee F01.06 on Silicon

Materials and Process Control.

2.1 ASTM Standards:

Current edition approved Dec. 10, 1997. Published October 1993. Originally

D1125 Test Methods for Electrical Conductivity and Re-

published as F42–64 T. Last previous edition F42–88.

sistivity of Water

DIN 50432 is an equivalent method. It is the responsibility of DIN Committee

NMP 221, with which Committee F-1 maintains close technical liaison.

F43 Test Methods for Resistivity of Semiconductor Mate-

DIN 50432, Testing of Inorganic Semiconductor Materials: Determining the 5

rials

Conductivity Type of Silicon or Germanium by Means of the Rectification Test or

F76 Test Methods for Measuring Resistivity and Hall

Hot Probe, is available from Beuth Verlag GmbH, Burggrafenstrasse 4-10, D-1000

Berlin 30, Federal Republic of Germany.

Keenan, W. A., Schneider, C. P., and Pillus, C. A., “Type-All System for

Determining Semiconductor Conductivity Type,” Solid State Technology, Vol 14, Annual Book of ASTM Standards, Vol 11.01.

No. 3, March 1971. Annual Book of ASTM Standards, Vol 10.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Please

contact ASTM International (www.astm.org) for the latest information.

F 42 – 93 (1997)

Coefficient and Determining Hall Mobility in Single- contact will be reverse-biased and will experience the major

Crystal Semiconductors portion of the voltage drop. During the following half-cycle

F84 Test Methods for Measuring Resistivity of Silicon this junction will be forward-biased and the voltage drop will

Slices with a Collinear Four-Probe Array besmallcomparedtothatofthefirsthalf-cycle.Thisinequality

of voltages results in a d-c component which is detected by a

3. Terminology

third point contact.

4.4 Test Method D, Thermal EMF Mode—In this test

3.1 Definitions of Terms Specific to This Standard:

method,athermalgradientisestablishedinthespecimenbyan

3.1.1 conductivity type—Defines the nature of the majority

alternatingcurrentpassingthroughapairofpointcontacts.The

of carriers in the specimen.

thermal emf resulting from the thermal gradient is then

3.1.2 n-type—avarietyofsemiconductivematerialinwhich

detected by a second pair of point contacts. The point contact

the majority current carriers are electrons, formed when donor

nearestthefirstpairwillbethewarmerand,in n-typematerial,

impurities are incorporated into the crystal structure in small

will be positive with respect to the second point contact of the

concentrations.

pair. With p-type material the warmer contact will be negative

3.1.3 p-type—avarietyofsemiconductivematerialinwhich

with respect to the second contact.

the majority current carriers are holes, formed when acceptor

impurities are incorporated into the crystal structure in small

concentrations. 5. Significance and Use

3.1.4 thermal emf—the net emf set up in a thermocouple

5.1 Thedeterminationofconductivitytypeandthepresence

under conditions of zero current. Synonymous with Seebeck

of junctions in semiconductors is important in research and

emf.

development, and in processing or inspection of semiconduct-

ing materials for device fabrication.

4. Summary of Test Methods

4.1 Test Methods A and B—In both of these test methods,

6. Interferences

thesignofthethermalemfgeneratedbetweentwometalprobe

6.1 Test Method A (Hot-Probe):

contacts to the specimen held at different temperatures is used

6.1.1 Some high-resistivity silicon and germanium speci-

to determine conductivity type. One of the probes is main-

mens may be nearly intrinsic at the hot-probe temperature;

tained at room temperature while the other is heated (Test

since the mobility of the electrons exceeds that of holes, the

MethodA) or cooled (Test Method B). The warmer probe will

thermoelectric power is always negative at these temperatures.

bepositivewithrespecttothecoolerprobewhenthespecimen

6.1.2 Oxide coating buildup on the hot probe can produce

is n-type and negative when the specimen is p-type. The

unreliable measurements.

polarityisobservedonacenter-zerometerwhichmaybeeither

6.1.3 n-typegermanium with room-temperature resistivity

voltage or current sensitive. Since most of the temperature

greater than 40 V·cm can show p-type conductivity due to

difference occurs in the region of the probe which is not at

insufficient probe force (Note 1).

room temperature, the sign observed is governed by the

6.2 Test Method B (Cold Probe):

conductivity type of the portion of the specimen at this probe

6.2.1 The cold probe should be maintained free of ice. Ice

contact.

formed during prolonged periods of usage in ordinary ambient

4.2 Test Method C—In this test method, the direction of the

air has been found to give erratic results.

current through a point contact is used to determine the

6.2.2 Oxide coating buildup on the cold probe can produce

conductivity type of the specimen. A metal point contact to a

unreliable measurements.

p-type semiconductor will pass current when the semiconduc-

6.2.3 n-type germanium with room-temperature resistivity

tor is positive while a metal point contact to an n-type

greater than 20 V·cm can show p-type conductivity due to

semiconductor will pass current when the semiconductor is

insufficient probe force (Note 1).

negative.An alternating potential is applied between the point

6.3 Test Method C (Rectification):

contact and a second large area contact. The direction of

6.3.1 Since this test method indicates primarily the surface-

current is observed on a zero-center current sensitive meter, an

conductivitytype,extremecaremustbetakeninpropersurface

oscilloscope, or a curve tracer. Since rectification occurs at the

preparation. A surface oxide can act as an insulator so that no

point contact rather than at the large area contact, the direction

voltage is indicated by the meter.

of current is governed by the conductivity type of the portion

6.3.2 Reversed readings can sometimes occur if the large-

of the specimen at the point contact.

area contact is not held firmly. In such cases, a heavy force on

4.3 Test Method D, Rectification Mode—Inthistestmethod,

thepointcontactcancausethelarge-areacontacttobecomethe

the polarity of the voltage required to reverse-bias a point

effective rectifying contact and give reversed meter readings.

contact is used to determine the conductivity type of the

6.3.3 Erroneous readings may arise from stray pickup

specimen. An alternating potential is applied between two

caused by touching the specimen with hands or objects other

point contacts to the specimen. During one half-cycle a given

than the probe.

6.3.4 An etched surface is not recommended because vari-

ousetchantsandetchingtechniquemayintroduceuncontrolled

Scaff, J. H. and Thearer, H. C., Edited by Scaff, J. H., Bridgers, H. E., and

variations in surface characteristics.

Shive, J. N., Transistor Technology, D. Van Nostrand Co., Inc., New York, Vol 1,

1958, p. 12. 6.4 Test Method D (Type-All):

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Please

contact ASTM International (www.astm.org) for the latest information.

F 42 – 93 (1997)

6.4.1 Erroneous indications may result if the rectification

modeisusedwithverylow-resistivitymaterialwhichresultsin

alowoutputsignal.Forsilicon,useoftherectificationmodein

cases where the output is less than 0.5 V is not recommended.

6.4.2 Erroneous indications may result if the thermal emf

mode is used with high-resistivity material.

6.5 All test methods may give erroneous readings if exces-

sivelightfallsonthespecimen,especiallywithhigh-resistivity

material.

6.6 Ambient radio-frequency energy may cause spurious

rectification and erroneous indications.

7. Apparatus

NOTE 3—The instrumentation described in these test methods was in

common use at the time the test methods were developed. It is now

possible to perform many of the necessary functions using more modern

instruments. Such instruments may be substitutes for the apparatus

described in this section provided the user can show equivalence for the

purposes of the measurement.

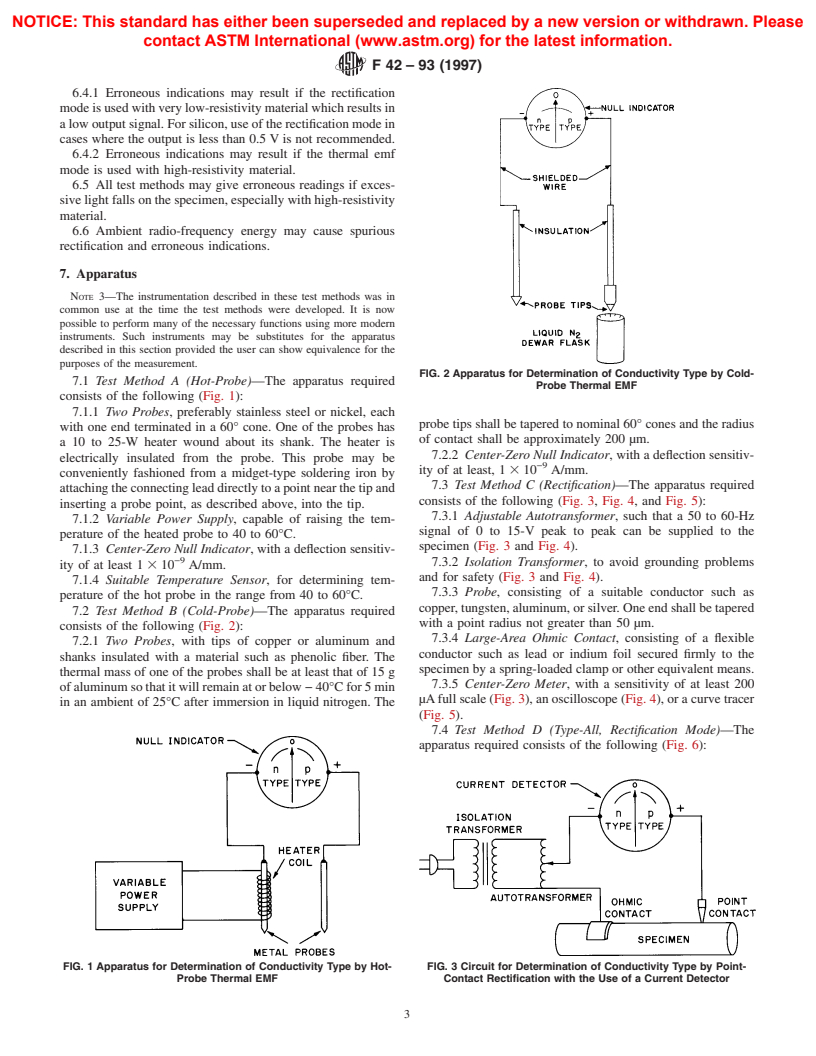

FIG. 2 Apparatus for Determination of Conductivity Type by Cold-

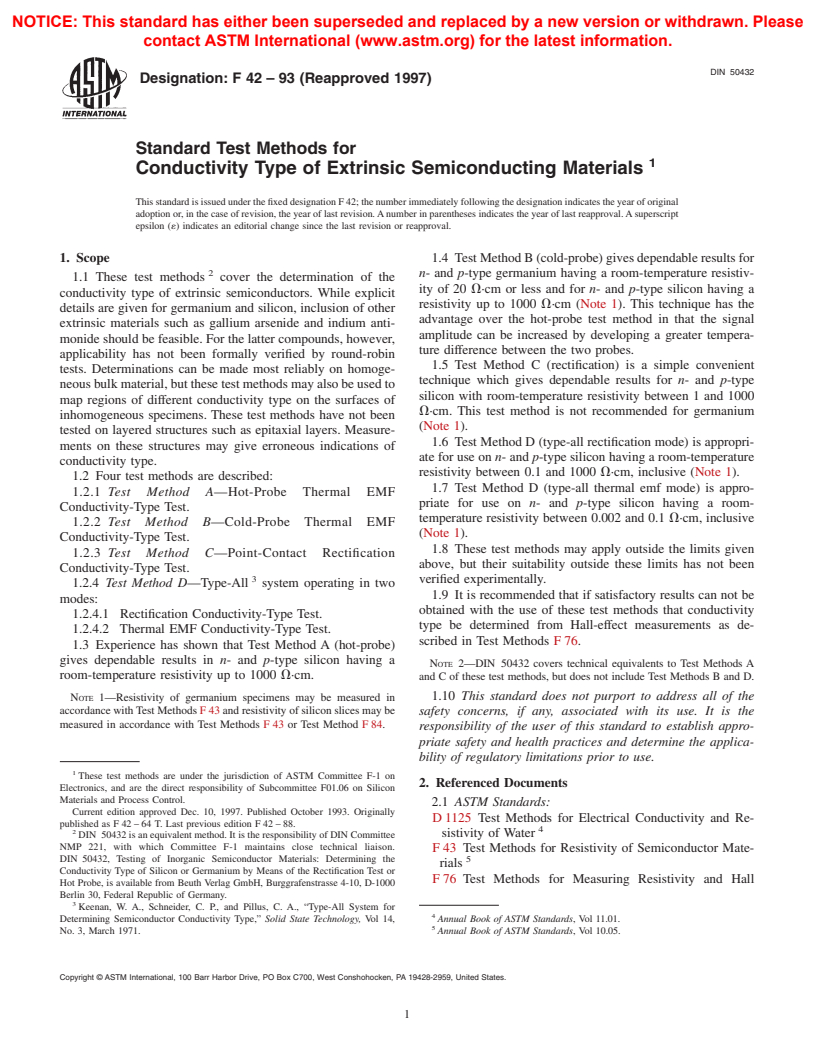

7.1 Test Method A (Hot-Probe)—The apparatus required

Probe Thermal EMF

consists of the following (Fig. 1):

7.1.1 Two Probes, preferably stainless steel or nickel, each

probe tips shall be tapered to nominal 60° cones and the radius

with one end terminated in a 60° cone. One of the probes has

of contact shall be approximately 200 µm.

a 10 to 25-W heater wound about its shank. The heater is

7.2.2 Center-Zero Null Indicator, with a deflection sensitiv-

electrically insulated from the probe. This probe may be

−9

ity of at least, 1 310 A/mm.

conveniently fashioned from a midget-type soldering iron by

7.3 Test Method C (Rectification)—The apparatus required

attachingtheconnectingleaddirectlytoapointnearthetipand

consists of the following (Fig. 3, Fig. 4, and Fig. 5):

inserting a probe point, as described above, into the tip.

7.3.1 Adjustable Autotransformer, such that a 50 to 60-Hz

7.1.2 Variable Power Supply, capable of raising the tem-

signal of 0 to 15-V peak to peak can be supplied to the

perature of the heated probe to 40 to 60°C.

specimen (Fig. 3 and Fig. 4).

7.1.3 Center-Zero Null Indicator, with a deflection sensitiv-

−9

7.3.2 Isolation Transformer, to avoid grounding problems

ity of at least 1 310 A/mm.

and for safety (Fig. 3 and Fig. 4).

7.1.4 Suitable Temperature Sensor, for determining tem-

7.3.3 Probe, consisting of a suitable conductor such as

perature of the hot probe in the range from 40 to 60°C.

copper,tungsten,aluminum,orsilver.Oneendshallbetapered

7.2 Test Method B (Cold-Probe)—The apparatus required

with a point radius not greater than 50 µm.

consists of the following (Fig. 2):

7.3.4 Large-Area Ohmic Contact, consisting of a flexible

7.2.1 Two Probes, with tips of copper or aluminum and

conductor such as lead or indium foil secured firmly to the

shanks insulated with a material such as phenolic fiber. The

specimen by a spring-loaded clamp or other equivalent means.

thermal mass of one of the probes shall be at least that of 15 g

7.3.5 Center-Zero Meter, with a sensitivity of at least 200

ofaluminumsothatitwillremainatorbelow−40°Cfor5min

µAfullscale(Fig.3),anoscilloscope(Fig.4),oracurvetracer

in an ambient of 25°C after immersion in liquid nitrogen. The

(Fig. 5).

7.4 Test Method D (Type-All, Rectification Mode)—The

apparatus required consists of the following (Fig. 6):

FIG. 1 Apparatus for Determination of Conductivity Type by Hot- FIG. 3 Circuit for Determination of Conductivity Type by Point-

Probe Thermal EMF Contact Rectification with the Use of a Current Detector

NOTICE: This stand

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.