ASTM F2091-01(2012)

(Specification)Standard Specification for Acetabular Prostheses

Standard Specification for Acetabular Prostheses

ABSTRACT

This specification covers acetabular resurfacing devices used to provide a functioning articulation between the bones of the acetabulum and the femur. Acetabular prostheses included within the scope of this specification are intended for mechanical fixation between the prosthesis and host bone, by the use of bone cement or through biological fixation. Acetabular prostheses shall be classified as: Type I and Type II. The following test methods shall be performed: mechanical strength; corrosion resistance; biocompatibility; structural requirements; metal and ceramic coating or surface texture integrity; component disassociation; fixation failure; device fracture; and articular surface wear.

SCOPE

1.1 This specification covers acetabular resurfacing devices used to provide a functioning articulation between the bones of the acetabulum and the femur.

1.2 This specification is intended to provide basic descriptions of materials and device geometry. Additionally, those characteristics determined to be important to in vivo performance of the device are defined.

1.3 Acetabular prostheses included within the scope of this specification are intended for mechanical fixation between the prosthesis and host bone, by the use of bone cement or through biological fixation.

1.4 Custom (designed explicitly for a single patient), revision, or constrained acetabular prostheses are not covered within the scope of this specification.

1.5 This specification does not cover the details for quality assurance, design control, production control contained in 21 CFR 820 (Quality System Regulation) and ISO 9001.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2091 −01(Reapproved 2012)

Standard Specification for

Acetabular Prostheses

This standard is issued under the fixed designation F2091; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F136 Specification for Wrought Titanium-6Aluminum-

4Vanadium ELI (Extra Low Interstitial)Alloy for Surgical

1.1 This specification covers acetabular resurfacing devices

Implant Applications (UNS R56401)

used to provide a functioning articulation between the bones of

F138 Specification for Wrought 18Chromium-14Nickel-

the acetabulum and the femur.

2.5Molybdenum Stainless Steel Bar andWire for Surgical

1.2 This specification is intended to provide basic descrip-

Implants (UNS S31673)

tions of materials and device geometry. Additionally, those

F562 Specification for Wrought 35Cobalt-35Nickel-

characteristics determined to be important to in vivo perfor-

20Chromium-10Molybdenum Alloy for Surgical Implant

mance of the device are defined.

Applications (UNS R30035)

F563 Specification for Wrought Cobalt-20Nickel-

1.3 Acetabular prostheses included within the scope of this

specification are intended for mechanical fixation between the 20Chromium-3.5Molybdenum-3.5Tungsten-5Iron Alloy

for Surgical Implant Applications (UNS R30563) (With-

prosthesis and host bone, by the use of bone cement or through

biological fixation. drawn 2005)

F601 Practice for Fluorescent Penetrant Inspection of Me-

1.4 Custom (designed explicitly for a single patient),

tallic Surgical Implants

revision, or constrained acetabular prostheses are not covered

F603 Specification for High-Purity Dense Aluminum Oxide

within the scope of this specification.

for Medical Application

1.5 This specification does not cover the details for quality

F629 Practice for Radiography of Cast Metallic Surgical

assurance, design control, production control contained in 21

Implants

CFR 820 (Quality System Regulation) and ISO 9001.

F648 Specification for Ultra-High-Molecular-Weight Poly-

ethylene Powder and Fabricated Form for Surgical Im-

2. Referenced Documents

plants

F745 Specification for 18Chromium-12.5Nickel-

2.1 ASTM Standards:

2.5Molybdenum Stainless Steel for Cast and Solution-

F67 Specification for Unalloyed Titanium, for Surgical Im-

Annealed Surgical Implant Applications (Withdrawn

plant Applications (UNS R50250, UNS R50400, UNS

2012)

R50550, UNS R50700)

F746 Test Method for Pitting or Crevice Corrosion of

F75 Specification for Cobalt-28 Chromium-6 Molybdenum

Metallic Surgical Implant Materials

Alloy Castings and Casting Alloy for Surgical Implants

F748 PracticeforSelectingGenericBiologicalTestMethods

(UNS R30075)

for Materials and Devices

F86 Practice for Surface Preparation and Marking of Metal-

F799 Specification for Cobalt-28Chromium-6Molybdenum

lic Surgical Implants

Alloy Forgings for Surgical Implants (UNS R31537,

F90 Specification for Wrought Cobalt-20Chromium-

R31538, R31539)

15Tungsten-10NickelAlloy for Surgical ImplantApplica-

tions (UNS R30605) F981 Practice for Assessment of Compatibility of Biomate-

rials for Surgical Implants with Respect to Effect of

Materials on Muscle and Bone

F983 Practice for Permanent Marking of Orthopaedic Im-

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of plant Components

Subcommittee F04.22 on Arthroplasty.

F1044 Test Method for Shear Testing of Calcium Phosphate

Current edition approved Jan. 15, 2012. Published January 2012. Originally

Coatings and Metallic Coatings

approved in 2001. Last previous edition approved in 2006 as F2091 – 01 (2006).

F1108 Specification for Titanium-6Aluminum-4Vanadium

DOI: 10.1520/F2091-01R11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2091−01 (2012)

Alloy Castings for Surgical Implants (UNS R56406) elements; instruments for insertion, extraction, and so forth; or

F1147 Test Method for Tension Testing of Calcium Phos- for manufacturing purposes.

phate and Metallic Coatings

3.1.3 fixation element, n—any peg, spike, threadform, or

F1160 Test Method for Shear and Bending Fatigue Testing

other protrusion from the exterior surface of the shell intended

of Calcium Phosphate and Metallic Medical and Compos-

toincreasethesurfacecontactormechanicalinterlockbetween

ite Calcium Phosphate/Metallic Coatings

the component, the bonding agent, the natural acetabulum, or a

F1185 Specification for Composition of Hydroxylapatite for

combination thereof.

Surgical Implants

3.1.4 flange, n—rim extending from the entry diameter of

F1377 Specification for Cobalt-28Chromium-6Molybdenum

bearing element.

Powder for Coating of Orthopedic Implants (UNS

3.1.5 porous coating, n—a region on the exterior surface of

R30075)

the shell characterized by interconnecting subsurface pores,

F1472 Specification for Wrought Titanium-6Aluminum-

generally with volume porosity between 30 and 70 %, average

4VanadiumAlloy for Surgical ImplantApplications (UNS

pore size between 100 and 1000 µm, and a thickness between

R56400)

500 and 1500 µm. This porous layer may be manufactured

F1501 Test Method for Tension Testing of Calcium Phos-

directly into the device by casting or by various electro/

phate Coatings (Withdrawn 2000)

chemical/thermal/mechanical means, or applied as a coating of

F1537 Specification for Wrought Cobalt-28Chromium-

particles, beads, or mesh by processes such as sintering or

6Molybdenum Alloys for Surgical Implants (UNS

plasma spray.

R31537, UNS R31538, and UNS R31539)

F1580 Specification for Titanium and Titanium-6

3.1.6 radiographic marker, n—nonstructural, generally thin

Aluminum-4 Vanadium Alloy Powders for Coatings of wire, designed to be apparent on X-rays taken after placement

Surgical Implants

of implants that otherwise would be unapparent on such

F1714 GuideforGravimetricWearAssessmentofProsthetic X-rays.

Hip Designs in Simulator Devices

3.1.7 retention element, n—any ring, taper, wire, or other

F1820 Test Method for Determining the Forces for Disas-

protrusion or cavity from the interior surface of the shell or the

sembly of Modular Acetabular Devices

exterior surface of the bearing element that is intended to affix

F1978 Test Method for Measuring Abrasion Resistance of

the bearing element to the shell.

Metallic Thermal Spray Coatings by Using the Taber

3.1.8 shell, n—metal structure supporting the articulating

Abraser

surface material, and which may be fixed rigidly to the

F2033 Specification for Total Hip Joint Prosthesis and Hip

articulating surface or fixed such that it allows the articulating

Endoprosthesis Bearing Surfaces Made of Metallic,

surface to rotate or translate.

Ceramic, and Polymeric Materials

3.1.9 surface texturing, n—repetitive or random deviations

2.2 ISO Standards:

from the nominal surface that forms the three dimensional

ISO 5832 Implants for surgery—Metallic materials for sur-

4 topography of the surface.

gical implants

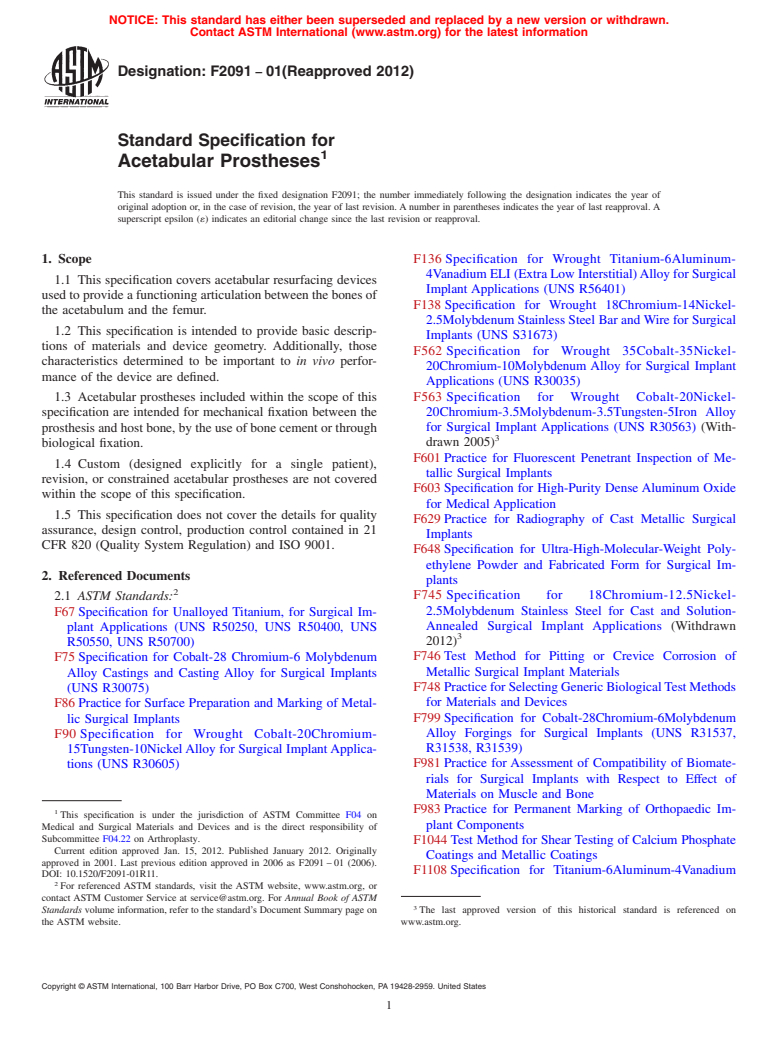

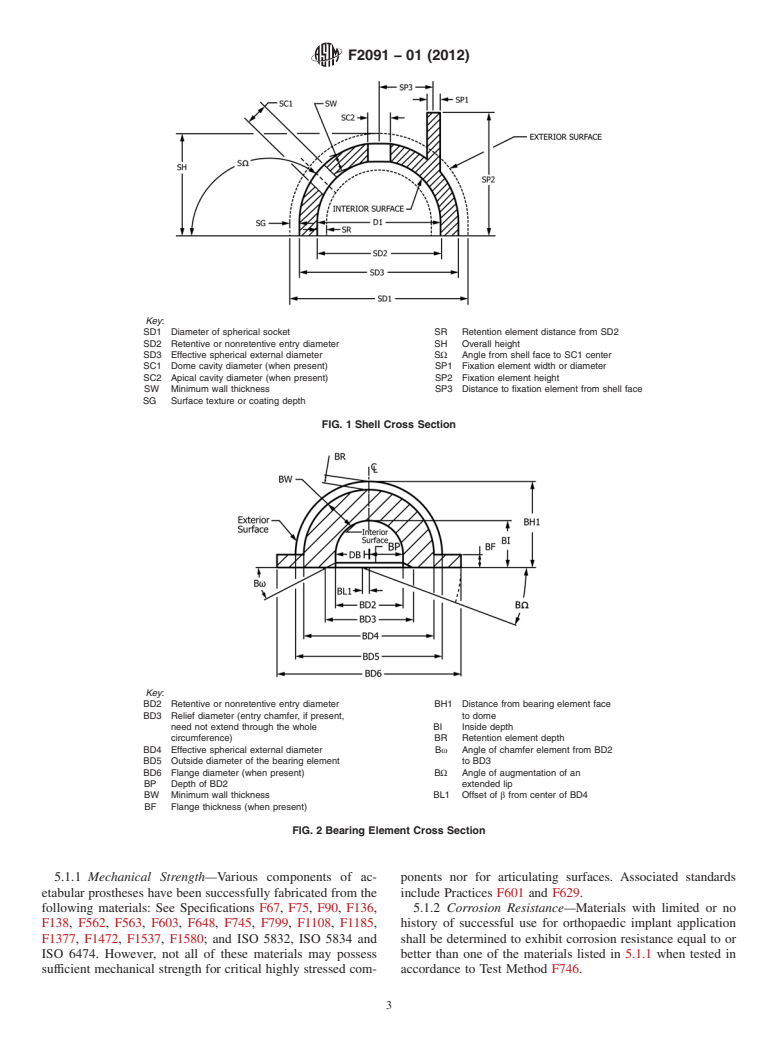

ISO 5834 Implants for surgery—Ultra high molecular 3.2 Dimensions of acetabular prostheses should be desig-

weight polyethylene nated in accordance with Figs. 1-3 or by an equally acceptable

ISO6474 Implantsforsurgery—Ceramicmaterialsbasedon and detailed method.

high purity alumina

NOTE 1—Figs. 1-3 are intended to be illustrative of typical acetabular

ISO 9001 Quality systems—Model for quality assurance in

prostheses and to designate dimensions, but representation of the compo-

design/development, production, installation, and servic-

nents does not otherwise form part of the standard.

ing

4. Types

2.3 Code of Federal Regulations:

4.1 Acetabular prostheses falling within the scope of this

21 CFR 820 Quality System Regulation

specification are of two types, as defined below. There are no

3. Terminology distinguishing features (for example, augmentation or lack

thereof,holes,andsoforth)thatwouldexemptanydevicefrom

3.1 Definitions:

any requirement of this specification.

3.1.1 bearing element, n—articulating surface element be-

4.1.1 Type I—Single-piece acetabular prostheses.

tween the femoral head and shell or bonding agent (bone

cement). NOTE 2—Specifications to both bearing elements and shell may apply.

3.1.2 cavity, n—any slot, cut, hole, or other feature within 4.1.2 Type II—Multipiece, modular structure prostheses.

the shell intended to accommodate modular adjunct fixation

5. Material

5.1 The choice of materials is understood to be a necessary,

Available from International Organization for Standardization (ISO), 1, ch. de

but not sufficient, assurance of function of the device made

la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

fromthem.Alldevicesconformingtothisspecificationshallbe

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

fabricated from materials with adequate mechanical strength

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

dodssp.daps.dla.mil. and durability, corrosion resistance, and biocompatibility.

F2091−01 (2012)

Key:

SD1 Diameter of spherical socket SR Retention element distance from SD2

SD2 Retentive or nonretentive entry diameter SH Overall height

SD3 Effective spherical external diameter SΩ Angle from shell face to SC1 center

SC1 Dome cavity diameter (when present) SP1 Fixation element width or diameter

SC2 Apical cavity diameter (when present) SP2 Fixation element height

SW Minimum wall thickness SP3 Distance to fixation element from shell face

SG Surface texture or coating depth

FIG. 1Shell Cross Section

Key:

BD2 Retentive or nonretentive entry diameter BH1 Distance from bearing element face

BD3 Relief diameter (entry chamfer, if present, to dome

need not extend through the whole BI Inside depth

circumference) BR Retention element depth

BD4 Effectiv

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.