ASTM D4801-95(2001)e1

(Specification)Standard Specification for Polyethylene Sheeting in Thickness of 0.25 mm (0.010 in.) and Greater

Standard Specification for Polyethylene Sheeting in Thickness of 0.25 mm (0.010 in.) and Greater

SCOPE

1.1 This specification covers requirements for extruded- and compression-molded sheeting made from low-, medium- and high-density polyethylenes and copolymers in thickness of 0.25 mm (0.010 in.) and greater. Sheeting conforming to this specification is intended for use in the thinner gages principally for chemical tank linings, spacers in electrical equipment, and for thermoforming into such items as trays, pallets, and shipping containers. The thicker gages are used principally as machine-shop stock.

1.2 Polyethylene materials, being thermoplastics, are reprocessable and recyclable (see Guide D5033). This specification allows for the use of those polyethylene plastic materials, provided that any specific requirements as governed by the producer and end user are met.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 4801 – 95 (Reapproved 2001)

Standard Specification for

Polyethylene Sheeting in Thickness of 0.25 mm (0.010 in.)

and Greater

This standard is issued under the fixed designation D 4801; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Practice D 1898 was deleted editorially from the Referenced Documents section in June 2001.

1. Scope D 374 Test Methods for Thickness of Solid Electrical Insu-

lation

1.1 Thisspecificationcoversrequirementsforextruded-and

D 618 Practice for Conditioning Plastics for Testing

compression-molded sheeting made from low-, medium- and

D 638 Test Method for Tensile Properties of Plastics

high-density polyethylenes and copolymers in thickness of

D 883 Terminology Relating to Plastics

0.25 mm (0.010 in.) and greater. Sheeting conforming to this

D 1204 Test Method for Linear Dimensional Changes of

specificationisintendedforuseinthethinnergagesprincipally

Nonrigid Thermoplastic Sheeting or Film at Elevated

for chemical tank linings, spacers in electrical equipment, and

Temperature

for thermoforming into such items as trays, pallets, and

D 1248 SpecificationforPolyethylenePlasticsMoldingand

shipping containers. The thicker gages are used principally as

Extrusion Materials

machine-shop stock.

D 2103 Specification for Polyethylene Film and Sheeting

1.2 Polyethylene materials, being thermoplastics, are repro-

D 3892 Practice for Packaging/Packing of Plastics

cessable and recyclable (see Guide D 5033). This specification

D 5033 GuidefortheDevelopmentofStandardsRelatingto

allows for the use of those polyethylene plastic materials,

the Proper Use of Recycled Plastics

provided that any specific requirements as governed by the

2.2 Military Standard:

producer and end user are met.

MIL-STD-105 Sampling Procedures and Tables for Inspec-

1.3 The values stated in SI units are to be regarded as the

tion by Attributes

standard. The values given in parentheses are for information

2.3 Federal Standard:

only.

Fed. Std. No. 406, Plastics: Methods of Testing

1.4 The following precautionary caveat pertains only to the

(Method 6051, Warpage)

test methods portion, Section 11, of this specification: This

2.4 Federal Specification:

standard does not purport to address all of the safety concerns,

L-P-390C-Plastic, Molding and Extrusion Material, Poly-

if any, associated with its use. It is the responsibility of the user

ethylene and Copolymers (Low, Medium, and High Den-

of this standard to establish appropriate safety and health

sity)

practices and determine the applicability of regulatory limita-

tions prior to use.

3. Terminology

NOTE 1—There is no similar or equivalent ISO standard.

3.1 Definitions:Unlessotherwiseindicated,theterminology

used in this specification is in accordance with Terminology

2. Referenced Documents

D 883.

2.1 ASTM Standards:

4. Classification

4.1 The polyethylene sheeting in accordance with this

This specification is under the jurisdiction of ASTM Committee D20 on

specification is classified by special types as follows:

Plastics and is the direct responsibility of Subcommittee D20.19 on Film and

Sheeting.

4.1.1 Type I—General purpose, natural and colors.

Current edition approved Nov. 10, 1995. Published January 1996. Originally

4.1.2 Type II—Dielectric, natural and colors.

published as D 4801 – 88. Last previous edition D 4801 – 88.

4.1.3 Type III—Weather-resistant, black.

Changes in this edition were made in the scope and referenced documents, and

a keywords section was added.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 4801 – 95 (2001)

5. Ordering Information the shipment equal to the quantity ordered.The diameter of the

roll may be specified.

5.1 Users should select the preferred options permitted

7.7 Color—The sheeting shall be of the color specified by

herein and include the following information in the purchase

the user.

contract.

7.8 Grade—The sheeting shall be of the grade specified by

5.1.1 Title, number, and date of this specification.

the user.

5.1.2 Classification according to Specification D 1248

7.9 Workmanship—The sheeting shall have a smooth finish

(Tables 4A, Tables 4B, and Tables 4C) of the material to be

and shall be free of cracks, blisters, bubbles, discolorations,

used to manufacture the sheet (see 6.1).

craze, surface scratches that form definite indentations, and

5.1.3 Length and width of sheets (see 7.5 and 7.6).

other defects that could affect appearance or serviceability.

5.1.4 Thickness of sheets (see 7.5).

7.9.1 Dimensional Defects—The sheeting shall show none

5.1.5 Color (see 7.7).

of the defects described in Table 2.

5.1.6 Requirements for packaging, packing, and marking

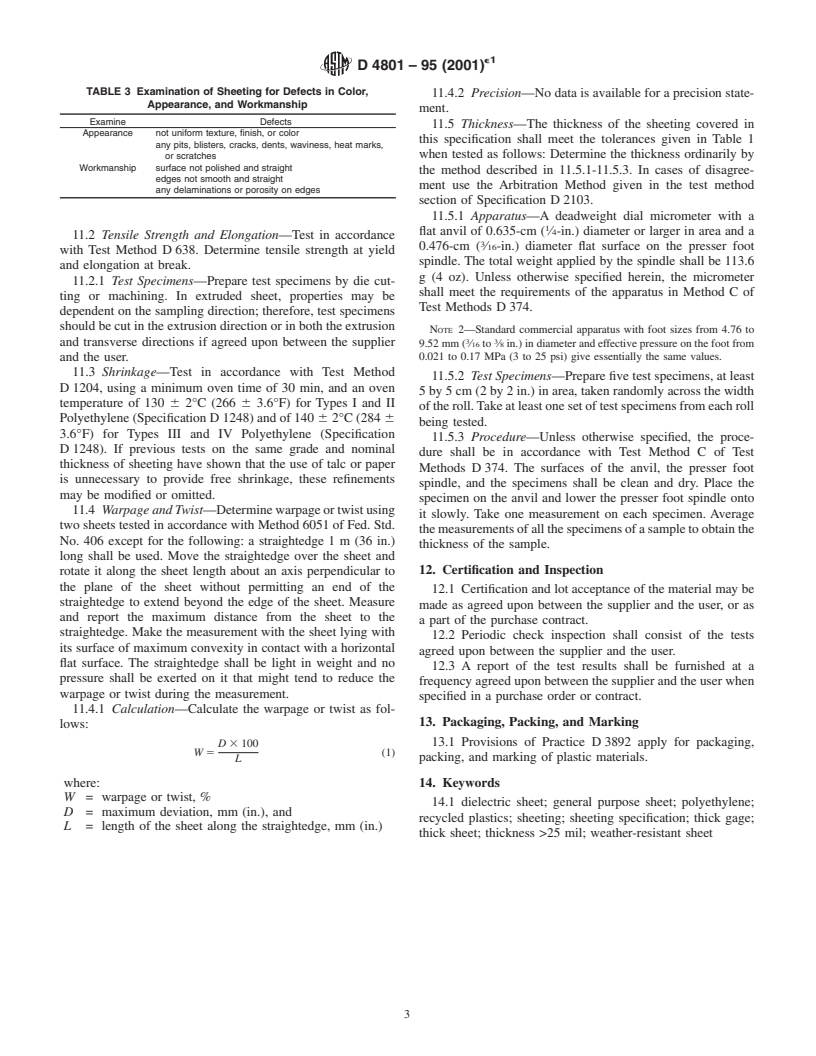

7.9.2 Defects in Color, Appearance, and Workmanship—

(see 13.1).

The sheeting shall show none of the defects described in Table

3.

6. Materials and Manufacture

6.1 Materials—The sheeting shall be manufactured from

8. Sampling

polyethylene thermoplastic material of the special grade speci-

8.1 Unless otherwise agreed upon between the user and the

fied in 5.1.2. The supplier shall furnish, for the material used,

supplier, the materials shall be sampled in accordance with the

data for the classification properties.

sampling procedure prescribed in Practice D 1898. Adequate

6.2 Manufacture—Sheeting shall be formed by extrusion

statistical sampling shall be considered an acceptable alterna-

molding and roll polishing, or compression molding.

tive. A lot of material shall be considered as a unit of

manufacture as prepared for shipment, and may consist of a

7. Detail Requirements

blend of two or more production runs or batches.

7.1 Form—The sheeting shall be furnished flat or in rolls in

the dimensions specified.

9. Testing

7.2 Tensile Strength and Elongation—Sheeting having a

9.1 Test the sheeting for the applicable characteristics listed

thickness of 3.2 mm (0.125 in.) and under shall have tensile

in 7.2, 7.3, and 7.4 and Table 1 and Table 2 in accordance with

strength and elongation not less than 90 % of the values

the test methods specified herein, for each lot submitted for

specified in Specification D 1248 (Tables 4A, Tables 4B, and

inspection.

Tables 4C) for the applicable type and grade. Sheeting greater

than 3.2 mm (0.125 in.) in thickness shall meet the tensile

10. Conditioning

strength and elongation requirements of Specification D 1248.

10.1 Condition the test specimens at 23 6 2°C (73.4 6

The type, class, and grade requirements for Fed. Spec. L-P-

3.6°F) and 50 6 5 % relative humidity for not less than 40 h

390C are included in the tables in Specification D 1248.

prior to testing in accordance with Procedure A of Practice

7.3 Shrinkage—The sheeting, when tested as specified in

D 618.

11.3, shall conform to the requirements as determined between

the user and the supplier.

11. Test Methods

7.4 Warpage and Twist—The sheeting, when tested as

11.1 Conduct tests at 23 6 2°C (73.4 6 3.6°F) and 50 6

specified in 11.4, shall conform to the requirements as deter-

5 % relative humidity.

mined between the user and the supplier.

7.5 Dimensions—Sheeting shall be supplied in the width,

length (or weight), and thickness as specified between the user

TABLE 2 Examination of the Sheeting for Defects in Dimensions

and the supplier, except a maximum of 4 % of the sheet in a

Examine Defects

shipment may be trimmed 55-mm (2-in.) undersize or half-

Length and width (sheet) not of the length and width specified

size. Such trimmed sheet shall be packed separately from

varies by more than +3.2,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.