ASTM D4966-98(2004)

(Test Method)Standard Test Method for Abrasion Resistance of Textile Fabrics (Martindale Abrasion Tester Method)

Standard Test Method for Abrasion Resistance of Textile Fabrics (Martindale Abrasion Tester Method)

SCOPE

1.1 This test method covers the determination of the abrasion resistance of textile fabrics using the Martindale abrasion tester. Fabrics of all types may be tested by this method but difficulties may arise with fabrics with a pile depth greater than 0.08 in. (2 mm).

1.2 The values stated in inch-pound units are to be regarded as standard; the values in SI units are provided as information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

For other current test methods of testing the abrasion resistance of textiles refer to Test Methods D 3884, D 3885, D 3886, D 4157, D 4158, and AATCC Test Method 93.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4966 – 98 (Reapproved 2004)

Standard Test Method for

Abrasion Resistance of Textile Fabrics (Martindale Abrasion

1

Tester Method)

This standard is issued under the fixed designation D 4966; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 AATCC Methods and Procedures:

3

Evaluation Procedure 1 Gray Scale for Color Change

1.1 This test method covers the determination of the abra-

TestMethod 93 AbrasionResistanceofFabrics:Accelerator

sion resistance of textile fabrics using the Martindale abrasion

3

Method

tester. Fabrics of all types may be tested by this method but

difficulties may arise with fabrics with a pile depth greater than

3. Terminology

0.08 in. (2 mm).

3.1 Definitions—For definitions of other textile terms used

1.2 The values stated in inch-pound units are to be regarded

in this test method, refer to Terminology D 123.

as standard; the values in SI units are provided as information

3.2 Definitions of Terms Specific to This Standard:

only.

3.2.1 abrasion, n—the wearing away of any part of a

1.3 This standard does not purport to address all of the

material by rubbing against another surface.

safety concerns, if any, associated with its use. It is the

3.2.2 abrasion cycle, n—total number of movements re-

responsibility of the user of this standard to establish appro-

quired to complete a geometric shape in a Martindale abrasion

priate safety and health practices and determine the applica-

tester.

bility of regulatory limitations prior to use.

3.2.3 cycle, n—16 movements required for the completion

NOTE 1—For other current test methods of testing the abrasion resis-

of one Lissajous figure on a Martindale tester.

tance of textiles refer to Test Methods D 3884, D 3885, D 3886, D 4157,

3.2.4 lissajous figure, n—a geometric figure that starts as a

D 4158, and AATCC Test Method 93.

straight line, then becomes a widening ellipse and narrows to

again become a straight line. There are 16 movements in one

2. Referenced Documents

2 Lissajous figure.

2.1 ASTM Standards:

3.2.5 movement, n—one rotation of the two outer gearing of

D 123 Terminology Relating to Textiles

the Martindale tester.

D 1776 Practice for Conditioning Textiles for Testing

3.2.6 standard atmosphere for preconditioning textiles,

D 3884 Test Method for Abrasion Resistance of Textile

n—anatmospherehavingarelativehumidityof10to25 %and

Fabrics (Rotary Platform, Double-Head Method)

a temperature not over 122°F (50°C).

D 3885 Test Method for Abrasion Resistance of Textile

3.2.7 standard atmosphere for testing, in textiles, n—an

Fabrics (Flexing and Abrasion Method)

atmosphere for testing in which the air is maintained at a

D 3886 Test Method for Abrasion Resistance of Textile

relative humidity of 65 6 2 % and at a temperature of 70 6

Fabrics (Inflated Diaphragm Method)

2°F (21 6 1°C).

D 4157 Test Method for Abrasion Resistance of Textile

Fabrics (Oscillatory Cylinder Method)

4. Summary of Test Method

D 4158 Test Method for Abrasion Resistance of Textile

4.1 Abrasion resistance is measured by subjecting the speci-

Fabrics (Uniform Abrasion Method)

men to rubbing motion in the form of a geometric figure, that

is, a straight line, which becomes a gradually widening ellipse,

1

until it forms another straight line in the opposite direction and

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

traces the same figure again under known conditions of

Specific.

pressure and abrasive action. Resistance to abrasion is evalu-

Current edition approved Dec. 1, 2004. Published January 2005. Originally

ated by various means which are described in Section 11.

approved in 1989. Last previous edition approved in 1998 as D 4966 – 98.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from the American Association of Textile Chemists and Colorists,

the ASTM website. P.O. Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

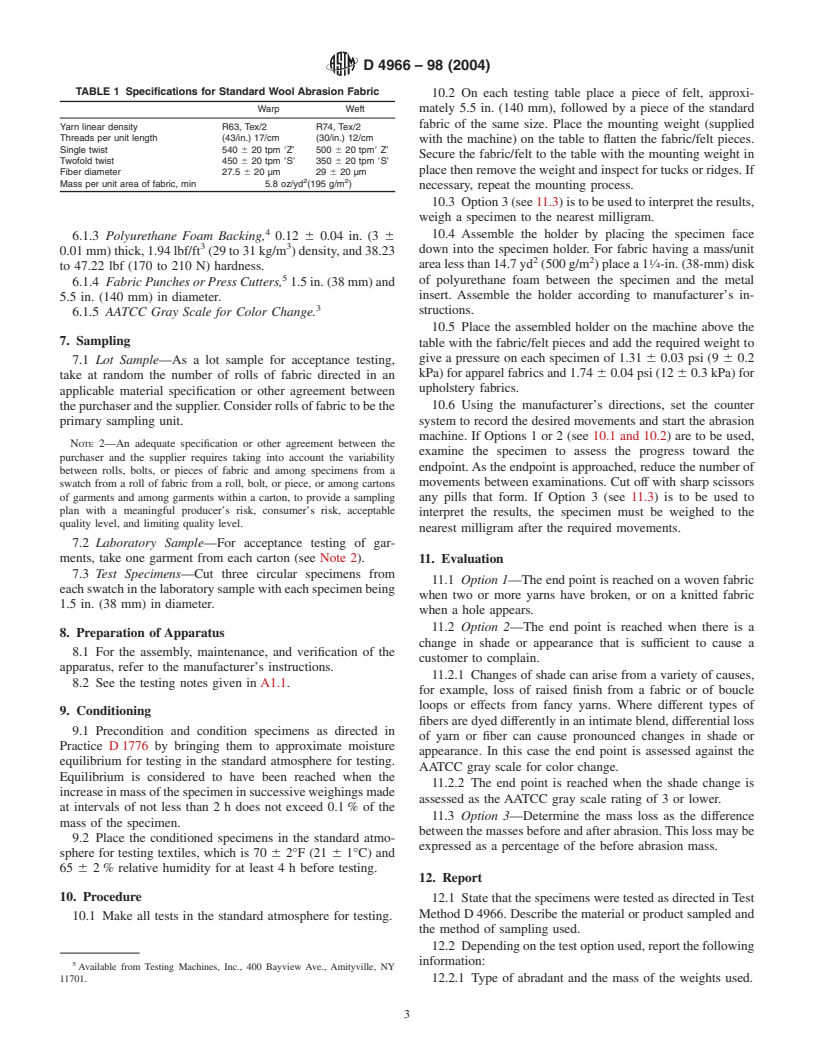

D 4966 – 98 (2004)

surfaces, it is assumed that the abradant will not change

appreciably in a specific series of tests, but obviously similar

abradantsusedindifferentlaboratorieswillnotlikelychangeat

the same rate due to differences in usage. Permanent abradants

also may chang

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.