ASTM F2791-14

(Guide)Standard Guide for Assessment of Surface Texture of Non-Porous Biomaterials in Two Dimensions

Standard Guide for Assessment of Surface Texture of Non-Porous Biomaterials in Two Dimensions

SIGNIFICANCE AND USE

4.1 The term “surface texture” is used to describe the local deviations of a surface from an ideal shape. Surface texture usually consists of long wavelength repetitive features that occur as results of chatter, vibration, or heat treatments during the manufacture of implants. Short wavelength features superimposed on the long wavelength features of the surface, which arise from polishing or etching of the implant, are referred to as roughness.

4.2 This guide provides an overview of techniques that are available for measuring the surface in terms of Cartesian coordinates and the parameters used to describe surface texture. It is important to appreciate that it is not possible to measure surface texture per se, but to derive values for parameters that can be used to describe it.

SCOPE

1.1 This guide describes some of the more common methods that are available for measuring the topographical features of a surface and provides an overview of the parameters that are used to quantify them. Being able to reliably derive a set of parameters that describe the texture of biomaterial surfaces is a key aspect in the manufacture of safe and effective implantable medical devices that have the potential to trigger an adverse biological reaction in situ.

1.2 This guide is not intended to apply to porous structures with average pore dimensions in excess of approximately 50 nm (0.05 μm).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2791 −14

StandardGuide for

Assessment of Surface Texture of Non-Porous Biomaterials

in Two Dimensions

This standard is issued under the fixed designation F2791; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Standards:

ISO 3274 Geometrical Product Specifications (GPS)—

1.1 This guide describes some of the more common meth-

Surface Texture: Profile Method—Nominal Characteris-

ods that are available for measuring the topographical features

tics of Contact (Stylus) Instruments

of a surface and provides an overview of the parameters that

ISO 4287 Geometrical Product Specifications (GPS)—

are used to quantify them. Being able to reliably derive a set of

Surface Texture: Profile Method—Terms, Definitions and

parameters that describe the texture of biomaterial surfaces is

Surface Texture Parameters

a key aspect in the manufacture of safe and effective implant-

ISO 4288 Geometrical Product Specifications (GPS)—

able medical devices that have the potential to trigger an

Surface Texture: Profile Method—Rules and Procedures

adverse biological reaction in situ.

for the Assessment of Surface Texture

1.2 This guide is not intended to apply to porous structures

ISO 13565–1 Geometrical Product Specifications (GPS)—

with average pore dimensions in excess of approximately 50

SurfaceTexture: Profile Method—Surfaces Having Strati-

nm (0.05 µm).

fiedFunctionalProperties;FilteringandGeneralMeasure-

ment Conditions

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions of Terms Specific to This Standard:

1.4 This standard does not purport to address all of the

3.1.1 biomaterial, n—any substance (other than a drug),

safety concerns, if any, associated with its use. It is the

synthetic or natural, that can be used as a system or part of a

responsibility of the user of this standard to establish appro-

system that treats, augments, or replaces any tissue, organ, or

priate safety and health practices and determine the applica-

function of the body. F2664

bility of regulatory limitations prior to use.

3.1.2 evaluation length, ln, n—length in the direction of the

2. Referenced Documents x-axis used to assess the profile under evaluation.

3.1.2.1 Discussion—The evaluation length may contain one

2.1 ASTM Standards:

or more sampling lengths. ISO 4287

C813 Test Method for Hydrophobic Contamination on Glass

by Contact Angle Measurement 3.1.3 hydrophilic, adj—having a strong affinity for water;

wettable.

F2312 Terminology Relating to Tissue Engineered Medical

Products 3.1.3.1 Discussion—Hydrophilic surfaces exhibit zero con-

F2450 Guide for Assessing Microstructure of Polymeric tact angles. C813

Scaffolds for Use in Tissue-Engineered Medical Products

3.1.4 hydrophobic, adj—having little affinity for water;

F2664 Guide for Assessing the Attachment of Cells to

nonwettable.

Biomaterial Surfaces by Physical Methods

3.1.4.1 Discussion—Hydrophobic surfaces exhibit contact

anglesappreciablygreaterthanzero:generallygreaterthan45°

for the advancing angle. C813

This guide is under the jurisdiction of ASTM Committee F04 on Medical and

3.1.5 implant, n—a substance or object that is put in the

Surgical Materials and Devices and is the direct responsibility of Subcommittee

body as a prosthesis, or for treatment or diagnosis. F2664

F04.42 on Biomaterials and Biomolecules for TEMPs.

Current edition approved Oct. 1, 2014. Published December 2014. Originally

3.1.6 lay, n—the direction of the predominant surface

approved in 2009. Last previous edition approved in 2009 as F2791–09. DOI:

pattern. ISO 13565–1

10.1520/F2791-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2791−14

NOTE 1—The surface shown in (A) has no directionality or lay, therefore profiles can be oriented at any angle. Profiles (dashed line arrow) are drawn

perpendicular to the lay (solid line arrow) in surfaces that have directionality (B).

FIG. 1Profile Orientation and Surface Features

3.1.7 primary profile, n—the profile after application of the measure surface texture per se, but to derive values for

short wavelength filters. ISO 3274 parameters that can be used to describe it.

3.1.8 profile peak, n—an outwardly directed (from the

5. The Relationship Between Surface Texture, Surface

material to the surrounding medium) portion of the assessed

Chemistry, Surface Energy, and Biocompatibility

profileconnectingtwoadjacentpointsoftheintersectionofthe

profile with the x-axis. ISO 4287 5.1 The biocompatibility of materials is influenced by many

factors such as size, shape, material bulk, and surface chemical

3.1.9 profile valley, n—aninwardlydirected(fromsurround-

composition, surface energy, and surface topography. Chang-

ing medium to material) portion of the assessed profile

ing any one of these related characteristics of a biocompatible

connecting two adjacent points of the intersection of the

material can have a significant effect on cell behavior. The

assessed profile with the x-axis. ISO 4287

response of a cell to a biomaterial can be assessed by

3.1.10 real surface, n—surface limiting the body and sepa-

measuring the adhesive strength between it and the underlying

rating it from the surrounding medium. ISO 4287

surface, monitoring changes in its shape or in the expression of

3.1.11 sampling length, lr, n— length in the direction of the

biomarkers.

x-axis used for identifying the irregularities characterizing the

5.2 The chemical species present on a surface can be

profile under evaluation. ISO 4287

mapped in detail using surface sensitive analysis techniques

3.1.12 scaffold, n—a support, delivery vehicle or metric for

(for example, X-ray photoelectron spectroscopy where the

facilitating the migration, binding, or transport of cells or 4

penetration depth is 10 nm or below (1)). The chemical

bioactive molecules used to replace, repair, or regenerate

species present on the surface together with the surface

tissues. F2450

topography determine how hydrophilic the surface is. Measur-

3.1.13 surface profile, n—profile that results from the inter-

ing the contact angle between the surface and a fluid, usually

section of the real surface by a specified plane.

water,canassessthedegreeofhydrophilicityofasurface.Care

3.1.13.1 Discussion—In practice, it is usual to choose a

should be taken when comparing contact angle measurements

plane with a normal that nominally lies parallel to the real

made on different surfaces, as the relative contributions from

surface and in a suitable direction. ISO 4287

the surface chemistry and texture are unlikely to be the same.

4. Significance and Use

6. Surfaces and Surface Profiles

4.1 The term “surface texture” is used to describe the local

6.1 Conventionally surfaces are described in Cartesian co-

deviations of a surface from an ideal shape. Surface texture

ordinates where the x-axis is defined as being perpendicular to

usually consists of long wavelength repetitive features that

the lay direction. The y-axis is in-plane and is perpendicular to

occur as results of chatter, vibration, or heat treatments during

the x-axis direction. The z-axis is out of plane. The profile of a

the manufacture of implants. Short wavelength features super-

surface that has a uniform, non-directional texture can be

imposed on the long wavelength features of the surface, which

measured at any in-plane orientation (see Fig. 1(A)); however,

arisefrompolishingoretchingoftheimplant,arereferredtoas

several profiles at different orientations should be measured to

roughness.

find the maximum amplitude (see Fig. 1(A)). For patterned

4.2 This guide provides an overview of techniques that are

available for measuring the surface in terms of Cartesian

coordinates and the parameters used to describe surface tex-

The boldface numbers in parentheses refer to a list of references at the end of

ture. It is important to appreciate that it is not possible to this standard.

F2791−14

surfacesthathaveperiodicfeatures,alay,theorientationofthe valleys that is in essence a form of filtering. This topic is

profile is at right angles to it (see Fig. 1(B)). further discussed in Section 11.

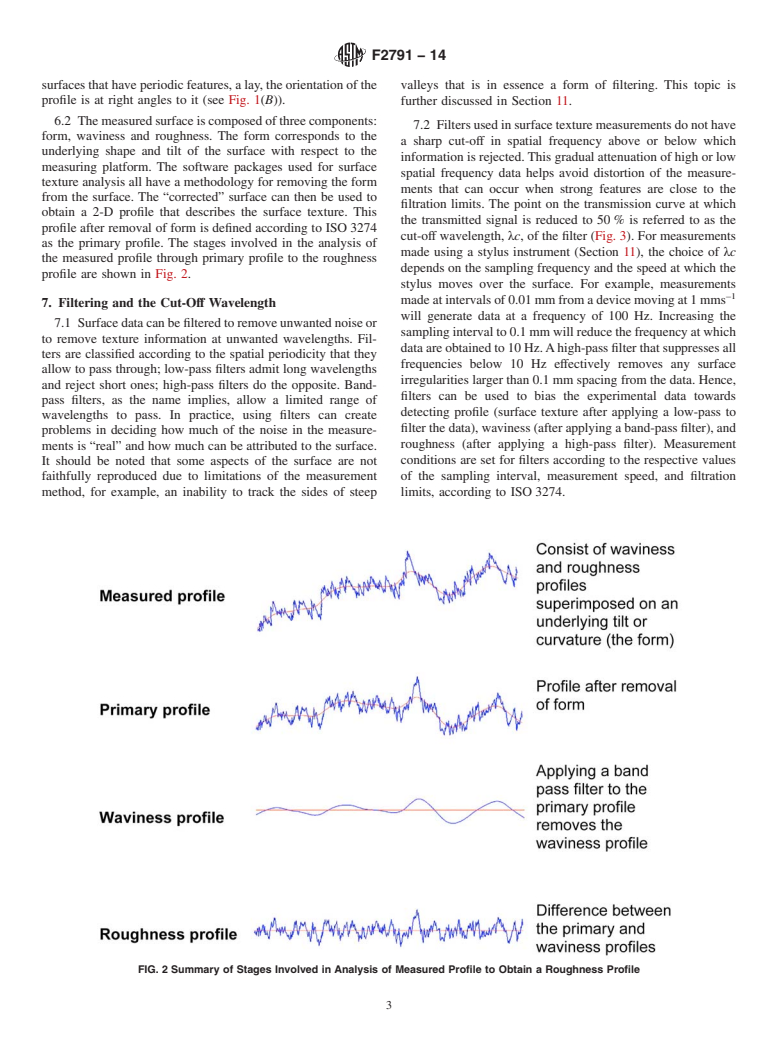

6.2 Themeasuredsurfaceiscomposedofthreecomponents:

7.2 Filtersusedinsurfacetexturemeasurementsdonothave

form, waviness and roughness. The form corresponds to the

a sharp cut-off in spatial frequency above or below which

underlying shape and tilt of the surface with respect to the

information is rejected.This gradual attenuation of high or low

measuring platform. The software packages used for surface

spatial frequency data helps avoid distortion of the measure-

texture analysis all have a methodology for removing the form

ments that can occur when strong features are close to the

from the surface. The “corrected” surface can then be used to

filtration limits. The point on the transmission curve at which

obtain a 2-D profile that describes the surface texture. This

the transmitted signal is reduced to 50 % is referred to as the

profile after removal of form is defined according to ISO 3274

cut-off wavelength,λc, of the filter (Fig. 3). For measurements

as the primary profile. The stages involved in the analysis of

made using a stylus instrument (Section 11), the choice of λc

the measured profile through primary profile to the roughness

depends on the sampling frequency and the speed at which the

profile are shown in Fig. 2.

stylus moves over the surface. For example, measurements

–1

madeatintervalsof0.01mmfromadevicemovingat1mms

7. Filtering and the Cut-Off Wavelength

will generate data at a frequency of 100 Hz. Increasing the

7.1 Surfacedatacanbefilteredtoremoveunwantednoiseor

samplingintervalto0.1mmwillreducethefrequencyatwhich

to remove texture information at unwanted wavelengths. Fil-

dataareobtainedto10Hz.Ahigh-passfilterthatsuppressesall

ters are classified according to the spatial periodicity that they

frequencies below 10 Hz effectively removes any surface

allow to pass through; low-pass filters admit long wavelengths

irregularities larger than 0.1 mm spacing from the data. Hence,

and reject short ones; high-pass filters do the opposite. Band-

filters can be used to bias the experimental data towards

pass filters, as the name implies, allow a limited range of

detecting profile (surface texture after applying a low-pass to

wavelengths to pass. In practice, using filters can create

filterthedata),waviness(afterapplyingaband-passfilter),and

problems in deciding how much of the noise in the measure-

roughness (after applying a high-pass filter). Measurement

ments is “real” and how much can be attributed to the surface.

conditions are set for filters according to the respective values

It should be noted that some aspects of the surface are not

faithfully reproduced due to limitations of the measurement of the sampling interval, measurement speed, and filtration

method, for example, an inability to track the sides of steep limits, according to ISO 3274.

FIG. 2Summary of Stages Involved in Analysis of Measured Profile to Obtain a Roughness Profile

F2791−14

FIG. 350% Reduction in Transmission Curve

7.3 ISO 4287 specifies that 2-D roughness parameters need 8.1.2 Spatial parameters, which describe in-plane variations

to be determined over five sequential sampling lengths, lr, of surface texture; and

unless otherwise specified. This grouping of five serial sam- 8.1.3 Hybrid parameters, which combine both amplitude

pling lengths is referred to as the evaluation length, ln. The and spatial information (for example, mean slope).

sampling length varies according to the length scale of the

8.2 Ra—The most widely used parameter to quantify sur-

texture being assessed; larger features require a long sampling

face texture is the arithmetical mean deviation of the absolute

length.Guidanceastowhichsamplinglengthtouseforagiven

ordinate values, Z(x), of the profile from a center line (see

range of feature sizes is shown in Table 1. It may be necessary

Table 2 and Fig. 5). Despite its common usage, Ra does not

to perform one or more iterations to identify the best value for

provideatrulyaccuraterepresentationofasurfaceprofilesince

lr. This can be achieved by calculating the mean width of a

any information regarding peak heights or valley depths can be

profile element, RSm (see Fig. 4), from a measured profile

lost in its derivation. This insensitivity to surface texture is

where the value for lr is based on a best guess. This initial

apparent in Fig. 6, which shows that quite different profiles can

iteration will enable a new value for RSm to be determined and

have the same Ra value. The statistical significance of Ra is

that leads to a potential revision of lr according to Table 1.

improved by averaging the values obtained for each of the five

sampling lengths.

8. Quantification of Surface Profiles

8.3 Rq—The root-mean-square value of all distances of the

8.1 Parameters that are used to characterize 2-D surface

measured profile away from the center line, Rq, although

profiles are grouped as:

similar in terms of its derivation to Ra, has a subtle but

8.1.1 Amplitude parameters, which are measures of varia-

significant difference. The deviations of the peak heights and

tions in profile height. These parameters are split into two

valley depths from the midline appear as a squared term in Rq.

subclasses: averaging parameters, and peak and valley param-

Thatincreasesitssensitivitytohighpeaksordeepvalleys.This

eters;

sensitivity can be useful, but it should be noted that the

presenceofaforeignbody,forexample,hairorascratchinthe

surface can have a significant influence on the value of Rq.

TABLE 1 Guide to Choosing Sampling Lengths for the

A

Measurement of Periodic Profiles 8.4 Rsk—Skewness, the distribution of peak heights and

Mean profile element Sampling length,

valley depths provides valuable information about surface

width, RSm (µm) lr (µm)

texture. A surface that has a range of peak heights and valley

13 < RSm# 40 80

depths will have a bell-shaped probability distributi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2791 − 09 F2791 − 14

Standard Guide for

Assessment of Surface Texture of Non-Porous Biomaterials

in Two Dimensions

This standard is issued under the fixed designation F2791; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide describes some of the more common methods that are available for measuring the topographical features of a

surface and provides an overview of the parameters that are used to quantify them. Being able to reliably derive a set of parameters

that describe the texture of biomaterial surfaces is a key aspect in the manufacture of safe and effective implantable medical devices

that have the potential to trigger an adverse biological reaction in situ.

1.2 This guide is not intended to apply to porous structures with average pore dimensions in excess of approximately 50 nm

(0.05 μm).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C813 Test Method for Hydrophobic Contamination on Glass by Contact Angle Measurement

F2312 Terminology Relating to Tissue Engineered Medical Products

F2450 Guide for Assessing Microstructure of Polymeric Scaffolds for Use in Tissue-Engineered Medical Products

F2664 Guide for Assessing the Attachment of Cells to Biomaterial Surfaces by Physical Methods

2.2 Other Standards:

ISO 3274 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Nominal Characteristics of Contact

(Stylus) Instruments

ISO 4287 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface

Texture Parameters

ISO 4288 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the

Assessment of Surface Texture

ISO 13565–1 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Surfaces Having Stratified

Functional Properties; Filtering and General Measurement Conditions

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 biocompatible, adj—a material may be considered biocompatible if the materials perform with an appropriate host

response in a specific application. F2312

3.1.1 biomaterial, n—any substance (other than a drug), synthetic or natural, that can be used as a system or part of a system

that treats, augments, or replaces any tissue, organ, or function of the body. F2664

This guide is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee F04.42

on Biomaterials and Biomolecules for TEMPs.

Current edition approved Aug. 1, 2009Oct. 1, 2014. Published September 2009December 2014. Originally approved in 2009. Last previous edition approved in 2009 as

F2791–09. DOI: 10.1520/F2791-09.10.1520/F2791-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2791 − 14

3.1.2 evaluation length, ln, n—length in the direction of the x-axis used to assess the profile under evaluation.

3.1.2.1 Discussion—

The evaluation length may contain one or more sampling lengths. ISO 4287

3.1.3 hydrophilic, adj—having a strong affinity for water; wettable.

3.1.3.1 Discussion—

Hydrophilic surfaces exhibit zero contact angles. C813

3.1.4 hydrophobic, adj—having little affinity for water; nonwettable.

3.1.4.1 Discussion—

Hydrophobic surfaces exhibit contact angles appreciably greater than zero: generally greater than 45° for the advancing angle.

C813

3.1.5 implant, n—a substance or object that is put in the body as a prosthesis, or for treatment or diagnosis. F2664

3.1.6 lay, n—the direction of the predominant surface pattern. ISO 13565–1

3.1.7 primary profile, n—the profile after application of the short wavelength filters. ISO 3274

3.1.8 profile peak, n—an outwardly directed (from the material to the surrounding medium) portion of the assessed profile

connecting two adjacent points of the intersection of the profile with the x-axis. ISO 4287

3.1.9 profile valley, n—an inwardly directed (from surrounding medium to material) portion of the assessed profile connecting

two adjacent points of the intersection of the assessed profile with the x-axis. ISO 4287

3.1.10 real surface, n—surface limiting the body and separating it from the surrounding medium. ISO 4287

3.1.11 sampling length, lr, n— length in the direction of the x-axis used for identifying the irregularities characterizing the profile

under evaluation. ISO 4287

3.1.12 scaffold, n—a support, delivery vehicle or metric for facilitating the migration, binding, or transport of cells or bioactive

molecules used to replace, repair, or regenerate tissues. F2450

3.1.13 surface profile, n—profile that results from the intersection of the real surface by a specified plane.

3.1.13.1 Discussion—

In practice, it is usual to choose a plane with a normal that nominally lies parallel to the real surface and in a suitable direction.

ISO 4287

NOTE 1—The surface shown in (A) has no directionality or lay, therefore profiles can be oriented at any angle. Profiles (dashed line arrow) are drawn

perpendicular to the lay (solid line arrow) in surfaces that have directionality (B).

FIG. 1 Profile Orientation and Surface Features

F2791 − 14

4. Significance and Use

4.1 The term “surface texture” is used to describe the local deviations of a surface from an ideal shape. Surface texture usually

consists of long wavelength repetitive features that occur as results of chatter, vibration, or heat treatments during the manufacture

of implants. Short wavelength features superimposed on the long wavelength features of the surface, which arise from polishing

or etching of the implant, are referred to as roughness.

4.2 This guide provides an overview of techniques that are available for measuring the surface in terms of Cartesian coordinates

and the parameters used to describe surface texture. It is important to appreciate that it is not possible to measure surface texture

per se, but to derive values for parameters that can be used to describe it.

5. The Relationship Between Surface Texture, Surface Chemistry, Surface Energy, and Biocompatibility

5.1 The biocompatibility of materials is influenced by many factors such as size, shape, material bulk, and surface chemical

composition, surface energy, and surface topography. Changing any one of these related characteristics of a biocompatible material

can have a significant effect on cell behavior. The response of a cell to a biomaterial can be assessed by measuring the adhesive

strength between it and the underlying surface, monitoring changes in its shape or in the expression of biomarkers.

5.2 The chemical species present on a surface can be mapped in detail using surface sensitive analysis techniques (for example,

X-ray photoelectron spectroscopy where the penetration depth is 10 nm or below (1)). The chemical species present on the surface

together with the surface topography determine how hydrophilic the surface is. Measuring the contact angle between the surface

and a fluid, usually water, can assess the degree of hydrophilicity of a surface. Care should be taken when comparing contact angle

measurements made on different surfaces, as the relative contributions from the surface chemistry and texture are unlikely to be

the same.

6. Surfaces and Surface Profiles

6.1 Conventionally surfaces are described in Cartesian coordinates where the x-axis is defined as being perpendicular to the lay

direction. The y-axis is in plane in-plane and is perpendicular to the x-axis direction. The z-axis is out of plane. The profile of a

surface that has a uniform, non-directional texture can be measured at any in plane in-plane orientation (see Fig. 1(A)); however,

several profiles at different orientations should be measured to find the maximum amplitude (see Fig. 1(A)). For patterned surfaces

that have periodic features, a lay, the orientation of the profile is at right angles to it (see Fig. 1(B)).

6.2 The measured surface is composed of three components: form, waviness and roughness. The form corresponds to the

underlying shape and tilt of the surface with respect to the measuring platform. The software packages used for surface texture

analysis all have a methodology for removing the form from the surface. The “corrected” surface can then be used to obtain a 2-D

profile that describes the surface texture. This profile after removal of form is defined according to ISO 3274 as the primary profile.

The stages involved in the analysis of the measured profile through primary profile to the roughness profile are shown in Fig. 2.

7. Filtering and the Cut-Off Wavelength

7.1 Surface data can be filtered to remove unwanted noise or to remove texture information at unwanted wavelengths. Filters

are classified according to the spatial periodicity that they allow to pass through; low-pass filters admit long wavelengths and reject

short ones; high-pass filters do the opposite. Band-pass filters, as the name implies, allow a limited range of wavelengths to pass.

In practice, using filters can create problems in deciding how much of the noise in the measurements is “real” and how much can

be attributed to the surface. It should be noted that some aspects of the surface are not faithfully reproduced due to limitations of

the measurement method, for example, an inability to track the sides of steep valleys that is in essence a form of filtering. This

topic is further discussed in Section 11.

7.2 Filters used in surface texture measurements do not have a sharp cut-off in spatial frequency above or below which

information is rejected. This gradual attenuation of high or low spatial frequency data helps avoid distortion of the measurements

that can occur when strong features are close to the filtration limits. The point on the transmission curve at which the transmitted

signal is reduced to 50 % is referred to as the cut-off wavelength, λc, of the filter, filter (Fig. 3.). For measurements made using

a stylus instrument (Section 11), the choice of λc depends on the sampling frequency and the speed at which the stylus moves over

–1

the surface. For example, measurements made at intervals of 0.01 mm from a device moving at 1 mms will generate data at a

frequency of 100 Hz. Increasing the sampling interval to 0.1 mm will reduce the frequency at which data are obtained to 10 Hz.

A high-pass filter that suppresses all frequencies below 10 Hz effectively removes any surface irregularities larger than 0.1 mm

spacing from the data. Hence, filters can be used to bias the experimental data towards detecting profile (surface texture after

applying a low-pass to filter the data), waviness (after applying a band-pass filter), and roughness (after applying a high-pass filter).

Measurement conditions are set for filters according to the respective values of the sampling interval, measurement speed, and

filtration limits, according to ISO 3274.

The boldface numbers in parentheses refer to a list of references at the end of this standard.

F2791 − 14

FIG. 2 Summary of Stages Involved in Analysis of Measured Profile to Obtain a Roughness Profile

FIG. 3 50 % Reduction in Transmission Curve

7.3 ISO 4287 specifies that 2-D roughness parameters need to be determined over five sequential sampling lengths, lr, unless

otherwise specified. This grouping of five serial sampling lengths is referred to as the evaluation length, ln. The sampling length

varies according to the length scale of the texture being assessed; larger features require a long sampling length. Guidance as to

which sampling length to use for a given range of feature sizes is shown in Table 1. It may be necessary to perform one or more

F2791 − 14

TABLE 1 Guide to Choosing Sampling Lengths for the

Measurement of Periodic Profiles

NOTE 1—Based on ISO 4288. The evaluation length is usually taken to

be five times the sampling length.

Mean profile element Sampling length,

width, RSm (μm) lr (μm)

13 < RSm # 40 80

40 < RSm # 130 250

130 < RSm # 400 800

400 < RSm # 1300 2500

1300 < RSm # 4000 8000

TABLE 1 Guide to Choosing Sampling Lengths for the

A

Measurement of Periodic Profiles

Mean profile element Sampling length,

width, RSm (μm) lr (μm)

13 < RSm # 40 80

40 < RSm # 130 250

130 < RSm # 400 800

400 < RSm # 1300 2500

1300 < RSm # 4000 8000

A

Based on ISO 4288. The evaluation length is usually taken to be five times the

sampling length.

iterations to identify the best value for lr. This can be achieved by calculating the mean width of a profile element, RSm (see Fig.

4), from a measured profile where the value for lr is based on a best guess. This initial iteration will enable a new value for RSm

to be determined and that leads to a potential revision of lr according to Table 1.

8. Quantification of Surface Profiles

8.1 Parameters that are used to characterize 2-D surface profiles are grouped as:

8.1.1 Amplitude parameters, which are measures of variations in profile height. These parameters are split into two subclasses:

averaging parameters, and peak and valley parameters;

8.1.2 Spatial parameters, which describe in-plane variations of surface texture; and

8.1.3 Hybrid parameters, which combine both amplitude and spatial information, forinformation (for example, mean

slope.slope).

8.2 Ra—The most widely used parameter to quantify surface texture is the arithmetical mean deviation of the absolute ordinate

values, Z(x),

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.