ASTM D3718-85a(2005)

(Test Method)Standard Test Method for Low Concentrations of Chromium in Paint by Atomic Absorption Spectroscopy

Standard Test Method for Low Concentrations of Chromium in Paint by Atomic Absorption Spectroscopy

SIGNIFICANCE AND USE

The permissible level of heavy metals in certain coatings is specified by governmental regulatory agencies. This test method provides a fully documented procedure for determining low concentrations of chromium present in both water- and solvent-reducible coatings to determine compliance.

SCOPE

1.1 This test method covers the determination of the content of chromium (including chromium oxide) in the range between 0.005 and 1.0 % present in the solids of liquid coatings or in dried films obtained from previously coated substrates. There is no reason to believe that higher levels could not be determined by this test method, provided that appropriate dilutions and adjustments in specimen size and reagent quantities are made.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D3718–85a(Reapproved2005)

Standard Test Method for

Low Concentrations of Chromium in Paint by Atomic

Absorption Spectroscopy

This standard is issued under the fixed designation D3718; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of the content 4.1 The permissible level of heavy metals in certain coat-

of chromium (including chromium oxide) in the range between ingsisspecifiedbygovernmentalregulatoryagencies.Thistest

0.005 and 1.0 % present in the solids of liquid coatings or in methodprovidesafullydocumentedprocedurefordetermining

dried films obtained from previously coated substrates. There low concentrations of chromium present in both water- and

is no reason to believe that higher levels could not be solvent-reducible coatings to determine compliance.

determined by this test method, provided that appropriate

5. Apparatus

dilutions and adjustments in specimen size and reagent quan-

5.1 Atomic Absorption Spectrophotometer, consisting of an

tities are made.

1.2 The values stated in SI units are to be regarded as the atomizer and either a single- or three-slot burner; gas pressure-

regulating and metering devices for nitrous oxide (N O) and

standard. The values given in parentheses are for information

only. acetylene; a chromium hollow cathode lamp with a regulated

constant current supply; a monochromator and associated

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the optics; a photosensitive detector connected to an electronic

amplifier; and a readout device.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 5.2 Muffle Furnace, maintained at 500 6 10°C.

5.3 Force-Draft Oven, maintained at 105 6 2°C.

bility of regulatory limitations prior to use. Specific hazard

statements are given in Section 7. 5.4 Acid Decomposition Vessel, with PTFE digestion cup.

5.5 Hot Plate, with variable surface temperature control

2. Referenced Documents

over the range from 70 to 200°C.

2.1 ASTM Standards: 5.6 Volumetric Flasks, 50, 100 and 1000-mL.

D1193 Specification for Reagent Water 5.7 Pipets, 5, 10, 15, and 20-mL capacity.

D2832 Guide for Determining Volatile and Nonvolatile 5.8 Filter Paper, ashless, medium filtering 15-cm.

Content of Paint and Related Coatings 5.9 Paint Shaker.

5.10 Crucibles, wide form, porcelain, approximately 30-mL

3. Summary of Test Method 4

capacity.

3.1 The sample of liquid coating or dried film is prepared

5.11 Mortar and Pestle.

for analysis by dry ashing at 500°C followed by digestion with 5.12 Paint Draw-Down Bar.

potassium permanganate and sulfuric acid in a polytetrafluo-

6. Reagents

roethylene (PTFE)-lined acid decomposition vessel at an

elevated temperature. The chromium in the filtered digestion 6.1 Purity of Reagents—Reagent grade chemicals shall be

mixture is determined by atomic absorption spectroscopy. used in all tests. Unless otherwise indicated, it is intended that

The sole source of supply of an acid decomposition cup, (Catalog Number

This test method is under the jurisdiction of ASTM Committee D01 on Paint 4745), known to the committee at this time is the Parr Instrument Co., 211

and Related Coatings, Materials, andApplications and is the direct responsibility of Fifty-third St., Moline, IL 61265. If you are aware of alternative suppliers, please

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials. provide this information toASTM International Headquarters. Your comments will

Current edition approved Jan. 1, 2005. Published February 2005. Originally receive careful consideration at a meeting of the responsible technical committee,

approved in 1978. Last previous edition approved in 1999 as D3718 – 85a (1999). which you may attend.

DOI: 10.1520/D3718-85AR05. The sole source of supply of No. 25007 crucibles, known to the committee at

For referenced ASTM standards, visit the ASTM website, www.astm.org, or this time is Coors Co. If you are aware of alternative suppliers, please provide this

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM information to ASTM International Headquarters. Your comments will receive

Standards volume information, refer to the standard’s Document Summary page on careful consideration at a meeting of the responsible technical committee, which

the ASTM website. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

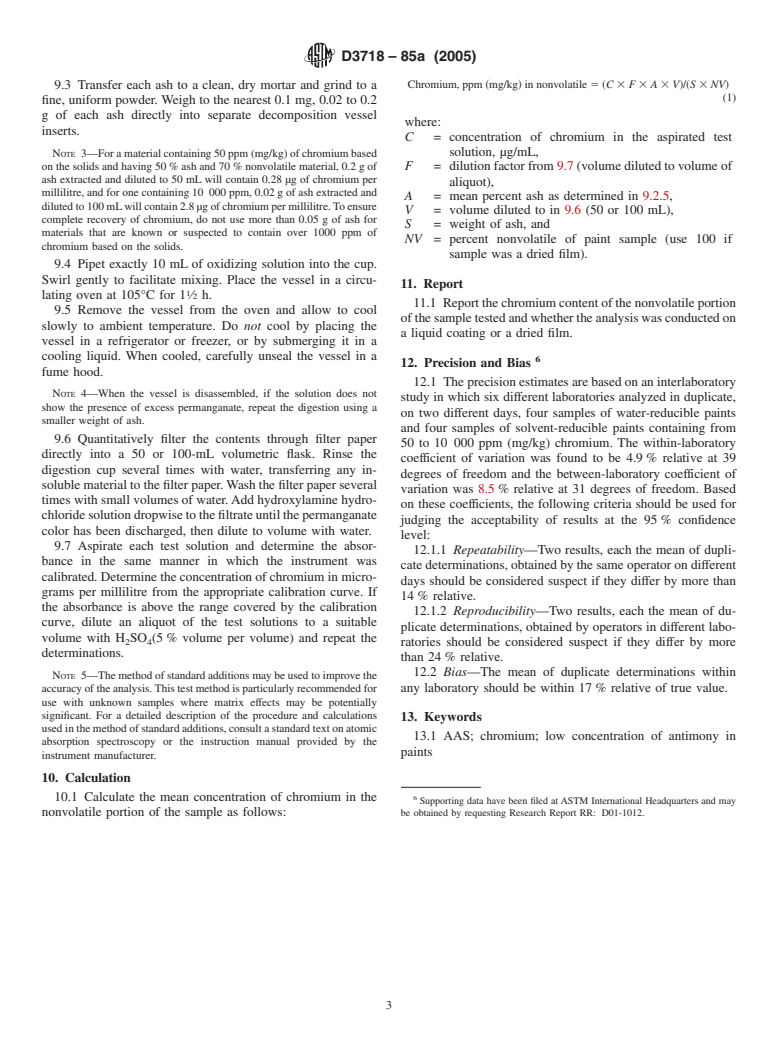

D3718–85a (2005)

all reagents shall conform to the specifications of the Commit- 8.2 Operational instructions for atomic absorption spectro-

tee onAnalytical Reagents of theAmerican Chemical Society, photometers vary with different models. Consult the manufac-

where such specifications are available. Other grades may be turer’s literature for establishing optimum conditions for the

used, provided it is first ascertained that the reagent is of specific instrument used.

sufficiently high purity to permit its use without lessening the

8.3 Turn the instrument on and set the wavelength to the

accuracy of the determination. 357.9-nm chromium line. Apply the recommended current to

6.2 Purity of Water—Unless otherwise indicated, references

the chromium hollow-cathode lamp. Allow the instrument to

towatershallbeunderstoodtomeanreagentwaterconforming warm up for about 15 min and set the slit width. Adjust the

to Type II of Specification D1193.

nitrous oxide and acetylene pressures and ignite the burner

6.3 Chromium Standard Stock Solution (1 mg/mL)— according to instructions.

Dissolve 3.735 g of potassium chromate (K CrO ) in 100 mL

8.4 Aspirate water to rinse the atomizer chamber.Aspirate a

2 4

of water and dilute to 1 L. standard solution and make any necessary readjustment in

6.4 Chromium Standard Working Solution (0.1 mg/mL)—

instrumentparameterstoobtainmaximumabsorption.Zerothe

Pipet 10 mL of the chromium standard stock solution into a instrument while aspirating reagent blank solution (6.7).Aspi-

100-mL volumetric flask and dilute to volume with water.

rate each of the appropriate standard solutions and record the

6.5 Oxidizing Solution—Dissolve 0.2 g of potassium per-

corresponding instrument readings. Aspirate water between

manganate (KMnO ) in 100 mL of H SO (1 + 1). Stir until

each standard.

4 2 4

completely dissolved. The color of this solution is dark brown.

8.5 Transfer a 25-mL aliquot from each of the standard

6.6 Reducing Solution—Dissolve1gof hydroxylamine

solutions prepared in 8.1 to 50-mLvolumetric flasks and dilute

hydrochloride (NH OH·HCl) in 100 mL of water.

to volume with water. Repeat the steps outlined in 8.4 for the

6.7 Reagent Blank—Pipet 5 mL of oxidizing solution into

diluted aliquot solutions.

25 mL of water contained in a 50-mL volumetric flask. Add

8.6 Construct a calibration curve on linear graph paper by

reducing solution dropwise until the permanganate color has

plotting the absorbance versus concentration (micrograms per

been discharged; then dilute to 50 mL with water.

millilitre) for each set of standard solutions.

6.8 Sulfuric Acid (1 + 1)—Carefully add 1 volume of con-

NOTE 1—To obtain maximum accuracy one should complete calibra-

centrated H SO (sp gr 1.84) to 1 volume of water.

2 4

tion and standardization just prior to sample analysis.

6.9 Sulfuric Acid (5 % volume per volume)—Carefully add

50 mL of concentrated H SO (sp gr 1.84) to 500 mL of water

2 4

9. Procedure

and dilute to 1 L.

9.1 If the sample is a liquid coating, mix it until homoge-

neous, preferably on a mechanical paint shaker. Determine the

7. Hazards

nonvolatile content in accordance with Guide D2832.

7.1 Use care in handling concentrated H SO because it is

2 4

9.2 Determine the ash content of the material under test in

corrosiveandmaycausesevereburnsoftheskinoreyes.Refer

duplicate.

to suppliers’ Material Safety Data Sheet.

9.2.1 Weigh to the nearest 0.1 mg approximately5gof

7.2 The National Institute for Occupational Safety and

liquid coating or3gof dried film into each of two tared

Health has stated that hexaval

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.