ASTM D6167-97e1

(Guide)Standard Guide for Conducting Borehole Geophysical Logging: Mechanical Caliper

Standard Guide for Conducting Borehole Geophysical Logging: Mechanical Caliper

SCOPE

1.1 This guide covers the general procedures necessary to conduct caliper logging of boreholes, wells, access tubes, caissons, or shafts (hereinafter referred as boreholes) as commonly applied to geologic, engineering, ground-water and environmental (hereinafter eeferred as geotechnical) investigations. Caliper logging for mineral or petroleum exploration and development are excluded.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 6167 – 97

Standard Guide for

Conducting Borehole Geophysical Logging: Mechanical

Caliper

This standard is issued under the fixed designation D 6167; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.9 This guide does not purport to address all of the safety

and liability problems (for example, lost or lodged probes and

1.1 This guide covers the general procedures necessary to

equipment decontamination) associated with its use.

conduct caliper logging of boreholes, wells, access tubes,

1.10 This standard does not purport to address all of the

caissons, or shafts (hereafter referred as boreholes) as com-

safety concerns, if any, associated with its use. It is the

monly applied to geologic, engineering, ground-water and

responsibility of the user of this standard to establish appro-

environmental (hereafter referred as geotechnical) investiga-

priate safety and health practices and determine the applica-

tions. Caliper logging for mineral or petroleum exploration and

bility of regulatory limitations prior to use.

development are excluded.

1.2 This guide defines a caliper log as a record of borehole

2. Referenced Documents

diameter with depth.

2.1 ASTM Standards:

1.2.1 Caliper logs are essential in the interpretation of

D 653 Terminology Relating to Soil, Rock and Contained

geophysical logs since they can be significantly affected by

Fluids

borehole diameter.

D 5088 Practice for Decontamination of Field Equipment at

1.2.2 Caliper logs are commonly used to: measure borehole

Non-Radioactive Waste Sites

diameter, shape, roughness, and stability; calculate borehole

D 5608 Practice for Decontamination of Field Equipment

volume; provide information on borehole construction; and

Used at Low Level Radioactive Waste Sites

delineate lithologic contacts, fractures, and solution cavities

D 5753 Guide for Planning and Conducting Borehole Geo-

and other openings.

physical Logging

1.3 This guide is restricted to mechanically based devices

with spring loaded arms, which are the most common calipers

3. Terminology

used in caliper logging with geotechnical applications.

3.1 Definitions: Definitions shall be in accordance with

1.4 This guide provides an overview of caliper logging

Terminology D 653, Section 12, Ref (1), or as defined below:

including: general procedures; specific documentation; calibra-

3.1.1 accuracy, n—how close a measured log values ap-

tion and standardization, and log quality and interpretation.

proaches true value. It is determined in a controlled environ-

1.5 To obtain additional information on caliper logs see

ment. A controlled environment represents a homogeneous

Section 9 of this guide.

sample volume with known properties.

1.6 This guide is to be used in conjunction with Guide

3.1.2 depth of investigation, n—the radial distance from the

D 5753.

measurement point to a point where the predominant measured

1.7 This guide should not be used as a sole criterion for

response may be considered centered, that is not to be confused

caliper logging and does not replace professional judgement.

with borehole depth (for example, distance) measured from the

Caliper logging procedures should be adapted to meet the

surface.

needs of a range of applications and stated in general terms so

3.1.3 measurement resolution, n—the minimum change in

that flexibility or innovation is not suppressed.

measured value that can be detected.

1.8 The geotechnical industry uses English or SI units. The

3.1.4 repeatability, n—the difference in magnitude of two

caliper log is typically recorded in units of inches, millimetres

measurements with the same equipment and in the same

or centimetres.

environment.

1 2

This guide is under the jurisdiction of ASTM Committee D-18 on Soil and Annual Book of ASTM Standards, Vol 04.08.

Rock and is the direct responsibility of Subcommittee D18.01 on Surface and Annual Book of ASTM Standards, Vol 04.09.

Subsurface Characterization. The boldface numbers given in parentheses refer to a list of references at the

Current edition approved Sept. 10, 1997. Published January 1998. end of the text.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D6167–97

3.1.5 vertical resolution, n—the minimum thickness that

can be separated into distinct units.

3.1.6 volume of investigation, n—the volume that contrib-

utes 90 % of the measured response. It is determined by a

combination of theoretical and empirical modeling. The vol-

ume of investigation is non-spherical and has gradational

boundaries.

4. Summary of Guide

4.1 This guide applies to borehole caliper logging and is to

be used in conjunction with Guide D 5753.

4.2 This guide briefly describes the significance and use,

apparatus, calibration and standardization, procedures, and

reports for conducting borehole caliper logging.

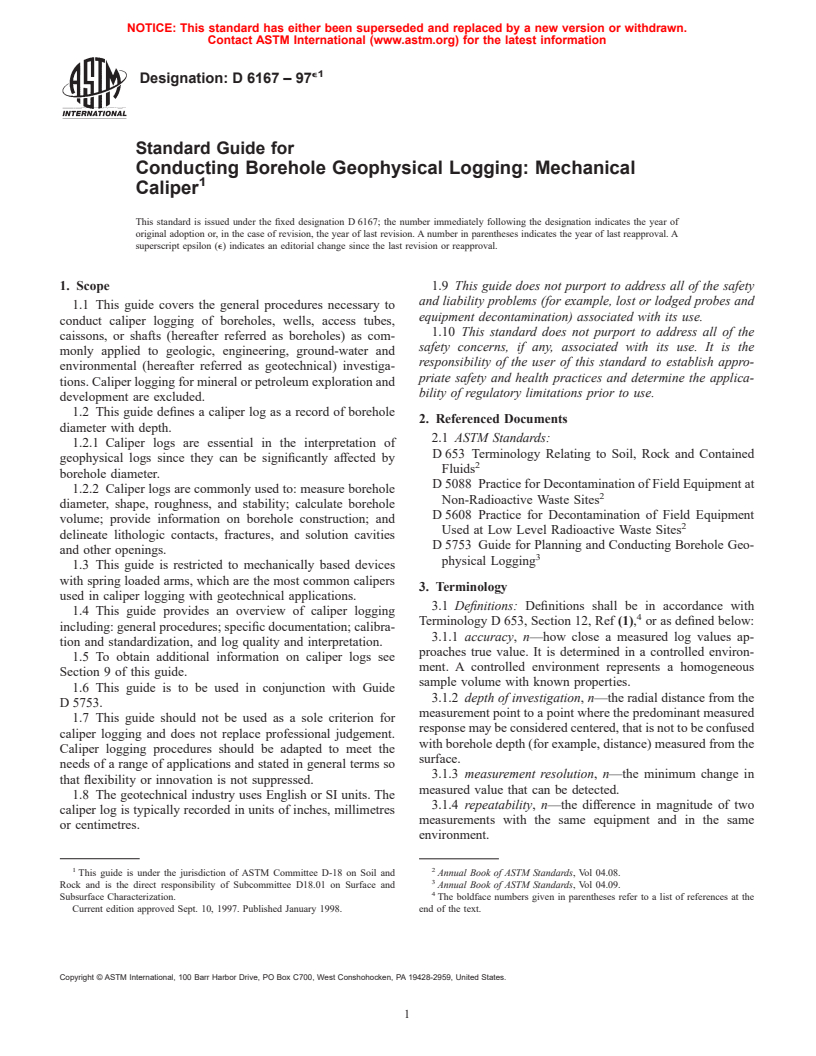

FIG. 1 Probe for Making Side-Collimated Gamma-Gamma Logs

5. Significance and Use

with Single-Arm Caliper (2)

5.1 An appropriately developed, documented, and executed

guide is essential for the proper collection and application of

caliper logs. This guide is to be used in conjunction with Guide

D 5753.

5.2 The benefits of its use include the following: improving

selection of caliper logging methods and equipment; caliper

log quality and reliability; and usefulness of the caliper log data

for subsequent display and interpretation.

5.3 This guide applies to commonly used caliper logging

methods for geotechnical applications.

5.4 It is essential that personnel (see 8.3.2 of Guide D 5753)

consult up-to-date textbooks and reports on the caliper tech-

nique, application, and interpretation methods.

6. Interferences

6.1 Most extraneous effects on caliper logs are caused by

instrument problems and borehole conditions.

6.2 Instrument problems include the following: electrical

leakage of cable and grounding problems; temperature drift;

wear of mechanical components including the hinge pins and

in the linear potentiometer (mechanical hysteresis); damaged

or bent arms; and lack of lubrication of the mechanical

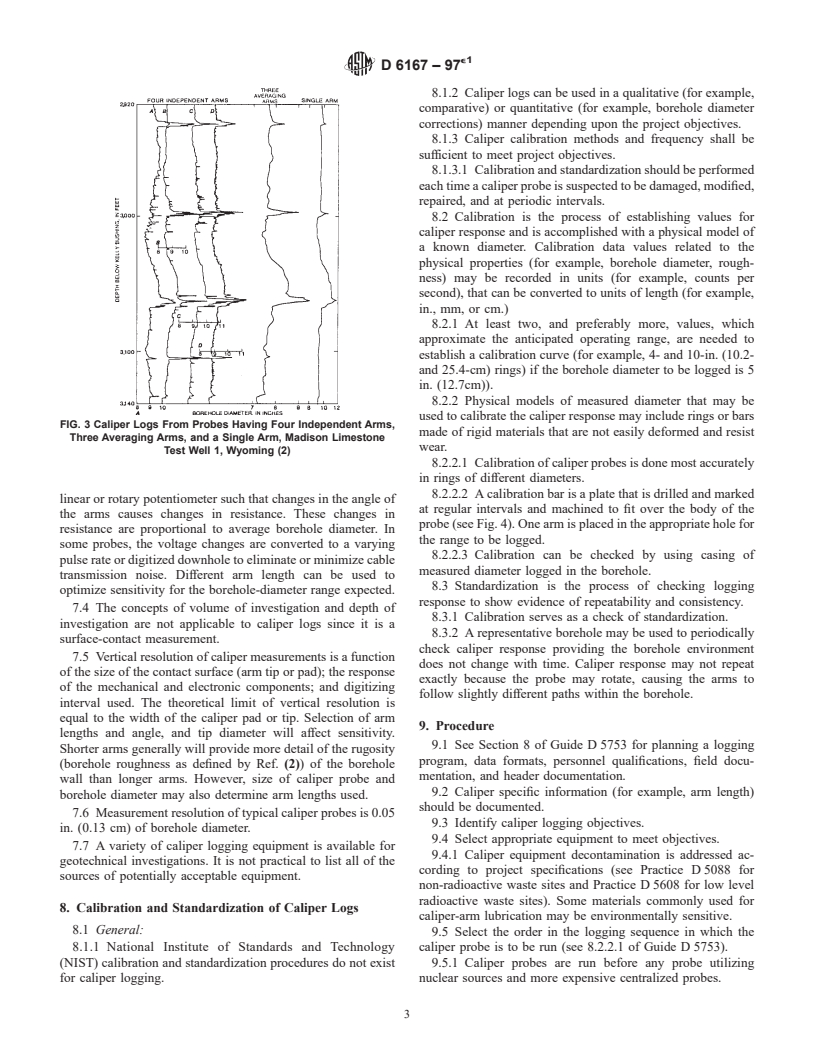

FIG. 2 Three-Arm Averaging Caliper

components.

6.3 Borehole conditions include heavy drilling mud; bore-

hole deviation; and drilling related borehole irregularities. move together, which provides an average diameter measure-

ment. This caliper provides higher resolution than the single-

7. Apparatus

arm caliper measurement (see Fig. 3).

7.1 A geophysical logging system has been described in the 7.2.3 Multiple independent arm calipers generally have

general guide (see Section 6 of Guide D 5753). three or four independent arms of equal length; these arms are

7.2 Caliper logs may be obtained with probes having a sometimes oriented. Horizontal resolution, that provides accu-

single arm, three arms (averaging or summation), multiple rate borehole-diameter measurement regardless of borehole

independent arms (x-y caliper), multiple-feeler arms, bow shape, is related to the number of independent arms. In general,

springs or gap wheels. Single-arm and three-arm averaging calipers with four or more independent arms will have higher

probes are most commonly used for geotechnical investiga- resolution than three-arm averaging (see Fig. 3). The four

tions. independent-arm caliper log may show borehole elongation

7.2.1 A single-arm caliper commonly provides a record of (elliptical borehole shape) and better indicates the actual

borehole diameter while being used to decentralize another irregularity of the borehole.

type of log, such as a side-collimated gamma-gamma probe 7.3 Caliper probes using arms are typically spring loaded.

(see Fig. 1). The caliper arm generally follows the high side of The arms are retracted and opened with an electric motor and

a deviated hole. The single-arm decentralizing caliper may not retention spring. The arms and gears are lubricated. Caliper

have the resolution needed for some applications. probes closed by hand are held closed with an electric solenoid

7.2.2 The three-arm averaging or summation caliper has or weighted retention ring that is released with a sudden drop.

arms of equal length oriented 120° apart (see Fig. 2). All arms Typically, the caliper arms are mechanically connected to a

e1

D6167–97

8.1.2 Caliper logs can be used in a qualitative (for example,

comparative) or quantitative (for example, borehole diameter

corrections) manner depending upon the project objectives.

8.1.3 Caliper calibration methods and frequency shall be

sufficient to meet project objectives.

8.1.3.1 Calibration and standardization should be performed

each time a caliper probe is suspected to be damaged, modified,

repaired, and at periodic intervals.

8.2 Calibration is the process of establishing values for

caliper response and is accomplished with a physical model of

a known diameter. Calibration data values related to the

physical properties (for example, borehole diameter, rough-

ness) may be recorded in units (for example, counts per

second), that can be converted to units of length (for example,

in., mm, or cm.)

8.2.1 At least two, and preferably more, values, which

approximate the anticipated operating range, are needed to

establish a calibration curve (for example, 4- and 10-in. (10.2-

and 25.4-cm) rings) if the borehole diameter to be logged is 5

in. (12.7cm)).

8.2.2 Physical models of measured diameter that may be

used to calibrate the caliper response may include rings or bars

FIG. 3 Caliper Logs From Probes Having Four Independent Arms,

made of rigid materials that are not easily deformed and resist

Three Averaging Arms, and a Single Arm, Madison Limestone

wear.

Test Well 1, Wyoming (2)

8.2.2.1 Calibration of caliper probes is done most accurately

in rings of different diameters.

8.2.2.2 A calibration bar is a plate that is drilled and marked

linear or rotary potentiometer such that changes in the angle of

at regular intervals and machined to fit over the body of the

the arms causes changes in resistance. These changes in

probe (see Fig. 4). One arm is placed in the appropriate hole for

resistance are proportional to average borehole diameter. In

the range to be logged.

some probes, the voltage changes are converted to a varying

8.2.2.3 Calibration can be checked by using casing of

pulse rate or digitized downhole to eliminate or minimize cable

measured diameter logged in the borehole.

transmission noise. Different arm length can be used to

8.3 Standardization is the process of checking logging

optimize sensitivity for the borehole-diameter range expected.

response to show evidence of repeatability and consistency.

7.4 The concepts of volume of investigation and depth of

8.3.1 Calibration serves as a check of standardization.

investigation are not applicable to caliper logs since it is a

8.3.2 A representative borehole may be used to periodically

surface-contact measurement.

check caliper response providing the borehole environment

7.5 Vertical resolution of caliper measurements is a function

does not change with time. Caliper response may not repeat

of the size of the contact surface (arm tip or pad); the response

exactly because the probe may rotate, causing the arms to

of the mechanical and electronic components; and digitizing

follow slightly different paths within the borehole.

interval used. The theoretical limit of vertical resolution is

equal to the width of the caliper pad or tip. Selection of arm

9. Procedure

lengths and angle, and tip diameter will affect sensitivity.

9.1 See Section 8 of Guide D 5753 for planning a logging

Shorter arms generally will provide more detail of the rugosity

program, data formats, personnel qualifications, field docu-

(borehole roughness as defined by Ref. (2)) of the borehole

mentation, and header documentation.

wall than longer arms. However, size of caliper probe and

9.2 Caliper specific information (for example, arm length)

borehole diameter may also determine arm lengths used.

should be documented.

7.6 Measurement resolution of typical caliper probes is 0.05

9.3 Identify caliper logging objectives.

in. (0.13 cm) of borehole diameter.

9.4 Select appropriate equipment to meet objectives.

7.7 A variety of caliper logging equipment is available for

9.4.1 Caliper equipment decontamination is addressed ac-

geotechnical investigations. It is not practical to list all of the

cording to project specifications (see Practice D 5088 for

sources of potentially acceptable equipment.

non-radioactive waste sites and Practice D 5608 for low level

radioactive waste sites). Some materials commonly used for

8. Calibration and Standardization of Caliper Logs

caliper-arm lubrication may be environmentally sensitive.

8.1 General:

9.5 Select the order in the logging sequence in which the

8.1.1 National Institute of Standards and Technology caliper probe is to be run (see 8.2.2.1 of Guide D 5753).

(NIST) calibration and standardization procedures do not exist 9.5.1 Caliper probes are run before any probe utilizing

for caliper logging. nuclear sources and more expensive centralized probes.

e1

D6167–97

9.10.1 Maximum vertical resolution requires the selection

of a digitizing interval at least as small as the arm tip contact

height.

9.10.2 Typically, this interval is no larger than 0.1 ft (0.03m)

for high resolution applications.

9.11 The caliper probe is lowered to the bottom of the

borehole.

9.11.1 Any time the caliper probe is lowered in the bore-

hole, the arms should be closed to avoid damaging equipment

or borehole.

9.11.2 Selection of probe speed while lowering is based on

knowledge of borehole depth, stability and other conditions.

9.12 Open caliper arm(s).

9.13 Select logging speed.

9.13.1 A logging speed of approximately 15 ft (5m) per min

is recommended for high resolution applications. Faster log-

ging speeds may induce noise due to the caliper probe bumping

the borehole wall. Slower logging speeds will not enhance

measurement resolution for most systems.

9.14 Collect caliper data while the probe is moving up the

borehole.

9.15 When the probe reaches the top of the borehole:

9.15.1 If surface casing is present, compare and document

caliper measurement.

9.15.2 Check depth reference and document after survey

depth error (ASDE).

9.15.3 Determine if ASDE meets project objectives.

9.15.4 Typical tolerance for ASDE is +/– 0.4 ft per 100 ft

(0.4m per 100m) interval logged.

9.16 Selected borehole intervals should be repeated (that is,

relog

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.