ASTM C76-00

(Specification)Standard Specification for Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe

Standard Specification for Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe

SCOPE

1.1 This specification covers reinforced concrete pipe intended to be used for the conveyance of sewage, industrial wastes, and storm water, and for the construction of culverts.

1.2 A complete metric companion to Specification C76 has been developed--C76M; therefore, no metric equivalents are presented in this specification.

Note 1-This specification is a manufacturing and purchase specification only, and does not include requirements for bedding, backfill, or the relationship between field load condition and the strength classification of pipe. However, experience has shown that the successful performance of this product depends upon the proper selection of the class of pipe, type of bedding and backfill, and care that installation conforms to the construction specifications. The owner of the reinforced concrete pipe specified herein is cautioned that he must correlate the field requirements with the class of pipe specified and provide inspection at the construction site.

Note 2-Attention is called to the specification for reinforced concrete D-load culvert, storm drain, and sewer pipe (Specification C655).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 76 – 00

Standard Specification for

Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe

This standard is issued under the fixed designation C 76; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope pounds for Curing Concrete

C 497 Test Methods for Concrete Pipe, Manhole Sections,

1.1 This specification covers reinforced concrete pipe

or Tile

intended to be used for the conveyance of sewage, industrial

C 595 Specification for Blended Hydraulic Cements

wastes, and storm water, and for the construction of culverts.

C 618 Specification for Coal Fly Ash and Raw or Calcined

1.2 A complete metric companion to Specification C 76 has

Natural Pozzolan for Use as a Mineral Admixture in

been developed—C 76M; therefore, no metric equivalents are

Concrete

presented in this specification.

C 655 Specification for Reinforced Concrete D-Load Cul-

NOTE 1—This specification is a manufacturing and purchase specifica- 5

vert, Storm Drain, and Sewer Pipe

tion only, and does not include requirements for bedding, backfill, or the

C 822 Terminology Relating to Concrete Pipe and Related

relationship between field load condition and the strength classification of

Products

pipe. However, experience has shown that the successful performance of

C 1116 Specification for Fiber-Reinforced Concrete and

this product depends upon the proper selection of the class of pipe, type

of bedding and backfill, and care that installation conforms to the Shotcrete

construction specifications. The owner of the reinforced concrete pipe

3. Terminology

specified herein is cautioned that he must correlate the field requirements

with the class of pipe specified and provide inspection at the construction

3.1 Definitions—For definitions of terms relating to con-

site.

crete pipe, see Terminology C 822.

NOTE 2—Attention is called to the specification for reinforced concrete

D-load culvert, storm drain, and sewer pipe (Specification C 655).

4. Classification

2. Referenced Documents 4.1 Pipe manufactured in accordance with this specification

shall be of five classes identified as Class I, Class II, Class III,

2.1 ASTM Standards:

Class IV, and Class V. The corresponding strength require-

A 82 Specification for Steel Wire, Plain, for Concrete Re-

ments are prescribed in Tables 1-5.

inforcement

A 185 Specification for Steel Welded Wire, Fabric, Plain,

5. Basis of Acceptance

for Concrete Reinforcement

5.1 Unless otherwise designated by the owner at the time

A 496 Specification for Steel Wire, Deformed, for Concrete

2 of, or before placing an order, two separate and alternative

Reinforcement

bases of acceptance are permitted as follows:

A 497 Specification for Steel Welded Wire Fabric, De-

2 5.1.1 Acceptance on the Basis of Plant Load-Bearing Tests,

formed, for Concrete Reinforcement

Material Tests, and Inspection of Manufactured Pipe for Visual

A 615/A 615M Specification for Deformed and Plain

2 Defects and Imperfections—Acceptability of the pipe in all

Billet-Steel Bars for Concrete Reinforcement

3 diameters and classes produced in accordance with 7.1 or 7.2

C 33 Specification for Concrete Aggregates

shall be determined by the results of the three-edge bearing

C 39 Test Method for Compressive Strength of Cylindrical

3 tests as defined in 11.3.1; by such material tests as are required

Concrete Specimens

4 in 6.1, 6.2, and 6.4; by absorption tests on selected samples of

C 150 Specification for Portland Cement

concrete from the wall of the pipe; and by visual inspection of

C 309 Specification for Liquid Membrane-Forming Com-

the finished pipe to determine its conformance with the

accepted design and its freedom from defects.

5.1.2 Acceptance on the Basis of Material Tests and Inspec-

This specification is under the jurisdiction of ASTM Committee C13 on

Concrete Pipe and is the direct responsibility of Subcommittee C13.02 on tion of Manufactured Pipe for Defects and Imperfections—

Reinforced Sewer and Culvert Pipe.

Acceptability of the pipe in all diameters and classes produced

Current edition approved June 10, 2000. Published September 2000. Originally

in accordance with 7.1 or 7.2 shall be determined by the results

published as C 76–30T. Last previous edition C 76–99.

Annual Book of ASTM Standards, Vol 01.04.

Annual Book of ASTM Standards, Vol 04.02.

4 5

Annual Book of ASTM Standards, Vol 04.01. Annual Book of ASTM Standards, Vol 04.05.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C76

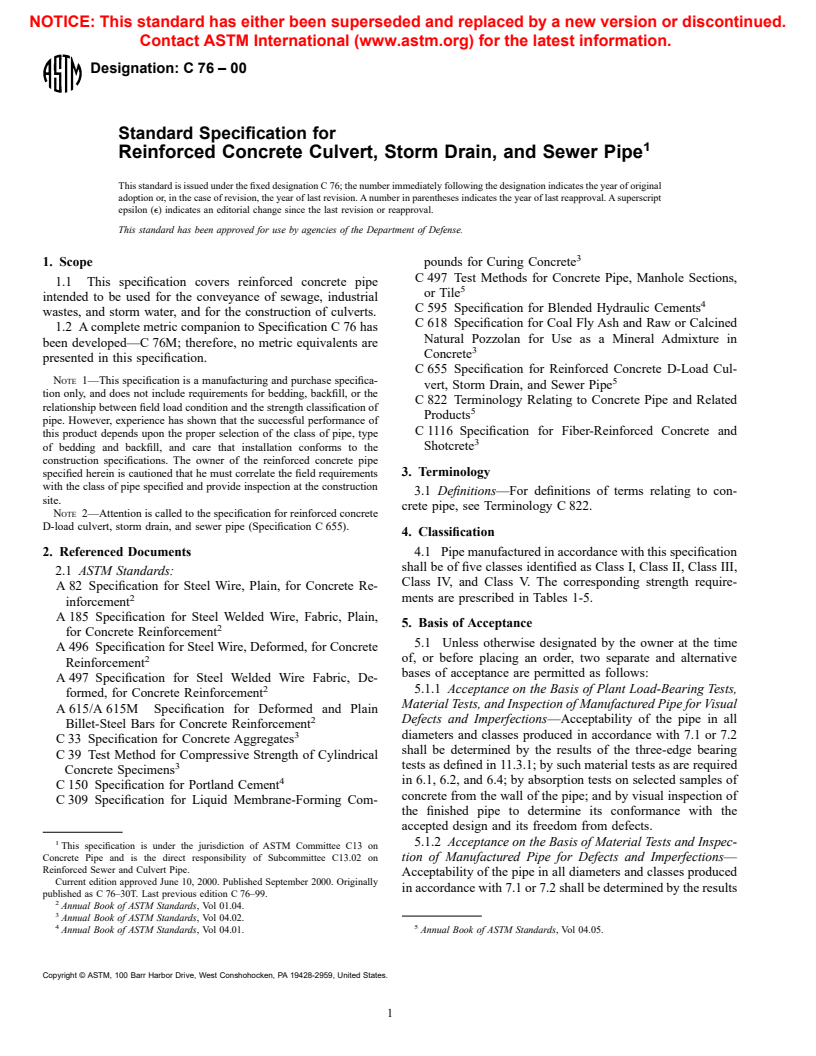

A

TABLE 1 Design Requirements for Class I Reinforced Concrete Pipe

NOTE 1—See Section 5 for basis of acceptance specified by the owner.

The strength test requirements in pounds-force per linear foot of pipe under the three-edge-bearing method shall be either the D-load (test load

expressed in pounds-force per linear foot per foot of diameter) to produce a 0.01-in. crack, or the D-loads to produce the 0.01-in. crack and the ultimate

load as specified below, multiplied by the internal diameter of the pipe in feet.

D-load to produce a 0.01-in. crack 800

D-load to produce the ultimate load 1200

Reinforcement, in. /linear ft of pipe wall

Wall A Wall B

Internal

Concrete Strength, 4000 psi Concrete Strength, 4000 psi

Designated

Diameter, Circular Circular

B B

Wall Wall

in.

Reinforcement Reinforcement

Elliptical Elliptical

Thickness, Thickness,

C C

Reinforcement Reinforcement

Inner Outer Inner Outer

in. in.

Cage Cage Cage Cage

60 5 0.25 0.15 0.28 6 0.21 0.13 0.23

1 1

66 5 ⁄2 0.30 0.18 0.33 6 ⁄2 0.25 0.15 0.28

72 6 0.35 0.21 0.39 7 0.29 0.17 0.32

1 1

78 6 ⁄2 0.40 0.24 0.44 7 ⁄2 0.32 0.19 0.36

84 7 0.45 0.27 0.50 8 0.37 0.22 0.41

1 1

90 7 ⁄2 0.49 0.29 0.54 8 ⁄2 0.41 0.25 0.46

96 8 0.54 0.32 0.60 9 0.46 0.28 0.51

Concrete Strength, 5000 psi

1 1

102 8 ⁄2 0.63 0.38 Inner Circular 0.25 9 ⁄2 0.54 0.32 Inner Circular 0.22

Plus Elliptical 0.38 Plus Elliptical 0.32

108 9 0.68 0.41 Inner Circular 0.27 10 0.61 0.37 Inner Circular 0.24

Plus Elliptical 0.41 Plus Elliptical 0.37

A A

114 . . . . . . . .

A A

120 . . . . . . . .

A A

126 . . . . . . . .

A A

132 . . . . . . . .

A A

138 . . . . . . . .

A A

144 . . . . . . . .

A

For modified or special designs see 7.2 or with the permission of the owner utilize the provisions of Specification C 655. Steel areas may be interpolated between those

shown for variations in diameter, loading, or wall thickness. Pipe over 96 in. in diameter shall have two circular cages or an inner circular plus one elliptical cage.

B

As an alternative to designs requiring both inner and outer circular cages the reinforcement may be positioned and proportioned in either of the following manners:

An inner circular cage plus an elliptical cage such that the area of the elliptical cage shall not be less than that specified for the outer cage in the table and the total area

of the inner circular cage plus the elliptical cage shall not be less than that specified for the inner cage in the table,

An inner and outer cage plus quadrant mats in accordance with Fig. 1, or

An inner and outer cage plus an elliptical cage in accordance with Fig. 2.

C

Elliptical and quadrant steel must be held in place by means of holding rods, chairs, or other positive means throughout the entire casting operation.

of such material tests as are required in 6.1, 6.2, and 6.4; by combination of Portland cement and supplementary cementing

crushing tests on concrete cores or cured concrete cylinders; by materials be less than 470 lb/yd .

absorption tests on selected samples from the wall of the pipe;

6.2 Cementitious materials:

and by inspection of the finished pipe including amount and

6.2.1 Cement—Cement shall conform to the requirements

placement of reinforcement to determine its conformance with

for portland cement of Specification C 150 or shall be portland

the accepted design and its freedom from defects.

blast-furnace slag cement or portland-pozzolan cement con-

5.1.3 When agreed upon by the owner and manufacturer,

forming to the requirements of Specification C 595, except that

any portion or any combination of the tests itemized in 5.1.1 or

the pozzolan constituent in the Type IP portland-pozzolan

5.1.2 may form the basis of acceptance.

cement shall be fly ash.

5.2 Age for Acceptance—Pipe shall be considered ready for

6.2.2 Fly Ash—Fly ash shall conform to the requirements of

acceptance when it conforms to the requirements as indicated

Class F or Class C of Specification C 618.

by the specified tests.

6.2.3 Allowable Combinations of Cementitious Materials—

The combination of cementitious materials used in the concrete

6. Materials

shall be one of the following:

6.1 The aggregate shall be so sized, graded, proportioned,

6.2.3.1 Portland cement only,

and mixed with such proportions of Portland cement, blended

6.2.3.2 Portland blast furnace slag cement only;

hydraulic cement, or Portland cement and supplementary

6.2.3.3 Portland pozzolan cement only, or

cementing materials, or admixtures, if used, or a combination

6.2.3.4 A combination of portland cement and fly ash.

thereof, and water to produce a homogenous concrete mixture

6.3 Aggregates—Aggregates shall conform to Specification

of such quality that the pipe will conform to the test and design

C 33 except that the requirement for gradation shall not apply.

requirements of the specification. In no case, however, shall the

proportion of Portland cement, blended hydraulic cement, or a 6.4 Admixtures and Blends—Admixtures and blends may be

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C76

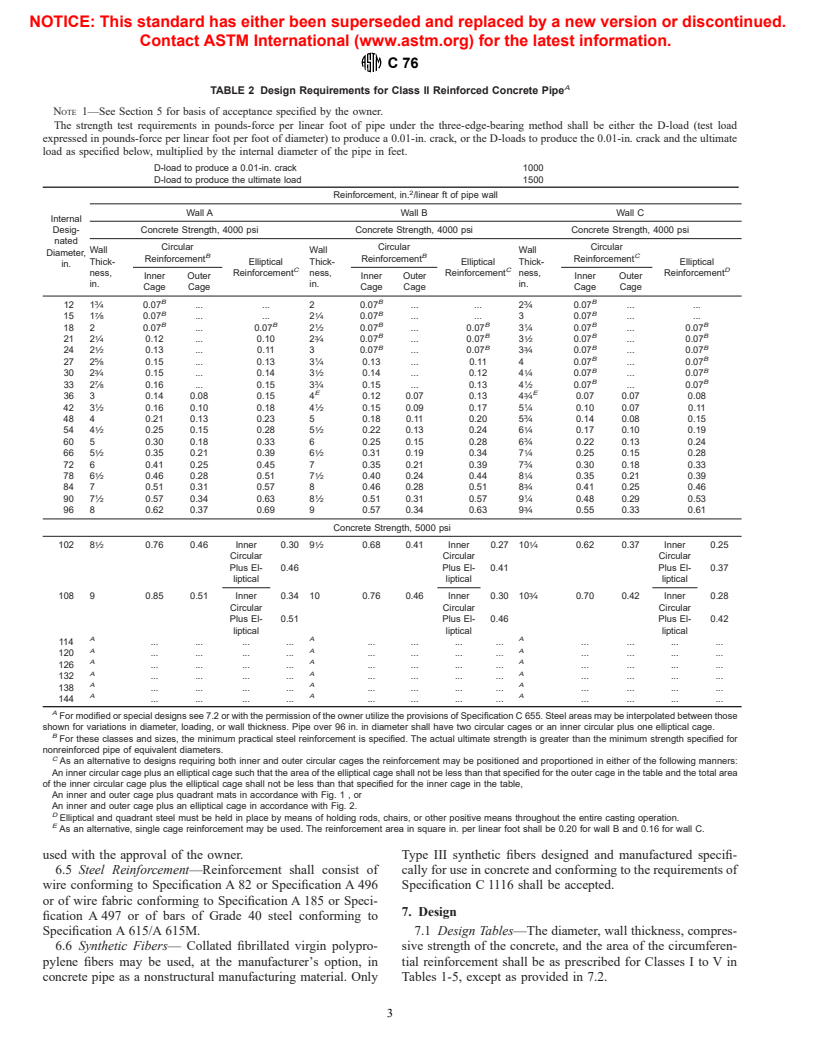

A

TABLE 2 Design Requirements for Class II Reinforced Concrete Pipe

NOTE 1—See Section 5 for basis of acceptance specified by the owner.

The strength test requirements in pounds-force per linear foot of pipe under the three-edge-bearing method shall be either the D-load (test load

expressed in pounds-force per linear foot per foot of diameter) to produce a 0.01-in. crack, or the D-loads to produce the 0.01-in. crack and the ultimate

load as specified below, multiplied by the internal diameter of the pipe in feet.

D-load to produce a 0.01-in. crack 1000

D-load to produce the ultimate load 1500

Reinforcement, in. /linear ft of pipe wall

Wall A Wall B Wall C

Internal

Desig- Concrete Strength, 4000 psi Concrete Strength, 4000 psi Concrete Strength, 4000 psi

nated

Circular Circular Circular

Wall Wall Wall

Diameter,

B B C

Reinforcement Reinforcement Reinforcement

Thick- Elliptical Thick- Elliptical Thick- Elliptical

in.

C C D

ness, Reinforcement ness, Reinforcement ness, Reinforcement

Inner Outer Inner Outer Inner Outer

in. in. in.

Cage Cage Cage Cage Cage Cage

3 B B 3 B

12 1 ⁄4 0.07 . . 2 0.07 . . 2 ⁄4 0.07 . .

B B B

7 1

15 1 ⁄8 0.07 . . 2 ⁄4 0.07 . . 3 0.07 . .

B B B B B B

1 1

18 2 0.07 . 0.07 2 ⁄2 0.07 . 0.07 3 ⁄4 0.07 . 0.07

B B B B

1 3 1

21 2 ⁄4 0.12 . 0.10 2 ⁄4 0.07 . 0.07 3 ⁄2 0.07 . 0.07

B B B B

1 3

24 2 ⁄2 0.13 . 0.11 3 0.07 . 0.07 3 ⁄4 0.07 . 0.07

B B

5 1

27 2 ⁄8 0.15 . 0.13 3 ⁄4 0.13 . 0.11 4 0.07 . 0.07

B B

3 1 1

30 2 ⁄4 0.15 . 0.14 3 ⁄2 0.14 . 0.12 4 ⁄4 0.07 . 0.07

7 3 1 B B

33 2 ⁄8 0.16 . 0.15 3 ⁄4 0.15 . 0.13 4 ⁄2 0.07 . 0.07

E E

36 3 0.14 0.08 0.15 4 0.12 0.07 0.13 4 ⁄4 0.07 0.07 0.08

1 1 1

42 3 ⁄2 0.16 0.10 0.18 4 ⁄2 0.15 0.09 0.17 5 ⁄4 0.10 0.07 0.11

48 4 0.21 0.13 0.23 5 0.18 0.11 0.20 5 ⁄4 0.14 0.08 0.15

1 1 1

54 4 ⁄2 0.25 0.15 0.28 5 ⁄2 0.22 0.13 0.24 6 ⁄4 0.17 0.10 0.19

60 5 0.30 0.18 0.33 6 0.25 0.15 0.28 6 ⁄4 0.22 0.13 0.24

1 1 1

66 5 ⁄2 0.35 0.21 0.39 6 ⁄2 0.31 0.19 0.34 7 ⁄4 0.25 0.15 0.28

72 6 0.41 0.25 0.45 7 0.35 0.21 0.39 7 ⁄4 0.30 0.18 0.33

1 1 1

78 6 ⁄2 0.46 0.28 0.51 7 ⁄2 0.40 0.24 0.44 8 ⁄4 0.35 0.21 0.39

84 7 0.51 0.31 0.57 8 0.46 0.28 0.51 8 ⁄4 0.41 0.25 0.46

1 1 1

90 7 ⁄2 0.57 0.34 0.63 8 ⁄2 0.51 0.31 0.57 9 ⁄4 0.48 0.29 0.53

96 8 0.62 0.37 0.69 9 0.57 0.34 0.63 9 ⁄4 0.55 0.33 0.61

Concrete Strength, 5000 psi

1 1 1

102 8 ⁄2 0.76 0.46 Inner 0.30 9 ⁄2 0.68 0.41 Inner 0.27 10 ⁄4 0.62 0.37 Inner 0.25

Circular Circular Circular

Plus El- 0.46 Plus El- 0.41 Plus El- 0.37

liptical liptical liptical

108 9 0.85 0.51 Inner 0.34 10 0.76 0.46 Inner 0.30 10 ⁄4 0.70 0.42 Inner 0.28

Circular Circular Circular

Plus El- 0.51 Plus El- 0.46 Plus El- 0.42

liptical liptical liptical

A A A

114 . . . . . . . . . . . .

A A A

120 . . . . . . . . . . . .

A A A

126 . . . . . . . . . . . .

A A A

132 . . . . . . . . . . . .

A A A

138 . . . . . . . . . . . .

A A A

144 . . . . . . . . . . . .

A

For modified or special designs see 7.2 or with the permission of the owner utilize the provisions of Specification C 655. Steel areas may be interpolated between those

shown for variations in diameter, loading, or wall thickness. Pipe over 96 in. in diameter shall have two circular cages or an inner circular plus one elliptical cage.

B

For these classes and sizes, the minimum practical steel reinforcement is specified. The actual ultimate strength is greater than the minimum strength specified for

nonreinforced pipe of equivalent diameters.

C

As an alternative to designs requiring both inner and outer circular cages the reinforcement may be positioned and proportioned in either of the following manners:

An inner circular cage plus an elliptical cage such that the area of the elliptical cage shall not be less than that specified for the outer cage in the table and the total area

of the inner circular cage plus the elliptical cage shall not be less than that specified for the inner cage in the table,

An inner and outer cage plus quadrant mats in accordance with Fig.1,or

An inner and outer cage plus an elliptical cage in accordance with Fig. 2.

D

Elliptical and quadrant steel must be held in place by means of holding rods, chairs, or other positive means throughout the entire casting operation.

E

As an alternative, single cage reinforcement may be used. The reinforcement area in square in. per linear foot shall be 0.20 for wall B and 0.16 for wall C.

used with the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.