ASTM D3884-92

(Guide)Standard Guide for Abrasion Resistance of Textile Fabrics (Rotary Platform, Double-Head Method)

Standard Guide for Abrasion Resistance of Textile Fabrics (Rotary Platform, Double-Head Method)

SCOPE

1.1 This guide covers the determination of the abrasion resistance of textile fabrics using the rotary platform, double-head tester (RPDH).

Note 1—Other procedures for measuring the abrasion resistance of textile fabrics are given in Test Methods D 3885, D 3886, D 1775, D 4158, D 4966, and AATCC 61.

1.2 The values stated in SI units are to be regarded as standard: the values in English units are provided as information only and are not exact equivalents.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3884 – 92 An American National Standard

Standard Test Method for

Abrasion Resistance of Textile Fabrics (Rotary Platform,

Double-Head Method)

This standard is issued under the fixed designation D 3884; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope method, refer to Terminology D 123.

1.1 This test method covers the determination of the abra-

4. Summary of Test Method

sion resistance of textile fabrics using the rotary platform,

4.1 A specimen is abraded using rotary rubbing action under

double-head tester (RPDH).

controlled conditions of pressure and abrasive action. The test

NOTE 1—Other procedures for measuring the abrasion resistance of

specimen, mounted on a platform, turns on a vertical axis,

textile fabrics are given in Test Methods D 3885, D 3886, D 1775, and

against the sliding rotation of two abrading wheels. One

AATCC 61.

abrading wheel rubs the specimen outward toward the periph-

1.2 The values stated in SI units are to be regarded as

ery and the other, inward toward the center. The resulting

standard: the values in English units are provided as informa-

abrasion marks form a pattern of crossed arcs over an area of

tion only and are not exact equivalents.

approximately 30 cm . Resistance to abrasion is evaluated by

1.3 This standard does not purport to address all of the

various means which are described in Section 12.

safety problems, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5.1 The measurement of the resistance to abrasion of textile

bility of regulatory limitations prior to use.

and other materials is very complex. The resistance to abrasion

is affected by many factors, such as the inherent mechanical

2. Referenced Documents

properties of the fibers; the dimensions of the fibers; the

2.1 ASTM Standards:

structure of the yarns; the construction of the fabrics; and the

D 123 Terminology Relating to Textiles

type, kind, and amount of finishing material added to the fibers,

D 1682 Test Methods for Breaking Load and Elongation of

yarns, or fabric.

Textile Fabrics

5.2 The resistance to abrasion is also greatly affected by the

D 1775 Test Method for Abrasion Resistance of Textile

conditions of the tests, such as the nature of abradant, variable

Fabrics (Oscillatory Cylinger and Uniform Abrasion Meth-

action of the abradant over the area of specimen abraded, the

ods)

tension of the specimen, the pressure between the specimen

D 1776 Practice for Conditioning Textiles for Testing

and abradant, and the dimensional changes in the specimens.

D 3885 Test Method for Abrasion Resistance of Textile

5.3 Abrasion tests are all subject to variation due to changes

Fabrics (Flexing and Abrasion Method)

in the abradant during specific tests. The abradant must

D 3886 Test Method for Abrasion Resistance of Textile

accordingly be discarded at frequent intervals or checked

Fabrics (Inflated Diaphragm Method)

periodically against a standard. With disposable abradants, the

2.2 Other Documents:

abradant is used only once or discarded after limited use. With

AATCC 61 Impeller Tumble Method

permanent abradants that use hardened metal or equivalent

surfaces, it is assumed that the abradant will not change

3. Terminology

appreciably in a specific series of tests. Similar abradants used

3.1 Definitions:

in different laboratories will not change at the same rate, due to

3.1.1 abrasion, n—the wearing away of any part of a

differences in usage. Permanent abradants may also change due

material by rubbing against another surface.

to pick up of finishing or other material from test fabrics and

3.2 For definitions of other textile terms used in this test

must accordingly be cleaned at frequent intervals. The mea-

surement of the relative amount of abrasion may also be

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles affected by the method of evaluation and may be influenced by

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

the judgment of the operator.

Specific.

5.4 The resistance of textile materials to abrasion as mea-

Current edition approved June 15, 1992. Published August 1992. Originally

sured on a testing machine in the laboratory is generally only

published as D 3884 – 80. Last previous edition D 3884 – 80.

Annual Book of ASTM Standards, Vol 07.01.

one of several factors contributing to wear performance or

Annual Book of ASTM Standards, Vol 07.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3884

durability as experienced in the actual use of the material. should be conducted and related to the abrasion test. Different

While “abrasion resistance’’ (often stated in terms of the types of wear (for example, wear on men’s clothing at cuffs,

number of cycles on a specified machine, using a specified crotch, etc.) may correspond to different ratings of the RPDH

technique to produce a specified degree or amount of abrasion) test.

and “durability’’ (defined as the ability to withstand deteriora- 5.9 In making a comparison of different fabrics (that is, of

tion or wearing out in use, including the effects of abrasion) are different fibers, weights, etc.) the RPDH test will not always

frequently related, the relationship varies with different end reveal a difference known to exist when the fabrics are actually

uses, and different factors may be necessary in any calculation used. Therefore, end-use trials should be conducted in conjunc-

of predicted durability from specific abrasion data. Laboratory tion with the RPDH abrasion test, at least as a guide for future

tests may be reliable as an indication of relative end-use testing of these fabrics.

performance in cases where the difference in abrasion resis- 5.10 Uncontrolled manufacturing or finishing variations

tance of various materials is large, but they should not be relied occurring within a fabric or within lots of the same style of

upon where differences in laboratory test findings are small. In fabric can, however, be detected satisfactorily with the RPDH

general, they should not be relied upon for prediction of actual tester.

wear-life in specific end uses unless there are data showing the 5.11 Because of the conditions mentioned above, techni-

specific relationship between laboratory abrasion tests and cians frequently fail to get good agreement between results

actual wear in the intended end-use. obtained on the same type of testing instrument both within and

5.5 These general observations apply to all types of fabrics, between laboratories, and the precision of these test methods is

including woven, nonwoven, and knit apparel fabrics, house- uncertain. This test method is accordingly not recommended

hold fabrics, industrial fabrics, and floor coverings. It is not for acceptance testing in contractual agreements between

surprising, therefore, to find that there are many different types purchaser and seller because of the poor between-laboratory

of abrasion testing machines, abradants, testing conditions, precision of the test method. In such a case, if there is a

testing procedures, methods of evaluation of abrasion resis- disagreement arising from differences in values reported by the

tance and interpretation of results. purchaser and the seller when using this test method for

5.6 All the test methods and instruments so far developed acceptance testing, the statistical bias, if any, between the

for measuring abrasion resistance may show a high degree of laboratory of the purchaser and laboratory of the seller should

variability in results obtained by different operators and in be determined with each comparison being based on testing

different laboratories; however, they represent the test methods specimens randomly drawn from one sampling unit of material

now most widely in use. of the type being evaluated.

5.7 Since there is a definite need for measuring the relative

6. Apparatus

resistance to abrasion, standardized test methods are needed

6.1 Rotary Platform, Double-Head (RPDH) Abraser (Fig.

and useful and may clarify the problem and lessen the

1), comprised of a housing of compact design, a removable

confusion.

flat-circular specimen holder, a pair of pivoted arms to which

5.8 Before definite predictions of fabric usefulness can be

the abrasive wheels are attached, a motor for rotating the

drawn from an abrasion test as made on the rotary platform,

platform and specimen, a fan for cooling the motor, a vaccum

double-head (RPDH) abraser (Fig. 1), actual end-use trials

nozzle and vacuum cleaner for removal of lint from specimen,

and a counter for indicating the revolutions of the specimen

holder. The specimen holder should be mounted so as to

produce a circular surface travel of an essentially flat specimen

in the plane of its surface.

6.1.1 The abrasive wheels, which are attached to the free

end of the pivoted arms, rotate and have, when resting on the

specimen, a peripheral engagement with the surface of the

specimen, the direction of travel of the periphery of the wheels

and of the specimen at the contacting portions being at acute

angles, and the angles of travel of one wheel periphery being

opposite to that of the other. Motion of the abrasive wheels, in

opposite directions, is provided by rotation of the specimen and

the associated friction therefrom.

6.1.2 The abrasive wheels are either rubber-based or

vitrified-based. Both types of wheels are manufactured in

Available from American Association of Textile Chemists and Colorists, P.O.

Box 12215, Research Triangle Park, NC 27709.

The Taber Abraser Model 503 has been found suitable and is available from

Teledyne Taber, 455 Bryant St., North Tonawanda, NY 14120.

Abrasive wheels of both the rubber-base type (trade name Calibrase) and the

vitrified-base type (trade name Calibrade) are manufactured by Teledyne Taber, 455

FIG. 1 Rotary Platform Double Head Abraser Bryant St., North Tonawanda NY 14120.

D 3884

different grades of abrasive quality. The wheels are lead square and cut off the folded corner to form a 6-mm ( ⁄4-in.)

bushed, 13 mm (0.5 in.) thick and approximately 50 mm (2 in.) diameter hole in the center of the specimen.

in diameter. The wheels customarily used for testing textiles

9. Preparation, Calibration, and Verification of

are the rubber-base, resilient type composed of abrasive grains

Apparatus

cushioned in rubber; consequently, they are distorted during

operation of the abraser. Accordingly, the wheels should be

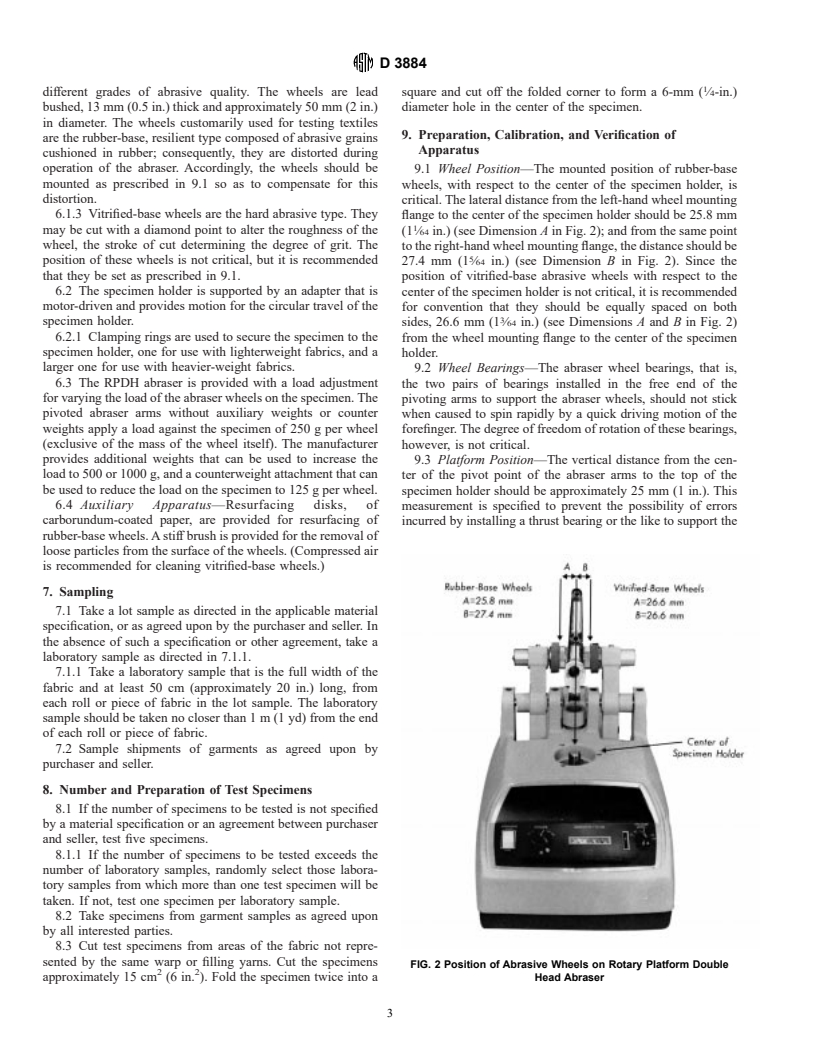

9.1 Wheel Position—The mounted position of rubber-base

mounted as prescribed in 9.1 so as to compensate for this

wheels, with respect to the center of the specimen holder, is

distortion. critical. The lateral distance from the left-hand wheel mounting

6.1.3 Vitrified-base wheels are the hard abrasive type. They

flange to the center of the specimen holder should be 25.8 mm

may be cut with a diamond point to alter the roughness of the (1 ⁄64 in.) (see Dimension A in Fig. 2); and from the same point

wheel, the stroke of cut determining the degree of grit. The

to the right-hand wheel mounting flange, the distance should be

position of these wheels is not critical, but it is recommended 27.4 mm (1 ⁄64 in.) (see Dimension B in Fig. 2). Since the

that they be set as prescribed in 9.1.

position of vitrified-base abrasive wheels with respect to the

6.2 The specimen holder is supported by an adapter that is center of the specimen holder is not critical, it is recommended

motor-driven and provides motion for the circular travel of the

for convention that they should be equally spaced on both

specimen holder. sides, 26.6 mm (1 ⁄64 in.) (see Dimensions A and B in Fig. 2)

6.2.1 Clamping rings are used to secure the specimen to the

from the wheel mounting flange to the center of the specimen

specimen holder, one for use with lighterweight fabrics, and a holder.

larger one for use with heavier-weight fabrics.

9.2 Wheel Bearings—The abraser wheel bearings, that is,

6.3 The RPDH abraser is provided with a load adjustment

the two pairs of bearings installed in the free end of the

for varying the load of the abraser wheels on the specimen. The

pivoting arms to support the abraser wheels, should not stick

pivoted abraser arms without auxiliary weights or counter

when caused to spin rapidly by a quick driving motion of the

weights apply a load against the specimen of 250 g per wheel

forefinger. The degree of freedom of rotation of these bearings,

(exclusive of the mass of the wheel itself). The manufacturer

however, is not critical.

provides additional weights that can be used to increase the

9.3 Platform Position—The vertical distance from the cen-

load to 500 or 1000 g, and a counterweight attachment that can

ter of the pivot point of the abraser arms to the top of the

be used to reduce the load on the specimen to 125 g per wheel.

specimen holder should be approximately 25 mm (1 in.). This

6.4 Auxiliary Apparatus—Resurfacing disks, of

measurement is specified to prevent the possibility of errors

carborundum-coated paper, are provided for resurfacing of incurred by installing a thrust bearing or the like to support the

rubber-base wheels. A stiff brush is provided for the removal of

loose particles from the surface of the wheels. (Compressed air

is recommended for cleaning vitrified-base wheels.)

7. Sampling

7.1 Take a lot sample as directed in the applicable material

specification, or as agreed upon by the purchaser and seller. In

the absence of such a specification or other agreement, take a

laboratory sample as directed in 7.1.1.

7.1.1 Take a laboratory sample that is the full width of the

fabric and at least 50 cm (approximately 20 in.) long, from

each roll or piece of fabric in the lot sample. The laboratory

sample should be taken no closer than1m(1yd) from the end

of each roll or piece of fabric.

7.2 Sample shipments of garments as agreed upon by

purchaser and seller.

8. Number and Preparation of Test Specimens

8.1 If the number of specimens to be tested is not specified

by a material specification or an agreement between purchaser

and seller, test five specimens.

8.1.1 If the number of specimens to be tested exceeds the

number of laboratory samples, randomly select those labora-

tory samples from which more than one test specimen will be

taken. If not, test one specimen per laboratory sample.

8.2 Take specim

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.