ASTM D2622-07

(Test Method)Standard Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry

Standard Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry

SIGNIFICANCE AND USE

This test method provides rapid and precise measurement of total sulfur in petroleum and petroleum products with a minimum of sample preparation. A typical analysis time is 1 to 2 minutes per sample.

The quality of many petroleum products is related to the amount of sulfur present. Knowledge of sulfur concentration is necessary for processing purposes. There are also regulations promulgated in federal, state, and local agencies that restrict the amount of sulfur present in some fuels.

This test method provides a means of determining whether the sulfur content of petroleum or a petroleum product meets specification or regulatory limits.

When this test method is applied to petroleum materials with matrices significantly different from the white oil calibration materials specified in this test method, the cautions and recommendations in Section 5 should be observed when interpreting results.

Note 1—The equipment specified for Test Method D 2622 tends to be more expensive than that required for alternative test methods, such as Test Method D 4294. Consult the Index to ASTM Standards for alternative test methods.

SCOPE

1.1 This test method covers the determination of total sulfur in petroleum and petroleum products that are single-phase and either liquid at ambient conditions, liquefiable with moderate heat, or soluble in hydrocarbon solvents. These materials can include diesel fuel, jet fuel, kerosene, other distillate oil, naphtha, residual oil, lubricating base oil, hydraulic oil, crude oil, unleaded gasoline, gasohol and biodiesel.

1.2 An estimate of this methods pooled limit of quantitation (PLOQ) is 3 mg/kg as calculated by the procedures in Practice D 6259.

1.2.1 The values of the limit of quantitation (LOQ) and method precision for a specific laboratorys instrument depends on instrument source power (low or high power), sample type, and the practices established by the laboratory to perform the method.

1.3 Samples containing more than 4.6 mass % sulfur should be diluted to bring the sulfur concentration of the diluted material within the scope of this test method. Samples that are diluted can have higher errors than indicated in Section than non-diluted samples.

1.4 Volatile samples (such as high vapor pressure gasolines or light hydrocarbons) may not meet the stated precision because of selective loss of light materials during the analysis.

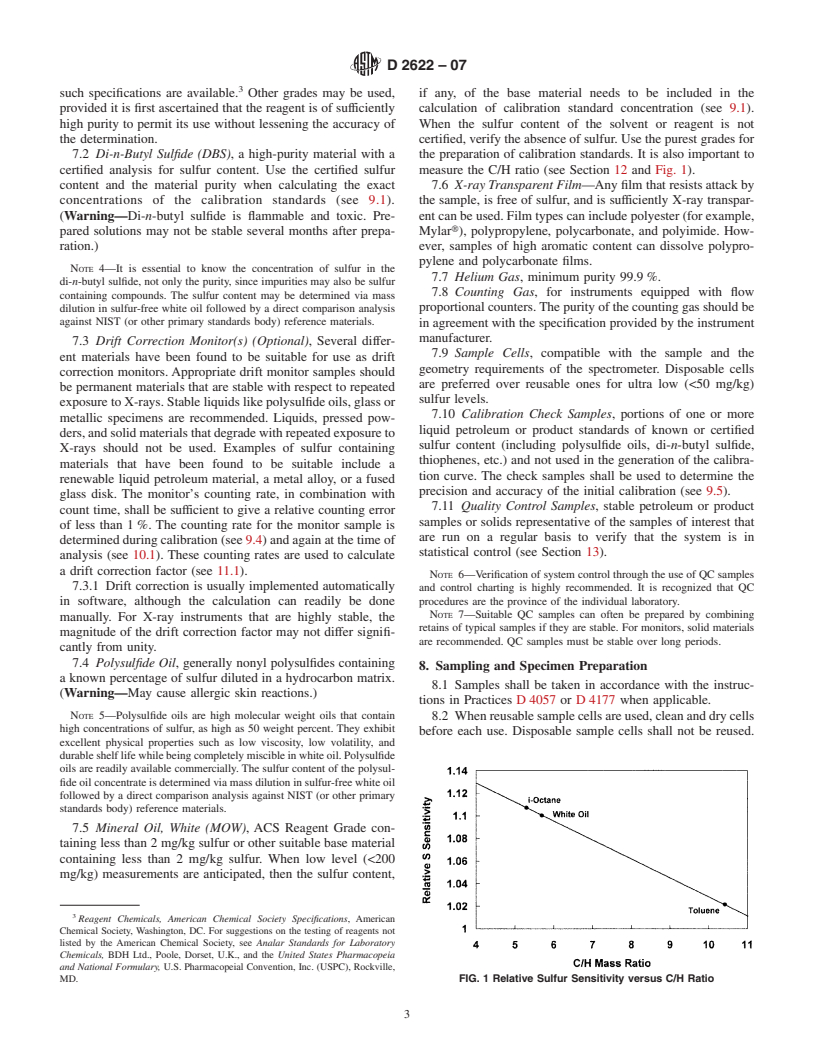

1.5 A fundamental assumption in this test method is that the standard and sample matrices are well matched, or that the matrix differences are accounted for (see 12.2). Matrix mismatch can be caused by C/H ratio differences between samples and standards or by the presence of other interfering heteroatoms or species (see Table 1).

1.6 The values stated in SI units are to be regarded as the standard. The values given in parenthess are for informaiton only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D2622–07

Standard Test Method for

Sulfur in Petroleum Products by Wavelength Dispersive

1

X-ray Fluorescence Spectrometry

This standard is issued under the fixed designation D 2622; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This test method covers the determination of total sulfur

in petroleum and petroleum products that are single-phase and

2. Referenced Documents

either liquid at ambient conditions, liquefiable with moderate

2

2.1 ASTM Standards:

heat, or soluble in hydrocarbon solvents. These materials can

D 4057 Practice for Manual Sampling of Petroleum and

include diesel fuel, jet fuel, kerosene, other distillate oil,

Petroleum Products

naphtha, residual oil, lubricating base oil, hydraulic oil, crude

D 4177 Practice for Automatic Sampling of Petroleum and

oil, unleaded gasoline, gasohol and biodiesel.

Petroleum Products

1.2 Anestimateofthismethod’spooledlimitofquantitation

D 4294 Test Method for Sulfur in Petroleum and Petroleum

(PLOQ) is 3 mg/kg as calculated by the procedures in Practice

Products by Energy-Dispersive X-ray Fluorescence Spec-

D 6259.

trometry

1.2.1 The values of the limit of quantitation (LOQ) and

D 4927 Test Methods for Elemental Analysis of Lubricant

methodprecisionforaspecificlaboratory’sinstrumentdepends

and Additive Components—Barium, Calcium, Phospho-

on instrument source power (low or high power), sample type,

rus, Sulfur, and Zinc by Wavelength-Dispersive X-Ray

and the practices established by the laboratory to perform the

Fluorescence Spectroscopy

method.

D 6259 Practice for Determination of a Pooled Limit of

1.3 Samples containing more than 4.6 mass % sulfur should

Quantitation

be diluted to bring the sulfur concentration of the diluted

D 6299 Practice for Applying Statistical Quality Assurance

material within the scope of this test method. Samples that are

Techniques to Evaluate Analytical Measurement System

dilutedcanhavehighererrorsthanindicatedinSection14than

Performance

non-diluted samples.

D 7343 Practice for Optimization, Sample Handling, Cali-

1.4 Volatile samples (such as high vapor pressure gasolines

bration, and Validation of X-Ray Fluorescence Spectrom-

or light hydrocarbons) may not meet the stated precision

etry Methods for the Elemental Analysis of Petroleum

because of selective loss of light materials during the analysis.

Products and Lubricants

1.5 Afundamental assumption in this test method is that the

E29 Practice for Using Significant Digits in Test Data to

standard and sample matrices are well matched, or that the

Determine Conformance with Specifications

matrix differences are accounted for (see 12.2). Matrix mis-

match can be caused by C/H ratio differences between samples

3. Summary of Test Method

and standards or by the presence of other interfering heteroa-

3.1 The sample is placed in the X-ray beam, and the peak

toms or species (see Table 1).

intensity of the sulfur Ka line at 0.5373 nm is measured. The

1.6 The values stated in SI units are to be regarded as the

background intensity, measured at a recommended wavelength

standard. The values given in parentheses are for information

of 0.5190 nm (0.5437 nm for a Rh target tube) is subtracted

only.

from the peak intensity. The resultant net counting rate is then

1.7 This standard does not purport to address all of the

compared to a previously prepared calibration curve or equa-

safety concerns, if any, associated with its use. It is the

tion to obtain the concentration of sulfur in mg/kg or mass %

responsibility of the user of this standard to establish appro-

(see Section 12).

1

This test method is under the jurisdiction of ASTM Committee D02 on

2

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

D02.03 on Elemental Analysis. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved July 15, 2007. Published August 2007. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1967. Last previous edition approved in 2005 as D 2622–05. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.