ASTM F1176-93

(Practice)Standard Practice for Design and Installation of Underground Thermoplastic Irrigation Systems With Maximum Working Pressure of 125 psi

Standard Practice for Design and Installation of Underground Thermoplastic Irrigation Systems With Maximum Working Pressure of 125 psi

SCOPE

1.1 This practice establishes procedures for the design and installation of thermoplastic flexible piping systems, for underground irrigation systems. Because there is considerable variability in end-use requirements, soil conditions, and thermoplastic piping characteristics, the intent of this practice is to outline general objectives and basics of systems design, proper installation procedures, and to provide pertinent references.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units which are for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

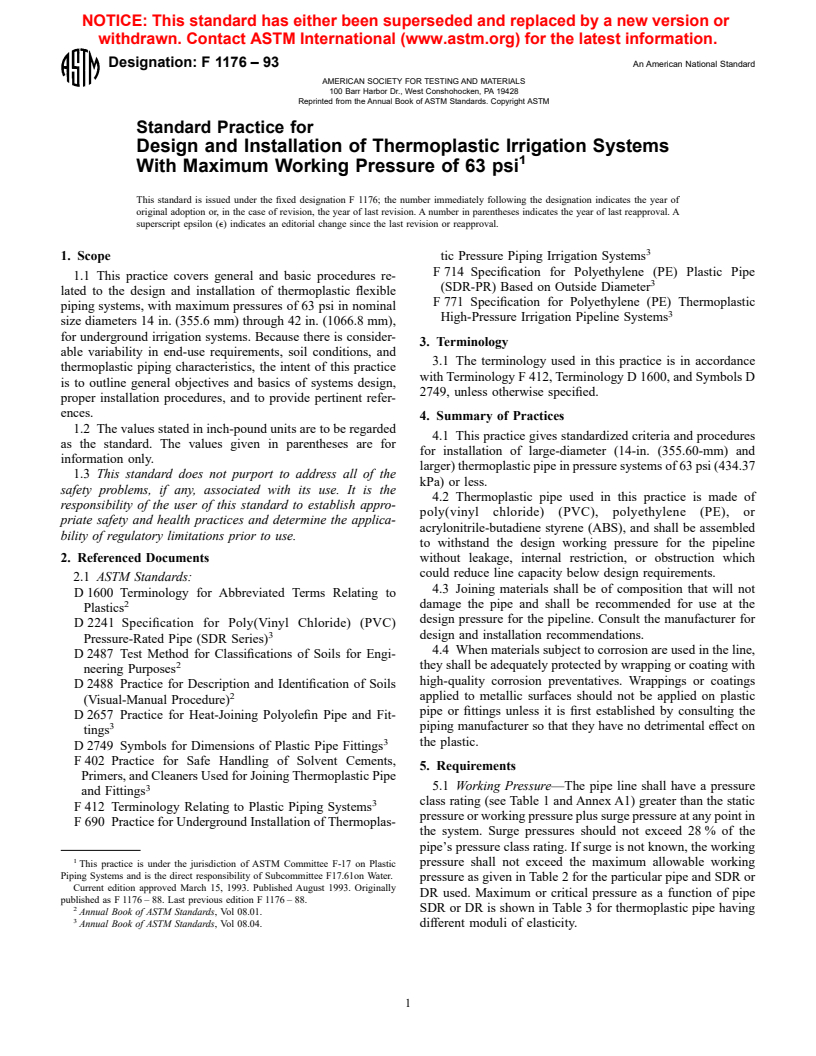

Designation: F 1176 – 93 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Design and Installation of Thermoplastic Irrigation Systems

1

With Maximum Working Pressure of 63 psi

This standard is issued under the fixed designation F 1176; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

3

1. Scope tic Pressure Piping Irrigation Systems

F 714 Specification for Polyethylene (PE) Plastic Pipe

1.1 This practice covers general and basic procedures re-

3

(SDR-PR) Based on Outside Diameter

lated to the design and installation of thermoplastic flexible

F 771 Specification for Polyethylene (PE) Thermoplastic

piping systems, with maximum pressures of 63 psi in nominal

3

High-Pressure Irrigation Pipeline Systems

size diameters 14 in. (355.6 mm) through 42 in. (1066.8 mm),

for underground irrigation systems. Because there is consider-

3. Terminology

able variability in end-use requirements, soil conditions, and

3.1 The terminology used in this practice is in accordance

thermoplastic piping characteristics, the intent of this practice

with Terminology F 412, Terminology D 1600, and Symbols D

is to outline general objectives and basics of systems design,

2749, unless otherwise specified.

proper installation procedures, and to provide pertinent refer-

ences.

4. Summary of Practices

1.2 The values stated in inch-pound units are to be regarded

4.1 This practice gives standardized criteria and procedures

as the standard. The values given in parentheses are for

for installation of large-diameter (14-in. (355.60-mm) and

information only.

larger) thermoplastic pipe in pressure systems of 63 psi (434.37

1.3 This standard does not purport to address all of the

kPa) or less.

safety problems, if any, associated with its use. It is the

4.2 Thermoplastic pipe used in this practice is made of

responsibility of the user of this standard to establish appro-

poly(vinyl chloride) (PVC), polyethylene (PE), or

priate safety and health practices and determine the applica-

acrylonitrile-butadiene styrene (ABS), and shall be assembled

bility of regulatory limitations prior to use.

to withstand the design working pressure for the pipeline

2. Referenced Documents without leakage, internal restriction, or obstruction which

could reduce line capacity below design requirements.

2.1 ASTM Standards:

4.3 Joining materials shall be of composition that will not

D 1600 Terminology for Abbreviated Terms Relating to

2

damage the pipe and shall be recommended for use at the

Plastics

design pressure for the pipeline. Consult the manufacturer for

D 2241 Specification for Poly(Vinyl Chloride) (PVC)

3 design and installation recommendations.

Pressure-Rated Pipe (SDR Series)

4.4 When materials subject to corrosion are used in the line,

D 2487 Test Method for Classifications of Soils for Engi-

2 they shall be adequately protected by wrapping or coating with

neering Purposes

high-quality corrosion preventatives. Wrappings or coatings

D 2488 Practice for Description and Identification of Soils

2 applied to metallic surfaces should not be applied on plastic

(Visual-Manual Procedure)

pipe or fittings unless it is first established by consulting the

D 2657 Practice for Heat-Joining Polyolefin Pipe and Fit-

3 piping manufacturer so that they have no detrimental effect on

tings

3

the plastic.

D 2749 Symbols for Dimensions of Plastic Pipe Fittings

F 402 Practice for Safe Handling of Solvent Cements,

5. Requirements

Primers, and Cleaners Used for Joining Thermoplastic Pipe

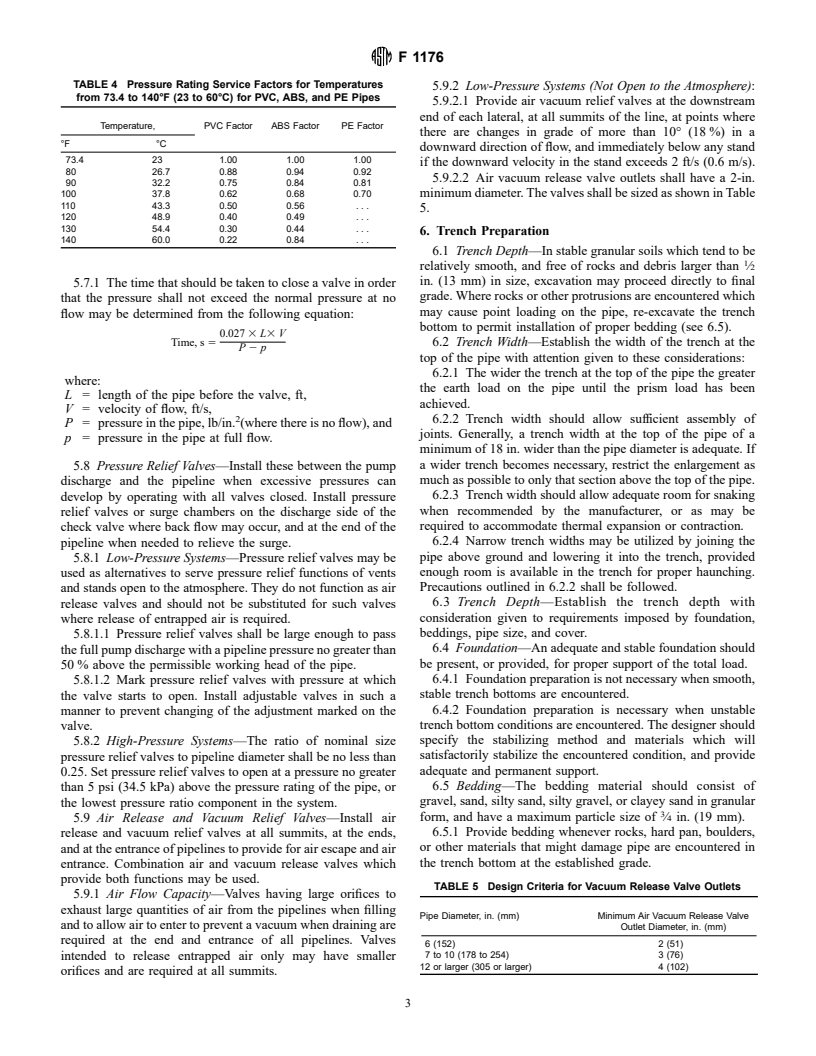

3 5.1 Working Pressure—The pipe line shall have a pressure

and Fittings

class rating (see Table 1 and Annex A1) greater than the static

3

F 412 Terminology Relating to Plastic Piping Systems

pressure or working pressure plus surge pressure at any point in

F 690 Practice for Underground Installation of Thermoplas-

the system. Surge pressures should not exceed 28 % of the

pipe’s pressure class rating. If surge is not known, the working

1

pressure shall not exceed the maximum allowable working

This practice is under the jurisdiction of ASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.61on Water.

pressure as given in Table 2 for the particular pipe and SDR or

Current edition approved March 15, 1993. Published August 1993. Originally

DR used. Maximum or critical pressure as a function of pipe

published as F 1176 – 88. Last previous edition F 1176 – 88.

2 SDR or DR is shown in Table 3 for thermoplastic pip

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.