ASTM B956-07

(Specification)Standard Specification for Welded Copper and Copper-Alloy Condenser and Heat Exchanger Tubes with Integral Fins

Standard Specification for Welded Copper and Copper-Alloy Condenser and Heat Exchanger Tubes with Integral Fins

SCOPE

1.1 This specification establishes the requirements for heat exchanger tubes manufactured from forge-welded copper and copper alloy tubing in straight lengths on which the external or internal surface, or both, has been modified by cold forming process to produce an integral enhanced surface for improved heat transfer.

1.2 UnitsThe values stated in either inch-pounds units or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems could result in nonconformance with the specification.

1.3 The tubes are typically used in surface condensers, evaporators, and heat exchangers.

1.4 The product shall be produced of the following coppers or copper alloys, as specified in the ordering information.Note 1

Designations listed in Classification B 224.

The following safety hazard caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 956 – 07

Standard Specification for

Welded Copper and Copper-Alloy Condenser and Heat

Exchanger Tubes with Integral Fins

This standard is issued under the fixed designation B 956; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior

1.1 This specification establishes the requirements for heat

to use.

exchanger tubes manufactured from forge-welded copper and

copper alloy tubing in straight lengths on which the external or

2. Referenced Documents

internal surface, or both, has been modified by cold forming

2.1 ASTM Standards:

process to produce an integral enhanced surface for improved

B 153 Test Method for Expansion (Pin Test) of Copper and

heat transfer.

Copper-Alloy Pipe and Tubing

1.2 Units—The values stated in either inch-pounds units or

B 154 Test Method for Mercurous Nitrate Test for Copper

SI units are to be regarded separately as the standard. Within

Alloys

the text, the SI units are shown in brackets. The values stated

B 224 Classification of Coppers

in each system are not exact equivalents; therefore, each

B 543 Specification for Welded Copper and Copper-Alloy

system shall be used independently of the other. Combining

Heat Exchanger Tube

values from the two systems could result in nonconformance

B 601 Classification for Temper Designations for Copper

with the specification.

and Copper Alloys—Wrought and Cast

1.3 The tubes are typically used in surface condensers,

B 846 Terminology for Copper and Copper Alloys

evaporators, and heat exchangers.

B 858 Test Method for Ammonia Vapor Test for Determin-

1.4 The product shall be produced of the following coppers

ing Susceptibility to Stress Corrosion Cracking in Copper

or copper alloys, as specified in the ordering information.

Alloys

Copper or Copper Alloy

Type of Metal

E8 Test Methods for Tension Testing of Metallic Materials

UNS No.

A

C12000 DLP Phosphorized, low residual phosphorus

E29 Practice for Using Significant Digits in Test Data to

A

C12200 DHP Phosphorized, high residual phosphorus

Determine Conformance with Specifications

C19200 Phosphorized, 1 % iron

E53 Test Method for Determination of Copper in Unal-

C23000 Red Brass

C44300 Admiralty, arsenical

loyed Copper by Gravimetry

C44400 Admiralty, antimonial

E54 Test Methods for Chemical Analysis of Special

C44500 Admiralty, phosphorized

Brasses and Bronzes

C68700 Aluminum Brass

C70400 95-5 Copper-Nickel

E62 Test Methods for Chemical Analysis of Copper and

C70600 90-10 Copper-Nickel

Copper Alloys (Photometric Methods)

C70620 90-10 Copper-Nickel (Modified for Welding)

E112 Test Methods for Determining Average Grain Size

C71000 80-20 Copper-Nickel

C71500 70-30 Copper-Nickel

E118 Test Methods for Chemical Analysis of Copper-

C71520 70-30 Copper-Nickel (Modified for Welding)

Chromium Alloys

C72200 Copper-Nickel

E 243 Practice for Electromagnetic (Eddy-Current) Exami-

A

Copper UNS Nos. C12000, and C12200 are classified in Classification B 224.

nation of Copper and Copper-Alloy Tubes

E 255 Practice for Sampling Copper and CopperAlloys for

NOTE 1—Designations listed in Classification B 224.

the Determination of Chemical Composition

1.5 The following safety hazard caveat pertains only to the

E 478 Test Methods for Chemical Analysis of Copper

test methods described in this specification. This standard does

Alloys

not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe Standards volume information, refer to the standard’s Document Summary page on

and Tube. the ASTM website.

Current edition approved Oct. 1, 2007. Published November 2007. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B956–07

E 527 Practice for Numbering Metals and Alloys in the 5.2.2.1 Whether a pressure test is be used along with the

Unified Numbering System (UNS) eddy-current test (13.3 and 13.4),

5.2.3 Whether cut ends of the tube are to be deburred,

3. Terminology

chamfered, or otherwise treated (Section 15),

3.1 For the definitions of terms related to copper and copper 5.2.4 If the product is to be subsequently welded,

alloys, refer to Terminology B 846.

5.2.5 Certification, if required (Section 23), and

3.2 Definitions of Terms Specific to This Standard:

5.2.6 Mill test report, if required (Section 24).

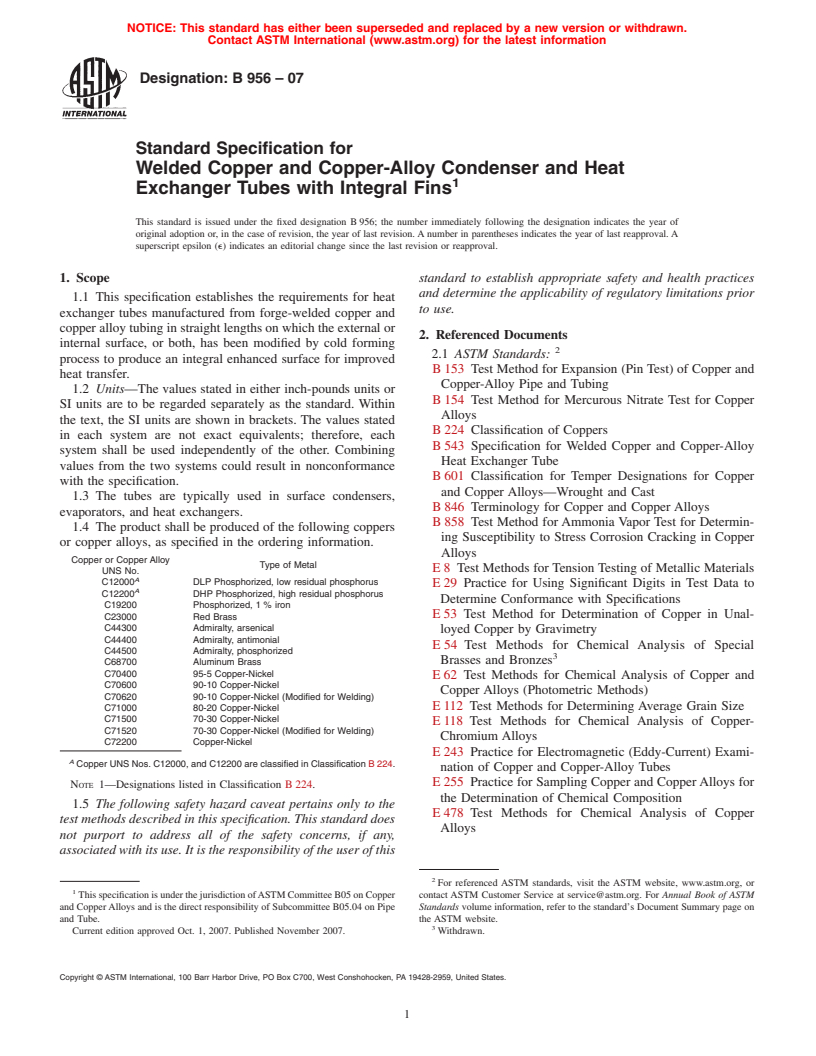

3.2.1 enhanced tube—tube having a series of metallic ribs

on the outside or inside surface, or both, either parallel to the

6. Materials and Manufacture

longitudinalaxisorcircumferentiallyextendedfromthetubeto

6.1 Material:

increase the effective surface for heat transfer (Figs. 1-3).

6.1.1 The material of manufacture shall be welded tube of

3.2.2 unenhanced tube—tube made by processing strip into

one of the CopperAlloy UNS Nos. listed in 1.1 of such purity

a tubular shape and forge welding the edges to make a

andsoundnessastobesuitableforprocessingintotheproducts

longitudinal seam with no enhancements on the O.D. or I.D.

prescribed herein.

6.1.2 In the event heat identification or traceability is

4. Types of Welded Tube

required, the purchaser shall specify the details desired.

4.1 Reference Specification B 543 for the types of forge

6.2 Manufacture:

welded tube products that will be supplied for the enhancing

6.2.1 The product shall be manufacture by cold forming the

operation (Section 6).

enhancement of the heat transfer surfaces.

6.3 Product described by this specification shall typically be

5. Ordering Information

furnished with unenhanced ends, but may be furnished with

5.1 Include the following information when placing orders

enhanced ends or stripped ends from which the O.D. enhance-

for product under this specification as applicable:

ment has been removed by machining.

5.1.1 ASTM designation and year of issue,

6.3.1 The enhanced sections of the tube in the as-fabricated

5.1.2 Copper UNS No. designation (for example, Copper

temper are in the cold formed condition produced by the

UNS No. C12000),

enhancing operation.

5.1.3 Tube type (Section 4),

6.3.2 The unenhanced sections of the tube shall be in the

5.1.4 Temper (Section 8),

annealed or as-welded temper, and shall be suitable for

5.1.5 Dimensions, the diameter, wall thickness, whether

rolling-in operations.

minimum or nominal wall, and length (Section 14),

5.1.6 Configuration of enhanced surfaces shall be agree

7. Chemical Composition

upon between the manufacturer and the purchaser (Figs. 1-3),

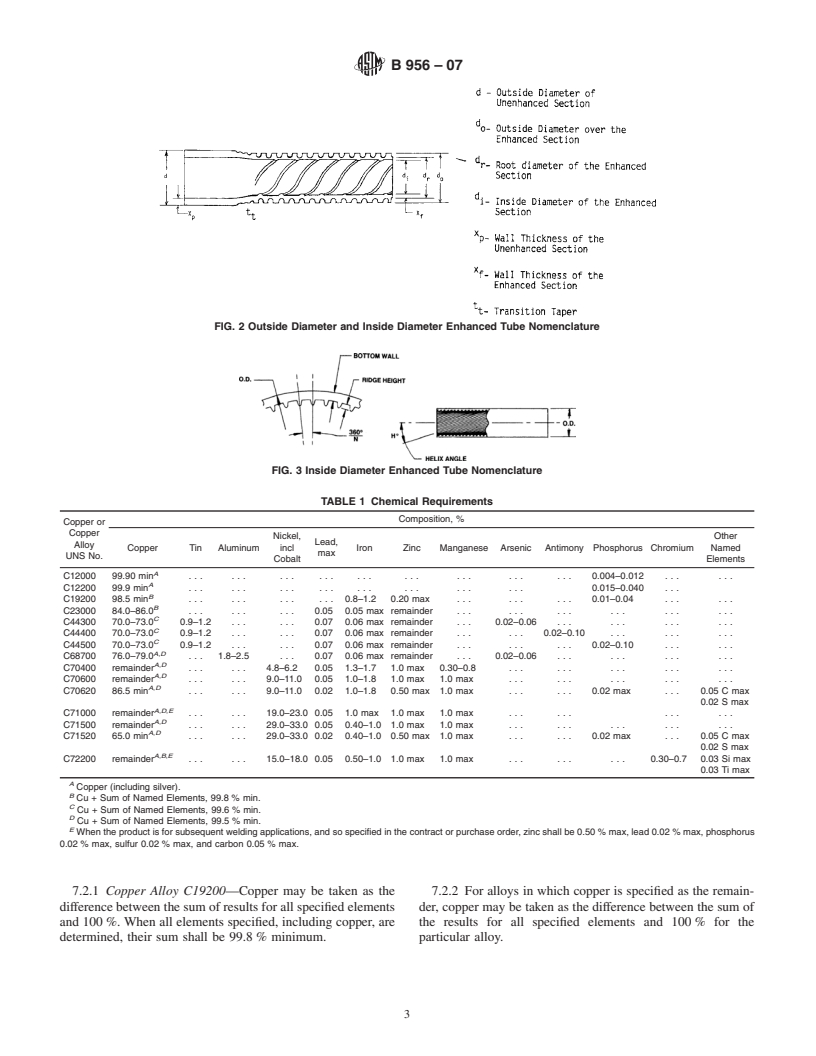

7.1 The material shall conform to the chemical composi-

and

5.1.7 Quantity. tionalrequirementsinTable1forCopperUNSNo.designation

specified in the ordering information.

5.2 The following options are available and shall be speci-

fied at the time placing the order, when required: 7.2 The composition limits do not preclude the presence of

5.2.1 When heat identification or traceability is required, other elements. By agreement between the manufacturer and

5.2.2 Whether a pressure test is to be used instead of the purchaser, limits may be established and analysis required for

eddy-current test (13.1), unnamed elements.

NOTE—The outside diameter over the enhanced section will not normally exceed the outside diameter of the unenhanced section.

FIG. 1 Outside Diameter Enhanced Tube Nomenclature

B956–07

FIG. 2 Outside Diameter and Inside Diameter Enhanced Tube Nomenclature

FIG. 3 Inside Diameter Enhanced Tube Nomenclature

TABLE 1 Chemical Requirements

Composition, %

Copper or

Copper

Nickel, Other

Lead,

Alloy

Copper Tin Aluminum incl Iron Zinc Manganese Arsenic Antimony Phosphorus Chromium Named

max

UNS No.

Cobalt Elements

A

C12000 99.90 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.004–0.012 . . . . . .

A

C12200 99.9 min . . . . . . . . . . . . . . . . . . . . . . . . 0.015–0.040 . . .

B

C19200 98.5 min . . . . . . . . . . . . 0.8–1.2 0.20 max . . . . . . . . . 0.01–0.04 . . . . . .

B

C23000 84.0–86.0 . . . . . . . . . 0.05 0.05 max remainder . . . . . . . . . . . . . . . . . .

C

C44300 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . 0.02–0.06 . . . . . . . . . . . .

C

C44400 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . . . . 0.02–0.10 . . . . . . . . .

C

C44500 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . . . . . . . 0.02–0.10 . . . . . .

A,D

C68700 76.0–79.0 . . . 1.8–2.5 . . . 0.07 0.06 max remainder . . . 0.02–0.06 . . . . . . . . . . . .

A,D

C70400 remainder . . . . . . 4.8–6.2 0.05 1.3–1.7 1.0 max 0.30–0.8 . . . . . . . . . . . . . . .

A,D

C70600 remainder . . . . . . 9.0–11.0 0.05 1.0–1.8 1.0 max 1.0 max . . . . . . . . . . . . . . .

A,D

C70620 86.5 min . . . . . . 9.0–11.0 0.02 1.0–1.8 0.50 max 1.0 max . . . . . . 0.02 max . . . 0.05 C max

0.02 S max

A,D,E

C71000 remainder . . . . . . 19.0–23.0 0.05 1.0 max 1.0 max 1.0 max . . . . . . . . . . . .

A,D

C71500 remainder . . . . . . 29.0–33.0 0.05 0.40–1.0 1.0 max 1.0 max . . . . . . . . . . . . . . .

A,D

C71520 65.0 min . . . . . . 29.0–33.0 0.02 0.40–1.0 0.50 max 1.0 max . . . . . . 0.02 max . . . 0.05 C max

0.02 S max

A,B,E

C72200 remainder . . . . . . 15.0–18.0 0.05 0.50–1.0 1.0 max 1.0 max . . . . . . . . . 0.30–0.7 0.03 Si max

0.03 Ti max

A

Copper (including silver).

B

Cu + Sum of Named Elements, 99.8 % min.

C

Cu + Sum of Named Elements, 99.6 % min.

D

Cu + Sum of Named Elements, 99.5 % min.

E

When the product is for subsequent welding applications, and so specified in the contract or purchase order, zinc shall be 0.50 % max, lead 0.02 % max, phosphorus

0.02 % max, sulfur 0.02 % max, and carbon 0.05 % max.

7.2.1 Copper Alloy C19200—Copper may be taken as the 7.2.2 For alloys in which copper is specified as the remain-

difference between the sum of results for all specified elements der, copper may be taken as the difference between the sum of

and 100 %. When all elements specified, including copper, are the results for all specified elements and 100 % for the

determined, their sum shall be 99.8 % minimum. particular alloy.

B956–07

7.2.2.1 When analyzed, copper plus the sum of results for 8.2 Tubes of Copper Alloy UNS Nos. C23000, C44300,

specified elements shall conform with the requirements shown C44400, C44500, and C68700 shall be furnished in the

in the following table: annealed temper or the stress relieved condition as specified in

the purchase order unless otherwise agreed upon between the

Copper Plus Named Elements,

Copper Alloy UNS No.

%min

purchaser and the manufacturer.

C70400 99.5

8.3 Tubes of Copper Alloy UNS Nos. C12200, C19400,

C70600 99.5

C70620 99.5 C70400, C70600, C71000, C71500, and C72200 are normally

C71000 99.5

supplied in the temper specified in the purchase order without

C71500 99.5

stress relief treatment.

C71520 99.5

C72200 99.8

NOTE 2—Some tubes, when subjected to aggressive environments, may

7.2.3 For alloys in which zinc is specified as the remainder, be subject to stress-corrosion cracking because of the residual tensile

stresses developed in the enhancing process. For such applications, it is

either copper or zinc may be taken as the difference between

suggested that tubes of Copper Alloy UNS Nos. C23000, C44300,

the sum of the results of specified elements analyzed and

C44400, C44500, and C68700 are subjected to a stress relieving thermal

100 %.

treatment subsequent to the enhancement process. In Specification B 359

7.2.3.1 Whenallspecifiedelementsaredetermined,thesum

the stress relief anneal is mandatory for brass alloys.

of results plus copper shall be as follows:

Copper Plus Named Elements,

9. Grain Size for Annealed Tempers

Copper Alloy UNS No.

%min

C23000 99.8 9.1 Samples of annealed temper tubes shall be examined at

C44300, C44400, C44500 99.6

a magnification of 75 diameters. The grain size shall be

C68700 99.5

determined in the wall beneath the internal enhancement.

While there is not grain size range, the microstructure shall

8. Temper

show complete recrystallization and the weld zone shall have a

8.1 Tempers, as defined in Classification B 601 and this

structure typical of hot-forged welds.

specification, are as follows:

8.1.1 The tube, after enhancing, shall be supplied, as speci-

10. Mechanical Property Requirements

fied, in the annealed (061) or as-fabricated temper.

10.1 Tensile Strength and Yield Strength Requirements:

8.1.1.1 The enhanced sections of tubes in the as-fabricated

10.1.1 Product furnished under this specification shall con-

temper are in the cold formed condition produced by the

fabricating operation. form to the tensile and yield strength requirements prescribed

in Table 2 when tested in accordance with Test MethodE8.

8.1.1.2 The unenhanced sections of tubes in the as-

fabricated temper are in the temper of the tube prior to 10.1.2 Acceptance or rejection based upon mechanical

enhancing, welded and annealed (WO61), welded and light properties shall depend only on tensile strength and yield

cold-worked (WC55) and suitable for rolling-in operations. strength.

TABLE 2 Tensile Requirements

B

Copper or Tensile Strength Yield Strength

Temper Designation

Copper Alloy min min

A A

Standard Former

UNS No. ksi [MPa] ksi [MPa]

C

C12000, C12200, WO61 annealed 30 [205] 9 [62]

C19200 WO61 annealed 38 [260] 12 [85]

C23000 WO61 annealed 40 [275] 12 [85]

C23000 WC55 light cold-worked 42 (290) 20 (138)

C44300, C44400, C44500 WO61 annealed 45 [310] 15 [105]

C44300, C44400, C44500 WC55 light cold-worked 50 (345) 35 (241)

C68700 WO61 annealed 50 [345] 18 [125]

D D

C68700 WC55 light cold-worked

C70400 WO61 annealed 38 [260] 12 [85]

C70400 WC55 light cold-worked 40 (275) 30 (207)

C70600 WO61 annealed 40 [275] 15 [105]

C70600 WC55 light cold-worked 45 (310) 35 (241)

C70620 WO61 annealed 40 [275] 15 [105]

C70620 WC55 light cold-worked

C71000 WO61 annealed 45 [310] 16 [110]

C71000 WC55 light cold-worked 50 (345) 35 (241)

C71500 WO61 annealed 52 [360] 18 [125]

C71500 WC55 light cold-worked 54 (372) 35 (241)

C71520 WO61 annealed 52 [360] 18 [125]

C71520 WC55 light cold-worked

C72200 WO61 annealed 45 [310] 16 [110]

C72200 WC55 light cold-worked 50 (345) 30 (207)

A

ksi = 1000 psi.

B

At 0.5 % extension under load.

C

Light straig

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.