ASTM E587-15(2020)

(Practice)Standard Practice for Ultrasonic Angle-Beam Contact Testing

Standard Practice for Ultrasonic Angle-Beam Contact Testing

SIGNIFICANCE AND USE

4.1 An electrical pulse is applied to a piezoelectric transducer which converts electrical to mechanical energy. In the angle-beam search unit, the piezoelectric element is generally a thickness expander which creates compressions and rarefactions. This longitudinal (compressional) wave travels through a wedge (generally a plastic). The angle between transducer face and the examination face of the wedge is equal to the angle between the normal (perpendicular) to the examination surface and the incident beam. Fig. 1 shows the incident angle φi, and the refracted angle φr, of the ultrasonic beam.

FIG. 1 Refraction

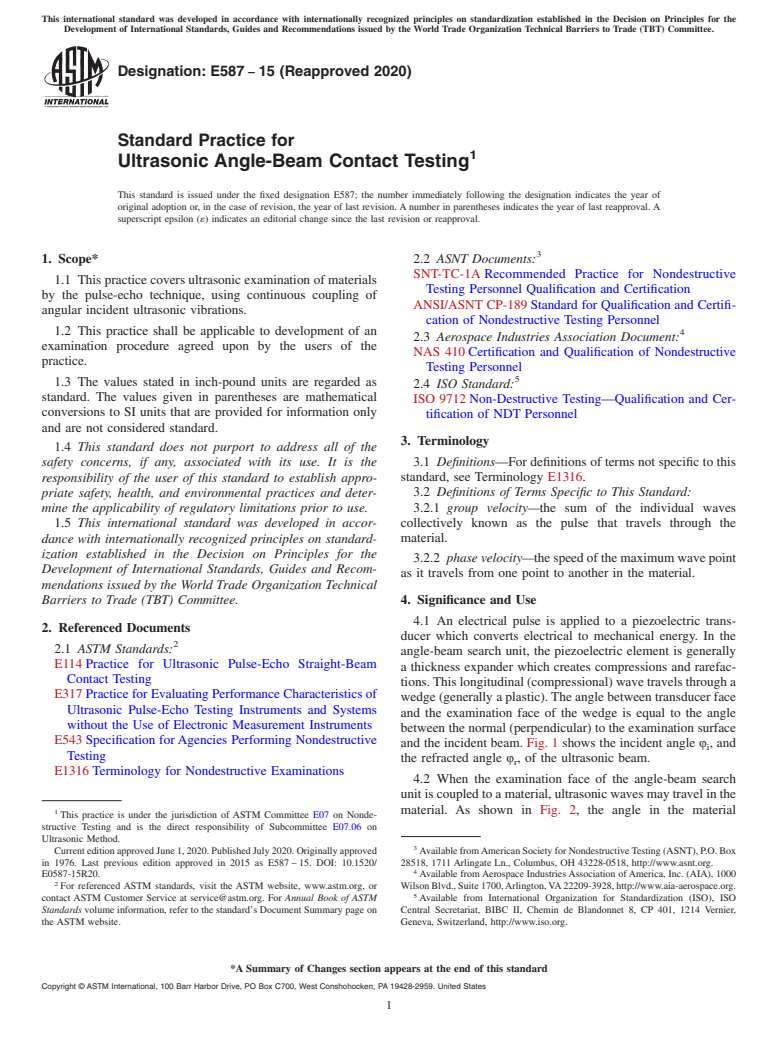

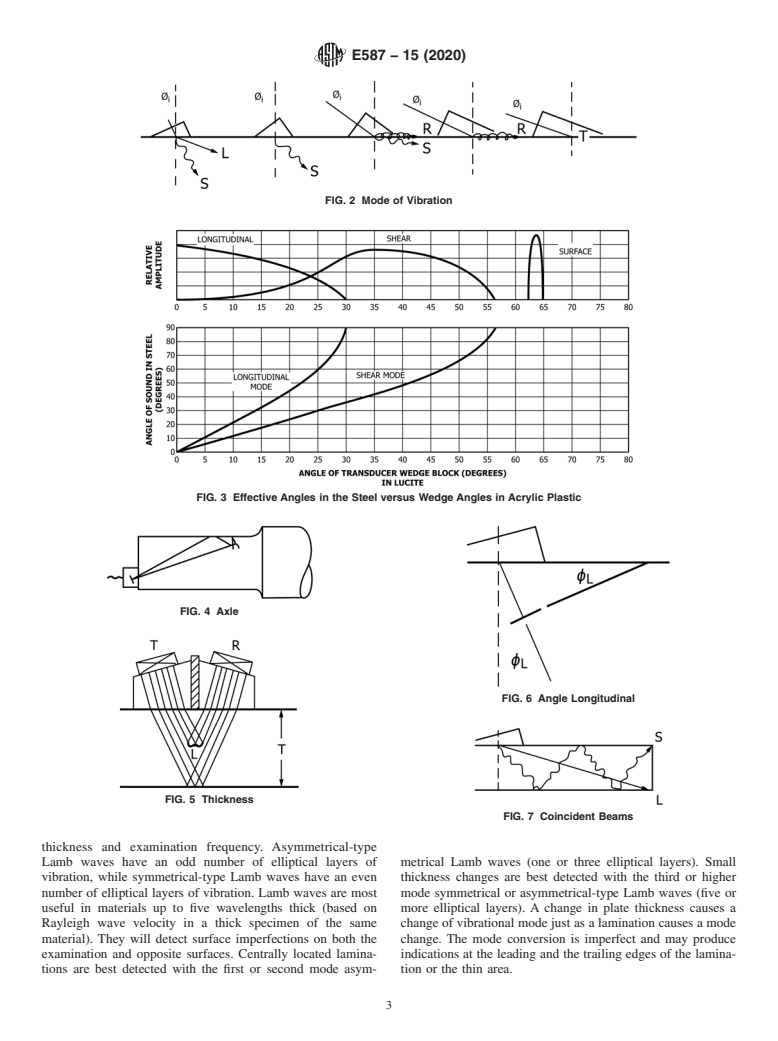

4.2 When the examination face of the angle-beam search unit is coupled to a material, ultrasonic waves may travel in the material. As shown in Fig. 2, the angle in the material (measured from the normal to the examination surface) and mode of vibration are dependent on the wedge angle, the ultrasonic velocity in the wedge, and the velocity of the wave in the examined material. When the material is thicker than a few wavelengths, the waves traveling in the material may be longitudinal and shear, shear alone, shear and Rayleigh, or Rayleigh alone. Total reflection may occur at the interface. (Refer to Fig. 3.) In thin materials (up to a few wavelengths thick), the waves from the angle-beam search unit traveling in the material may propagate in different Lamb wave modes.

FIG. 2 Mode of Vibration

FIG. 3 Effective Angles in the Steel versus Wedge Angles in Acrylic Plastic

4.3 All ultrasonic modes of vibration may be used for angle-beam examination of material. The material forms and the probable flaw locations and orientations determine selection of beam directions and modes of vibration. The use of angle beams and the selection of the proper wave mode presuppose a knowledge of the geometry of the object; the probable location, size, orientation, and reflectivity of the expected flaws; and the laws of physics governing the propagation of ultrasonic...

SCOPE

1.1 This practice covers ultrasonic examination of materials by the pulse-echo technique, using continuous coupling of angular incident ultrasonic vibrations.

1.2 This practice shall be applicable to development of an examination procedure agreed upon by the users of the practice.

1.3 The values stated in inch-pound units are regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E587 − 15 (Reapproved 2020)

Standard Practice for

Ultrasonic Angle-Beam Contact Testing

This standard is issued under the fixed designation E587; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2 ASNT Documents:

SNT-TC-1A Recommended Practice for Nondestructive

1.1 This practice covers ultrasonic examination of materials

Testing Personnel Qualification and Certification

by the pulse-echo technique, using continuous coupling of

ANSI/ASNT CP-189 Standard for Qualification and Certifi-

angular incident ultrasonic vibrations.

cation of Nondestructive Testing Personnel

1.2 This practice shall be applicable to development of an 4

2.3 Aerospace Industries Association Document:

examination procedure agreed upon by the users of the

NAS 410 Certification and Qualification of Nondestructive

practice.

Testing Personnel

1.3 The values stated in inch-pound units are regarded as

2.4 ISO Standard:

standard. The values given in parentheses are mathematical

ISO 9712 Non-Destructive Testing—Qualification and Cer-

conversions to SI units that are provided for information only

tification of NDT Personnel

and are not considered standard.

3. Terminology

1.4 This standard does not purport to address all of the

3.1 Definitions—For definitions of terms not specific to this

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- standard, see Terminology E1316.

3.2 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3.2.1 group velocity—the sum of the individual waves

collectively known as the pulse that travels through the

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard- material.

ization established in the Decision on Principles for the

3.2.2 phase velocity—thespeedofthemaximumwavepoint

Development of International Standards, Guides and Recom-

as it travels from one point to another in the material.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 4. Significance and Use

4.1 An electrical pulse is applied to a piezoelectric trans-

2. Referenced Documents

ducer which converts electrical to mechanical energy. In the

2.1 ASTM Standards:

angle-beam search unit, the piezoelectric element is generally

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam

a thickness expander which creates compressions and rarefac-

Contact Testing

tions.Thislongitudinal(compressional)wavetravelsthrougha

E317 Practice for Evaluating Performance Characteristics of

wedge (generally a plastic).The angle between transducer face

Ultrasonic Pulse-Echo Testing Instruments and Systems

and the examination face of the wedge is equal to the angle

without the Use of Electronic Measurement Instruments

between the normal (perpendicular) to the examination surface

E543 Specification for Agencies Performing Nondestructive

and the incident beam. Fig. 1 shows the incident angle φ, and

i

Testing

the refracted angle φ , of the ultrasonic beam.

r

E1316 Terminology for Nondestructive Examinations

4.2 When the examination face of the angle-beam search

unit is coupled to a material, ultrasonic waves may travel in the

material. As shown in Fig. 2, the angle in the material

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.06 on

Ultrasonic Method.

CurrenteditionapprovedJune1,2020.PublishedJuly2020.Originallyapproved AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

in 1976. Last previous edition approved in 2015 as E587 – 15. DOI: 10.1520/ 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

E0587-15R20. Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

For referenced ASTM standards, visit the ASTM website, www.astm.org, or WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Organization for Standardization (ISO), ISO

Standards volume information, refer to the standard’s Document Summary page on Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

the ASTM website. Geneva, Switzerland, http://www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E587 − 15 (2020)

angle up to 40° with respect to the examination surface,

provide optimum reflection to an angle-beam longitudinal

wave that is normal to the plane of the reflector. Angle-beam

longitudinal waves in the range from 45 to 85° become weaker

as the angle increases; at the same time, the coexisting

angle-beam shear waves become stronger. Equal amplitude

angle beams of approximately 55° longitudinal wave and 29°

shear wave will coexist in the material, as shown in Fig. 7.

Confusion created by two beams traveling at different angles

and at different velocities has limited use of this range of angle

beams.

4.3.2 Angle-Beam Shear Waves (Transverse Waves)—

FIG. 1 Refraction Angle-beam shear waves in the range from 40 to 75° are the

most used angle beams. They will detect imperfections in

materials by corner reflection and reradiation (as shown in Fig.

(measured from the normal to the examination surface) and

8) if the plane of the reflector is perpendicular to a material

mode of vibration are dependent on the wedge angle, the

surface, and by direct reflection if the ultrasonic beam is

ultrasonic velocity in the wedge, and the velocity of the wave

normal to the plane of the reflector (as shown in Fig. 9).

in the examined material. When the material is thicker than a

Reflectors parallel to the examination surface (such as lamina-

few wavelengths, the waves traveling in the material may be

tions in plate, as shown in Fig. 10) can rarely be detected by an

longitudinal and shear, shear alone, shear and Rayleigh, or

angle beam unless accompanied by another reflector; for

Rayleigh alone. Total reflection may occur at the interface.

example, a lamination at the edge of a plate (as shown in Fig.

(Refer to Fig. 3.) In thin materials (up to a few wavelengths

11) can be detected by corner reflection from the lamination

thick), the waves from the angle-beam search unit traveling in

and plate edge. Generally, laminations should be detected and

the material may propagate in different Lamb wave modes.

evaluated by the straight-beam technique. Angle-beam shear

4.3 All ultrasonic modes of vibration may be used for

waves applied to weld testing will detect incomplete penetra-

angle-beam examination of material. The material forms and

tion (as shown in Fig. 12) by corner reflection, incomplete

the probable flaw locations and orientations determine selec-

fusion (as shown in Fig. 13) by direct reflection (when the

tion of beam directions and modes of vibration. The use of

beam angle is chosen to be normal to the plane of the weld

angle beams and the selection of the proper wave mode

preparation), slag inclusion by cylindrical reflection (as shown

presuppose a knowledge of the geometry of the object; the

in Fig. 14), porosity by spherical reflection, and cracks (as

probable location, size, orientation, and reflectivity of the

shown in Fig. 15) by direct or corner reflection, depending on

expected flaws; and the laws of physics governing the propa-

their orientation. Angle-beam shear waves of 80 to 85° are

gation of ultrasonic waves. Characteristics of the examination

frequently accompanied by a Rayleigh wave traveling on the

system used and the ultrasonic properties of the material being

surface. Confusion created by two beams at slightly different

examined must be known or determined. Some materials,

angles, traveling at different velocities, has limited applications

because of unique microstructure, are difficult to examine

in this range of angle beams.

using ultrasonics. Austenitic material, particularly weld

4.3.3 Surface-Beam Rayleigh Waves—Surface-beam Ray-

material, is one example of this material condition. Caution

leigh waves travel at 90° to the normal of the examination

should be exercised when establishing examination practices

surface on the examination surface. In material greater than

for these type materials. While examination may be possible,

two wavelengths thick, the energy of the Rayleigh wave

sensitivity will be inferior to that achievable on ferritic

penetrates to a depth of approximately one wavelength; but,

materials. When examining materials with unique

duetotheexponentialdistributionoftheenergy,onehalfofthe

microstructures, empirical testing should be performed to

energyiswithinone-quarterwavelengthofthesurface.Surface

assure that the examination will achieve the desired sensitivity.

cracks with length perpendicular to the Rayleigh wave can be

This may be accomplished by incorporating known reflectors

detected and their depth evaluated by changing the frequency

in a mock up of the weld or part to be examined. For material

of the Rayleigh wave, thus changing its wavelength and depth

with such unique microstructures, a technique and procedure

of penetration. Wavelength equals velocity divided by fre-

shall be agreed upon between contracting parties.

quency.

4.3.1 Angle-Beam Longitudinal Waves—AsshowninFig.4,

V

angle-beam longitudinal waves with refracted angles in the

λ 5

f

range from 1 to 40° (where coexisting angle-beam shear waves

are weak, as shown in Fig. 3) may be used to detect fatigue Subsurface reflectors may be detected by Rayleigh waves if

cracks in axles and shafts from the end by direct reflection or they lie within one wavelength of the surface.

by corner reflection. As shown in Fig. 5, with a crossed-beam 4.3.4 Lamb Waves—Lamb waves travel at 90° to the normal

dual-transducer search unit configuration, angle-beam longitu- of the test surface and fill thin materials with elliptical particle

dinal waves may be used to measure thickness or to detect vibrations.These vibrations occur in various numbers of layers

reflectors parallel to the examination surface, such as lamina- and travel at velocities varying from slower than Rayleigh up

tions. As shown in Fig. 6, reflectors with a major plane at an to nearly longitudinal wave velocity, depending on material

E587 − 15 (2020)

FIG. 2 Mode of Vibration

FIG. 3 Effective Angles in the Steel versus Wedge Angles in Acrylic Plastic

FIG. 4 Axle

FIG. 6 Angle Longitudinal

FIG. 5 Thickness

FIG. 7 Coincident Beams

thickness and examination frequency. Asymmetrical-type

Lamb waves have an odd number of elliptical layers of metrical Lamb waves (one or three elliptical layers). Small

vibration, while symmetrical-type Lamb waves have an even thickness changes are best detected with the third or higher

number of elliptical layers of vibration. Lamb waves are most mode symmetrical or asymmetrical-type Lamb waves (five or

useful in materials up to five wavelengths thick (based on more elliptical layers). A change in plate thickness causes a

Rayleigh wave velocity in a thick specimen of the same change of vibrational mode just as a lamination causes a mode

material). They will detect surface imperfections on both the change. The mode conversion is imperfect and may produce

examination and opposite surfaces. Centrally located lamina- indications at the leading and the trailing edges of the lamina-

tions are best detected with the first or second mode asym- tion or the thin area.

E587 − 15 (2020)

FIG. 12 Incomplete Penetration

FIG. 8 Corner

FIG. 13 Incomplete Fusion

FIG. 9 Normal Plane

FIG. 14 Slag and Porosity

FIG. 10 Laminar

FIG. 15 Cracks

FIG. 11 Edge Lamination

5.1.2 Qualification of NondestructiveAgencies—Ifspecified

5. Basis of Application

in the contractual agreement, NDT agencies shall be qualified

and evaluated as described in Specification E543. The appli-

5.1 Purchaser-Supplier Agreements: The following items

cable edition of Specification E543 shall be specified in the

require agreement between using parties for this practice to be

contractual agreement.

used effectively:

5.1.1 Personnel Qualification—If specified in the contrac-

6. Apparatus

tual agreement, personnel performing examinations to this

practice shall be qualified in accordance with a nationally 6.1 A complete ultrasonic system shall include the follow-

recognized NDT personnel qualification practice or standard ing:

such as ANSI/ASNT-CP-189, SNT-TC-1A, NAS-410, ISO 6.1.1 Instrumentation—The ultrasonic instrument shall be

9712, or a similar document and certified by the employer or capable of generating, receiving, amplifying, and displaying

certifying agency, as applicable. The practice or standard used high-frequency electrical pulses.

and its applicable revision shall be identified in the contractual 6.1.2 Search Units—The ultrasonic search units shall be

agreement between the using parties. capable of transmitting and receiving ultrasonic waves in the

E587 − 15 (2020)

material at frequencies and energy levels necessary for discon- liquid-filled flexible tire. A minimum amount of couplant

tinuity detection as determined by the standardization proce- provides ultrasonic transmission into the examination surface

dure. The search units are fitted with wedges in order to since the elastic tire material is in rolling contact and conforms

transmit ultrasonic waves into the examination object at the closely to the surface.

desired angle and mode of operation. 6.1.4 Reference Reflectors—Reference reflectors of known

6.1.3 Couplant—A couplant, usually a liquid or semiliquid, dimension, artificial reflectors, or distance-amplitude relation-

is required between the face of the search unit and the ships of known reflector sizes for a particular search unit and

examination surface to permit the transmission of ultrasonic material may be used for standardization. The artificial reflec-

waves from the search unit into the material under examina- tors may be in the form of side-drilled holes, notches, or

tion. Typical couplants i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.