ASTM D5210-92

(Test Method)Standard Test Method for Determining the Anaerobic Biodegradation of Plastic Materials in the Presence of Municipal Sewage Sludge

Standard Test Method for Determining the Anaerobic Biodegradation of Plastic Materials in the Presence of Municipal Sewage Sludge

SCOPE

1.1 This test method determines the degree and rate of anaerobic biodegradation of synthetic plastic materials (including formulation additives) on exposure to anaerobic-digester municipal sewage sludge from a waste-water plant, under laboratory conditions.

1.2 This test method is designed to index plastic materials that are more or less biodegradable relative to a positive standard in an anaerobic environment.

1.3 This test method is applicable to all plastic materials that are not inhibitory to the microorganisms present in anaerobic sewage sludge.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards are given in Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5210 – 92 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determining the Anaerobic Biodegradation of Plastic

Materials in the Presence of Municipal Sewage Sludge

This standard is issued under the fixed designation D 5210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method determines the degree and rate of 4.1 This test method consists of selecting plastic material

anaerobic biodegradation of synthetic plastic materials (includ- for testing, obtaining sludge from an anaerobic-digester at a

ing formulation additives) on exposure to anaerobic-digester waste-treatment plant, exposing the plastic material to the

municipal sewage sludge from a waste-water plant, under inoculum obtained from the sewage sludge, measuring total

laboratory conditions. gas, carbon dioxide and methane (CO and CH ), evolved as a

2 4

1.2 This test method is designed to index plastic materials function of time; soluble organic carbon (SOC), and residual

that are more or less biodegradable relative to a positive polymer weight at the termination of the test, and assessing

standard in an anaerobic environment. degree of biodegradability.

1.3 This test method is applicable to all plastic materials that 4.2 The percent of theoretical gas production based on

are not inhibitory to the microorganisms present in anaerobic measured or calculated carbon content is reported with respect

sewage sludge. to time from which the degree of biodegradability is assessed.

1.4 The values stated in SI units are to be regarded as the

5. Significance and Use

standard.

5.1 The degree and rate of anaerobic biodegradability of a

1.5 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the plastic material in this test method may be predictive of the

time period required to eliminate that plastic from the environ-

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- ment depending on the similarities of the environments. With

increasing use of plastics, disposal is a major issue. This test

bility of regulatory limitations prior to use. Specific hazards are

given in Section 8. method may be useful to estimate the degree and persistence of

plastics in biologically active anaerobic disposal sites. This test

2. Referenced Documents

method determines the rate and degree of anaerobic biodegra-

2.1 ASTM Standards: dation by measuring the evolved volume of carbon dioxide and

D 883 Terminology Relating to Plastics methane, as a function of time of exposure to anaerobic-

D 1193 Specification for Reagent Water digester sludge.

D 3593 Test Method for Molecular Weight Averages and 5.2 Anaerobic sewer-digester sludge from treatment of

Molecular Weight Distribution of Certain Polymers by clarifier sludge at a waste-water treatment plant that treats

Liquid Size-Exclusion Chromatography (Gel Permeation principally municipal waste is an acceptable active anerobic

Chromatography—GPC) Using Universal Calibration environment (available over a wide geographical area) in

which to test a broad range of plastic materials. This test

3. Terminology

method may be considered an accelerated test with respect to

3.1 Definitions: a typical anaerobic environment, such as landfill sites that

3.1.1 Definitions of terms applying to this test method

plastics encounter in usual disposal methods because of the

appear in Terminology D 883. highly active microbial population of anaerobic-digester

sludge.

6. Apparatus

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

6.1 Gas generated will be collected in either an inverted

and is the direct responsibility of Subcommittee D20.96 on Environmentally

Degradable Plastics. graduated cylinder submerged in water, water acidified to pH

Current edition approved Aug. 15, 1992. Published October 1992. Originally

<3 with sulfuric acid, a syringe with a freely moving plunger,

published as D 5210 – 91. Last previous edition D 5210 – 91.

or other suitable devices for measuring gas volume such as a

Annual Book of ASTM Standards, Vol 08.01.

pressure transducer.

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 08.02.

D 5210

TABLE 1 Stock Solutions for Anaerobic Biodegradation Test

6.2 Gas Chromatograph, or other apparatus, equipped with

a suitable detector and column(s), shall be used to quantify Amount, mL, Concentration

Stock Concentration,

Compound added per in media,

methane and carbon dioxide evolution using an analytical

Solution g/L

4L m moles

procedure specific for these gases.

S-1 Resazurin 0.5 8 .

6.3 Incubator, sufficient to store the test bottles at 356 2°C

S-2 KH PO 69.0 . 1.0

2 4

in the dark for the duration of the test.

K HPO 88.0 . 1.0

2 4

(NH ) HPO 10.0 8 0.15

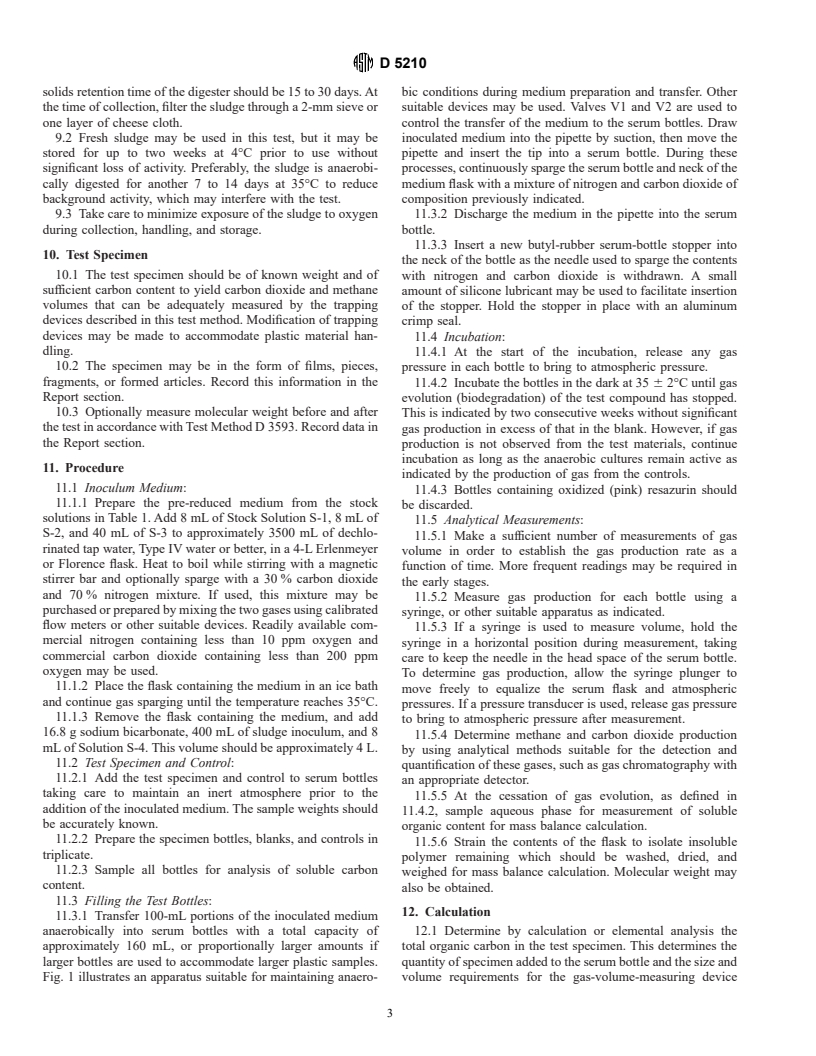

6.4 Medium Handling Apparatus, suitable for maintaining 4 2 4

NH Cl 100.0 . 3.7

anaerobic conditions during medium preparation and inocula-

A

S-3 MgCl ·6H O 60.0 . 3.0

2 2

tion (See Fig. 1).

FeCl ·4H O 20.0 . 1.0

2 2

KCI 10.0 . 1.3

6.5 Serum Bottles, with sufficient capacity for the experi-

CaCl 10.0 . 0.90

ment, with butyl-rubber stoppers and crimp clamps to hold the

KI 1.0 . 0.060

rubber stoppers.

MnCl ·4H O 0.40 . 0.020

2 2

CoCl ·6H O 0.40 40 0.017

6.6 Analytical Balance, to weigh samples before and after 2 2

NiCl ,6H O 0.050 . 0.0021

2 2

test.

CuCl 0.050 . 0.0037

6.7 Analytical Instrument, to measure soluble organic car-

ZnCl 0.050 . 0.0037

H BO 0.050 . 0.0081

3 3

bon content of aqueous medium before and after test.

Na MoO ·H O 0.050 . 0.0018

2 4 2

NaIO ·nH O 0.050 . 0.0041

3 2

7. Reagents and Materials

Na SeO 0.010 . 0.00054

2 3

S-4 Na S·9H O 50.0 8 0.40

2 2

7.1 Reagent grade chemicals shall be used in all tests.

Bicarbonate NaHCO . 16.8 g 50.0

7.2 Purity of Water—Purity of water unless indicated oth-

A

S-3 may form a small amount of precipitate on standing, shake well before

erwise shall be understood to mean reagent water as defined by

using.

Type IV of Specification D 1193.

7.3 Stock solutions are prepared as shown in Table 1.

NOTE 1—Precaution: This test method involves the use of sludge from

7.4 Up to 1 mL of concentrated HCl may be added to Stock

a waste-treatment plant. Avoid contact with the sludge by using gloves and

Solution S-3 to improve the solubility of salts. Shake well

other appropriate protective equipment. Use good personal hygiene to

before use in order to distribute any undissolved material

minimize exposure to potentially harmful microbiological agents.

throughout the solution.

9. Inoculum—Test Organisms

8. Hazards

9.1 The inoculum consists of sludge from a well-operated

8.1 This test method involves the use of hazardous chemi- anaerobic-sludge digester with a total organic solids level of at

cals. Avoid contact with the chemicals and follow manufactur- least 1 to 2 % (W/V). The sewage treatment plant should

er’s instructions and material safety data sheets. receive no more than minimal effluent from industry and the

FIG. 1 Schematic Diagram of Apparatus Suitable for Maintenance of Anaerobic Conditions During Medium Preparation and Inoculation

D 5210

solids retention time of the digester should be 15 to 30 days. At bic conditions during medium preparation and transfer. Other

the time of collection, filter the sludge through a 2-mm sieve or suitable devices may be used. Valves V1 and V2 are used to

one layer of cheese cloth. control the transfer of the medium to the serum bottles. Draw

9.2 Fresh sludge may be used in this test, but it may be inoculated medium into the pipette by suction, then move the

stored for up to two weeks at 4°C prior to use without pipette and insert the tip into a serum bottle. During these

significant loss of activity. Preferably, the sludge is anaerobi- processes, continuously sparge the serum bottle and neck of the

cally digested for another 7 to 14 days at 35°C to reduce medium flask with a mixture of nitrogen and carbon dioxide of

background activity, which may interfere with the test. composition previously indicated.

9.3 Take care to minimize exposure of the sludge to oxygen 11.3.2 Discharge the medium in the pipette into the serum

during collection, handling, and storage. bottle.

11.3.3 Insert a new butyl-rubber serum-bottle stopper into

10. Test Specimen

the neck of the bottle as the needle used to sparge the contents

10.1 The test specimen should be of known weight and of

with nitrogen and carbon dioxide is withdrawn. A small

sufficient carbon content to yield carbon dioxide and methane

amount of silicone lubricant may be used to facilitate insertion

volumes that can be adequately measured by the trapping

of the stopper. Hold the stopper in place with an aluminum

devices described in this test method. Modification of trapping

crimp seal.

devices may be made to accommodate plastic material han-

11.4 Incubation:

dling.

11.4.1 At the start of the i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.