ASTM C50-00(2006)

(Practice)Standard Practice for Sampling, Sample Preparation, Packaging, and Marking of Lime and Limestone Products

Standard Practice for Sampling, Sample Preparation, Packaging, and Marking of Lime and Limestone Products

SIGNIFICANCE AND USE

The following practices are to be used in obtaining samples that are representative of the lot being sampled. The methodology used will be dependent upon the size and type of material sampled and testing requirements.

The following practices are intended for use in obtaining samples from material that is ready for sale and are not intended as sampling procedures for quality control purposes. These practices are to be used in obtaining a laboratory sample that will yield results serving as a basis for acceptance or rejection of the lot of material sampled. This does not preclude the use of these practices for quality control purposes.

The following practices can be used to eliminate bias in sampling. The person or persons responsible for using these practices must be trained and they will be conscientious and timely in their use.

An agreement between the producer and the consumer on location of sampling, either at the producer’plant or at the destination, is encouraged. Product quality can be affected through careless handling, improper protection, and delayed shipment. It is preferable to sample at the point of loading. The consumer has the right to witness the sampling practices being used.

This practice may be used to provide a representative sample of lime or limestone products. Due to the variability of limestone and lime and the wide variety of sampling equipment, caution must be exercised in all stages of sampling, from system specification and equipment procurement to equipment acceptance testing and actually taking the final sample.

SCOPE

1.1 This practice covers procedures for the collection and reduction of samples of lime and limestone products to be used for physical and chemical tests.

1.2 This practice further covers inspection, rejection, retesting, packing, and marking of lime and limestone products as it may be used in the chemical, agricultural, and process industries.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C50–00 (Reapproved 2006)

Standard Practice for

Sampling, Sample Preparation, Packaging, and Marking of

Lime and Limestone Products

This standard is issued under the fixed designation C50; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E122 Practice for Calculating Sample Size to Estimate,

With Specified Precision, the Average for a Characteristic

1.1 This practice covers procedures for the collection and

of a Lot or Process

reduction of samples of lime and limestone products to be used

E141 Practice for Acceptance of Evidence Based on the

for physical and chemical tests.

Results of Probability Sampling

1.2 This practice further covers inspection, rejection, retest-

E177 Practice for Use of the Terms Precision and Bias in

ing, packing, and marking of lime and limestone products as it

ASTM Test Methods

may be used in the chemical, agricultural, and process indus-

tries.

3. Terminology

1.3 This standard does not purport to address all of the

3.1 accuracy—a term generally used to indicate the reliabil-

safety concerns, if any, associated with its use. It is the

ity of a sample, a measurement, or an observation and is a

responsibility of the user of this standard to establish appro-

measure of closeness of agreement between an experimental

priate safety and health practices and determine the applica-

result and the true value.

bility of regulatory limitations prior to use.

3.2 bias (systematic error)—an error that is consistently

2. Referenced Documents negative or consistently positive. The mean of errors resulting

fromaseriesofobservationswhichdoesnottendtowardszero.

2.1 ASTM Standards:

3.3 chance error—error that has equal probability of being

C51 Terminology Relating to Lime and Limestone (as used

positive or negative. The mean of the chance errors resulting

by the Industry)

from a series of observations that tends toward zero as the

C702 Practice for Reducing Samples of Aggregate to Test-

number of observations approach infinity.

ing Size

3.4 combined water—water that is chemically bonded to

D75 Practice for Sampling Aggregates

calcium or magnesium oxide to form hydrate.

D2234/D2234M Practice for Collection of a Gross Sample

3.5 error—the difference of an observation or a group of

of Coal

observations from the best obtainable estimate of the true

D3665 Practice for Random Sampling of Construction Ma-

value.

terials

3.6 free water—water that is not chemically bonded to

E11 SpecificationforWovenWireTestSieveClothandTest

calcium or magnesium oxide.

Sieves

3.7 grosssample—a sample representing one lot of material

E105 Practice for Probability Sampling of Materials

and composed of a number of increments on which neither

reduction nor division has been performed.

This practice is under the jurisdiction of ASTM Committee C07 on Lime and

3.8 increment—a small portion of the lot collected by one

is the direct responsibility of Subcommittee C07.06 on Physical Tests.

operation of a sampling device and normally combined with

Current edition approved Nov. 15, 2006. Published December 2006. Originally

other increments from the lot to make a gross sample.

approved in 1922. Last previous edition approved in 2000 as C50 – 00. DOI:

10.1520/C0050-00R06.

3.9 laboratory sample—refers to the sample after the initial

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

preparation from which the analytical sample is obtained.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.10 lot—a discrete quantity of material for which the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. overall quality to a particular precision needs to be determined.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C50–00 (2006)

3.11 precision—a term used to indicate the capability of a 4.4 An agreement between the producer and the consumer

person, an instrument, or a method to obtain repeatable results; on location of sampling, either at the producer’s plant or at the

specifically, a measure of the chance error as expressed by the destination, is encouraged. Product quality can be affected

variance, the standard error, or a multiple of the standard error through careless handling, improper protection, and delayed

(see Practice E177). shipment. It is preferable to sample at the point of loading.The

3.12 representative sample—a sample collected in such a consumer has the right to witness the sampling practices being

manner that every particle in the lot to be sampled is equally used.

represented in the gross or divided sample.

4.5 This practice may be used to provide a representative

3.13 sample—a quantity of material taken from a larger

sample of lime or limestone products. Due to the variability of

quantity for the purpose of estimating properties or composi-

limestone and lime and the wide variety of sampling equip-

tion of the larger quantity.

ment, caution must be exercised in all stages of sampling, from

3.14 sample division—the process whereby a sample is

system specification and equipment procurement to equipment

reduced in weight without change in particle size.

acceptance testing and actually taking the final sample.

3.15 sample preparation—the process that may include

crushing, dividing, and mixing of a gross or divided sample for

5. Incremental Collection

the purpose of obtaining a representative analysis sample.

5.1 For the number and weight of increments refer to

3.16 sampling unit—a quantity of material from which a

Practice E122.

gross sample is obtained. A lot may contain several sampling

5.2 The number of samples required depends on the in-

units.

tended use of the material, the quantity of material involved,

3.17 segregation variance of increment collection, Ss —the

and the variations both in quality and size.Asufficient number

variance caused by nonrandom distribution of inert material or

of samples shall be obtained to cover all variations in the

other constituent in the lot.

material.

3.18 sizeconsist—the particle size distribution of quicklime

5.3 The quantity of sample to be taken will depend on the

or hydrated lime.

size of the material to be sampled and the amount of informa-

3.19 standard deviation—the square root of the variance.

tion to be obtained from the sample. Caution must be taken to

3.20 subsample—a sample taken from another sample.

ensure a statistically correct amount of material is selected for

3.21 top size—the opening of the smallest screen in the

all testing, and sufficient quantities of material retained for

series upon which is retained less than 5 % of the sample.

reserved purposes. Recommended reference documents would

3.22 total variance, So —the overall variance resulting

include Practices E105 and E122.

from collecting single increments, and including division and

5.4 Particle Size:

analysis of the single increments.

3.23 unbiased sample—a sample free of bias or a represen- 5.4.1 Generally, a large range of particle sizes for a given

tative sample. material requires a larger bulk sample size. The amount of the

3.24 unit variance (random variance of increment collec- sample increment is then dependent upon the largest particle

tion), Sr —the theoretical variance calculated for a uniformly

size encountered. The sample amount is determined by re-

mixed lot and extrapolate to 0.5-kg (1-lb) increment size. peated testing to determine the bias between successive incre-

3.25 variance—the mean square of deviation (or errors) of

ments, and then to reduce this bias to acceptable limits.

a set of observations; the sum of squared deviations (or errors)

5.4.2 The chemistry may change relative to the particle size.

ofindividualobservationswithrespecttotheirarithmeticmean

It is important that all particle sizes proportioned relative to

divided by the number of observations less one (degrees of

their distribution be in the parent material.

freedom); the square of the standard deviation (or standard

5.5 Large material transfer rates result in large incremental

error).

samples. The sample must be representative of the entire

cross-section flow of material. The amount of sample and

4. Significance and Use

number of increments must be determined prior to sampling.

4.1 The following practices are to be used in obtaining

Randomized sampling should be used where appropriate to

samples that are representative of the lot being sampled. The

minimize unintentional bias.

methodology used will be dependent upon the size and type of

material sampled and testing requirements.

6. Random Sampling

4.2 Thefollowingpracticesareintendedforuseinobtaining

6.1 Practices D3665, E105, and E122 can be used to

samples from material that is ready for sale and are not

minimize unintentional bias when obtaining a representative

intended as sampling procedures for quality control purposes.

sample. Depending upon what comprises the lot of material,

These practices are to be used in obtaining a laboratory sample

sampling can be extended to specific shipping units chosen on

that will yield results serving as a basis for acceptance or

a random basis.

rejection of the lot of material sampled. This does not preclude

the use of these practices for quality control purposes. 6.2 Collect increments with such frequency that the entire

4.3 The following practices can be used to eliminate bias in quantity of material will be represented in the gross sample.

sampling. The person or persons responsible for using these Due to the variability of lime and limestone products and the

practices must be trained and they will be conscientious and wide variety of sampling equipment, caution must exercised in

timely in their use. all stages of sampling.

C50–00 (2006)

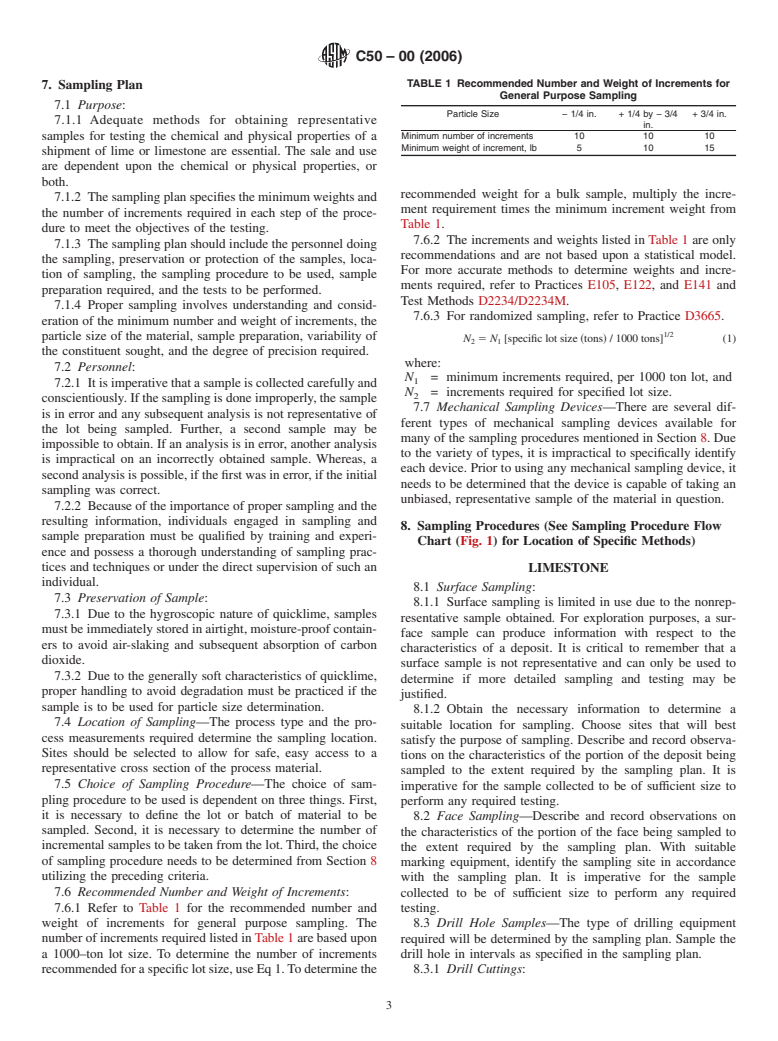

TABLE 1 Recommended Number and Weight of Increments for

7. Sampling Plan

General Purpose Sampling

7.1 Purpose:

Particle Size − 1/4 in. + 1/4 by − 3/4 + 3/4 in.

7.1.1 Adequate methods for obtaining representative

in.

Minimum number of increments 10 10 10

samples for testing the chemical and physical properties of a

Minimum weight of increment, lb 5 10 15

shipment of lime or limestone are essential. The sale and use

are dependent upon the chemical or physical properties, or

both.

recommended weight for a bulk sample, multiply the incre-

7.1.2 The sampling plan specifies the minimum weights and

ment requirement times the minimum increment weight from

the number of increments required in each step of the proce-

Table 1.

dure to meet the objectives of the testing.

7.6.2 The increments and weights listed in Table 1 are only

7.1.3 The sampling plan should include the personnel doing

recommendations and are not based upon a statistical model.

the sampling, preservation or protection of the samples, loca-

For more accurate methods to determine weights and incre-

tion of sampling, the sampling procedure to be used, sample

ments required, refer to Practices E105, E122, and E141 and

preparation required, and the tests to be performed.

Test Methods D2234/D2234M.

7.1.4 Proper sampling involves understanding and consid-

7.6.3 For randomized sampling, refer to Practice D3665.

eration of the minimum number and weight of increments, the

1/2

particle size of the material, sample preparation, variability of

N 5N [specific lot size ~tons! / 1000 tons] (1)

2 1

the constituent sought, and the degree of precision required.

where:

7.2 Personnel:

N = minimum increments required, per 1000 ton lot, and

7.2.1 It is imperative that a sample is collected carefully and

N = increments required for specified lot size.

conscientiously. If the sampling is done improperly, the sample

7.7 Mechanical Sampling Devices—There are several dif-

is in error and any subsequent analysis is not representative of

ferent types of mechanical sampling devices available for

the lot being sampled. Further, a second sample may be

many of the sampling procedures mentioned in Section 8. Due

impossible to obtain. If an analysis is in error, another analysis

to the variety of types, it is impractical to specifically identify

is impractical on an incorrectly obtained sample. Whereas, a

each device. Prior to using any mechanical sampling device, it

second analysis is possible, if the first was in error, if the initial

needs to be determined that the device is capable of taking an

sampling was correct.

unbiased, representative sample of the material in question.

7.2.2 Because of the importance of proper sampling and the

resulting information, individuals engaged in sampling and

8. Sampling Procedures (See Sampling Procedure Flow

sample preparation must be qualified by training and experi-

Chart (Fig. 1) for Location of Specific Methods)

ence and possess a thorough understanding of sampling prac-

tices and techniques or under the direct supervision of such an

LIMESTONE

individual.

8.1 Surface Sampling:

7.3 Preservation of Sample:

8.1.1 Surface sampling is limited in use due to the nonrep-

7.3.1 Due to the hygroscopic nature of quicklime, samples

resentative sample obtained. For exploration purposes, a sur-

must be immediately stored in airtight, moisture-proof contain-

face sample can produce information with respect to the

ers to avoid air-slaking and subsequent absorption of carbon

characteristics of a deposit. It is critical to remember that a

dioxide.

surface sample is not representative and can only be used to

7.3.2 Due to the generally soft characteristics of quicklime,

determine if more detailed sampling and testing may be

proper handling to avoid degradation must be practiced if the

justified.

sample is to be used for particle size determination.

8.1.2 Obtain the necessary information to determine a

7.4 Location of Sampling—The process type and the pro-

suitable location for sampling. Choose sites that will best

cess measurements required determine the sampling location.

satisfy the purpose of sampling. Describe and record observa-

Sites should be selected to allow for safe, easy access to a

tions on the characteristics of the portion of the deposit being

representative cross section of the process material.

sampled to the extent required by the sampling plan. It is

7.5 Choice of Sampling Procedure—The choice of sam-

imperative for the sample collected to be of sufficient size to

pling procedure to be used is dependent on three things. First,

perform any required testing.

it is necessary to d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.