ASTM D6856-03

(Guide)Standard Guide for Testing Fabric-Reinforced "Textile" Composite Materials

Standard Guide for Testing Fabric-Reinforced "Textile" Composite Materials

SIGNIFICANCE AND USE

This guide is intended to serve as a reference for the testing of textile composite materials.

The use of this guide ensures that proper consideration is given to the unique characteristics of these materials in testing. In addition, this guide also assists the user in selecting the best currently available ASTM test method for measurement of commonly evaluated material properties.

SCOPE

1.1 This guide is applicable to the testing of textile composites fabricated using fabric preforms, such as weaves, braids, stitched preforms, and so forth, as the reinforcement. The purpose of this guide is to:

1.1.1 Ensure that proper consideration is given to the unique characteristics of these materials in testing.

1.1.2 Assist the user in selecting the best currently available ASTM test method for the measurement of commonly evaluated material properties for this class of materials.

1.2 Areas where current ASTM test methods do not meet the needs for testing of textile composites are indicated.

1.3 It is not the intent of this guide to cover all test methods which could possibly be used for textile composites. Only the most commonly used and most applicable standards are included.

1.4 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6856–03

Standard Guide for

Testing Fabric-Reinforced “Textile” Composite Materials

This standard is issued under the fixed designation D 6856; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

A variety of fabric-reinforced composite materials have been developed for use in aerospace,

automotive, and other applications. These composite materials are reinforced with continuous fiber

yarns that are formed into two-dimensional or three-dimensional fabrics.Various fabric constructions,

such as woven, braided, stitched, and so forth, can be used to form the fabric reinforcement. Due to

the nature of the reinforcement, these materials are often referred to as “textile” composites.

Textile composites can be fabricated from 2-dimensional (2-D) or 3-dimensional (3-D) fabrics.

Stitched preforms and 3-D fabrics contain through-thickness yarns, which can lead to greater

delamination resistance. Textile composites are also amenable to automated fabrication. However, the

microstructure (or fiber architecture) of a textile composite, which consists of interlacing yarns, can

lead to increased inhomogeneity of the local displacement fields in the laminate. Depending upon the

size of the yarns and the pattern of the weave or braid, the inhomogeneity within a textile composite

can be large compared to traditional tape laminates.

Thus, special care should be exercised in the use of the currentASTM standards developed for high

performance composites. In many cases, the current ASTM standards are quite adequate if proper

attention is given to the special testing considerations for textile composites covered in this guide.

However, in some cases, current standards do not meet the needs for testing of the required properties.

This guide is intended to increase the user’s awareness of the special considerations necessary for the

testing of these materials. It also provides the user with recommended ASTM standards that are

applicable for evaluating textile composites. The specific properties for which current ASTM

standards might not apply are also highlighted in this guide.

1. Scope 1.4 The values stated in SI units are to be regarded as the

standard. The values in parentheses are for information only.

1.1 This guide is applicable to the testing of textile com-

1.5 This standard does not purport to address all of the

posites fabricated using fabric preforms, such as weaves,

safety concerns, if any, associated with its use. It is the

braids, stitched preforms, and so forth, as the reinforcement.

responsibility of the user of this standard to establish appro-

The purpose of this guide is to:

priate safety and health practices and determine the applica-

1.1.1 Ensurethatproperconsiderationisgiventotheunique

bility of regulatory requirements prior to use.

characteristics of these materials in testing.

1.1.2 Assist the user in selecting the best currently available

2. Referenced Documents

ASTM test method for the measurement of commonly evalu-

2.1 ASTM Standards:

ated material properties for this class of materials.

D 790 TestMethodsforFlexuralPropertiesofUnreinforced

1.2 Areas where current ASTM test methods do not meet

and Reinforced Plastics and Electrical Insulating Materi-

the needs for testing of textile composites are indicated.

als

1.3 It is not the intent of this guide to cover all test methods

D 792 TestMethodsforDensityandSpecificGravity(Rela-

which could possibly be used for textile composites. Only the

tive Density) of Plastics by Displacement

most commonly used and most applicable standards are

D 883 Terminology Relating to Plastics

included.

This guide is under the jurisdiction of ASTM Committee D30 on Composite

Materials and is the direct responsibility of Subcommittee D30.04 on Lamina and

Laminate Test Methods.

Current edition approved Jan. 10, 2003. Published February 2003. Annual Book of ASTM Standards, Vol 08.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6856–03

D 2344/D 2344M Test Method for Short-Beam Strength of E 122 Practice for Calculating Sample Size to Estimate,

Polymer Matrix Composite Materials and Their Lami- With a Specified Tolerable Error, the Average for Charac-

3 7

nates teristic of a Lot or Process

D 3039/D 3039M Test Method for Tensile Properties of E 251 Test Methods for Performance Characteristics of

3 6

Polymer Matrix Composite Materials Metallic Bonded Resistance Strain Gages

D 3171 Test Method for Constituent Content of Composite E 456 Terminology Relating to Quality and Statistics

Materials E 1237 Guide for Installing Bonded Resistance Strain

D 3410/D 3410M Test Method for Compressive Properties Gages

of Polymer Matrix Composite Materials with Unsupported

3. Terminology

Gage Section by Shear Loading

D 3479/D 3479M Test Method for Tension-Tension Fatigue

3.1 Definitions—Definitions used in this guide are defined

of Polymer Matrix Composite Materials

by variousASTM methods.Terminology D 3878 defines terms

D 3518/D 3518M TestMethodforIn-PlaneShearResponse

relating to high-modulus fibers and their composites. Termi-

of Polymer Matrix Composite Materials by Tensile Test of nology D 883 defines terms relating to plastics. Terminology

a 645° Laminate

E 6 defines terms relating to mechanical testing. Terminology

D 3846 Test Method for In-Plane Shear Strength of Rein-

E 456 defines terms relating to statistics. In the event of a

forced Plastics

conflict between definitions of terms, Terminology D 3878

D 3878 Terminology for Composite Materials

shall have precedence over the other standards. Terms relating

D 4255/D 4255M Test Method for In-Plane Shear Proper-

specifically to textile composites are defined by Ref (1).

ties of Polymer Matrix Composite Materials by the Rail

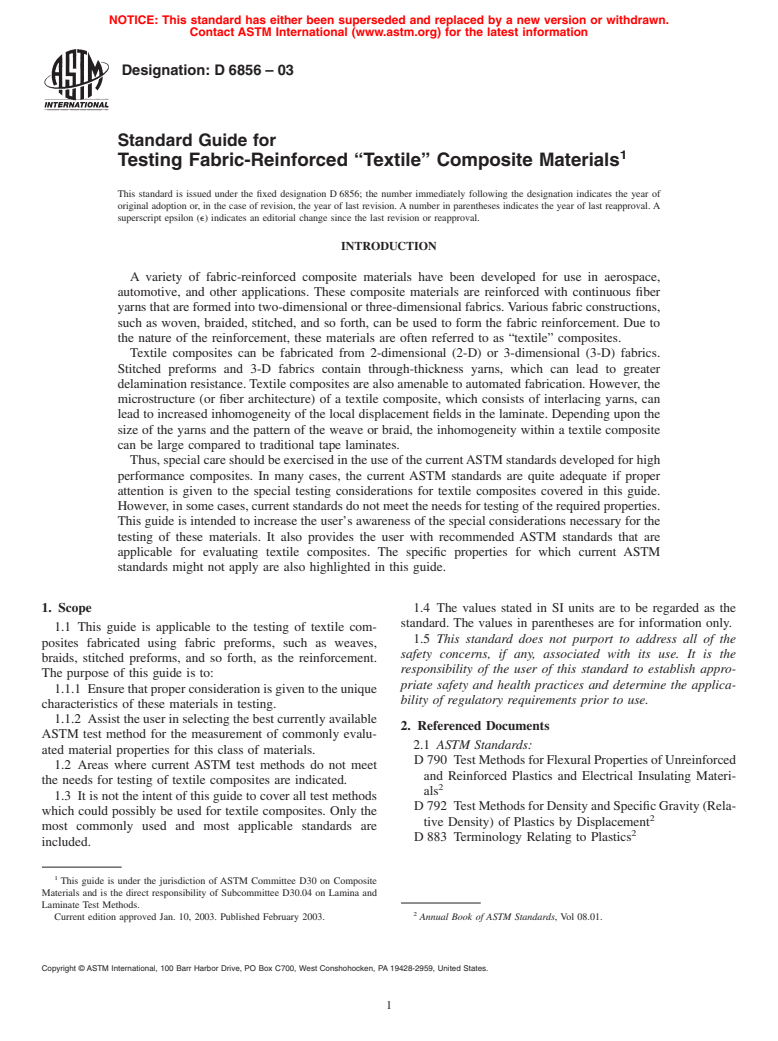

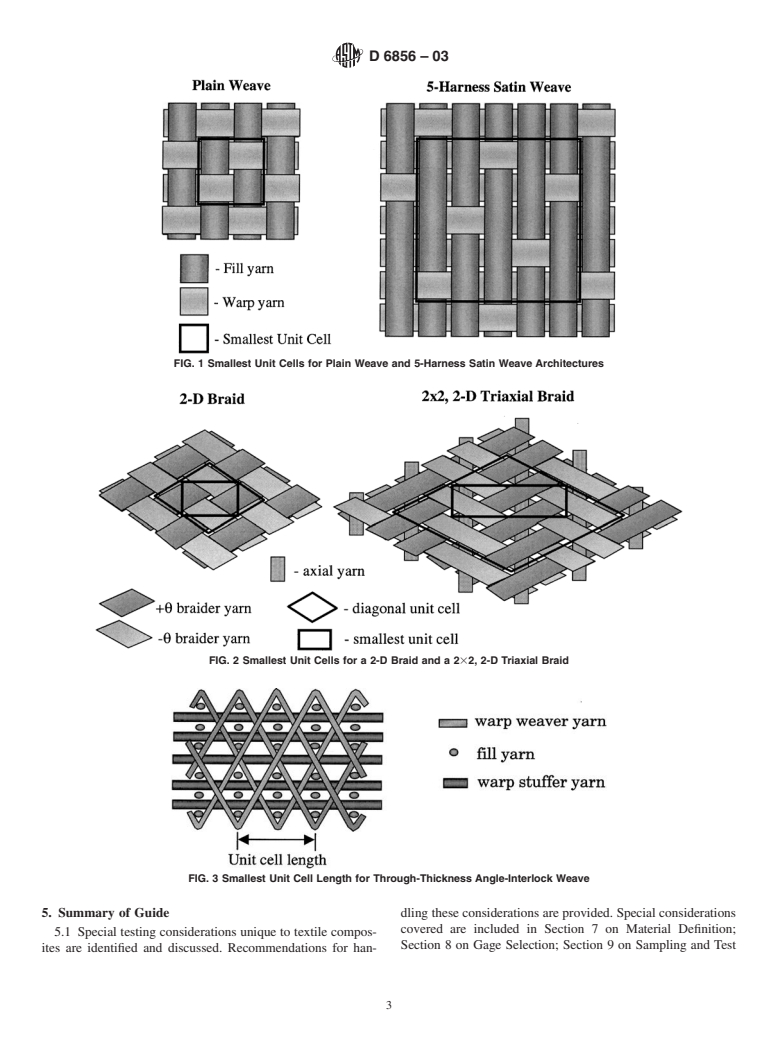

3.2 textile unit cell—In theory, textile composites have a

Shear Method

repeating geometrical pattern based on manufacturing param-

D 5229/D 5229M Test Method for Moisture Absorption

eters.This repeating pattern is often referred to as the materials

Properties and Equilibrium Conditioning of Polymer Ma-

“unit cell.” It is defined as the smallest section of architecture

trix Composite Materials

required to repeat the textile pattern (see Figs. 1-4). Handling

D 5379/D 5379M Test Method for Shear Properties of

and processing can distort the “theoretical” unit cell. Param-

Composite Materials by the V-Notched Beam Method

eters such as yarn size, yarn spacing, fabric construction, and

D 5528 Test Method for Mode I Interlaminar Fracture

fiber angle may be used to calculate theoretical unit cell

Toughness of Unidirectional Fiber-Reinforced Polymer

dimensions. However, several different “unit cells” may be

Matrix Composites

defined for a given textile architecture. For example, Fig. 2

D 5766/D 5766M Test Method for Open Hole Tensile

shows two different unit cells for the braided architectures.

Strength of Polymer Matrix Composite Laminates

Thus, unit cell definition can be somewhat subjective based on

D 5961/D 5961M Test Method for Bearing Response of

varying interpretations of the textile architecture. The user is

Polymer Matrix Composite Laminates

referred to Refs (1, 2) for further guidance. In this guide, to be

D 6115 Test Method for Mode I Fatigue Delamination

consistent, the term “unit cell” is used to refer to the smallest

Growth Onset of Unidirectional Fiber-Reinforced Polymer

unit cell for a given textile architecture. This smallest unit cell

Matrix Composites

is defined as the smallest section of the textile architecture

D 6415 Test Method for Measuring the Curved Beam

required to replicate the textile pattern by using only in-plane

Strength of a Fiber-Reinforced Polymer-Matrix Compos-

translations (and no rotations) of the unit cell. Examples of the

ite

smallest unit cells for some of the commonly used textile

D 6272 Test Method for Flexural Properties of Unrein-

composites are shown in Figs. 1-4. For the 3-D weaves in Figs.

forced and Reinforced Plastics and Electrical Insulating

3and4,thesmallestunitcelllength(asindicated)isdefinedby

Materials by Four-Point Bending

the undulating pattern of the warp yarns. The smallest unit cell

D 6484/D 6484M Test Method for Open-Hole Compressive

width is the distance between two adjacent warp stuffer yarn

Strength of Polymer Matrix Composite Laminates

columns (in the fill yarn direction) and the smallest unit cell

D 6641/D 6641M Test Method for Determining the Com-

height is the consolidated woven composite thickness.

pressive Properties of Polymer Matrix Composite Lami-

4. Significance and Use

natesUsingaCombinedLoadingCompression(CLC)Test

Fixture

4.1 This guide is intended to serve as a reference for the

D 6671 Test Method for Mixed Mode I-Mode II Interlami-

testing of textile composite materials.

nar FractureToughness of Unidirectional Fiber Reinforced

4.2 The use of this guide ensures that proper consideration

Polymer Matrix Composites

is given to the unique characteristics of these materials in

E 6 Terminology Relating to Methods of Mechanical Test-

testing. In addition, this guide also assists the user in selecting

ing

the best currently available ASTM test method for measure-

ment of commonly evaluated material properties.

Annual Book of ASTM Standards, Vol 15.03.

4 7

Annual Book of ASTM Standards, Vol 08.02. Annual Book of ASTM Standards, Vol 14.02.

5 8

Annual Book of ASTM Standards, Vol 08.03. The boldface numbers in parentheses refer to the list of references at the end of

Annual Book of ASTM Standards, Vol 03.01. this standard.

D6856–03

FIG. 1 Smallest Unit Cells for Plain Weave and 5-Harness Satin Weave Architectures

FIG. 2 Smallest Unit Cells for a 2-D Braid and a 232, 2-D Triaxial Braid

FIG. 3 Smallest Unit Cell Length for Through-Thickness Angle-Interlock Weave

5. Summary of Guide dling these considerations are provided. Special considerations

covered are included in Section 7 on Material Definition;

5.1 Special testing considerations unique to textile compos-

Section 8 on Gage Selection; Section 9 on Sampling and Test

ites are identified and discussed. Recommendations for han-

D6856–03

FIG. 4 Smallest Unit Cell Length for Layer-to-Layer Angle-Interlock Weave

Specimens; Section 10 on Test Specimen Conditioning; Sec- significantly. Each of these items should be defined and

tion 11 on Report of Results; and Section 12 on Recommended documented prior to testing to avoid misinterpretation of the

Test Methods. test results.

5.2 RecommendedASTM test methods applicable to textile

7.3.1 The amount of debulking of the preform during

composites and any special considerations are provided in

processing can affect the fiber volume and also the fiber

Section 12 for mechanical and physical properties. Section 13

orientation through the thickness. In-plane fiber orientation can

identifies areas where revised or new standards are needed for be adversely affected during the placement of the preform in

textile composites.

the mold. Both overall and local variations in fiber orientation

should be documented.

6. Procedure for Use

7.3.2 As a minimum the following process conditions

6.1 Review Sections 7-12 to become familiar with the

should be documented for each material tested: preform

special testing considerations for textile composites.

thickness, preform tackifier (or resin compatible binder) used,

6.2 Follow the recommended ASTM test method identified

molding technique, molding temperature, molding pressure,

inSection12fordeterminingarequiredpropertybutreferback

molding time, and panel dimensions.

to this guide for recommendations on test specimen geometry,

strain measurement, and reporting of results.

8. Strain Gage Selection

8.1 The surface preparation, gage installation, lead wire

7. Material Definition

connection,andverificationcheckproceduresdescribedinTest

7.1 Constituent Definition—Variations in type and amount

Methods E 251 and Guide E 1237 are applicable to textile

of sizing on the fibers can significantly influence fabric quality

composites and should be used in the application of bonded

and subsequently material property test results. Each constitu-

resistance strain gages.

ent, that is, the fiber, fiber sizing type and amount, and resin

8.2 The strain gage size selected for each particular textile

should be carefully documented prior to testing to avoid

composite should take into consideration the size of the unit

misinterpretation of test results.

cell for the particular textile composite architecture. Each

7.1.1 Fiber and resin content should be measured and

different textile architecture has an independent unit cell size,

recordedusingatleastoneunitcellofthematerialfromatleast

which defines the extent of inhomogeniety in the displacement

one location in each panel from which test specimens are

fields. The size of the gage should be large enough relative to

machined. Section 12 covers methods for measuring these

the textile unit cell to provide a reliable measurement of the

values.

average strain magnitude. It is recommended for most textile

7.1.2 The following items should be documented each time

architectures that the gage length and width should, at a

a material is tested: fiber type, fiber diameter, fiber surface

minimum, equal the length and width of the smallest unit cell.

treatment or sizing type and amount, and resin type.

This applies to specimens loaded in the axial fiber direction

7.2 Fabric Definition—Due to the limitless possibilities

(longitudinal direction) and to specimens loaded perpendicular

involved in placing yarns during the weaving and braiding

to the axial fibers (transverse direction). For stitched compos-

operations, it is important to carefully document the yarn

ites, it is recommended that the gage length and width should,

counts (or yarn sizes), yarn spacings, yarn orientations, yarn

at a minimum, equal the stitch spacing and stitch pitch,

contents, weave or braid pattern identification, and yarn

respectively. The user is also referred to Ref (3) for further

interlocking through the preform thickness. Such documenta-

guidance.

tion is required to properly define the textile unit cell and also

to properly identify the textile material that was tested and to

9. Sampling and Test Specimens

avoid any possible misinterpretations of the test results.

7.3 Process Definition—Processing techniques can affect 9.1 Sampling—It is recommended that at least five speci-

fiber orientation,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.